1993 Jeep Cherokee

1993 CHRYSLER CORP. ENGINES 2.5L 4-Cylinder

Jeep: Cherokee, Wrangler

ENGINE IDENTIFICATION

NOTE: For engine repair procedures not covered in this article,

see ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION article in the GENERAL INFORMATION section.

Engine can be identified by eighth character of Vehicle Identification Number (VIN). The VIN is stamped on a plate attached to top left corner of instrument panel.

Engine code is on a machined surface on right side of cylinder block between cylinders No. 3 and 4. This code may be required when ordering replacement parts.

ENGINE IDENTIFICATION CODES TABLE

Application VIN Code

2 . 5L 4-Cylinder PFI P

Some engines are manufactured with oversize or undersize components. These engines are identified by a letter code stamped on oil filter boss near distributor. Letters are decoded as follows:

"B" indicates all cylinder bores .010" (.25 mm) oversize.

"C" indicates all camshaft bearing bores .010" (.25 mm)

oversize.

* "M" indicates all main bearing journals .010" (.25 mm)

undersize.

* "P" indicates one or more connecting rod journals .010" (.25

mm) undersize.

* "PM" indicates all crankshaft main bearing journals and one

or more connecting rod journals .010" (.25 mm) undersize.

ADJUSTMENTS

VALVE CLEARANCE ADJUSTMENT

Engine is equipped with hydraulic valve lifters. No valve adjustment is required.

REMOVAL & INSTALLATION

NOTE: For reassembly reference, label all electrical connectors, vacuum hoses and fuel lines before removal. Also place mating marks on engine hood and other major assemblies before removal.

CAUTION: When battery is disconnected, vehicle computer and memory systems may lose memory data. Driveability problems may exist until computer systems have completed a relearn cycle. See COMPUTER RELEARN PROCEDURES article in GENERAL INFORMATION before disconnecting battery.

FUEL PRESSURE RELEASE

CAUTION: Fuel system is under constant pressure. This pressure must be released before disconnecting or servicing any fuel supply or return system component. Wear proper eye protection when releasing fuel system pressure.

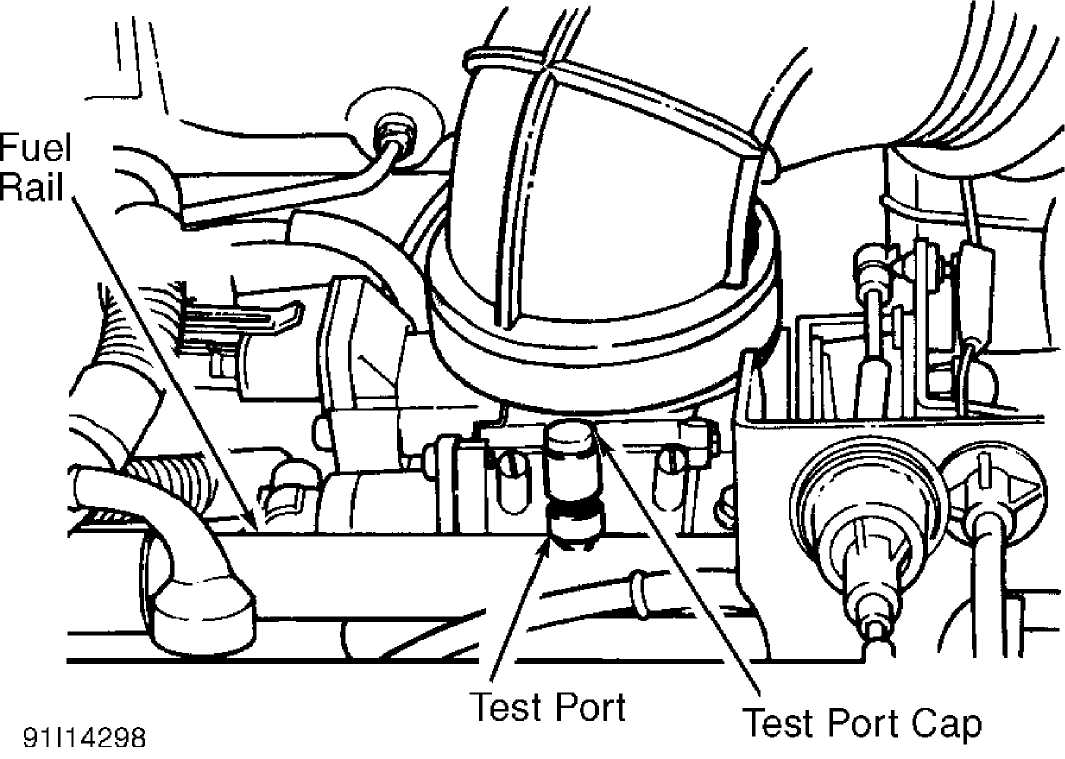

Disconnect negative battery cable. Remove fuel filler cap. Remove cap from pressure test port on fuel rail. See Fig. 1. Place shop towels around pressure test port to absorb spilled fuel. Press test port valve with a small screwdriver or punch wrapped in shop towels. Remove shop towels and dispose of properly. Install pressure test port cap.

CAUTION: Always replace "O" rings, spacers and retainers whenever

fuel system quick-connect fittings are disconnected. Ensure fuel connections are secure by verifying that only retainer tabs protrude from connectors, and by pulling on tubes to verify that they are secure.

Fig. 1: Locating Fuel Pressure Bleeding Test Port Courtesy of Chrysler Corp.

COOLING SYSTEM BLEEDING

CAUTION: Engine coolant may be hot. To avoid scalding, carefully

release system pressure before removing radiator cap or drain cock.

Fill radiator completely and install pressure cap. Fill reserve/overflow tank to FULL mark. Operate engine until it reaches normal operating temperature. Shut off engine and allow it to cool. Recheck coolant level in reserve/overflow tank as necessary. Add coolant ONLY when engine is cold.

ENGINE

Removal (Cherokee)

Remove

battery and air cleaner. Remove hood. Drain cooling

system.

Remove radiator hoses, coolant recovery hose and fan

shroud.

Disconnect transmission fluid cooler lines (if equipped).

Discharge

A/C system (if equipped). Discharge A/C

system

using approved refrigerant recovery/recycling equipment.

Remove A/C

condenser (if equipped) and

radiator. Remove fan. To maintain pulley

and

water pump alignment, install a 5/16 x

1/2" bolt through fan

pulley

into water pump flange.

Disconnect

heater hoses, throttle linkage, cruise control

cable

(if equipped) and throttle valve rod. Disconnect wires from

starter

solenoid, oxygen (O2) sensor and all fuel

injection harness

connections.

