A/C SYSTEM GENERAL SERVICING

1993 Jeep Cherokee

1993 GENERAL SERVICING General Servicing Procedures

Jeep

USING R-12 & R-134a REFRIGERANT

HANDLING/SAFETY PRECAUTIONS

1) Always

work in a well-ventilated, clean area. Refrigerant

(R-12 or

R-134a) is colorless and invisible as a gas. Refrigerant is

heavier than oxygen and will displace oxygen in a confined area. Avoid breathing refrigerant vapors. Exposure may irritate eyes, nose and throat.

The

system’s high pressure can cause severe injury to eyes

and skin

if a hose were to burst. Always wear eye protection when

working

around A/C system and refrigerant. If necessary, wear rubber

gloves

or other protective clothing.

Refrigerant

evaporates quickly when exposed to atmosphere,

freezing

anything it contacts. If liquid refrigerant contacts eyes or

skin

(frostbite), DO NOT rub eyes or skin. Immediately flush

affected

area with cool water for 15

minutes and consult a doctor or hospital.

Never

use R-134a in combination with compressed air for

leak

testing. Pressurized R-134a in the presence of oxygen

(air

concentrations greater than 60 percent

by volume) may form a

combustible mixture. DO NOT introduce

compressed air into R-134a

containers (full or empty), A/C

system components, or service

equipment.

DO

NOT expose A/C system components to high temperatures

(steam

cleaning for example) as excessive heat will

cause

refrigerant/system pressure to

increase. Never expose refrigerant

directly to open flame. If

refrigerant needs to be warmed, place

bottom

of refrigerant tank in warm water. Water temperature MUST NOT

exceed

125F (52C).

Use

care when handling refrigerant containers. DO NOT

drop,

strike, puncture, or incinerate containers. Use Department

Of

Transportation (DOT) approved (DOT

4BW or DOT 4BA) refrigerant

containers.

Never

overfill refrigerant containers. The safe filling

level

of a refrigerant container MUST NOT exceed 60% of

the

container’s gross weight rating.

Store refrigerant containers below

125F (52C).

Freon

(R-12) will be sold and stored in White colored

containers,

while R-134a refrigerant will be sold and stored in 30 or

50

pound Light Blue containers.

Refrigerant

R-12 and R-134a must never be mixed, as they

and their desiccants

and lubricants are not compatible. If the

refrigerants are mixed,

system cross-contamination or A/C system

component failure may

occur. Always use separate servicing and

refrigerant

recovery/recycling equipment.

10) Read

and follow equipment manufacturer’s instructions for

all

service equipment to be used. The Material Safety Data Sheet

(MSDS),

provided by refrigerant manufacturer/suppliers,

contains

valuable information regarding the safe handling of R-12 or R-134a refrigerants.

CAUTION: Keep work areas ventilated, and avoid operating engines near work area.

IDENTIFYING R-134a SYSTEMS & COMPONENTS

To prevent refrigerant cross-contamination, use following methods to identify R-134a based systems and components.

Fittings & "O" Rings

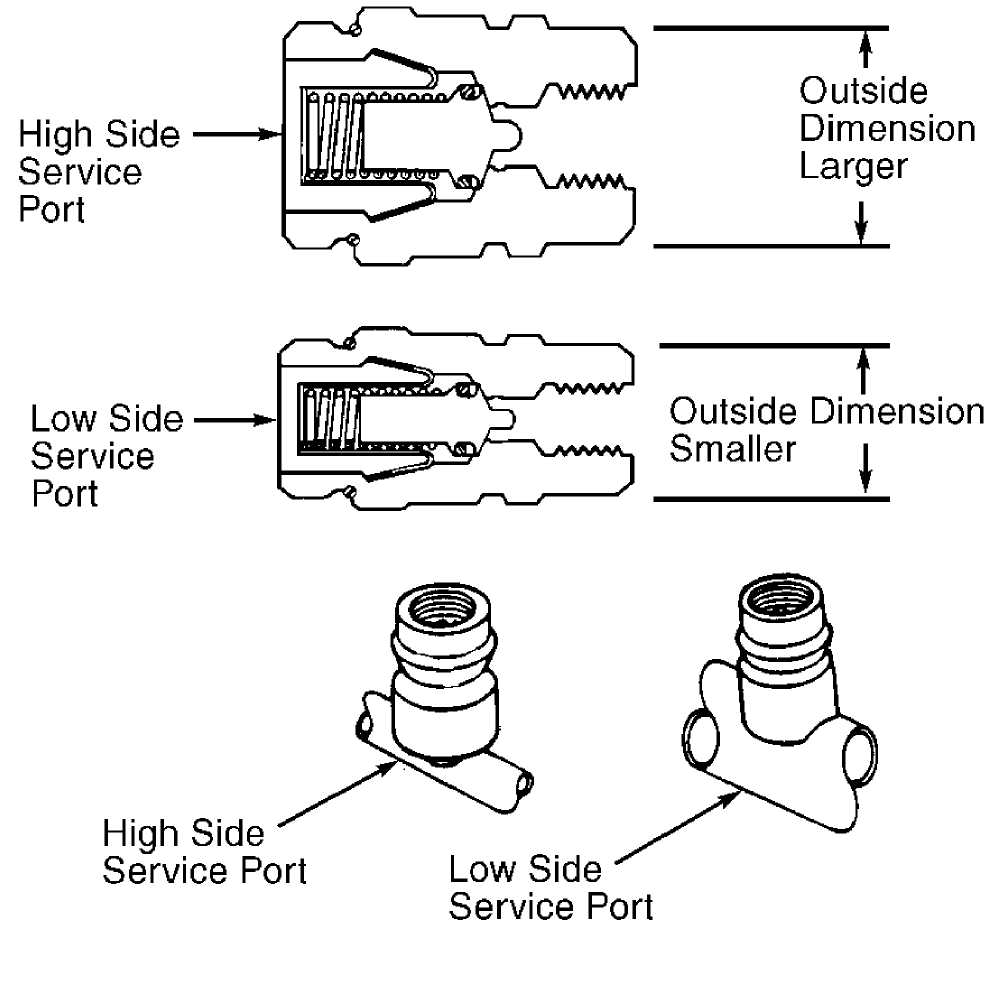

All R-134a based A/C systems use 1/2" - 16 ACME threaded fittings (identifiable by square threads) and quick-connect service couplings. See Fig. 1.

93128488

Fig. 1: Identifying R-134a Service Couplings Courtesy of Chrysler Corp.

