Ā

1993 Jeep Cherokee

1993 ENGINE PERFORMANCE

Chrysler Corp. 2 . 5L & 4.0L System & Component Testing

Jeep; Cherokee, Grand Cherokee, Wrangler

INTRODUCTION

NOTE: For Grand Cherokee with 5.2L engine, see I - 5.2L SYS/COMP TESTS article in this section.

Before testing separate components or systems, perform procedures in F - 2.5L & 4.0L BASIC TESTING article in this section. Since many computer-controlled and monitored components set a trouble code if they malfunction, also perform procedures in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

NOTE: Testing individual components does not isolate possible short or open circuits. Unless stated otherwise in test procedure, perform all voltage tests with a Digital Volt-Ohmmeter (DVOM) having a minimum 10-megohm input impedance. Use ohmmeter to isolate wiring harness short or open circuits.

COMPUTERIZED ENGINE CONTROLS

POWERTRAIN CONTROL MODULE (PCM)

Power & Ground Circuits

Check power and ground circuits using a DVOM and appropriate wiring diagram in L - WIRING DIAGRAMS article in this section.

ENGINE SENSORS & SWITCHES

Camshaft Position Sensor

Use an analog voltmeter. DO NOT remove distributor

connector from distributor. Insert voltmeter leads into backside of

distributor wiring harness connector to make contact with terminals.

Ensure connector is not damaged when inserting test probes.

Insert positive voltmeter lead into camshaft position

sensor signal output circuit (Tan/Yellow wire on Cherokee and

Wrangler; Gray/Black wire on Grand Cherokee) at distributor wiring

harness connector. Insert negative voltmeter lead into ground circuit

(Black/Light Blue wire) at distributor wiring harness connector. Set voltmeter to 15-volt DC scale.

With distributor cap removed, manually rotate engine until

pulse ring enters sync signal generator on camshaft position sensor.

Distributor rotor should be at 9 oÆclock position. Turn ignition

switch to ON position. With pulse ring positioned in the sync signal

generator, reading should be approximately 5 volts.

If no voltage is present, check voltmeter leads for good

connections. If connections are okay and there is still no voltage,

check for voltage at supply circuit (Orange wire on Cherokee and

Wrangler; White/Black wire on Grand Cherokee).

If no voltage is present at supply wire, remove PCM

connector. Check voltage at PCM pin No. 7 and ground with wiring

harness connected. PCM is located on left side of engine compartment.

If there is no voltage at PCM, see appropriate camshaft position

sensor circuit tests in G - 2.5L & 4.0L TESTS W/ CODES article in this

section.

If voltage is present at supply wire, replace camshaft

position sensor. If voltage is present at PCM pin No. 7, but not at

supply wire, check continuity of supply wire between the distributor

connector and the PCM. If no continuity exists, repair wiring harness

as necessary.

If supply wire is okay, check continuity between camshaft

position sensor signal output wire at the distributor connector and

PCM pin No. 44. If no continuity exists, repair wiring harness as

necessary.

If camshaft position sensor signal output wire is okay,

check continuity between ground circuit wire at the distributor

connector and ground. If no continuity exists, repair wiring harness

as necessary. If ground wire is okay, go to next step.

While observing voltmeter, crank engine. Voltmeter needle

should fluctuate from 0-5 volts while the engine is cranking. This

verifies that camshaft position sensor in distributor is operating

properly and that a sync pulse signal is being generated. If voltmeter

does not fluctuate, replace camshaft position sensor.

Charge Air Temperature Sensor (Grand Cherokee) See MANIFOLD AIR TEMPERATURE (MAT) SENSOR below.

Coolant Temperature Sensor

1) Disconnect coolant temperature sensor. Using a DVOM, check

sensor resistance. Resistance should be as specified in the

COOLANT TEMP SENSOR & MANIFOLD AIR TEMP SENSOR RESISTANCE table. Replace sensor if necessary.

2) Check continuity between PCM wiring harness terminal No. 2

and sensor connector terminal. Also check continuity between PCM

wiring harness terminal No. 4 and sensor connector terminal. Repair

wiring if an open circuit is indicated.