Release fuel pressure. See FUEL PRESSURE RELEASE.

Disconnect fuel supply and return lines at fuel rail. Disconnect TDC sensor wire connector. Remove A/C service valves and cap compressor ports (if equipped).

Remove

vacuum check valve from power brake booster (if

equipped).

Disconnect power steering hoses at steering gear

(if

equipped). Drain

power steering pump reservoir. Cap power steering

hoses

and fittings.

Tag and

disconnect any remaining hoses or electrical

connectors. Raise

and support vehicle. Disconnect exhaust pipe from

exhaust

manifold. Remove starter and flywheel cover.

On

automatic transmission equipped models, mark converter

and

flexplate for installation reference. Remove converter-to-

flexplate

bolts. On all models, remove upper bellhousing bolts and

loosen

bottom bolts. Remove engine mount bolts.

Remove

engine shock damper bracket. Lower vehicle. Attach

lifting

device to engine. Raise engine from front supports. Place

support

under bellhousing. Remove remaining bellhousing bolts.

Remove

engine.

Removal (Wrangler)

Pad

windshield with cloth. Raise hood and rest it against

windshield

frame. Drain cooling system. Remove battery. Disconnect

wiring

from alternator, ignition coil, distributor, oil pressure

sender

and fuel injection wire harness.

Disconnect

fuel line quick-connect couplings at fuel rail.

Remove engine

ground strap. Remove air cleaner. Disconnect vacuum

purge hose

from vapor canister tee. Unplug idle speed actuator

connector.

Disconnect throttle cable and remove it from bracket.

Disconnect

throttle rod at bellcrank. Unplug oxygen (O2)

sensor

connector. Disconnect coolant hoses at radiator, intake

manifold

and thermostat housing. Remove fan shroud and radiator.

Remove

fan and spacer. Install a 5/16 x 1/2"

bolt through fan pulley

into

water pump flange to maintain pulley and water pump alignment.

Remove

check valve from power brake booster (if equipped).

Disconnect

power steering hoses at steering gear (if equipped).

Drain

power steering pump reservoir. Cap power

steering hoses and fittings.

Tag and

disconnect any remaining hoses or electrical

connectors. Raise

and support vehicle. Disconnect exhaust pipe from

exhaust manifold. Remove starter. Remove flywheel housing access cover. Remove engine mount through-bolts. Remove upper bellhousing bolts. Loosen lower bellhousing bolts.

6) Lower vehicle. Attach lifting device to engine. Raise engine from front supports. Place support under bellhousing. Remove remaining bellhousing bolts. Lift engine from engine compartment.

Installation (All Models)

Remove engine mount cushions from brackets to aid alignment of engine and transmission. To complete installation, reverse removal procedure. Adjust throttle and cruise control linkage (if equipped). Tighten bolts to specification. See TORQUE SPECIFICATIONS table. Refill and check fluid levels.

INTAKE MANIFOLD

Removal

Disconnect

negative battery cable. Remove air inlet hose

at throttle body

and air cleaner. Remove power steering pump with

hoses attached

and wire it aside.

Release

fuel pressure. See FUEL PRESSURE RELEASE. Remove

power steering

pump brackets at water pump and intake manifold.

Disconnect fuel

supply and return lines at fuel rail.

Disconnect

accelerator cable. Unplug cruise control

connector at throttle

body, using finger pressure only. Remove

crankcase ventilation

and manifold pressure sensor hoses. Tag and

disconnect all wiring

and hoses.

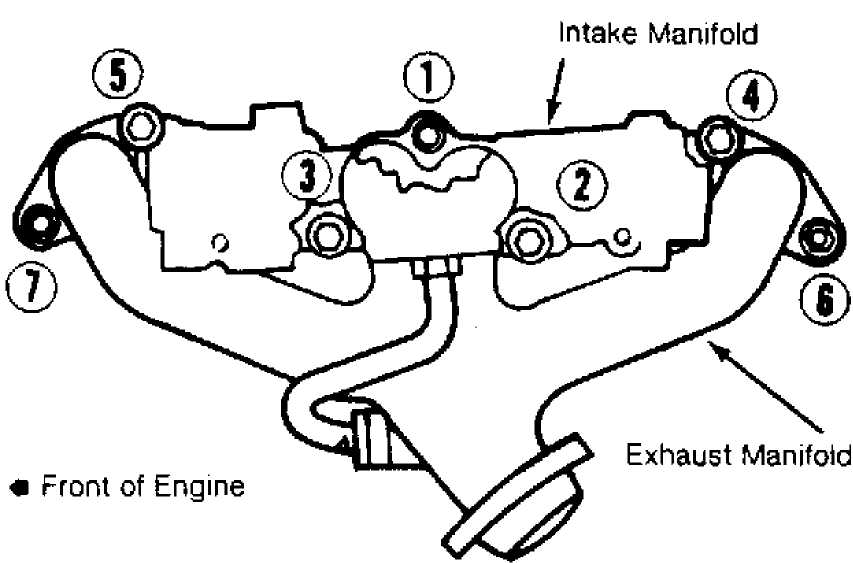

Remove

bolts No. 2 through 5 securing

intake manifold to

cylinder head. See Fig. 2. Slightly

loosen bolt No. 1 and nuts No. 6

and

7. Remove intake manifold. Drain coolant

from manifold.

Fig. 2: Intake & Exhaust Manifold Bolt Tightening Sequence Courtesy of Chrysler Corp.

Installation

Ensure all gasket surfaces are clean. Install intake

manifold. Finger tighten all bolts. Tighten intake manifold bolts to specification in correct sequence. See Fig. 2. Also see

TORQUE SPECIFICATIONS table. To complete installation, reverse removal procedure. Fill and bleed cooling system.

EXHAUST MANIFOLD

Removal

Disconnect negative battery cable. Remove intake manifold. See INTAKE MANIFOLD. Raise and support vehicle. Disconnect exhaust pipe from exhaust manifold. Lower vehicle. Remove retaining nuts and bolts. Remove exhaust manifold.

Installation

Clean

all gasket surfaces. Install intake and exhaust

manifolds

together, using NEW gasket. Ensure exhaust manifold is

centrally

located over end studs and spacer. Tighten bolt No. 1

to

specification.

See TORQUE SPECIFICATIONS table. Tighten bolts No. 2

through

5 to specification in sequence. See Fig.

2.

Install

new spacers over cylinder head studs. Tighten nuts

No.

6 and 7 to

specification. To complete installation, reverse

removal

procedure. Start engine and check for leaks.