Underhood A/C Specification Labels

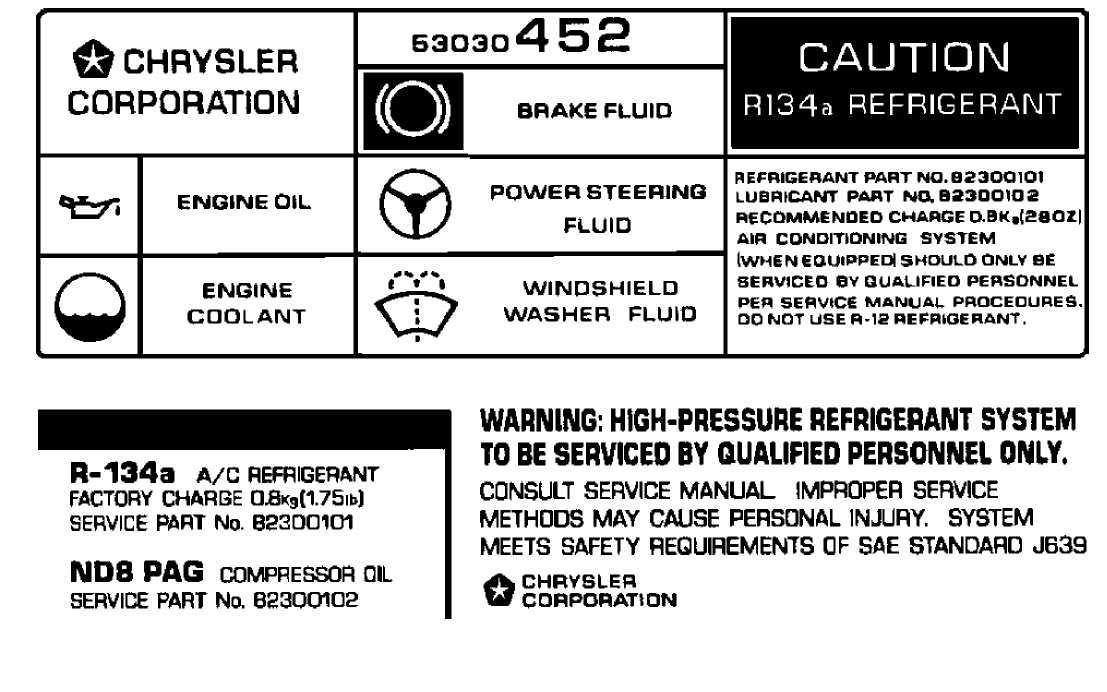

Most R-134a based systems will be identified through the use

of underhood labels with R-134a refrigerant clearly printed on labels. See Fig. 2. The underhood label used on Ford Motor Co. vehicles is Yellow. Most manufacturers will identify refrigerant type with labels affixed to compressor. Before servicing an A/C system, always determine which refrigerant is being used.

93D28483

93D28483

Fig. 2: Underhood Refrigerant Identification Labels Courtesy of Chrysler Corp.

(Chrysler)

Other Means Of Identification

Refrigerant R-134a, when viewed through a sight glass, may have a "milky" appearance due to the mixture of refrigerant and lubricating oil. As the refrigerant and oil DO NOT exhibit a "clear" sight glass on a properly charged A/C system, most R-134a systems have no sight glass.

REFRIGERANT OILS

Refrigerant R-12 based systems use mineral oil, while R-134a systems use synthetic/Polyalkylene Glycol (PAG) oils. Using a mineral oil based lubricant with R-134a will result in A/C compressor failure due to lack of proper lubrication.

Use only specified oil for the appropriate system and A/C compressor. Always check the underhood A/C specification label or A/C compressor label before adding refrigerant oil to A/C

compressor/system. See Fig. 2. The following R-134a refrigerant oils are currently available.

Jeep

Use PAG (ND8)

Refrigerant Oil (Part No. 82300102).

NOTE: Synthetic/PAG oils absorb moisture very rapidly, 2.3-5.6% by weight, as compared to a mineral oil absorption rate of .005% by weight.

SERVICE EQUIPMENT

NOTE: Ensure "O" rings are designed for use with specified refrigerant. Deterioration of "O" rings and system contamination will result if incorrect "O" rings are used.

Because R-134a is not interchangeable with R-12, separate sets of hoses, gauges and recovery/recycling equipment are required to service vehicles. This is necessary to avoid cross-contamination and damaging system.

All equipment used to service systems using R-134a must meet SAE standard J1991. The service hoses on the manifold gauge set must have manual (turn wheel) or automatic back-flow valves at the service port connector ends. This will prevent refrigerant from being released into the atmosphere.

For identification purposes, R-134a service hoses must have a Black stripe along their length and be clearly labeled SAE J2196/R-134a. The low pressure test hose is Blue with a Black stripe. The high pressure test hose is Red with a Black stripe. The center test hose is Yellow with a Black stripe.

NOTE: Refrigerant R-12 service hoses will ONLY be labeled SAE J2196.

R-134a manifold gauge sets can be identified by one or all of the following.

Labeled FOR USE WITH R-134a on set

Labeled HFC-134 or R-134a on gauge face

Light Blue color on gauge face

In addition, pressure/temperature scales on R-134a gauge sets are different from R-12 manifold gauge sets.

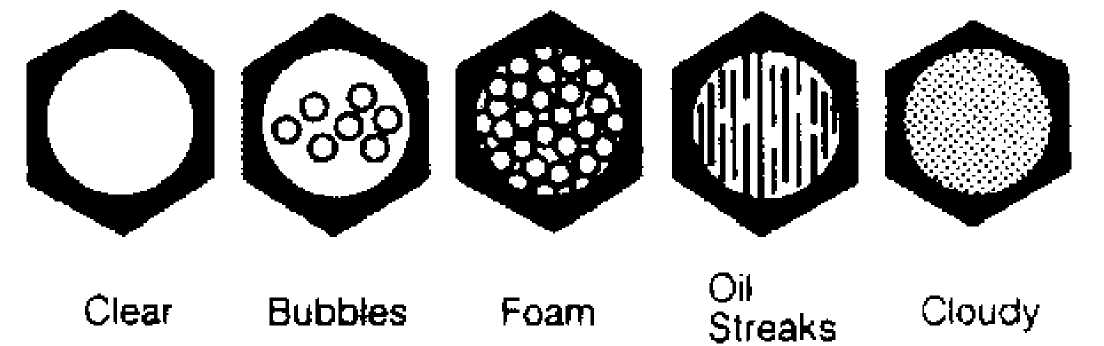

SIGHT GLASS INDICATOR

NOTE: Sight glass indicator conditions listed are for R-12

systems. Information for R-134a systems is not available from manufacturer.

