ALTERNATOR - NIPPONDENSO

1993 Jeep Cherokee

1993 ELECTRICAL

Chrysler Corp. Alternators - Nippondenso

Cherokee, Grand Cherokee, Grand Wagoneer, Wrangler

DESCRIPTION

Charging system consists of a Powertrain Control Module (PCM), alternator, CHECK ENGINE light and battery. Voltage regulation is controlled within the PCM and cannot be serviced.

The PCM monitors charging system input and output to ensure correct operation. The PCM stores any charging system failures in memory and outputs fault code(s) when on-board diagnostics are entered.

The PCM monitors several different engine control system circuits. If a problem is detected within a monitored circuit, a fault code is stored in the PCM memory. The CHECK ENGINE light will illuminate and system may enter limp-in mode. In limp-in mode, engine controller compensates for component or circuit failure by using information from other sources until repairs are made.

NOTE: Fault codes remain in memory for 50 engine starts. Fault is erased from memory if failure does not reoccur.

ADJUSTMENTS

BELT TENSION

BELT ADJUSTMENT TABLE (1)

Application Lbs. (kg)

New Belt 180-200 (81.72-90.8)

Used Belt 140-160 (63.56-72.64)

(1) - Tension in lbs. (kg) using belt tension gauge.

TROUBLE SHOOTING

PRELIMINARY CHECKS

Visually inspect wiring and drive belts. If charging system is not working, ensure drive belts are properly tightened. Ensure 12 volts exist at alternator field terminal with ignition on. Ensure battery cables, alternator ground cables and alternator and terminal block connections are clean and tight. Ensure alternator field circuit is not grounded (overcharging).

UNSTEADY OR LOW CHARGING

Check for loose alternator belt, defective alternator, loose alternator ground wire or corroded battery terminals.

OVERCHARGING

Check for grounded alternator field wiring or faulty

alternator.

TESTING (ON-VEHICLE)

ALTERNATOR OUTPUT

Output Wire Resistance (Voltage Drop) Test

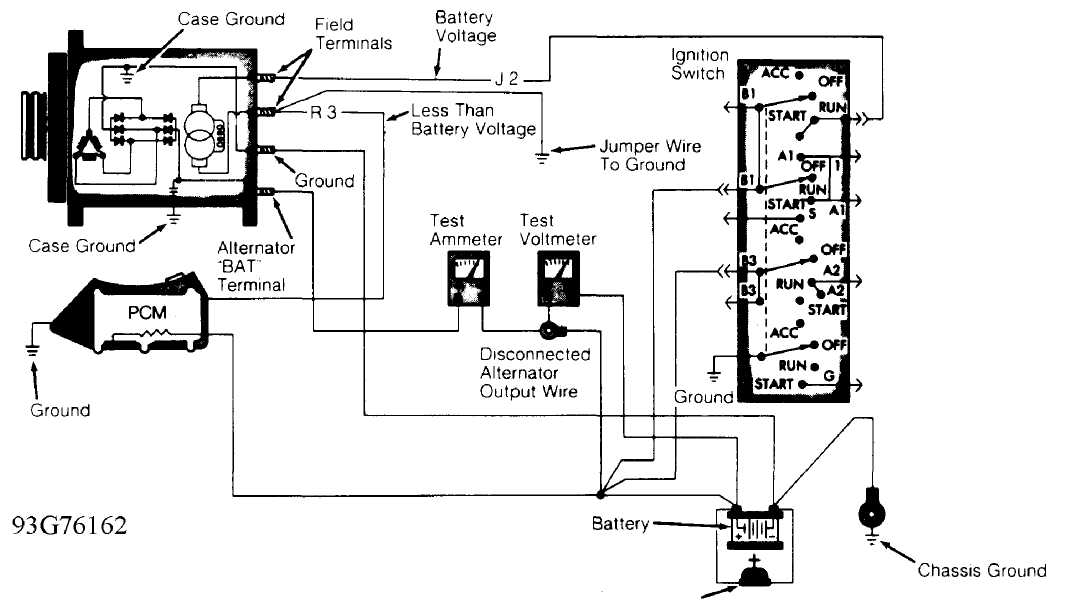

Ensure

battery is charged. Turn ignition off. Disconnect

negative

battery cable. Connect a 0-150 DC ammeter

and a voltmeter (0-

18 volts) to

vehicle’s charging system. See Fig. 1.