NOTE: Also see appropriate coolant temperature sensor tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

COOLANT TEMP SENSOR & MANIFOLD AIR TEMP SENSOR RESISTANCE TABLE Temperature F (C) Minimum Ohms Maximum Ohms

-40 (-40) 291,490 381,710

-4 (-20) 85,850 108,390

14 (-10) 49,250 61,430

32 (0) 29,330 35,990

50 (10) 17,990 21,810

68 (20) 11,370 13,610

77 (25) 9120 10,880

86 (30) 7370 8750

104 (40) 4900 5750

122 (50) 3330 3880

140 (60) 2310 2670

158 (70) 1630 1870

176 (80) 1170 1340

194 (90) 860 970

212 (100) 640 720

230 (110) 480 540

248 (120) 370 410

Crankshaft Position Sensor

1) Disconnect crankshaft position sensor. Connect ohmmeter across sensor terminal No. 2 (Black/Light Blue wire) and terminal No. 1 (Gray/Black wire on Cherokee and Wrangler; Red/Light Green wire on

Grand Cherokee).

2) Ohmmeter should indicate an open circuit. Replace sensor if reading is not as specified. Also see appropriate crankshaft position sensor tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

Manifold Absolute Pressure (MAP) Sensor

Inspect MAP sensor vacuum hose connections at throttle

body and sensor. Replace or repair vacuum hose if necessary.

Turn ignition on with engine off. Using DVOM, check MAP

sensor output voltage. Connect DVOM to MAP sensor terminal "B" (Dark

Green/Red wire on Cherokee and Wrangler; Red/White wire on Grand

Cherokee) and ground. Terminal identification letters are marked on

sensor body.

Output voltage should be 4-5 volts. Voltage should drop to

1.5-2.1 volts with a hot engine operating in Neutral and at idle

speed. Also check for output voltage at PCM wiring harness terminal

No. 1 on Cherokee and Wrangler or terminal No. 5 on Grand Cherokee. If

voltage is not as previously specified, repair wiring harness as

necessary.

With ignition on, check MAP sensor supply voltage at

sensor connector terminal "C" (Violet/White wire). Supply voltage

should be 4.5-5.5 volts. Also check for supply voltage at PCM wiring

harness terminal No. 6. If supply voltage is not as specified, repair

wiring harness if necessary.

Check continuity of MAP sensor ground circuit at sensor

connector terminal "A" (Black/Light Blue wire) and PCM wiring harness

terminal No. 4. Check continuity of MAP sensor ground circuit at

sensor connector terminal No. 1 (Black/Light Blue wire) and PCM wiring

harness terminal No. 4. Repair wiring harness if necessary.

Check continuity of MAP sensor ground circuit between PCM

wiring harness terminals No. 4 and 11. If ohmmeter indicates an open

circuit, go to next step. If ground connection is okay, replace PCM.

NOTE: If terminal No. 4 has a short circuit to 12 volts, correct this condition before replacing PCM. If necessary, perform appropriate MAP sensor tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

7) Check for defective sensor ground connection. Connection

is located on right side of engine block, at oil dipstick tube

mounting block. Repair connection as necessary.

Manifold Air Temperature (MAT) Sensor

Disconnect manifold air temperature sensor. Using DVOM,

check sensor resistance. Resistance should be as specified in the

COOLANT TEMP SENSOR & MANIFOLD AIR TEMP SENSOR RESISTANCE table. If

resistance is not as specified, replace sensor.

Check resistance between PCM wiring harness terminal No.

21 and sensor connector terminal. Also check resistance between PCM

wiring harness terminal No. 4 and sensor connector terminal. Repair

wiring if resistance is greater than one ohm.

Oxygen (O2) Sensor (Heating Element)

Disconnect oxygen sensor connector. Using an ohmmeter, check sensor heating element resistance. On Cherokee, connect ohmmeter to Black/Tan and Dark Green/Black sensor wires. On Wrangler, connect ohmmeter to Black and Dark Green/Orange sensor wires. On Grand Cherokee, connect ohmmeter to Black/Tan and Orange/Dark Blue sensor wires. Heating element resistance should be 5-7 ohms. Replace oxygen sensor if ohmmeter reads infinity.