Not all systems use a sight glass. If used, a sight glass may be mounted in receiver-drier (accumulator) or in discharge line. Refrigerant’s condition can be visually checked while passing through sight glass. The following are possible conditions of sight glass indicator, which may help in the diagnosis of problems. See Fig. 3.

Clear Sight Glass

A clear sight glass indicates refrigerant level is correct or is excessively low for system circulation. Sight glass may be clear, but system may contain excessive refrigerant. This must be verified by test gauge readings.

Bubbly/Foamy Sight Glass

A bubbly or foamy sight glass indicates system is low on refrigerant, and air has probably entered system. However, if only occasional bubbles are noticed, during clutch cycling or system startup, this may be a normal condition.

Oil Streaked Sight Glass

If oil streaks appear on sight glass, a lack of refrigerant may be indicated, and the system’s compressor oil is circulating through the system.

Cloudy Sight Glass

A cloudy sight glass indicates desiccant contained in

receiver-drier or accumulator has broken down and is being circulated through system.

Sight glass readings are not positive identification of a problem. Readings should be relied upon only when other system symptoms exist.

Fig. 3: Identifying Sight Glass Indicator Conditions

SYSTEM SERVICE VALVES

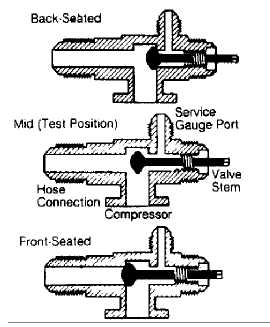

STEM-TYPE VALVES

This manually operated service valve has adjustable stem located under a protective cap. Valve stem must be manually positioned when making gauge connections and/or reading system pressure on the gauges. See Fig. 4.

Fig. 4: Identifying Stem-Type Service Valve Positions

Back-Seated (Operating) Position

This is the normal operating position, which is also used for connecting and disconnecting manifold gauge set. Stem is turned fully

outward to seal the service gauge port.

Mid (Test) Position

After installing manifold gauge set (valve stem in back-seated position), turn valve stem 1 1/2 - 2 turns inward. This positions valve stem midway, allowing full system operation and permitting refrigerant pressure to reach gauges.

Front-Seated (Off) Position

With service valve stem turned inward, valve blocks refrigerant flow through system, isolating compressor for service.

CAUTION: NEVER operate A/C system with service valves in

front-seated position, as the compressor will be damaged.

SCHRADER-TYPE VALVES

NOTE: Although similar in construction and operation to a tire

valve, NEVER replace a Schrader-type valve with a tire valve.

Schrader valve is similar in construction and operation to a tire valve. When a test gauge hose is attached (hose has built-in valve core depressor), Schrader stem is pushed inward to the open position and allows system pressure to reach the gauge.

If test hose being used does not have a built-in core

depressor, an adapter must be used. Never attach hoses or adapters to a Schrader valve unless it is first connected to manifold gauge set.

SERVICE VALVE LOCATIONS

For service valve locations, see SERVICE VALCE LOCATIONS (TRUCKS & VANS) table.

SERVICE VALVE LOCATIONS TABLE (TRUCKS & VANS)

Vehicle High Low

Jeep

Cherokee & Wrangler (1) (1)

Grand Cherokee (1) (2)

- On A/C compressor.

- In suction line, near accumulator.

SPECIAL VALVE CONNECTORS

All vehicles with R-134a refrigerant use quick-disconnect service valves. To help prevent installing hoses and other parts used on R-12 systems, all fittings on R-134a systems use 1/2"-16 ACME threads.

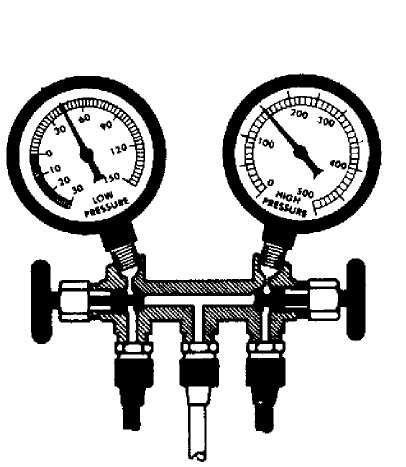

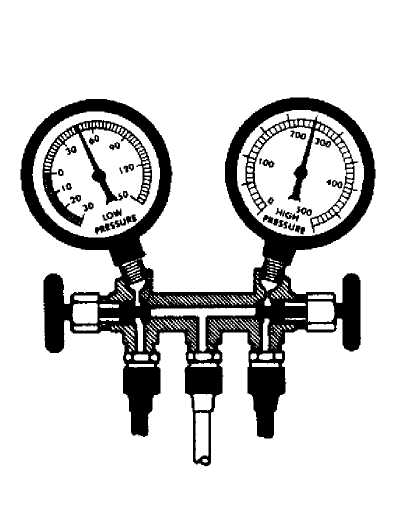

MANIFOLD GAUGE SET

A manifold gauge set is used to determine system’s high-side and low-side pressures, correct refrigerant charge, system diagnosis and operating efficiency. High (discharge) and low (suction) pressures must be compared to determine system operation. Manifold gauge sets for the two refrigerant types are basically the same. The fittings at the ends of the hoses are different to ensure connection only to a system using the type of refrigerant specified for that manifold gauge set.

Low-Side Gauge

The low-side gauge, which may have a Blue identifying feature, is used to measure low-side (suction) pressure. Low-side gauge is also called a compound gauge because it can measure pressure and vacuum. Pressure scale ranges from 0 to 150 psi; vacuum scale ranges from 0 to 30 in. Hg.

High-Side Gauge

The high-side gauge, which may have a Red identifying feature, is used to measure high-side (discharge) pressure. Gauge scale ranges from 0 to 500 psi.

CONNECTING GAUGE SET

Schrader-Type Valves

1) Put

on safety goggles, and cover vehicle’s fender. Remove

protective

caps from Schrader valves. Do this slowly to check for

leaky

valves.

CAUTION: Ensure hand valves on manifold gauge set are closed before connecting test hoses to Schrader valves.