Connect a

carbon pile rheostat between battery terminals.

Ensure carbon

pile is in OFF position before connecting leads.

CAUTION: Alternator has 2 field terminals. In step 3), DO NOT connect jumper wire to alternator field terminal Dark Green/Orange wire.

Connect

one end of jumper wire to ground and other end to

alternator

field terminal Dark Green wire on rear side of alternator.

See

Fig. 2. Connect negative battery cable.

Start

engine. Reduce engine speed to idle. Adjust engine

speed

and carbon pile to maintain 20-amp current flow. Observe

voltmeter

reading. Voltage drop should be .5 volt or

less.

If

voltage drop is greater than .5 volt,

inspect, clean

and tighten all connections between alternator BAT

(B+) terminal and

positive battery

post. If wire resistance (voltage drop) is okay, test

is

complete. Remove all test equipment.

Carbon Pile Rheostat

Fig. 1: Testing Alternator Output Wire Resistance (Typical) Courtesy of Chrysler Corp.

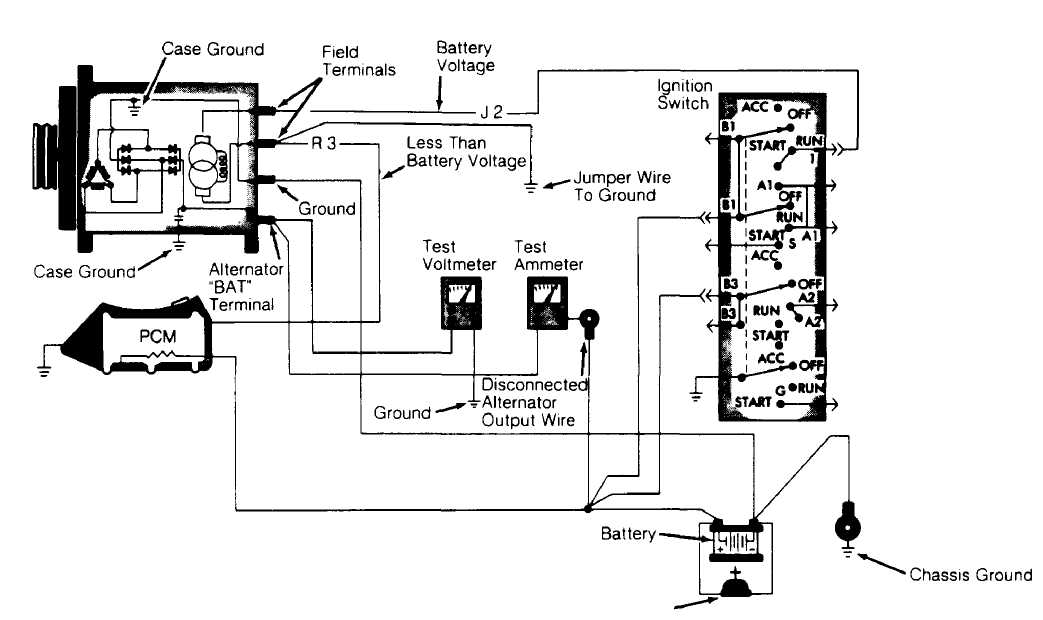

Current Output Test

1) Ensure battery is charged. Turn ignition off. Disconnect

negative battery cable. Connect a 0-150 DC ammeter and a voltmeter (0-18 volts) to vehicle charging system. See Fig. 3.

2) Connect

a carbon pile rheostat between battery terminals.