CYLINDER HEAD

Removal

Disconnect

negative battery cable. Drain cooling system.

Remove accessory

drive belt. Remove A/C compressor (if equipped) and

wire it

aside. DO NOT discharge A/C system. Remove air cleaner.

Remove A/C

compressor mounting bracket-to-cylinder head

bolts. Loosen A/C

compressor mounting bracket-to-cylinder block bolts.

Disconnect

upper radiator hose and heater hoses. Remove valve cover.

Remove

rocker arms, bridges, pivots and push rods. Tag all

parts for

installation reference. See ROCKER ARMS. Remove manifolds.

See

INTAKE MANIFOLD and EXHAUST MANIFOLD.

Tag and

disconnect spark plug wires. Remove spark plugs.

Remove cylinder

head bolts. Remove cylinder head. Stuff clean lint-

free shop

towels into cylinder bores.

Inspection

Inspect

cylinder head for cracks or damage. Using

straightedge, check

cylinder head for warpage across bolt holes and

diagonals.

Resurface or replace cylinder head if warpage exceeds

specification

or damage exists. See CYLINDER HEAD table under

ENGINE

SPECIFICATIONS.

Cylinder

head bolts may be REUSED ONLY ONCE. If this is

the first time

cylinder head has been removed, put a dab of paint on

the head of

each bolt. If the bolts already have paint on them, or if

it is

unknown whether they have been used before, DISCARD THEM and

replace

with NEW bolts.

Installation

Clean

carbon from combustion chambers and tops of pistons.

Ensure all

gasket surfaces, head bolts and head bolt holes are clean.

Install

NEW cylinder head gasket with numbers or word TOP upward. DO

NOT

apply sealant to cylinder head gasket. Ensure all holes

align

properly.

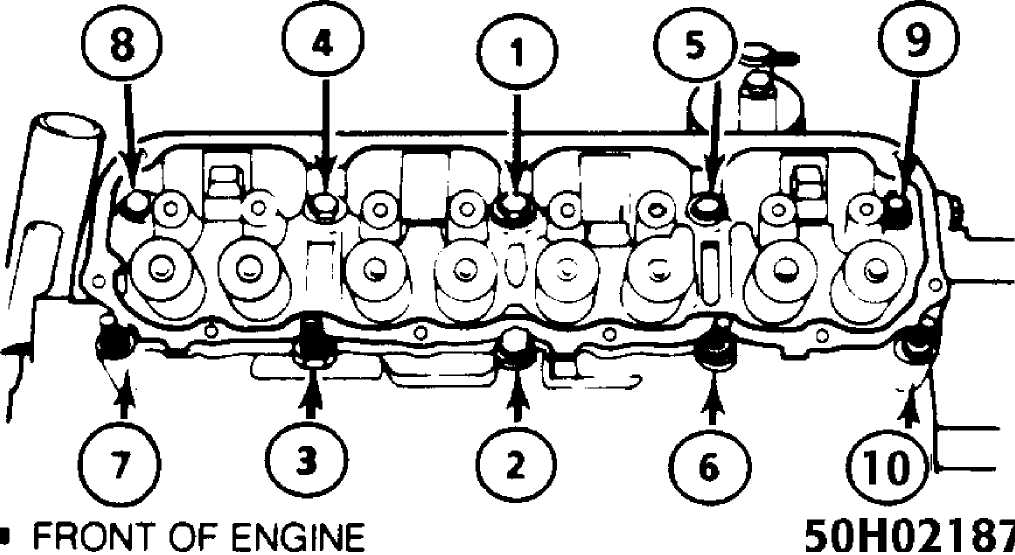

Install

cylinder head. Apply sealing compound to threads

of

cylinder head bolt No. 7 before

installation. Install cylinder head

bolts. Tighten all bolts in 3

stages in sequence to specs. See Fig. 3.

For

torque specifications see TORQUE SPECIFICATIONS table.

NOTE: During the final tightening sequence, bolt No. 7 will be

tightened to a lower torque than the others.

3) To complete installation, reverse removal procedure. Install all valve train components into their original locations. Refill cooling system. Remove coolant temperature sensor to bleed air from system while filling.

Fig. 3: Cylinder Head Bolt Tightening Sequence Courtesy of Chrysler Corp.

FRONT COVER OIL SEAL

Removal & Installation

1) Remove drive belt. Remove vibration damper. Remove

radiator shroud. Remove seal from front cover. Apply sealant to outer diameter of new seal. Coat crankshaft lightly with oil.

2) Drive

seal into front cover, using Front Cover

Aligner/Seal

Installer (6139). Lightly coat seal contact

area of

vibration damper with oil.

Lubricate vibration damper bolt with oil

before

installation. Reverse removal procedure to complete

installation.

See TORQUE SPECIFICATIONS table.

TIMING CHAIN & SPROCKETS

Removal

Disconnect

negative battery cable. Remove drive belt, fan

and hub assembly.

Remove fan shroud. Remove accessory drive brackets

attached to

timing case cover. Remove A/C compressor (if equipped)

with hoses

attached and wire it aside. DO NOT discharge A/C system.

Remove

alternator bracket assembly from cylinder head.

Remove

vibration damper retaining bolt and washer. Remove

vibration

damper and key. Remove front cover retaining bolts and front

cover.

Cut oil pan gasket flush with face of cylinder block. Remove

cut-off

pieces.