Ensure

service hoses are equipped with valve core

depressor to match

Schrader valve. Special adapters are required if

service hoses do

not have built-in core depressor. Ensure both

manifold gauge hand

valves are closed.

Connect

low-side service hose to low-side (suction)

service valve, and

finger tighten connections. Connect high-side

service hose to

high-side (discharge) service valve, and finger

tighten

connections.

Stem-Type Valves

1) Put

on safety goggles, and cover vehicle’s fender. Place

valves

in back-seated position. Remove protective caps from service

valves.

Do this slowly to check for leaky valves.

CAUTION: Ensure hand valves on manifold gauge set are closed before turning service valve to mid-position.

2) Attach

low-side service hose to low-side (suction) service

valve. Connect

high-side service hose to high-side (discharge) service

valve.

Finger-tighten both connections.

NOTE: After test gauges are installed, test hoses must be purged of all air before proceeding with testing.

PURGING TEST HOSES

Ensure

high-side and low-side hoses are properly connected

to service

valves, and all hose connections are tight.

If

stem-type service valves are used, turn stems inward 1

1/2

- 2 turns to mid-position. On all applications,

place clean shop

towel over end of

center service hose.

Purge

high-side test hose by opening hand valve on high-

side

gauge for 3-5 seconds. This allows

system’s refrigerant to force

air

through test hoses and out of center service hose into the

shop

towel. Immediately close high-side gauge hand valve.

Purge

low-side test hose in the same manner using hand

valve of

low-side gauge. Close hand valve after 3-5 seconds.

Purging

of test hoses is now complete, and system is ready for

testing.

STABILIZING A/C SYSTEM

Once

manifold gauge set is attached to system and test

hoses have been

purged (if required), system is ready for

testing.

Place all test hoses, gauge

set and other equipment away from all

moving

parts of engine.

Start

engine, and turn A/C controls to maximum cooling

position. Set

blower fan on high speed. Open doors and/or windows, and

operate

system for 5-10 minutes. System should now

be stabilized and

ready for test

readings.

PRESSURE GAUGE INDICATIONS

NOTE: Pressure gauge indications are for R-12 systems only. Information for R-134a systems is not available from manufacturers.

The following typical pressure gauge indications represent conditions that may be encountered during system servicing. See Figs. 8-14. Temperature and humidity, as well as other factors, affect pressure gauge readings. Pressure gauge indications should be used only as a guide.

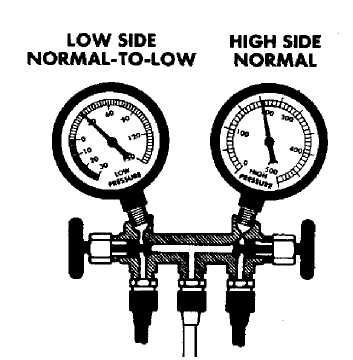

EXCESSIVE MOISTURE GAUGE READINGS

Low Side Gauge - Normal-to-Low High Side Gauge - Normal

Other Symptoms

Sight Glass - Tiny bubbles.

Discharge Air - Becomes warm as low side cycles into vacuum. As moisture is released by saturated desiccant, it becomes released by saturated desiccant, it becomes trapped and freezes at expansion valve or orifice tube, blocking R-12 flow into the evaporator. As low side drops to a vacuum, high side may rise.

EXCESSIVE MOISTURE

GAUGE

READINGS

GAUGE

READINGS

Law Side Gauge - Normal-to-Low High Side Gauge - Normal

OTHER SYMPTOMS

SigM Glut - Tiny bubbles.

Discharge Air - Becomes warm as low side

cycles into vacuum. As moisture is released

by saturated desiccant, it becomes trapped

and freezes at expansion valve or orifice tube.

Slocking R-12 (low into me evaporator.

As low side drops to a vacuum, high side may rise.

CORRECTION

Discharge refrigerant from system.

Replace

receiver-drier,

accumulator or desiccant bag.

Evacuate system with vacuum pump.

Charge system with R-12.

Operate system and check performance.

Fig. 5: Excessive Moisture Pressure Gauge Indications Courtesy of Ford Motor Co.

Correction

Discharge refrigerant from system.

Replace receiver-drier, accumulator or desiccant bag.

Evacuate system with vacuum pump.

Charge system with R-12.

Operate system and check performance.

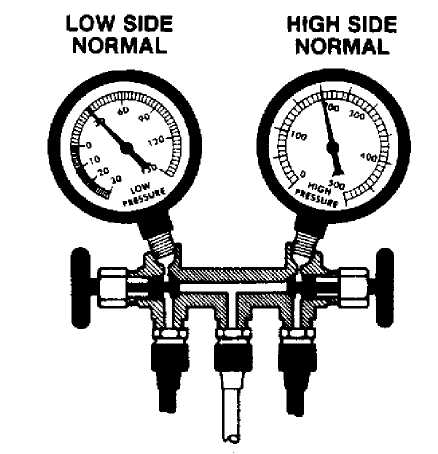

DEFECTIVE THERMOSTATIC SWITCH GAUGE READINGS

Low Side Gauge - Normal High Side Gauge - Normal

Other Symptoms

Compressor - Cycles on and off too fast.

Low Side Gauge - Not enough range shown on low side gauge.

DEFECTIVE THERMOSTATIC SWITCH

GAUGE

READINGS

Law Side Gauge - Normal High Side Gauge - Normal

OTHER SYMPTOMS

Compressor - Cycles on and off too fast.

Low Side Gauge - Not enough range shown on low side gauge.

CORRECTION

Stop

vehicle engine and

turn air conditioner "OFF".

Remove

and discard old

clutch cycling switch, install a

new switch

of same type,

Operate system and check performance.

Fig. 6: Defective Thermostatic Switch Pressure Gauge Indications Courtesy of Ford Motor Co.

Correction

Stop vehicle engine and turn air conditioner "OFF".

Remove

and discard old clutch cycling switch, install a

new switch of

same type.

Operate system and check performance.

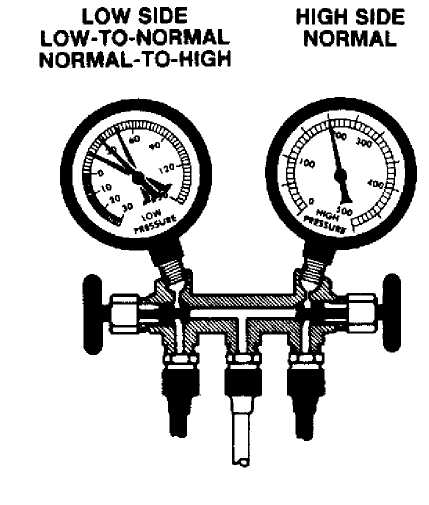

MISADJUSTED THERMOSTATIC SWITCH GAUGE READINGS

See DEFECTIVE CLUTCH CYCLING SWITCH PRESSURE GAUGE READINGS below.