Ensure

carbon pile is in OFF position before connecting leads.

CAUTION: Alternator has 2 field terminals. In step 3), DO NOT connect jumper wire to alternator field terminal Dark Green/Orange wire.

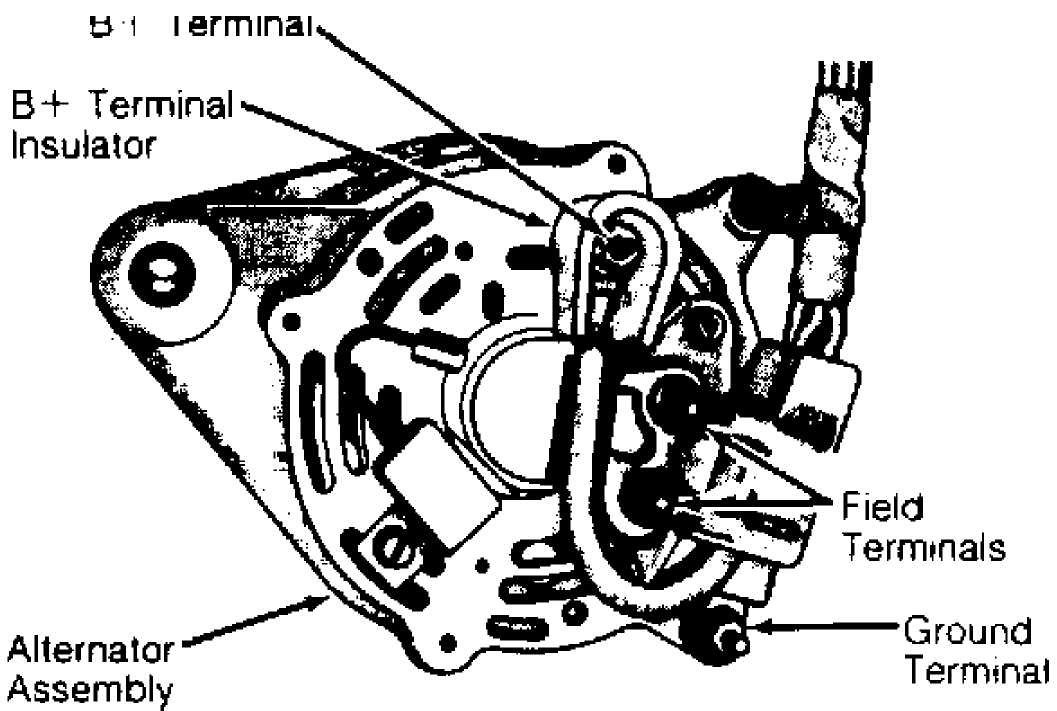

Fig. 2: Identifying Alternator Terminals Courtesy of Chrysler Corp.

Connect

one end of jumper wire to ground and other end to

alternator

field terminal Dark Green wire on rear side of alternator.

See

Fig. 2. Connect negative battery cable.

Start

engine and reduce engine speed to idle. Adjust

carbon pile and

engine speed until engine speed is 1250 RPM

and

voltmeter reads 15 volts. DO NOT

allow voltage to read greater than 16

volts.

Ammeter

should read within 10 amps of rating

listed on

back of alternator. If

reading is not as specified, replace

alternator.

Remove all test equipment.

93H76163 Carbon Pile Rheostat

Fig. 3: Testing Alternator Current Output (Typical) Courtesy of Chrysler Corp.

ENTERING ON-BOARD DIAGNOSTICS

CAUTION: Before entering on-board diagnostics, check charging system for other problems. See PRELIMINARY CHECKS under TROUBLE SHOOTING. DO NOT connect DRB-II to vehicle with battery charger connected. Damage to DRB-II may result.

Reading Trouble Codes

Trouble codes may be read by using the CHECK ENGINE light on instrument panel or using DRB-II. See CHECK ENGINE LIGHT DIAGNOSTIC MODE and DIAGNOSIS USING DRB-II headings below. A more complete diagnosis is possible using DRB-II.