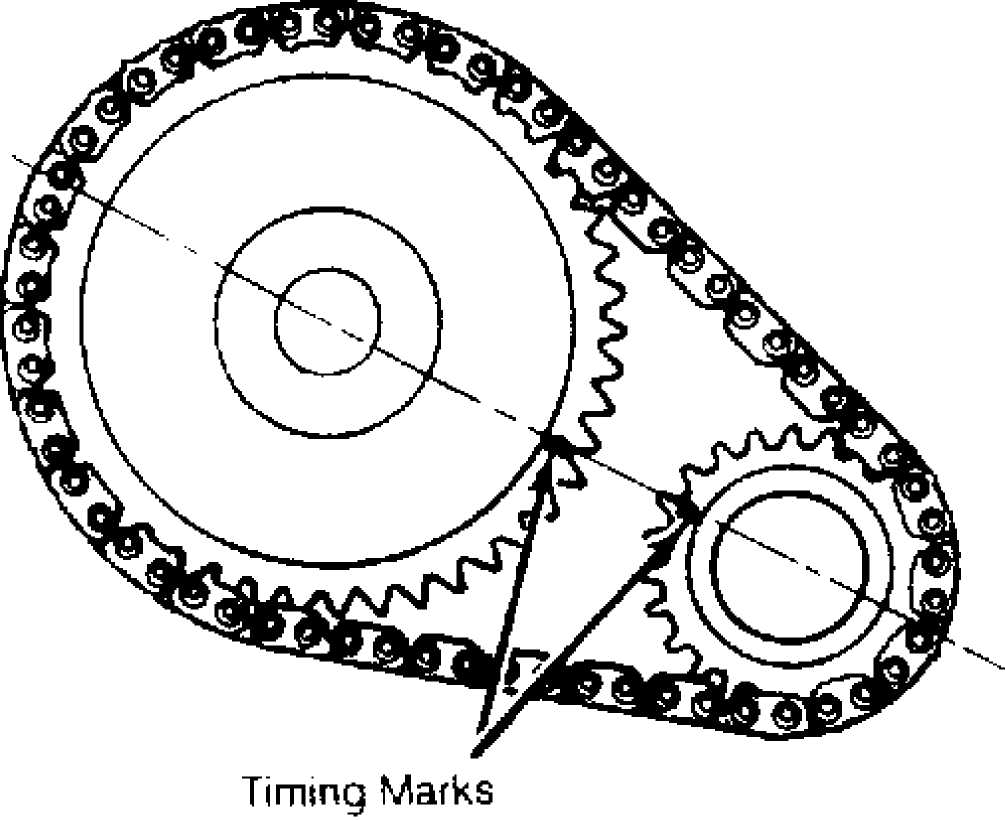

Rotate

crankshaft until timing marks on crankshaft and

camshaft

sprockets align. See Fig. 4. Remove oil

slinger and camshaft

sprocket retaining bolt. Remove sprockets and chain as an assembly. Remove front cover oil seal.

Fig. 4: Aligning Sprocket Timing Marks Courtesy of Chrysler Corp.

Installation

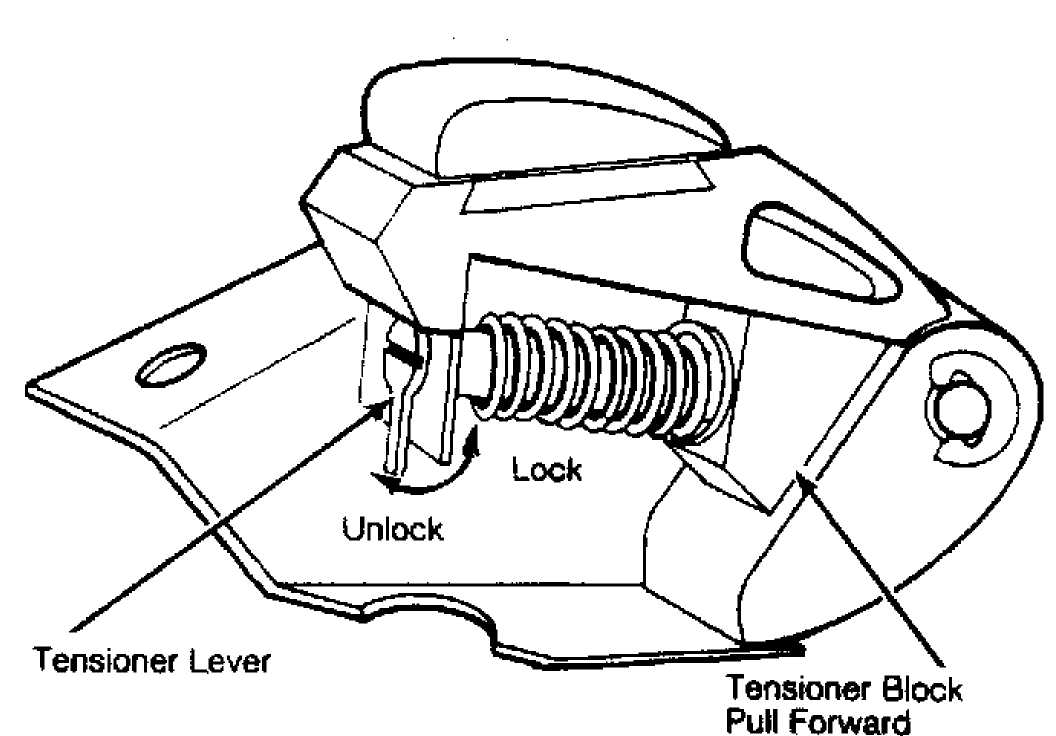

1) Turn tensioner lever down to unlock position. Pull

tensioner block toward lever to compress spring. Turn lever up to lock position. See Fig. 5. Install timing chain and sprockets as an assembly. Ensure timing marks align. Install camshaft sprocket retaining bolt and washer. Tighten to specification. See the TORQUE SPECIFICATIONS table.

NOTE: Ensure chain tensioner is in unlock (down) position before installing front cover.

Fig. 5: Locating Chain Tensioner Lock Courtesy of Chrysler Corp.

Verify

proper installation by rotating crankshaft until

timing mark on

camshaft is at approximately one o’clock position.

Timing

sprockets are installed correctly if there are 20 timing

chain

pins between timing marks on both

sprockets.

Clean all

gasket surfaces. Install oil slinger. Apply

sealing compound to

both sides of front cover gasket. Install gasket

onto cylinder

block. Replace front section of oil pan seal with

similar piece

cut from new seal.

Coat

outer surface of NEW seal with RTV sealant and place

into

position. Apply sealant where oil pan and cylinder block meet.

Place

front cover onto cylinder block. Place Front Cover

Aligner/Seal

Installer (6139) in front

engine cover seal area.

Install cover retaining bolts, and tighten to

specification. To complete installation, reverse removal procedure. Lubricate vibration damper retaining bolt before installation, and tighten to specification. See TORQUE SPECIFICATIONS table.

ROCKER ARMS

Removal

Remove valve cover. Alternately loosen rocker arm cap screws one turn at a time to prevent damaging bridges. Remove bridges, pivots, rocker arms and push rods. Tag all parts for reassembly reference.

Installation

1) Lubricate

push rod ends with Mopar Engine Oil Supplement

(4318002).

Install push rods into their original locations.

Ensure

bottom end of each push rod is centered in valve lifter.

Lubricate

pivot contact area of each rocker arm with

engine oil supplement.

Install rocker arms, pivots and bridges into

their original

locations. Loosely install cap screws, then tighten

alternately

one turn at a time to specification. Reverse removal

procedure to

complete installation.

Pour

remaining engine oil supplement over entire valve

train.

Supplement must remain in engine oil for at least 1000 miles

(1600 km), but need not be drained until next scheduled oil change.