DEFECTIVE CLUTCH CYCLING SWITCH PRESSURE GAUGE READINGS

Low Side Gauge - Low-to-Normal/Normal-to-High High Side Gauge - Normal

Other Symptoms

Compressor - Cycles at incorrect temperature or pressure.

Evaporator - May freeze and restrict airflow if switch is allowing compressor to remain on too long.

MISADJUSTED THERMOSTATIC SWITCH OR DEFECTIVE CLUTCH CYCLING SWITCH

GAUGE READINGS

Low Side Gauge - Low-to-Normal/Norma(-to-High High Side Gauge - Normal

OTHER SYMPTOMS

Compressor - Cyctes at incorrect temperature or pressure.

Evaporator - May freeze and restrict airflow

if switch 15 allowing compressor to remain on too long.

CORRECTION

With Thermottatie Switch

1) Stop engine and turn air conditioner off.

2} Remove components necessary to gain access to thermostatic adjustment screw.

NOTE: If no adjusting screw is provided, the switch it Ronedjuatable end must be replaced.

3} Make certain that all wiring Is positioned so that no short-circuiting can occur. Connect battery ¸ð█õ so that engine can be operated while making switch adjustment. Adjust thermostatic switch.

With Clutch Cycling Switch

1) Stop engine and turn air conditioner oil.

NOTE: Switch it nonedjuttable and it mounted on a Schrader valve fitting. Therefore, no system discharge is required,

Detach

electrical connector from

pressure sensing switch at

accumulator.

Remove

pressure sensing switch,

and install a new switch.

NOTE: A pressure sensing-mritch is used on most late

Ford Motor Co., General Motors and Eagle model» with accumulator-type systems. It perform* the same (unction as trrarmoslailc switch.

Fig. 7: Misadjusted Thermostatic Switch or Defective Clutch Cycling Switch Gauge Indications Courtesy of Ford Motor Co.

Correction With Thermostatic Switch

NOTE: If no adjusting screw is provided, the switch is nonadjustable and must be replaced.

Stop engine and turn air conditioner off.

Remove

components necessary to gain access to thermostatic

adjustment

screw.

Make

certain that all wiring is positioned so that no

short-circuiting

can occur.

Connect battery cable so that engine can be operated while making switch adjustment.

Adjust thermostatic switch. Correction With Clutch Cycling Switch

NOTE: Switch is non adjustable and is mounted on a Schrader valve fitting. Therefore, no system discharge is required.

Stop engine and turn air conditioner off.

Detach

electrical connector from pressure sensing switch

at accumulator.

Remove pressure sensing switch, and install a new switch.

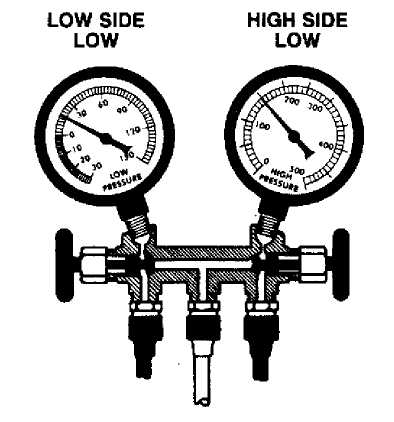

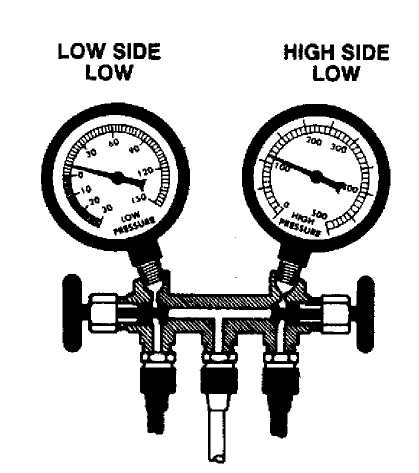

LOW R-12 CHARGE GAUGE READINGS

Low Side Gauge - Low High Side Gauge - Low

Other Symptoms

Discharge Air - Slightly cool. Sight Glass - Some bubbles.

LOW R-12 CHARGE

GAUGE

READINGS

Low Side Gauge - Low High Side Gauge - Law

OTHER SYMPTOMS

Discharge Air - Slightly cool. Sight Glass - Some bubWes.

CORRECTION

Leak test system.

Discharge

refrigerant from system if

necessary to replace units or lines.

Repair leaks.

Check compressor oil level.

System may have lost oil due to leakage.

Evacuate system using vacuum pump.

Charge system with R-12.

Operate system and check performance.

Fig. 8: Low R-12 Charge Pressure Gauge Indications Courtesy of Ford Motor Co.

Correction

Leak test system.

Discharge

refrigerant from system if necessary to replace

units or lines.

Repair leaks.

Check

compressor oil level. System may have lost oil due

to leakage.

Evacuate system using vacuum pump.

Charge system with R-12.

Operate system and check performance.

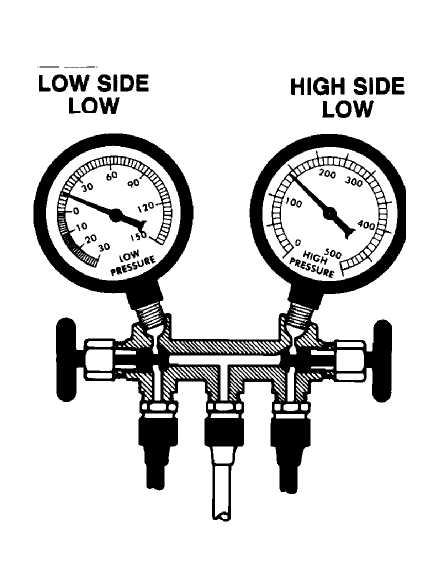

VERY LOW R-12 CHARGE GAUGE READINGS

Low Side Gauge - Low High Side Gauge - Low

Other Symptoms

Discharge Air - Warm.

Sight Glass - Clear or Oil Streaks.

Compressor - Operation may have stopped if system is equipped

with a refrigerant pressure sensing switch.