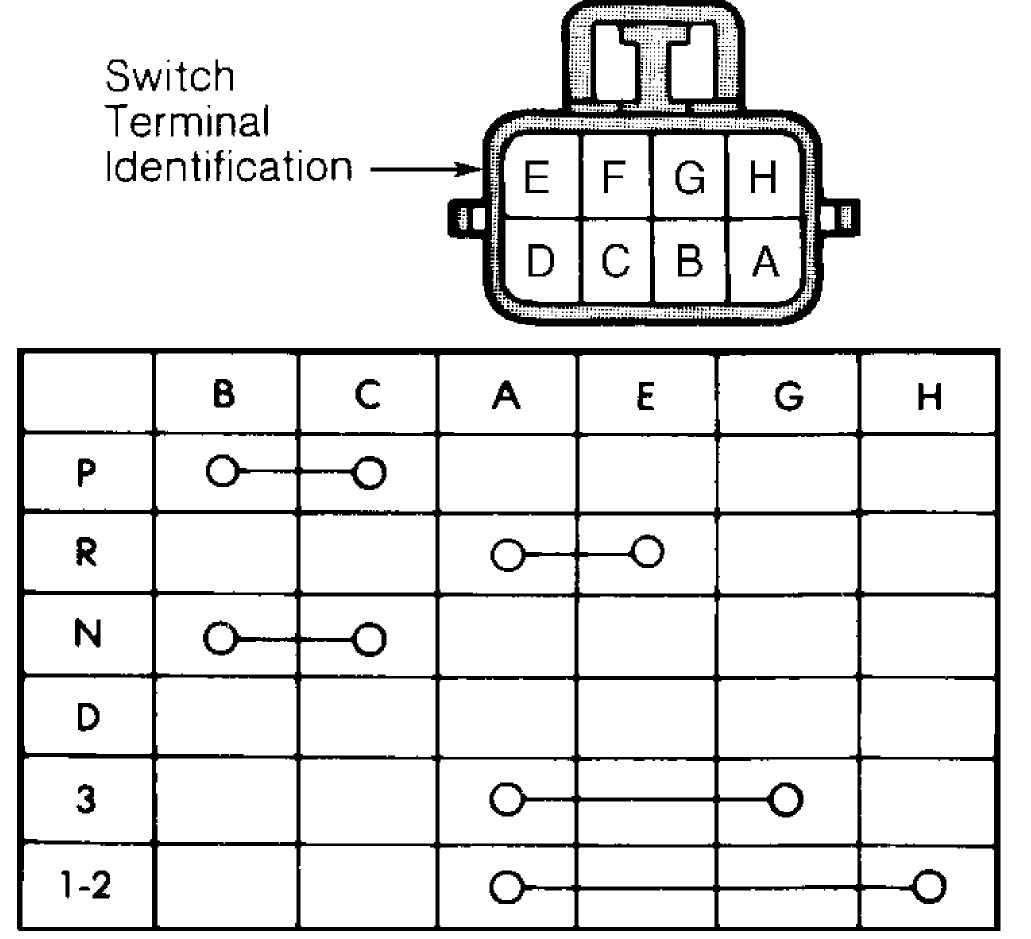

Park/Neutral Switch (AW-4 Auto. Trans.)

Disconnect park/neutral switch. Ensure continuity exists

between terminals "B" and "C" with transmission in Park or Neutral.

See Fig. 1.

Ensure continuity exists between terminals "A" and "E"

with transmission in Reverse. See Fig. 1. Ensure continuity exists

between terminals "A" and "G" with transmission in 3rd gear.

Ensure continuity exists between terminals "A" and "H"

with transmission in 1st or 2nd gear. See Fig. 1. If switch continuity

tests are okay, check gearshift adjustment or back-up light circuit.

If switch fails any continuity test, replace park/neutral switch.

91C13971

Fig. 1: Testing Park/Neutral Switch Continuity (AW-4 Auto. Trans.) Courtesy of Chrysler Corp.

NOTE: Also see appropriate park/neutral switch input test

procedures in G - 2.5L & 4.0L TESTS W/ CODES article in

this section.

Park/Neutral Switch (32RH Auto. Trans.)

Disconnect park/neutral switch. Check continuity between

switch center terminal and transmission case. Continuity should exist

only when transmission is in Park or Neutral.

Shift transmission into Reverse. Check continuity between

the 2 outside terminals on switch. Continuity should exist only when

transmission is in Reverse. Check continuity between each outer

terminal and transmission case.