CAMSHAFT

Removal

Disconnect

negative battery cable. Drain cooling system.

Discharge

A/C system (if equipped) , using approved

refrigerant

recovery/recycling

equipment. Remove A/C condenser (if equipped) and

radiator. Mark

distributor and engine block for installation

reference.

Remove distributor and ignition wiring. Remove rocker arms,

bridges,

pivots and push rods. See ROCKER ARMS.

Remove valve lifters using Hydraulic Valve Lifter

Remover/Installer (C-4129-A). Tag each valve lifter for installation reference. Remove timing chain and sprockets. See TIMING CHAIN & SPROCKETS. Remove camshaft.

Inspection

Inspect lobes, journals, bearings and distributor drive gear for wear. If camshaft sprocket or chain rubs against engine front cover, examine oil pressure relief holes in rear camshaft journal. Oil pressure relief holes MUST be free of debris.

Installation

Lubricate

camshaft and dip valve lifters into Mopar Engine

Oil

Supplement (4318002). Install camshaft.

Reverse removal procedure

to complete

installation.

Pour

remaining oil supplement over entire valve train.

Supplement must

remain in engine oil for at least 1000 miles

(1600

km), but need not be drained

until next scheduled oil change. Refill

cooling

system. Adjust ignition timing. Check for leaks.

REAR CRANKSHAFT OIL SEAL

Removal

Remove transmission, clutch housing and flywheel or flexplate. Pry oil seal from housing. Avoid damage to surrounding area.

Installation

Coat outer lip of replacement seal with engine oil. Using Installer (6271), install seal flush with cylinder block. Use only NEW bolts when installing flywheel or flexplate. Ensure felt lip is inside flywheel mounting surface to avoid tearing seal. To complete installation, reverse removal procedure. Tighten flywheel or flexplate bolts to specification, then an additional 60 degrees. See the TORQUE SPECIFICATIONS table.

WATER PUMP

Removal

Disconnect negative battery cable. Drain cooling system. Remove fan shroud and drive belts. Remove fan assembly. Disconnect

heater hoses and lower radiator hose at water pump. Remove water pump retaining bolts. Remove water pump.

Installation

Install water pump. Tighten bolts to specification. See TORQUE SPECIFICATIONS table. Ensure pump turns freely. Ensure belt is installed correctly to prevent engine overheating because water pump rotates in wrong direction. To complete installation, reverse removal procedure. Fill and purge air from cooling system. Remove coolant temperature sensor to bleed air from system while filling.

OIL PAN

Removal

Disconnect

negative battery cable. Raise and support

vehicle at side sills.

Drain engine oil. Disconnect exhaust pipe at

exhaust manifold.

Disconnect exhaust hanger at catalytic converter.

Lower exhaust

pipe. Remove starter. Remove flywheel access cover.

Position

jackstand directly under vibration damper. Place

wooden block

between vibration damper and jackstand. Remove through

bolts from

engine mounts. Raise engine enough to remove oil pan.

Remove oil

pan retaining bolts. Remove oil pan by sliding it to rear.

Installation

1) Ensure all gasket surfaces are clean. Fabricate 4

alignment dowels from 1 1/2 x 1/4" bolts. Cut heads off bolts and cut slot in end of bolts to allow removal with screwdriver. Install 2 dowels in timing cover and 2 dowels in block. Slide gasket over dowels into position against block and timing cover.

2) Install

oil pan. Install sufficient bolts to hold oil pan

in

place. Remove alignment dowels. Install remaining oil pan bolts

and

tighten to specification. See TORQUE

SPECIFICATIONS table. To complete

installation,

reverse removal procedure. Fill crankcase. Start engine.

Check

for leaks.

OVERHAUL

CYLINDER HEAD

Inspection

Inspect for cracks in combustion chambers, coolant passages, ports and exhaust valve seats. Using straightedge, check cylinder head for warpage in several areas. Repair or replace cylinder head if warpage exceeds specification or damage exists. See CYLINDER HEAD table under ENGINE SPECIFICATIONS.

Valve Springs

Use Valve Spring Tester (J-22738-02) to test each valve spring. Measure free length of each valve spring. Replace valve springs that do not meet specifications. See VALVES & VALVE SPRINGS table under ENGINE SPECIFICATIONS.

Valve Stem Oil Seals

Replace valve stem oil seals if they have deteriorated or whenever valves are serviced. Oil seals are marked INT and EXH for intake and exhaust valves, respectively. Oversize oil seals must be used with valves having .015" (.38 mm) oversize stems.

Valve Guides

Measure diameter of valve guide approximately 3/8" (10 mm) from valve spring side of head, both parallel and at right angle to long axis of head. If difference between measurements exceeds .0025"

(.063 mm), or if diameter exceeds specification by .003" (.08 mm), ream valve guide for oversize valve stem. See CYLINDER HEAD table under ENGINE SPECIFICATIONS. Reface valve seats after reaming valve guides.

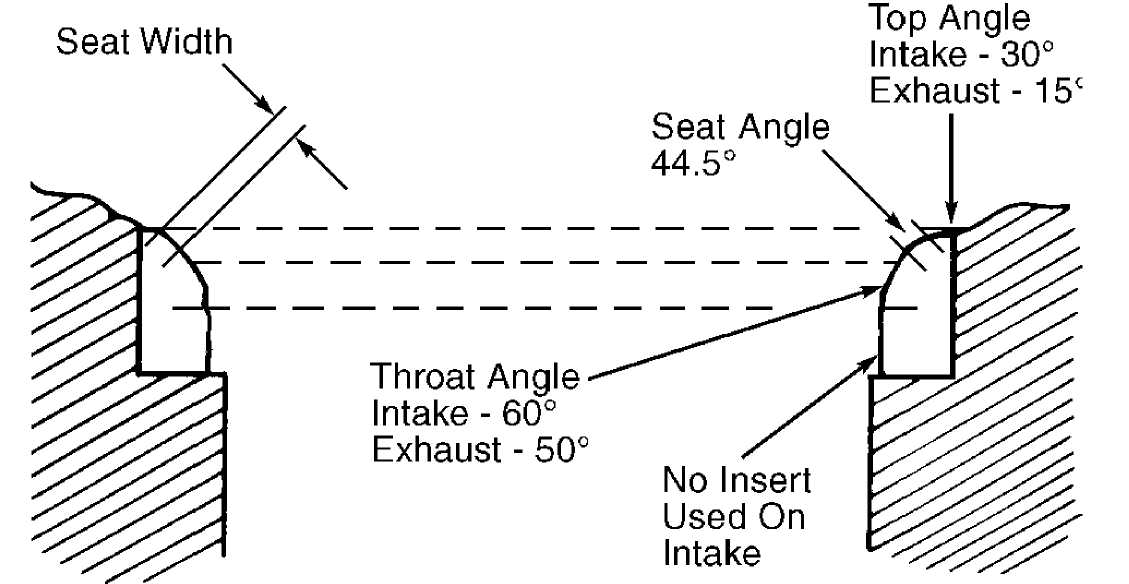

Valve Seats

Reface valve seats to specification. Remove only enough metal to provide smooth finish. Use tapered stones to obtain specified seat width. See Fig. 6. Seat width runout should not exceed .0025" (.063 mm) after refacing. See CYLINDER HEAD table under ENGINE SPECIFICATIONS.