VERY LOW R-12 CHARGE

GAUGE

READINGS

Low Side Gauge - Low High Side Gauge - Low

OTHER SYMPTOMS

Discharge Air - Warm.

Sight Glass - Clear or Oil Streaks.

Compressor - Operation may have stopped if system is equipped with a refrigerant pressure sensing switch.

CORRECTION

if

compressor operation is stopped

due to a pressure sensing

switch,

by-pass switch with jumper wire until

lasting and

correction are complete.

Add a partial refrigerant charge

(to at least 50 percent system capacity), !hen make thorough leak test.

Discharge refrigerant from system.

Check compressor oil level.

System may have lost oil due to leakage.

Evacuate system using vacuum pump.

Charge system with fl-12.

Operate system and check performance.

Fig. 9: Very Low R-12 Charge Pressure Gauge Indications Courtesy of Ford Motor Co.

Correction

If

compressor operation is stopped due to a pressure

sensing

switch, by-pass switch with jumper wire until

testing and

correction are complete.

Add

a partial refrigerant charge (to at least 50 percent

system

capacity), then make thorough leak test.

Discharge refrigerant from system.

Check

compressor oil level. System may have lost oil due

to leakage.

Evacuate system using vacuum pump.

Charge system with R-12.

Operate system and check performance.

EXPANSION OR "H" VALVE STUCK CLOSED GAUGE READINGS

Low-Side Gauge - Low High-Side Gauge - Low

Other Symptoms

Discharge Air - Slightly cool

Evaporator Inlet Pipe - Sweating or frost build up

Testing

1) If evaporator inlet is cool to touch, proceed as follows:

a. Set air conditioner for maximum

cooling,

and operate the system.

b. Spray

liquid R-12 on head of valve or capillary tube

(if

equipped). Note low-side gauge reading.

Low-side

gauge should drop into a vacuum.

c. If low-side vacuum reading was obtained,

warm expansion

valve diaphragm chamber with hand, then repeat

test

step b.

d. If expansion valve test indicates valve

operation is

satisfactory, clean contact surface of

evaporator

outlet pipe and temperature sensing bulb. Ensure

bulb

is securely in contact with pipe.

e. If expansion valve test indicates the valve

is

defective, discharge the system, replace expansion

valve,

and proceed with correction procedure.

2) If

expansion valve inlet shows sweating or frost proceed

as

follows:

a. Discharge system.

b. Disconnect inlet line at expansion valve.

Remove and

inspect screen.

c. Clean and replace screen, and reconnect inlet line.

d. Proceed with correction procedure.

EXPANSION OR "H" VALVE STUCK CLOSED

GAUGE

READINGS

Low Side Gauge - Low High Side Gauge - Low

OTHER SYMPTOMS

Discharge Air - Slightly cool

Evaporator Inlet Pipe - Sweating or frost build up

TESTING

1) If evaporator inlet is

cool to touch, proceed as follows:

a. Set

air conditioner for maximum

cooling and operate the system.

b. Spray

liquid R-12 on head of valve

or capillary tube (if equipped). Note

low side gauge reading. Low side gauge should drop into a vacuum.

¸ If low side vacuum reading was obtained,

warm expansion valve diaphragm chamber with hand, then repeat test step b.

d. If expansion valve test indicates valve operation

is satisfactory, clean contact surface of evaporator outlet pipe and temperature sensing bulb. Make sure bulb is securely in contact with pipe.

e. If

expansion valve test indicates

the valve is defective, discharge

the system, replace expansion valve, and proceed with correction procedure.

2) If

expansion valve inlet shows sweating

or

frost proceed as follows:

a. Discharge system.

b. Disconnect

inlet line at expansion valve.

Remove and inspect screen.

¸ Clean and replace screen and reconnect inlet line. d. Proceed with correction procedure.

CORRECTION

Evacuate system using vacuum pump.

Charge system with R-12.

Operate system and check performance.

104008

Fig. 10: Expansion or "H" Valve Stuck Closed Courtesy of Ford Motor Co.

Correction

Evacuate system using vacuum pump.

Charge system with R-12.

Operate system and check performance.

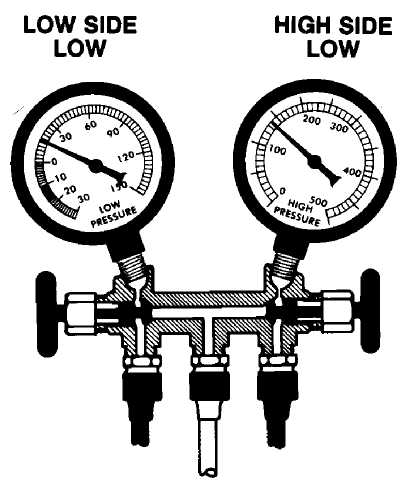

ORIFICE TUBE PLUGGED GAUGE READINGS

Low Side Gauge - Low High Side Gauge - Low

Other Symptoms

Discharge Air - Slightly cool.

Evaporator Inlet Pipe - Sweating or frost build up just ahead

of orifice tube.

Testing

If evaporator inlet pipe after orifice tube and accumulator surface are warm, orifice tube is plugged.

ORIFICE TUBE PLUGGED

GAUGE

READINGS

Low Side Gauge - Low High Side Gauge - Low

OTHER SYMPTOMS

Discharge Air - Slightly cool

Evaporator Inlet Pipe - Sweating or frost build up just ahead of orifice tube.

TESTING

If evaporator inlet pipe

after orifice tube and accumulator

surface are warm, orifice tube is plugged.

CORRECTION

Evacuate system using vacuum pump.

Replace orifice tube.

Charge system with R-12.

Operate system and check performance.

104009

Fig. 11: Orifice Tube Plugged Pressure Courtesy of Ford Motor Co.

Correction

Gauge Indications

Evacuate system using vacuum pump.

Replace orifice tube.

Charge system with R-12.

Operate system and check performance.

EXPANSION OR "H" VALVE STUCK OPEN GAUGE READINGS

Low Side Gauge - High High Side Gauge - High

Other Symptoms

Discharge Air - Warm Evaporator - Sweating or frost.

Testing

Check for expansion valve stuck open, or incorrect mounting of temperature sensing bulb as follows:

a. Set air conditioner for maximum cooling and

operate

system several minutes.

b. Spray liquid R-12 on head of valve or

capillary bulb, and

note low side gauge reading. It should drop

into a vacuum

(if not, a stuck open valve or incorrect bulb mounting is

indicated). This test may not be possible on applications where sensing bulb is not accessible.

c. If low side vacuum reading is obtained, warm expansion valve diaphragm chamber with hand, then repeat test.