Continuity should not exist between either terminal and

case while in Reverse. If switch continuity tests are okay, check

gearshift adjustment or back-up light circuit. If switch fails any

continuity test, replace park/neutral switch.

Throttle Position Sensor (TPS)

Turn ignition on. Check TPS output voltage at sensor

wiring harness center terminal. At idle, output voltage should be

greater than .2 volt.

Gradually open throttle plate. Output voltage should

gradually increase as throttle plate is opened. At wide open throttle,

output voltage must be less than 4.8 volts.

NOTE: Also see appropriate throttle position sensor tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

Vehicle Speed Sensor

See appropriate vehicle speed sensor tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

MODULES, MOTORS & RELAYS

MODULES

Theft Alarm Module (Cherokee & Grand Cherokee)

Turn ignition switch to ACC position 3 times and leave in

ACC position to activate Security Alarm Module (SAM) self-diagnostics.

If headlights do not flash, go to step 3).

If horn does not sound twice, go to step 9). If exterior

lights do not flash, go to step 10). If parking lights and taillights

do not flash, go to step 11). If horn sounds twice and headlights,

parking lights and taillights flash, go to step 12).

NOTE: For identifying circuits referred to in testing, see

appropriate wiring diagram in L - WIRING DIAGRAMS article in this section.

3) Check for battery voltage at terminal No. 1 of security

alarm module relay (located in relay center under glove box). If less

than battery voltage is present, repair open to fuse No. 7 (15-amp)

and retest. If system does not operate properly, go to next step. If

battery voltage is present, go to step 5). If system operates

properly, stop test procedure.

NOTE: If SECURITY light comes and remains on with ignition on, the Chrysler Collision Detection (CCD) bus communication with the PCM has been lost. After servicing vehicle ensure that system operates properly. A malfunctioning anti-theft system may keep engine from starting.

4) Using an ohmmeter, check continuity between security alarm

module relay terminal No. 2 and headlight feed wires. If continuity

exists, replace security alarm module relay and retest. If continuity does not exist, repair open in wiring circuit as necessary and retest.

Check for battery voltage at security alarm module relay

terminal No. 3. If battery voltage is not present, repair open in

wiring circuit as necessary. If battery voltage is present, go to step

7) . If less than battery voltage is present, turn ignition switch to

RUN position, then turn ignition off.

Check continuity between security alarm module relay pins

No. 3 and 5. If continuity does not exist, replace security alarm

module relay and retest. If continuity exist, check continuity between

security alarm module terminal No. 7 (located behind center cluster

bezel on instrument panel) and security alarm module relay pin No. 5.

If continuity exists, replace security alarm module and retest. If

continuity does not exist, repair open in wiring circuit as necessary

and retest.

Turn ignition switch to RUN position, then turn ignition

off. Check continuity between security alarm module relay pin No. 3

and ground. If continuity does not exist, repair open in wiring

circuit as necessary and retest. If continuity exists, replace

security alarm module relay with known good relay. If system does not

operate properly, go to next step. If system operates properly, stop

test procedure.

Using an ohmmeter, check continuity between security alarm

module relay terminal No. 2 and headlights. If continuity exists,

replace security alarm module relay and retest. If continuity does not

exist, repair open in wiring circuit as necessary and retest.

Turn ignition switch to RUN position, then turn ignition

off. If horn does not operate properly, check horn system for

malfunction. Repair as necessary and retest. If horn operates

properly, check continuity between security alarm module terminal No.

12 and horn relay connector. If continuity exists, replace security

alarm module. If continuity does not exist, repair open in wiring

circuit and retest.

10) Turn ignition switch to RUN position, then turn ignition

off. If flash-to-pass does not operate, check and repair fuse No. 7

(15-amp) as necessary and retest. If flash-to-pass operates, check for

battery voltage at security alarm module pin No. 21. If battery voltage is present, replace security alarm module. If voltage is less than battery voltage, repair open in wiring circuit to fuse and retest.

Check for battery voltage at lamp outage module pin No.

6. If battery voltage is present, repair open in light system. If

voltage is less than battery voltage, check for battery voltage at

security alarm module pin No. 14. If battery voltage is present,

repair open in wiring circuit between security alarm module and rear

lights. If less than battery voltage is present, replace security

alarm module.