NOTE: The PCM CANNOT diagnose every charging system problem. If a fault still exists after performing self-diagnostic procedures, go to TESTING (ON-VEHICLE).

Trouble Code Explanation

See the

CHARGING SYSTEM FAULT CODES table for charging-

related faults.

Code

41 will set if alternator field control

fails to

switch properly. PCM monitors

this circuit whenever ignition is on.

If

battery temperature sense voltage goes out of range,

Code

44 will set in memory. PCM monitors this

circuit any time

ignition is on.

If

battery voltage is more than one volt above desired

control

voltage for longer than 20 seconds, Code

46 will be set in

memory.

PCM monitors this signal whenever engine is running.

If

battery is more than one volt below desired control

voltage

for more than 20 seconds, Code 47

will be set. Code 47 will

also

set if no significant change in voltage is detected

during

alternator test. PCM monitors this signal whenever engine

speed is

more than 1500 RPM.

CHARGING SYSTEM FAULT CODES TABLE

Code Circuit Light Status

41 (1) Alternator Field Control On

44 (1) (2) Battery Temp. Sensor On

(1) High Battery Voltage On

(1) Low Battery Voltage Off

55 End Of Diagnostic Mode Off

- This code will cause limp-in mode.

- Sensor inside PCM. If failed, replace PCM.

NOTE: Only charging system-related codes are listed here. For engine-related codes, see appropriate G - TESTS W/CODES article in the ENGINE PERFORMANCE Section.

CHECK ENGINE Light Diagnostic Mode

Start

engine (if possible). On models equipped

with

automatic transmission, place foot

on brake and cycle transmission

shift

lever through all positions, ending in Park. On all models, turn

A/C

switch on and then off (if equipped).

Turn

engine off. Without starting engine, turn ignition

on,

off, on, off and on. CHECK ENGINE light will come on for 2

seconds

as a bulb

check, followed by fault codes. Record 2-digit fault codes

as

displayed by flashing CHECK ENGINE light.

Once

CHECK ENGINE light begins to flash fault codes, it

cannot be

stopped. Repeat step 1) to enter

diagnostic mode. Code 55

indicates end

of fault code display. For more information on

vehicle

self-diagnostics, see

appropriate SELF-DIAGNOSTICS article in the

ENGINE

PERFORMANCE section.

Refer

to CHARGING SYSTEM FAULT CODES table to relate

trouble

code number to a system fault description (DRB-II display).

Once

trouble area is known, go to appropriate charging system test.

NOTE: CHECK ENGINE light cannot be used to perform actuation test mode, sensor test modes or engine running test. Fault codes can only be erased using DRB-II. Fault codes will be erased from PCM memory after 50 engine starts if fault does not occur again.

Diagnosis Using DRB-II

The DRB-II is used as part of the charging system diagnostic procedure. Perform TEST CH-1, BATTERY CONDITION CHECK and also the CHARGING VERIFICATION (CH-VER) test.

Erasing Fault Codes

To

erase faults, press ATM key. At DRB-ll display, press

"2"

(ERASE) key. DRB-II will display ERASE FAULTS ARE

YOU SURE? (ENTER

TO ERASE).

Press ENTER key.

When

DRB-II is finished erasing fault codes, it will

display FAULTS

ERASED. This display will remain until ATM key is

pressed. After

ATM key is pressed, display will return to CHARGING

MENU screen.

DRB-II TEST FUNCTIONS

NOTE: DO NOT touch DRB-II keypad during DRB-II power-up sequence, or an error message will result.

To

diagnose system with DRB-II, DRB-II must be in CHARGING

MENU. At

CHARGING MENU, fault codes and DRB-II test functions can be

used.

To get to

CHARGING MENU, turn ignition off. Attach DRB-II

to engine

diagnostic connector. Connector is located in engine

compartment,

near PCM. Turn ignition switch to RUN position.