EXPANSION OR "H" VALVE STUCK OPEN

Indications

Low SkM Gauge - High High Side Gauge - High

OTHER SYMPTOMS

Dlscharg* Air - Warm Evaporator - Sweating or frost.

TESTING

Check for expansion valve stuck open, or incorrect mounting of temperature sensing bulb as follows:

a. Set

air conditioner lor maximum cooling

and operate system several

minutes.

b. Spray

liquid R-12 on head of valve or

capillary bulb, and note low side

gauge reading.

It should drop into a vacuum (if not, a stuck

open

valve oc incorrect bulb mounting is indicated).

This test

may not be possible on applications

where sensing bulb is not

accessible.

c. if

low side vacuum reading is obtained,

warm expansion valve

diaphragm chamber

with hand, then repeat test.

CORRECTION

1) If expansion valve test indicates valve operation is satisfactory, proceed as follows:

a. Clean

contact surface of evaporator outlet

pipe and temperature sensing

bulb, then clamp

bulb securely in contact with pipe and

recover

with proper insulation tape.

b. Operate system and check performance.

12: Expansion or "H" Valve Stuck Open Pressure Gauge

Fig.

Courtesy of Ford Motor Co. Correction

2) If expansion valve test indicates valve is defective, proceed as Follows:

a. Discharge system.

b. Replace

expansion valve, making sure

all contacts are clean and secure.

c. Evacuate

system using vacuum pump,

then charge system with R-12.

d. Operate system and check performance.

1) If

expansion valve test indicates valve operation is

satisfactory,

proceed as follows:

a. Clean contact surface of evaporator outlet

pipe and

temperature sensing bulb, then clamp bulb securely

in

contact with pipe and recover with proper insulation

tape.

b. Operate system and check performance.

2) If

expansion valve test indicates valve is defective,

proceed as

follows:

a. Discharge system.

b. Replace expansion valve, making sure all

contacts are

clean and secure.

c. Evacuate system using vacuum pump, then

charge system

with R-12.

d. Operate system and check performance. COMPRESSOR MALFUNCTION GAUGE READINGS

Low Side Gauge - High High Side Gauge - Low

Other Symptoms Compressor - Noisy.

gauge READINGS COMPRESSOR MALFUNCTION

Low Ski» Gauge - High

Hieh3«.G.ofl.-Lo* LOW SIDE HIGH SIDE

OTHER SYMPTOMS HIGH LOW

Compressor - Noisy.

CORRECTION

1) Isolate compressor (If equipped with

stem-type service valves) or discharge entire system.

2) Remove compressor cylinder head and Inspect compressor.

a. Replace reed valve plate assembly if necessary.

b. Install cylinder head using NEW gasket.

Check compressor oil leva*.

Replace receiver-drter. desiccant or accumulator If:

a. System previously opened.

b. System operated two or more seasons with present unit.

c. Compressor

Inspection revealed desiccant particles

(very fine golden or brown

particles).

Using

vacuum pump, evacuate compressor or entire

system (depending on

procedure used in step 1».

Charge system wrtti R-12.

Operate system and check performance.

Fig. 13: Compressor Malfunction Pressure Gauge Indications Courtesy of Ford Motor Co.

Correction

Isolate

compressor (if equipped with stem-type service

valves) or

discharge entire system.

Remove compressor cylinder head and inspect compressor.

a. Replace reed valve plate assembly if necessary.

b. Install cylinder head using NEW gasket.

Check compressor oil level.

Replace receiver-drier, desiccant or accumulator if:

a. System previously opened.

b. System operated two or more seasons with present unit.

c. Compressor inspection revealed desiccant particles

(very fine golden or brown particles).

5) Using vacuum pump, evacuate compressor or entire system

(depending on procedure used in step 1).

Charge system with R-12.

Operate system and check performance.

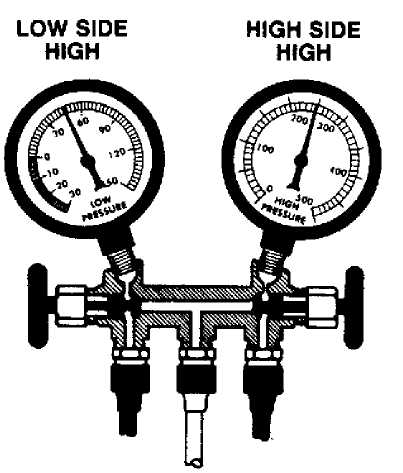

CONDENSER MALFUNCTION OR R-12 OVERCHARGE GAUGE READINGS

Low Side Gauge - High High Side Gauge - High

Other Symptoms

Discharge Air - Warm.

High Side Lines - Very Hot.

Sight Glass - Bubbles.

CONDENSER MALFUNCTION OR R-12 OVERCHARGE

GAUGE READINGS

Low Side Gauge - High High Side Gauge - High

OTHER SYMPTOMS

Discharge Air - Warm,

High Side Lines - Very Not.

Sight Glass - Bubbles. LOW SIDE HIGH SIDE

CORRECTION HIGH HtGH

Check electric cooling fan operation.

Inspect

condenser for clogged air passages.

bug screen, or other

obstructions preventing

airflow through condenser.

inspect

condenser mounting for proper

radiator clearance, inspect clutch

type fan for

proper operation. Inspect radiator pressure cap

for

correct type and proper operation.

After Making Above Correction*

Operate system and check performance. If Condition is Not Corrected

1) Inspect system for overcharge

of refrigerant and correct as follows:

a. Discharge

refrigerant until stream of

bubbles appears in sight glass and

both

high and low gauge readings drop below normal.

b. Add

R-12 until bubbles disappear and

pressures are normal, then add

an

additional 1/4-1/2 Ib.

of refrigerant.

2) Operate

system and check performance,

If

Gauge Readings Still Too High

1) Discharge

system, and remove and inspect

condenser

to ensure free passage

of refrigerant or replace condenser.

Repiace receiver-drier, desiccant bag or accumulator.

Evacuate system using vacuum pump.

Charge system with R-12.

Operate system and check performance.

Fig. 14: Condenser Malfunction or R-12 Overcharge Pressure Gauge

Indications

Courtesy of Ford Motor Co.

Correction

Check electric cooling fan operation.