Ensure all doors and liftgate are closed. Verify that

SECURITY light is flashing. If SECURITY light is not flashing, check

bulb and wiring harness. Repair or replace as necessary. If bulb and

wiring are okay, replace security alarm module and retest system.

If SECURITY light is flashing, turn ignition switch to

OFF position. Remove illuminated entry relay from vehicle. Relay is

located on a bracket behind instrument panel.

Check theft alarm switches by opening and closing doors

and liftgate. Replace switch(es) or repair wiring harness as

necessary. If switches are okay, check hood switch by opening and

closing hood.

Replace hood switch or repair wiring harness as

necessary. If hood switch is okay, unlock (with key) each front door and liftgate one at a time to test disarm switches. Replace switch(es) or repair wiring harness as necessary and retest system.

16) If disarm switches are okay, cycle power door locks to

lock position and then unlock. If power door locks do not operate properly, replace door lock switch(es), lock/unlock relay(s) or repair wiring harness as necessary. Retest system.

If power door locks operate properly, lock and unlock

vehicle with keyless entry transmitter. If power door locks do not

operate properly, replace keyless entry transmitter, receiver or

repair wiring harness as necessary and retest system.

If keyless entry system operates properly, turn ignition

switch to ON position and wait 30 seconds. If SECURITY light comes on

and stays on, repair or replace CCD bus and wiring as necessary and

retest system. If SECURITY light remains off, theft alarm system is

operating properly.

NOTE: A functional PCM that has been used in a vehicle equipped with theft alarm system CANNOT be used in another vehicle that is NOT equipped with theft alarm system.

MOTORS

Idle Air Control (IAC) Motor See IDLE CONTROL SYSTEM.

RELAYS

A/C Compressor Clutch Relay

See A/C COMPRESSOR CLUTCH under MISCELLANEOUS CONTROLS.

Automatic Shutdown (ASD) Relay

See appropriate ASD relay tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

Fuel Pump Relay

See FUEL PUMP RELAY under FUEL DELIVERY.

Radiator (Cooling) Fan Relay

See RADIATOR (COOLING) FAN under MISCELLANEOUS CONTROLS.