All DRB-II

character positions will glow and copyright

information will

appear on screen for several seconds.

After

several seconds DRB-II menu will appear. At DRB-II

menu,

press "4" (SELECT SYSTEM) key.

Press ENTER key. At SELECT SYSTEM

menu,

press "1" (ENGINE) key. Press

ENTER key. DRB-II menu will

appear, indicating engine year and

size, type of transmission and PCM

part

number.

5) After

several seconds AIR COND menu will appear. Press "1"

(WITH

A/C) or press "2" (WITHOUT A/C).

DRB-II display will change to

ENGINE SYSTEMS menu. At ENGINE SYSTEMS menu, press "2" (CHARGING) key. Press ENTER key.

6) Display

will change to CHARGING MENU. At CHARGING menu of

engine

diagnostic program, specific test functions programmed into

DRB-II

can be performed. Following DRB-II modes can be accessed:

SYSTEM

TEST, READ FAULTS, STATE DISPLAYS, ACTUATOR TEST and

ADJUSTMENTS.

READ FAULTS Mode

This allows technician to read and erase fault codes. Fault counter will appear along with fault displayed on DRB-II. For example, DRB-II will display 1 OF 2 FAULTS. PCM will store up to 8 fault messages.

Faults are numbered in reverse order of setting. Most recent fault to occur will be number one. Vehicles without A/C will always have A/C CLUTCH RELAY CKT (circuit) stored in memory. This fault will always be number one if vehicle is not equipped with A/C. If no fault messages are stored, DRB-II will display NO FAULTS DETECTED and start counter will show 0 STARTS SINCE ERS.

A start counter will appear below DRB-II fault counter display. Start counter counts the number of times vehicle is started since faults were last set, erased or battery was disconnected. This helps determine if fault is intermittent.

Memory space limits start counter to first 3 faults. Start counter of zero equals a hard fault. Start counter of more than zero indicates an intermittent fault. Start counter will count up to 255 starts. If no fault messages are stored, DRB-II will display NO FAULTS DETECTED and start counter will show 0 STARTS SINCE ERS.

STATE DISPLAYS Mode

This allows technician to read status or values of sensors, inputs/outputs and components. PCM can only recognize high and low status on switch circuits. PCM cannot detect the difference between an open or short circuit or a defective switch. If DRB-II displays a change between INPUT HIGH and INPUT LOW, it can be assumed that entire switch circuit to PCM is working.

ACTUATOR TEST Mode

This function allows the technician to check operation of output circuits or devices, which PCM cannot detect. DRB-II allows PCM to activate these outputs or devices. so technician can check for proper operation.

Most tests available in this mode provide an audible or visual indication of device operation (click of relay contacts, fuel spray, etc.). With exception of an intermittent condition, if a device functions properly during its test, it, its wiring and its driver circuit are presumably working properly.

ADJUSTMENTS Mode

This function allows user to erase fault codes. Function also allows user to reset Emission Maintenance Reminder (EMR) light and mileage.

DRB-II Volt/Ohmmeter Mode

To access volt/ohmmeter mode of DRB-II, connect Red

volt/ohmmeter test lead to Red port, located on right-top side of DRB-II .

NOTE: Because DRB-II is grounded through engine diagnostic

connector, only one volt/ohmmeter test is required when using volt/ohmmeter option.

To access voltmeter, press VOLT/OHM key once. DRB-II is now in voltmeter mode. Touch test probe to connector or wire to be measured. Read voltage on DRB-II display. When voltage testing is complete, press VOLT/OHM key 3 times to exit voltmeter mode.

To access ohmmeter, press VOLT/OHM key t,vice. DRB-II is now in ohmmeter mode. Touch test probe to connector or wire to be measured. Read resistance to circuit ground on DRB-II display. When resistance testing is complete, press VOLT/OHM key twice to exit ohmmeter mode.