Valves

Reface valves to specification. At least 1/32" (.79 mm) margin must remain after refacing valve. Valve stem tip can be resurfaced and chamfered when worn. DO NOT remove more than .01" (.25 mm). See VALVES & VALVE SPRINGS table under ENGINE SPECIFICATIONS.

91C143.00

Fig. 6: Checking Valve Seat Dimensions Courtesy of Chrysler Corp.

VALVE TRAIN

Rocker Arms

Inspect pivot and valve stem contact surfaces of each rocker arm. Replace any rocker arm that is scuffed, pitted, cracked or excessively worn.

Push Rods

Inspect push rods for excessive wear. If wear is excessive because of lack of oil, replace and inspect corresponding valve lifter for excessive wear. Roll push rods on a flat surface to check for straightness. Replace push rod and/or valve lifter, if necessary. If

wear exists along length of push rod, inspect cylinder head for obstruction.

CYLINDER BLOCK ASSEMBLY

Piston & Rod Assembly

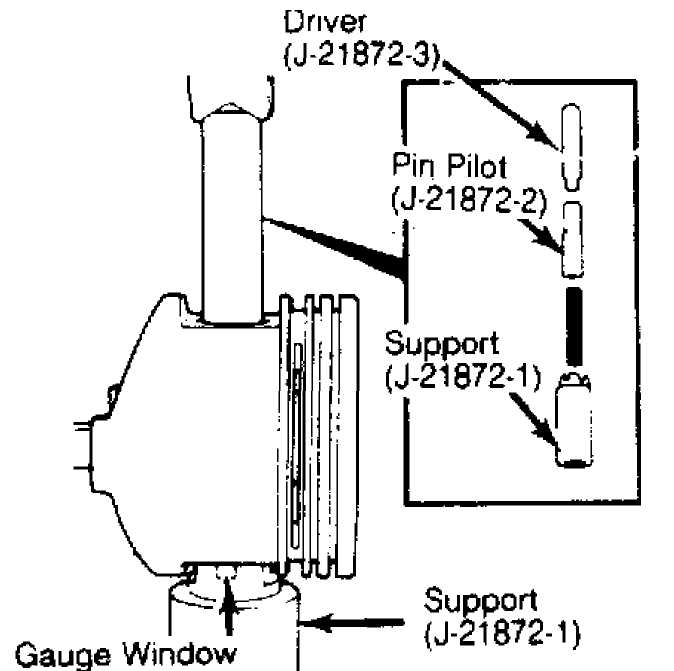

Fig. 7: Removing & Installing Piston Pin Courtesy of Chrysler Corp.

Fitting Pistons

Measure cylinder bore 2 5/16" (59 mm) below top of bore.

Note

locations of arrow on piston crown and oil squirt

hole in

connecting rod. Position piston and rod assembly on support.

See

Fig. 7. Press piston pin from piston.

Discard pin.Piston pin

CANNOT be reused

after removal. Inspect piston pin bore in connecting

rod for

nicks or burrs and remove as necessary.

Clean

piston pin bore and replacement piston pin. Piston

and piston pin

must be at room temperature when measuring fit. Piston

pin should

fall through piston at room temperature. If pin jams in pin

bore,

replace piston.

Position

piston on support so that arrow on piston crown

will point to

front of engine and connecting squirt hole will face

camshaft

when installed. Insert piston pin through piston pin bore and

into

connecting rod pin bore.

Press

pin through rod and piston until pilot aligns with

mark

on support. Pin should be centered in rod. Piston pin

installation

requires approximately 2000 lbs. (900

kg) of force.

Replace

connecting rod if noticeably less force is required, or if rod

moves

on pin.

Measure piston diameter at right angle to piston pin at center line of pin. Piston clearance is difference between measurements. Pistons up to .004" (.10 mm) undersize may be enlarged by knurling or shot peening. Replace pistons if clearance is greater than .004" (.10 mm) or more.

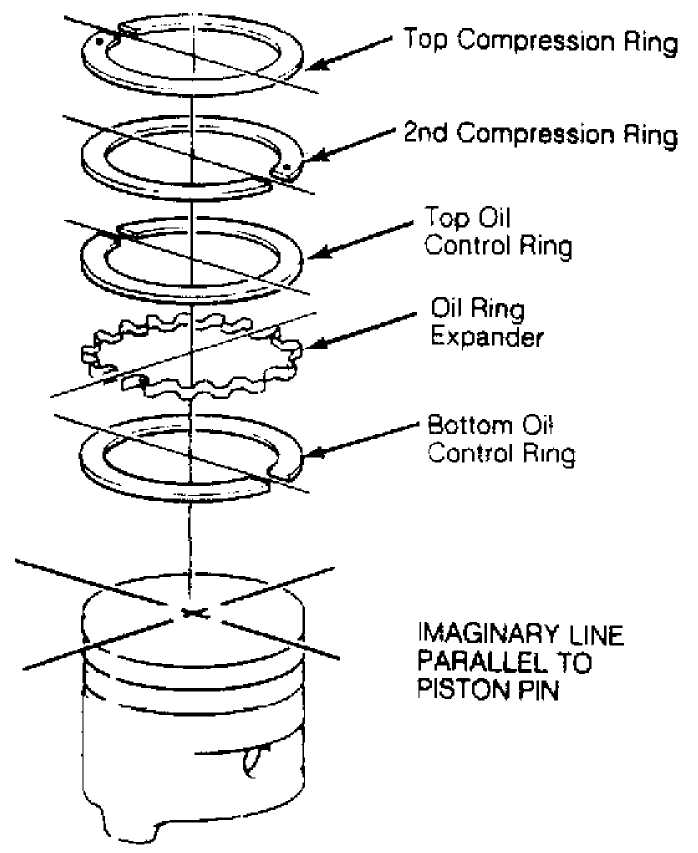

Piston Rings

Install piston rings. DO NOT interchange piston rings. Top ring has a Gray scraping surface; second ring is Black. Ensure ring end gap and side clearance are within specifications. Install compression rings with dot(s) on ring surface toward top of piston. Position ring end gaps in specified area. Ring gaps may vary 20 degrees from locations illustrated. See Fig. 8. Also see PISTONS, PINS & RINGS table under ENGINE SPECIFICATIONS.