Starter Motor Relay

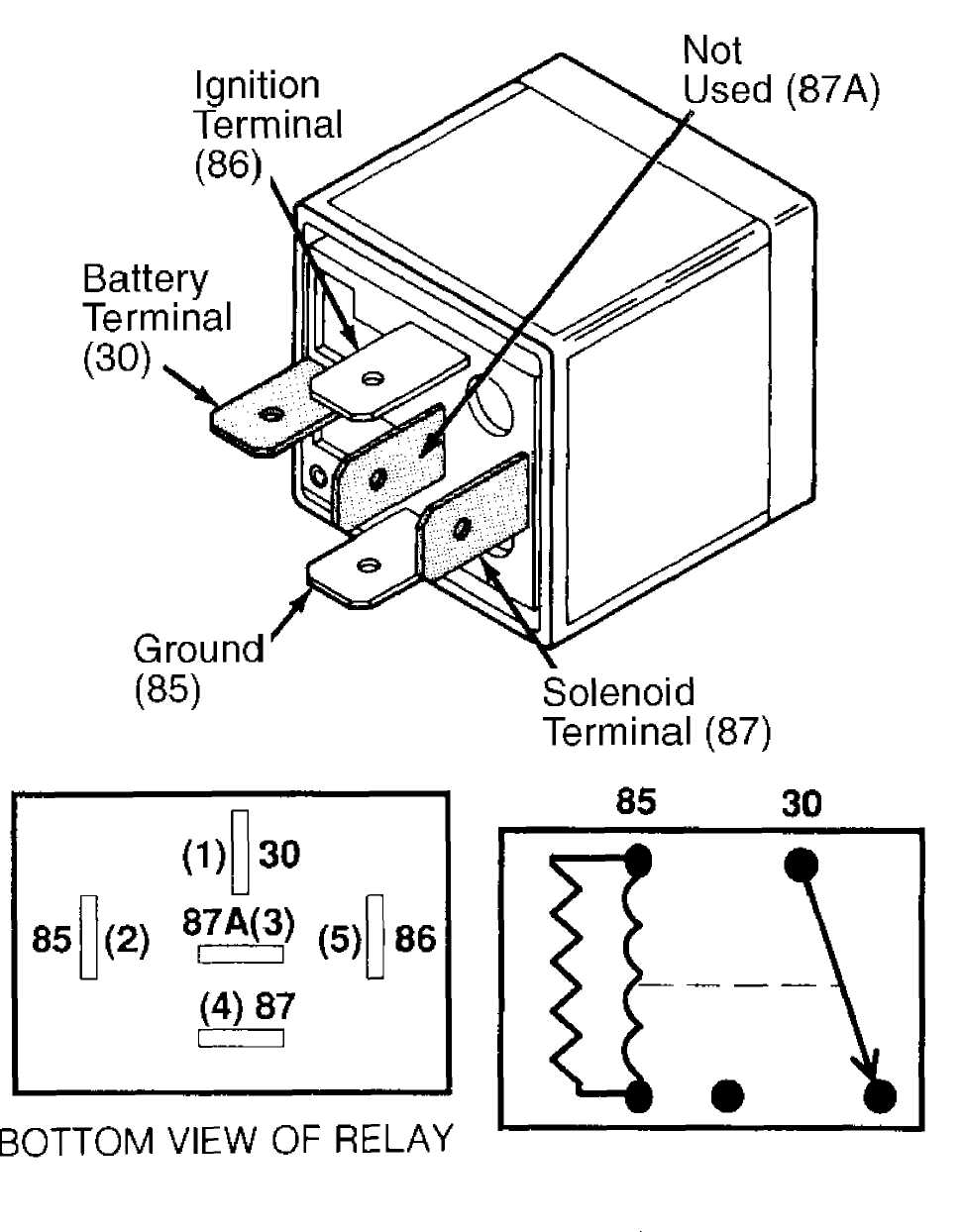

Some relays have battery voltage supplied to terminal No. 30. Others have battery voltage supplied to terminals No. 87 or 87A. See Fig. 2. In de-energized position, relay should have continuity between terminals No. 87A and No. 30. Resistance value between terminals No. 85 and No. 86 should be 70-80 ohms for resistor type relays or 81-91 ohms for diode type relays.

86 87 87A

9ą«13972 DE-ENERGIZED RELAY

Fig. 2: Identifying Relay Terminals & Testing Relays (Typical) Courtesy of Chrysler Corp.

FUEL SYSTEM

FUEL DELIVERY

NOTE: Always relieve fuel pressure before disconnecting any fuel injection-related component. Also see appropriate fuel delivery system or fuel injector control circuit tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

Fuel System Pressure Release Procedure

Disconnect negative battery cable. Slowly open fuel tank

cap to release fuel tank pressure. Remove protective cap from pressure

test port on fuel rail.

Using Fuel Pressure Gauge Tool Set (5069), obtain fuel

pressure gauge and hose assembly. Remove gauge from hose. Place gauge

end of hose in approved gasoline container. Place shop towel under

test port. Screw other end of hose onto fuel pressure test port.

Release fuel pressure. After pressure is released, remove hose from

test port. Install protective cap on pressure test port.

If gauge tool set is not available, perform step 1). Using

a small screwdriver, wrapped in shop towels, push test port valve in

to relieve fuel pressure. Absorb spilled fuel with shop towels. Remove

shop towels and dispose properly. Install protective cap on pressure

test port.

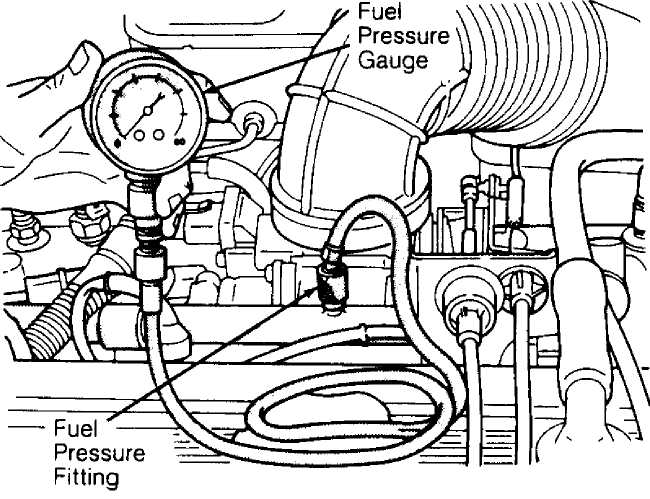

Fuel System Pressure Test

1) Remove cap from pressure fitting in fuel rail. See Fig. 3. Using a shop towel to absorb any spilled fuel, connect a 0-60 psi (0-4.22 kg/cm) fuel pressure gauge to pressure fitting on fuel rail. Disconnect vacuum hose from fuel pressure regulator. Start engine.