Inspect

condenser for clogged air passages, bug screen, or

other

obstructions preventing airflow through condenser.

Inspect

condenser mounting for proper radiator clearance.

Inspect clutch

type fan for proper operation. Inspect

radiator pressure cap for

correct type and proper

operation.

After Making Above Corrections. Operate system and check performance. If Condition is Not Corrected.

1) Inspect

system for overcharge of refrigerant and correct

as

follows:

a. Discharge refrigerant until stream of

bubbles appears

in sight glass and both high and low gauge

readings

drop below normal.

b. Add

R-12 until bubbles disappear and pressures are

normal,

then add an additional 1/4-1/2 lb.

of

refrigerant.

2) Operate

system and check performance. If Gauge Readings

Still Too High

a. Discharge system, and remove and inspect

condenser to

ensure free passage of refrigerant or

replace

condenser.

b. Replace receiver-drier, desiccant bag or accumulator.

c. Evacuate system using vacuum pump.

d. Charge system with R-12.

e. Operate system and check performance.

JEEP

The orifice tube is located in the liquid refrigerant line near the condenser. Orifice tube cannot be replaced as a separate component. If orifice tube is faulty or if compressor is replaced, liquid line must be replaced.

REFRIGERANT RECOVERY/RECYCLING

NOTE: The use of recovery/recycling equipment is required by law.

Refrigerant recovery/recycling equipment is used to remove refrigerant from vehicle’s A/C system without polluting atmosphere. To remove and recycle refrigerant, ALWAYS follow instructions provided with the refrigerant/recovery equipment being used.

The removed refrigerant is filtered, dried and stored in a tank within the recovery/recycling equipment until it is ready to be pumped back into the vehicle’s A/C system.

NOTE: Separate sets of hoses, gauges and refrigerant

recovery/recycling equipment MUST be used for R-12 and R-134a based systems. DO NOT mix R-12 and R-134a refrigerants, as their refrigerant oils and desiccants are NOT compatible.

Manufacturer recommends using refrigerant recovery/recycling equipment which meets SAE standard J1991. Always use instructions provided with the recovery/recycling equipment being used.

DISCHARGING A/C SYSTEM

NOTE: When discharging refrigerant from A/C system, use

refrigerant recovery/recycling equipment to prevent refrigerant from entering the atmosphere. The use of recovery/recycling equipment is required by law.

Manufacturer does not provide procedures for discharging A/C system. Discharge A/C system using approved refrigerant recovery/recycling equipment. Follow instructions provided with

recovery/recycling equipment for recovery and recycling of refrigerant.

FLUSHING A/C SYSTEM

Information is not available from manufacturer.

EVACUATING A/C SYSTEM

CHRYSLER CORP.

Close both

valves on manifold gauge set. Connect manifold

gauge set to

high-side and low-side service valves. See SERVICE VALVE

LOCATIONS

under SYSTEM SERVICE VALVES. Connect a hose to center

connector

on manifold gauge set and evacuation pump.

Fully open both valves on manifold gauge set. Start

evacuation pump, and operate it until a vacuum reading of 2 6 in. Hg is obtained on low-side gauge. If vacuum reading of 2 6 in. Hg cannot be reached,either A/C system or gauge set leaks, or evacuation pump is defective. Repair or replace as necessary.

When

specified vacuum reading has been reached, close both

valves

on manifold gauge set. Turn off evacuation pump. Observe low-

side

gauge. If vacuum drops within 30 minutes,

system has a leak and

must be repaired.

If

vacuum remains steady, reopen valves, and continue

operating

evacuation pump for an additional 10 minutes.

Close both

valves, and stop evacuation pump.

CHARGING A/C SYSTEM

NOTE: Manufacturer does not recommend using one-pound cans. Using a charging station will allow precise measurement of refrigerant charge. See REFRIGERANT OIL & REFRIGERANT SPECIFICATIONS at the end of this article for system capacities.

System

must be evacuated before charging. With manifold

gauge set

attached from evacuation procedures, attach refrigerant

container(s)

to hose on center connector of manifold gauge set. Fully

open

refrigerant container valve(s), purge air from center hose,

and

close valves.

Adjust

service valves on the compressor to the mid-

position (if

equipped). Slowly open low-side valve, and

allow

refrigerant to enter the system.

Start and operate engine. Place A/C

heater controls to

maximum cold position.

When

proper amount of refrigerant has been added, close

low-side valve

on manifold gauge set. Stop engine, close service

valves

on compressor, and disconnect manifold gauge set. Start engine,

and

operate A/C system for 10 minutes to

stabilize the system.

LEAK TESTING

Operate system to stabilize high-side and low-side pressures. Turn engine off. Using a refrigerant leak detector, check all refrigerant line connections for leaks. Check compressor seal area and condenser.

Refrigerants are heavier than air. Always check for leaks at bottom of refrigerant lines and components. Refrigerant oil will leak with refrigerant. Visually check all connections and compressor clutch area for oil stains. If compressor shaft seal is leaking, a fresh oil

streak will normally be seen on underside of hood, above compressor clutch.

Always perform leak testing after A/C service. Move

refrigerant leak detector slowly to check for leaks, as leaks will not be detected if leak testing is performed too quickly.

REFRIGERANT OIL & REFRIGERANT SPECIFICATIONS

NOTE: Due to late changes, always refer to underhood A/C

Specification Label in engine compartment or A/C compressor label while servicing A/C system. If A/C Specification Label and specifications in table differ, use label specifications.

REFRIGERANT OIL & REFRIGERANT CAPACITY TABLE (LIGHT TRUCKS & VANS)

(1) Oil Refrigerant

Application Ounces Ounces

Jeep

Cherokee 4.6 38

Grand Cherokee (2) 8.0 28

Wrangler 4.6 32

- Total system capacity, unless otherwise noted.

- Models use R-134a refrigerant and PAG (ND8) Refrigerant Oil

(Part No. 82300102).

COMPRESSOR APPLICATIONS

NOTE: Due to late changes, always refer to underhood A/C

Specification Label in engine compartment or A/C compressor label while servicing A/C system. If A/C Specification Label and specifications differ, use label specifications.

COMPRESSOR APPLICATIONS TABLE (LIGHT TRUCKS & VANS)

Application Compressor

Jeep

Cherokee & Wrangler Sanden SD-709 7-Cyl.

Grand Cherokee Nippondenso 10PA17 10-Cyl.

(1) - Series codes are determined by fifth character of VIN code.