DRB-II Continuity Meter Mode

Press VOLT/OHM key 3 times. Display will read NO CONTINUITY. Touch test probe to connector or wire to be measured. Read continuity on DRB-II display. When continuity testing is complete, press VOLT/OHM key once to exit continuity meter mode.

VEHICLES TESTED Mode

Mode is used to show what vehicles are covered by DRB-II cartridge. To access VEHICLES TESTED mode, turn ignition off. Attach DRB-II to engine diagnostic connector. Connector is located in engine compartment, near PCM.

Turn ignition switch to RUN position. All DRB-II character positions will glow and copyright information will appear on screen for several seconds. After several seconds DRB-II menu will appear.

At DRB-II menu, press VEHICLES TESTED) key. Press ENTER key. DRB-II will display vehicles covered by cartridge. Screen will display for 5 seconds and return to DRB-II menu.

HOW TO USE Mode

Enter DRB-II menu display. Refer to VEHICLES TESTED MODE. At DRB-II menu, press 2 (HOW TO USE) key. Press ENTER key. A series of screens will be displayed explaining use of DRB-II keys used to move through engine diagnostic program.

TEST CH-1, BATTERY CONDITION CHECK

NOTE: Perform PRELIMINARY CHECKS under TROUBLE SHOOTING before

proceeding. If battery shows signs of freezing or leakage, battery posts are loose or battery has low electrolyte level, DO NOT test.

If

battery has a built-in hydrometer, go to step 2).

Turn

ignition and

all accessories off. Ensure battery voltage is 12.0 volts

or

greater. If voltage is less than 12.0 volts,

charge battery and go

to step 3).

If

battery hydrometer is Green, go to step 3).1f

battery

hydrometer is Yellow or a

bright color, replace battery and perform

CHARGING

VERIFICATION (CH-VER) test. If battery hydrometer is dark in

color,

charge battery and go to next step.

Ensure

battery cables, terminals and posts are clean and

tight. Perform

a battery load test by applying a 300-amp load for 15

seconds.

Wait 15 seconds to allow battery to

stabilize. Apply a load

equal to 50

percent of battery cold cranking rating for 15

seconds and

record

minimum voltage reading.

See

MINIMUM BATTERY VOLTAGE table. If battery is below

volt age,

replace battery and perform CHARGING VERIFICATION (CH-VER)

test.

If voltage reading is okay, go to next step.

MINIMUM BATTERY VOLTAGE TABLE

Battery Temperature Minimum Volts

70F (21C) Or More 9.6

60F (16C) 9.5

50F (1 0C) 9.4

40F (4C) 9.3

30F (-1C) 9.1

20F (-7C) 8.9

1 0F (-1 2C) 8.7

0F (-18C) 8.5

Reconnect

battery cables. Inspect alternator belt tension

and

condition. Replace belt as necessary. Start engine. Set engine

speed

to 2000 RPM for 30 seconds.

Turn ignition off. Connect DRB-II.

Turn ignition on with engine

off. Read faults.

If DRB-II displays BATTERY TEMP SENSOR OUT OF LIMIT,

replace PCM and perform CHARGING VERIFICATION (CH-VER) test. If DRB-II displays other messages, go to appropriate test. If DRB-II does not display any faults, neither fault messages nor faults are intermittent. Go to TEST CH-5, CHECKING FOR INTERMITTENT PROBLEMS.

TEST CH-2, ALTERNATOR FIELD NOT SWITCHING PROPERLY (CODE 41 )

NOTE: Perform TEST CH-1, BATTERY CONDITION CHECK before proceeding.

Put

DRB-II in voltmeter mode. Check voltage of Automatic

Shutdown

(ASD) circuit by probing Dark Green/Orange wire (Dark

Green/Black

wire on Grand Cherokee and Grand Wagoneer) at back of

alternator.

If voltage is less than 10 volts, repair

open circuit from

ignition switch. If voltage is 10 volts

or greater. go to next step.