Fig. 8: Positioning Piston Ring Gaps Courtesy of Chrysler Corp.

Rod Bearings

1) Inspect bearings for wear or damage. Replace as necessary.

Using Plastigage, check bearing clearance. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS table under ENGINE SPECIFICATIONS. Bearings are available for standard and undersize applications.

2) If necessary, different size upper and lower bearings may be combined to obtain correct oil clearance. Tighten bolts to specification. Check rod side play. Rotate crankshaft to ensure freedom of movement. See TORQUE SPECIFICATIONS table. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS table.

NOTE: Never combine bearing inserts that differ by more than .001" (.03 mm) in size. Odd size inserts must be on bottom (rod cap) side.

Crankshaft & Main Bearings

1) Inspect

bearings for damage or wear. Replace as necessary.

Using

Plastigage, measure bearing clearance. See CRANKSHAFT, MAIN

&

CONNECTING ROD BEARINGS table

under ENGINE SPECIFICATIONS. Bearings

are

available in standard and undersize. If necessary, different

size

upper and lower bearings may be installed to obtain correct

oil

clearance. Lubricate bearings before

installation.

NOTE: If different size bearings are installed, the odd size

bearings must all be uniform in location (upper or lower). Never combine bearing inserts that differ by more than .001" (.03 mm).

2) Install

upper bearing inserts. Install bearing caps and

lower

inserts. Tighten bearing caps No. 1, 3, 4 and

5 in 3 stages

to

specification. Pry crankshaft to front or rear and tighten

bolts for

cap No. 2 to

specification in 3 stages. Rotate

crankshaft to ensure

freedom of movement after tightening each

cap. See the

TORQUE SPECIFICATIONS table. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS table.

Thrust Bearing

Check crankshaft end play. If end play is not within

specification, replace bearing No. 2. If end play is still not within specification, replace crankshaft. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS table under ENGINE SPECIFICATIONS.

Cylinder Block

Measure

cylinder bore diameter crosswise to cylinder block

near top of

bore. Repeat measurement at bottom of bore. Subtract

smaller

diameter from larger diameter to determine taper.

Repeat

measurements for each cylinder.

Repeat

measurements with measuring device rotated 120

degrees.

Repeat this step for a total of 3 measurements.

Cylinder out-

of-round is the

difference between measurements. Repeat for each

cylinder.

Bore

and hone cylinders for oversize pistons if taper or

out-of-round

exceeds specification. Move hone up and down to provide a

60-degree

crosshatch pattern. DO NOT use a rigid hone or exceed 10

strokes

per cylinder. See CYLINDER BLOCK table under

ENGINE SPECIFICATIONS.

LUBRICATION

ENGINE OILING

A distributor-driven pump supplies oil through a full-flow oil filter to an oil gallery on right side of block and intersecting lifter bores. Oil then flows to camshaft and crankshaft bearings. The

rocker arms receive oil through the push rods and lifters.

Crankcase Capacity

Crankcase capacity is 4 qts. (3.8L) with oil filter change.

Oil Pressure

Normal oil pressure should be 25-35 psi (1.8-2.5 kg/cm) at 800 RPM or 37-75 psi (2.6-5.3 kg/cm) at 1600 RPM. Oil pressure relief occurs at 75 psi (5.3 kg/cm).

OIL PUMP

Removal & Disassembly

Remove oil pump retaining bolts. DO NOT move oil pick-up pipe in pump body. If oil pick-up pipe is moved, pick-up pipe must be replaced to ensure an airtight seal. Remove pump cover. Disassemble pump.

Inspection

Inspect

for wear and damage. Place Plastigage across full

width

of each gear. Temporarily install cover, and tighten bolts to

70

INCH lbs. (8 N.m).

Remove cover. Examine Plastigage to determine

end

clearance.

Rotate

gears, and measure clearance between each tooth and

oil pump

body, directly opposite point of mesh. Replace oil pump if

not

within specification. See OIL PUMP SPECIFICATIONS table.

OIL PUMP SPECIFICATIONS TABLE

Application In. (mm)

Gear End Clearance 002-.006 (.05-.15)

Gear-to-Body Clearance 002-.004 (.05-.10)

Reassembly & Installation

Apply

sealant to pick-up pipe and pump cover area prior to

installation.

To install pick-up tube, use Pipe Installer (7624).

Ensure

pick-up pipe support bracket is aligned with pump cover bolt.

If

relief valve is replaced, ensure replacement valve is same

diameter

as that removed.

Fill pump

cavity with petroleum jelly. Install cover.

Tighten cover bolts

to specification. Check pump gears for freedom of

rotation.

Install new gasket and oil pump. Tighten retaining bolts

to

specification. See TORQUE SPECIFICATIONS table.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft. Lbs. (N.m)

Camshaft Sprocket Bolt 80 (108)

Connecting Rod Cap Nuts 33 (45)

Cylinder Head Bolts (1)

Stage 1 22 (30)

Stage 2 45 (61)

Stage 3 (2) 110 (149)

Drive Plate-To-Converter Bolts 40 (54)

Exhaust Manifold Bolts (3)

Bolt No. 1 30 (41)

Bolt No. 2-5 23 (31)

Nut No. 6 & 7 30 (41)

Fan Bolts 18 (24)

Flexplate-To-Crankshaft Bolts (4) 50 (68)

Flywheel-To-Crankshaft Bolts (4) 50 (68)

Intake Manifold Bolts (3)

Bolt No. 1 30 (41)

Bolt No. 2-5 23 (31)

Nut No. 6 & 7 30 (41)

Main Bearing Cap Bolts

Stage 1 40 (54)

Stage 2 70 (95)

Stage 3 80 (108)

Oil Pump Retaining Bolts

Long 17 (23)

Short 10 (14)

Oxygen (O2) Sensor 23 (31)

Pulley-To-Vibration Damper Bolts 20 (27)

Rocker Arm Bolts 21 (28)

Starter Bolts 33 (45)

Throttle Body-To-Intake Bolts 10 (14)

Vibration Damper Bolt (5) 80 (108)

Water Pump Bolts 25 (34)

INCH Lbs. (N.m)

Front Cover-To-Block Bolts 62 (7)

Oil Pan Bolts

1/4" X 20 114 (13)

5/16" X 18 156 (18)

Oil Pump Cover Bolts 70 (8)

Valve Cover Bolts 85 (9)

- Tighten in sequence. See Fig. 3.