Check voltage of alternator field driver circuit by

probing Dark Green wire at back of alternator. If voltage is less than 10 volts, go to next step. If voltage is 10 volts or greater, go to step 6).

Turn

ignition off. Disconnect and inspect PCM connector.

Repair,

if necessary. Disconnect alternator harness from back of

alternator.

Using an external ohmmeter, check field driver circuit

(Dark

Green wire) for resistance. If resistance is less than 5.0

ohms,

replace PCM.

If resistance is 5.0 ohms or greater,

repair open in Dark

Green wire.

Turn

ignition off. Disconnect PCM connector. Disconnect

alternator

harness from back of alternator. Using an external

ohmmeter,

check for resistance between alternator field terminals.

If

resistance is 5.0 ohms

or greater, replace alternator. If resistance

is

less than 5.0 ohms, go to next step.

With

DRB-II in ohmmeter mode, check resistance in field

circuit

of alternator harness. If resistance is 5.0 ohms

or greater,

repair short to ground in

field driver circuit (Dark Green wire). If

resistance

is less than 5.0 ohms, replace PCM.

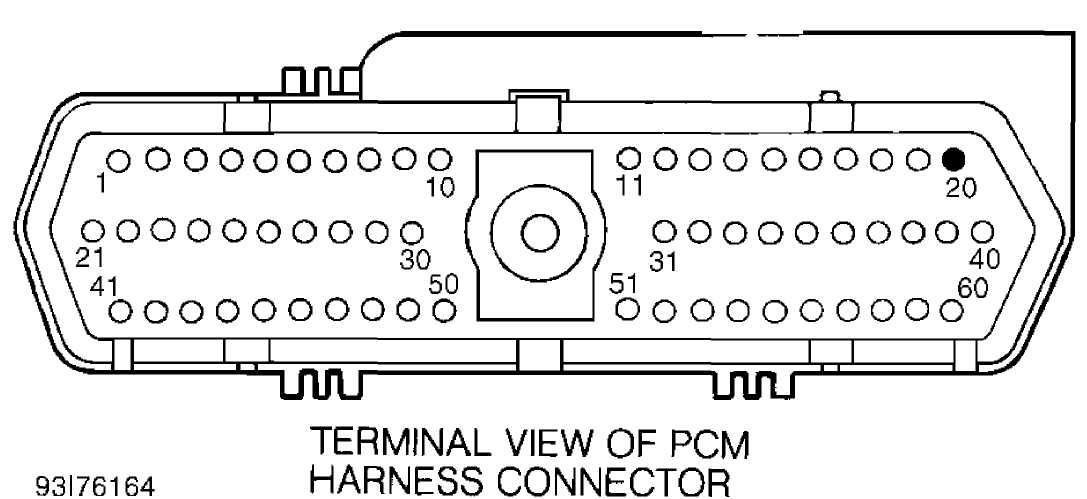

Turn

ignition off. Disconnect PCM connector. Disconnect

alternator

harness from back of alternator. Using an external

ohmmeter, check for resistance in field driver circuit alternator harness terminal and cavity No. 20 on PCM connector. See Fig. 4. If resistance is 5.0 ohms or greater, repair short to ground in field driver circuit (Dark Green wire). If resistance is less than 5.0 ohms, replace PCM. Perform CHARGING VERIFICATION (CH-VER) test.

JW1

TEST CH-3, CHARGING SYSTEM VOLTAGE LOW (CODE 47)

NOTE:

Perform TEST CH-1, BATTERY CONDITION CHECK before proceeding.

1)1f alternator voltage is 15.1 volts or greater, replace PCM. If less than 15.1 volts, ensure no resistance is present between alternator BAT (B+) and battery positive terminal.

CAUTION: Ensure all wires are clear of moving engine parts.

2) Check alternator case for good continuity to ground and negative battery cable. If continuity is good, manually set engine speed to 1600 RPM. Compare voltage on DRB-II and voltage on an external meter. If voltage difference is one volt or greater, replace the alternator. If the difference is less than one volt, proceed to TEST CH-5, CHECKING FOR INTERMITTENT PROBLEMS.

TEST CH-4, CHARGING SYSTEM VOLTAGE HIGH (CODE 46)

NOTE:

Perform TEST CH-1, BATTERY CONDITION CHECK before proceeding.

Turn

ignition on. Put DRB-II in voltmeter mode. Probe Dark

Green wire

at back of alternator. If voltage is 10.0 volts

or more, go

to step 4).1f voltage is

less than 10.0 volts, turn ignition

off.

Disconnect PCM connector, inspect and repair if necessary.

If

connector is okay, turn ignition on. Probe Dark Green

wire

at back of alternator. If voltage is 10.0 volts

or greater, go to

step 6). If voltage

is less than 10.0 volts, go to next step.

Turn

ignition off. Disconnect alternator harness from

alternator. Put

DRB-II in ohmmeter mode. Probe Dark Green wire in

alternator harness. If resistance is less than 10.0 ohms, repair Dark Green wire for short to ground. If resistance is 10.0 ohms or greater, replace alternator. Perform CHARGING VERIFICATION (CH-VER) test.

4) With ignition on and engine off, read voltage. If less than 13.0 volts, replace PCM. Perform CHARGING VERIFICATION (CH-VER) test. If voltage is 13.0 volts or greater, start engine and read voltage. Compare voltage readings before and after engine is running. Watch for a one-volt difference, waiting up to 5 minutes,.

5)1f voltage difference is one volt or greater, replace PCM. Perform CHARGING VERIFICATION (CH-VER) test. If difference is less than one volt, go to TEST CH-5, CHECKING FOR INTERMITTENT PROBLEMS.

6) Disconnect negative battery cable. Disconnect PCM

connector. Disconnect alternator harness from back of alternator. With DRB-II in ohmmeter mode, check resistance between field driver circuit alternator harness terminal and cavity No. 20 on PCM connector. If resistance is 5.0 ohms or greater, repair short to ground in field driver circuit (Dark Green wire). If resistance is less than 5.0 ohms, go to next step.

7) Probe

one of the alternator field terminals. If resistance

is 5.0

ohms or greater, replace alternator. If resistance

is less than

5.0 ohms, Replace PCM.

Perform CHARGING VERIFICATION (CH-VER) test.

TEST CH-5, CHECKING FOR INTERMITTENT PROBLEMS

NOTE: Perform TEST CH-4, CHARGING SYSTEM VOLTAGE HIGH (CODE 46) before proceeding.

Actuate

alternator field. Put DRB-II in voltmeter mode.

Probe Dark Green

wire at back of alternator. Voltage should cycle from

zero

to battery voltage every 1.4 seconds.

While

watching DRB-II, wiggle wires between alternator and

PCM. If any

interruption in the voltage cycle, repair wire at point at

which

cycle was interrupted. If there is no interruption of voltage

cycle,

test is complete. Perform CHARGING VERIFICATION (CH-VER) test.

CHARGING VERIFICATION (CH-VER)

Ensure

all engine components are connected. If PCM has

been changed and

if vehicle is equipped with a factory theft alarm

system,

start vehicle at least 20 times so alarm

will activate when

desired.

Write

Emission Maintenance Reminder (EMR) mileage into new

PCM. Connect

DRB-II to engine diagnostic connector. and erase faults.

Recheck

system for fault codes.

1f fault

codes reset, charging system still needs repair.

Check all

pertinent TECHNICAL SERVICE BULLETINS, and return to the

TEST

CH-1, BATTERY CONDITION CHECK.

BENCH TESTING

NOTE: Alternators are not serviceable. Replace, if defective.

OVERHAUL

Overhaul information is not available.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft. Lbs (N.m)

Alternator Mounting Bolts 28 (38)

Idler Pulley (Power Steering) 20 (27)