- All except bolt No. 7. Tighten bolt No. 7 to

100 ft. lbs. (136 N.m).

- Tighten bolts in sequence. See Fig. 2.

- Tighten to specification and an additional 60 degrees.

- With bolt cleaned and threads lubricated with oil.

ENGINE SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS TABLE

Application Specification

Displacement 150 Cu. In. (2.5L)

Bore 3.88" (98.5mm)

Stroke 3.19" (81.0mm)

Compression Ratio

Cherokee 9.2:1

Wrangler 9.1:1

Fuel System PFI

Horsepower @ RPM

Cherokee 130 @ 5250

Wrangler 123 @ 5250

Torque Ft. Lbs. @ RPM

Cherokee 149 @ 3000

Wrangler 139 @ 3250

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS SPECS

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS SPECS TABLE

Application

In. (mm)

Crankshaft

End Play 0015-.0065 (.038-.165)

Runout ( 1)

Main Bearings

Journal Diameter 2.4996-2.5001 (63.490-63.503)

Journal Out-Of-Round 0005 (.013)

Journal Taper 0005 (.013)

Oil Clearance 0010-.0025 (.025-.063)

Connecting Rod Bearings

Journal Diameter 2.0934-2.0955 (53.172-53.226)

Journal Out-Of-Round 0005 (.013)

Journal Taper 0005 (.013)

Oil Clearance 0015-.0025 (.038-.063)

(1) - Information not available from manufacturer.

CONNECTING RODS SPECIFICATIONS

CONNECTING RODS SPECIFICATIONS TABLE

Application

In. (mm)

Bore Diameter

Pin Bore 9288-.9298 (23.591-23.617)

Crankpin Bore 2.2080-2.2085 (56.083-56.096)

Center-To-Center Length 6.123-6.127 (155.52-155.63)

Maximum Bend 003 (.08)

Maximum Twist 006 (.15)

Side Play 010-.019 (.25-.48)

PISTONS, PINS & RINGS SPECIFICATIONS

PISTONS, PINS & RINGS SPECIFICATIONS TABLE Application

In. (mm)

Piston

Clearance 0013-.0021 (.033-.053)

Diameter ( 1)

Pins

Diameter 9306-.9307 (23.637-23.640)

Piston Fit 0003-.0007 (.007-.018)

Rod Fit Press Fit

Rings

No. 1 & 2

End Gap 010-.020 (.25-.51)

Side Clearance 0017-.0032 (.043-.081)

No. 3 (Oil)

End Gap 015-.055 (.38-1.40)

Side Clearance 001.010 (.03-.24)

(1) - Information is not available from manufacturer. Replace pistons if piston clearance exceeds .004" (.10 mm).

CYLINDER BLOCK SPECIFICATIONS

CYLINDER BLOCK SPECIFICATIONS TABLE

Application In. (mm)

Cylinder Bore

Standard Diameter 3.875-3.877 (98.42-98.48)

Maximum Taper 001 (.03)

Maximum Out-Of-Round 001 (.03)

Minimum Deck Height 9.320 (236.73)

Maximum Deck Warpage 008 (.20)

VALVES & VALVE SPRINGS SPECIFICATIONS

VALVES & VALVE SPRINGS SPECIFICATIONS TABLE

Application Specification

Intake Valves

Face Angle 45

Head Diameter 1.90" (48.3 mm)

Minimum Margin 031" (.79 mm)

Minimum Refinish Length 4.889" (124.18mm)

Stem Diameter 311-.312" (7 . 89-7 . 92 mm)

Valve Tip Maximum Refinish 010" (.25 mm)

Exhaust Valves

Face Angle 45 °

Head Diameter 1.50" (38.1 mm)

Minimum Margin 031" (.79 mm)

Minimum Refinish Length 4.927" (125.15 mm)

Stem Diameter 311-.312" (7 . 90-7 . 92 mm)

Valve Tip Maximum Refinish 010" (.25 mm)

Valve Springs

Free Length 2.0" (51 mm)

Installed Height (1)

Out-Of-Square (1)

Pressure (2)

Valve Closed 80-90 @ 1.64 (36.3-40.8 @ 40.8)

Valve Open 200 @ 1.216 (90.7 @ 30.9)

- Information is not available from manufacturer.

- Lbs. @ In. (kg @ mm).

CYLINDER HEAD SPECIFICATIONS

CYLINDER HEAD SPECIFICATIONS TABLE

Application Specification

Cylinder Head Height ( 1)

Maximum Warpage 008" (.20 mm)

Valve Seats Intake Valve

Seat Angle 44 . 5-45 °

Seat Width 040-.060" (1.02-1.52 mm)

Maximum Seat Runout 0025" (.063 mm)

Exhaust Valve

Seat Angle 44.5-45 °

Seat Width 040-.060" (1.02-1.52 mm)

Maximum Seat Runout 0025" (.063 mm)

Seat Bore Diameter ( 1)

Valve Guides Intake Valve

Valve Guide I.D 313-.314" (7.95-7.98 mm)

Valve Stem-To-Guide

Oil Clearance 001-.003" (.03-.08 mm)

Exhaust Valve

Valve Guide I.D 313-.314" (7.95-7.98 mm)

Valve

Stem-To-Guide

Oil Clearance

001-.003"

(.03-.08 mm)

(1) - Information is not available from manufacturer. CAMSHAFT SPECIFICATIONS

CAMSHAFT SPECIFICATIONS TABLE

Application

In. (mm)

Bore Diameter ( 1)

End Play (2) 0 (0)

Journal Diameter

No. 1 2.029-2.030 (51.54-51.56)

No. 2 2.019-2.020 (51.28-51.31)

No. 3 2.009-2.010 (51.03-51.05)

No. 4 1.999-2.000 (50.78-50.80)

Journal Runout ( 3)

Lobe Height ( 1)

Lobe Lift 265 (6.73)

Oil Clearance 001-.003 (.03-.08)

- Information is not available from manufacturer.

- Engine running.

- Information is not available from manufacturer.

Manufacturer specifies .001" (.03 mm) maximum base circle runout.

VALVE LIFTERS SPECIFICATIONS

VALVE LIFTERS SPECIFICATIONS TABLE

Application

In. (mm)

Bore Diameter 9055-.9065 (22.987-23.025)

Lifter Diameter 9040-.9045 (22.962-22.974)

Oil Clearance 001-.002 (.03-.05)