Fig. 3: Testing Fuel System Pressure Courtesy of Chrysler Corp.

2) Pressure should be approximately 39 psi (2.74 kg/cm) with vacuum hose disconnected and 31 psi (2.18 kg/cm) with vacuum hose

connected to fuel pressure regulator.

If fuel pressure is not 8-10 psi (.56-.70 kg/cm) higher

with vacuum hose disconnected from fuel pressure regulator, inspect

vacuum hose for blockage, leaks, kinks or other damage. If vacuum hose

is okay, replace fuel pressure regulator.

If fuel pressure exceeds 45 psi (3.1 kg/cm), check fuel

return line for kinks or blockage. If fuel pressure is low, release

fuel system pressure. See FUEL SYSTEM PRESSURE RELEASE PROCEDURE

heading above. Disconnect fuel return line on fuel rail near fuel

pressure regulator. Connect 5/16" fuel hose between disconnected fuel

return line and fuel rail.

CAUTION: Fuel pressure will rise as high as 100 psi (6.9 kg/cm) when fuel return line is pinched off. Ensure connections are properly secured. DO NOT pinch off hose for longer than 5 seconds.

Restart vehicle and let engine idle. Momentarily pinch off

hose connected to fuel return line. Note fuel gauge pressure reading.

Pressure should rise to approximately 75 psi (5.2 kg/cm) within 2

seconds.

If fuel pressure rises as specified, pressure is operating

at maximum capacity and is correct. If fuel pressure does not rise as

specified, turn engine off. Release fuel system pressure. See FUEL

SYSTEM PRESSURE RELEASE PROCEDURE heading above. Raise and support

vehicle. Disconnect fuel supply line at inlet (fuel tank side) of fuel

filter. Connect 3/8" fuel hose between fuel filter and fuel supply

line.

Restart vehicle and let engine idle. Momentarily pinch off

hose connected to fuel supply line. Note fuel pressure gauge reading.

Pressure should rise to approximately 75 psi (5.2 kg/cm) within 2

seconds. If fuel pressure rises as specified, but pressure is not same

at fuel rail, check for plugged or restricted fuel filter. Also check

fuel supply line between fuel filter and fuel rail for kinks or

blockage.

Fuel Pressure Leak-Down Test

Remove cap from pressure fitting on fuel rail. See Fig. 3.

Connect a 0-100 psi (0-6.9 kg/cm) fuel pressure gauge to pressure

fitting on fuel rail. Start and run engine at idle.

Turn engine off and note fuel pressure gauge reading.

Leave fuel pressure gauge connected. Allow 30 minutes to elapse and

then compare fuel pressure gauge reading to reading taken when engine

was turned off.

A pressure drop up to 20 psi (1.4 kg/cm) within 30

minutes is within specification. If pressure drop is not within

specification, go to next step. If pressure drop is within

specification, the fuel pump outlet check valve and fuel pressure

regulator are operating correctly.

Release fuel system pressure. See FUEL SYSTEM PRESSURE

RELEASE PROCEDURE heading above. Disconnect both fuel lines at fuel

rail near fuel pressure regulator. Connect 3/8" fuel hose between

disconnected fuel supply line and fuel rail. Connect 5/16" fuel hose

between disconnected fuel return line and fuel rail.

Start engine and record fuel pressure gauge reading. Turn

engine off. Pinch off hose connected to fuel return line. Allow 30

minutes to elapse. If pressure drop is within specification, go to

next step. A pressure drop of more than 20 psi (1.4 kg/cm) within 30

minutes indicates pressure is bleeding past fuel pump outlet check

valve. Replace fuel pump assembly, located in fuel tank.

Pinch off hose connected to fuel supply line. Allow 30

minutes to elapse. A pressure drop of more than 20 psi (1.4 kg/cm)

within 30 minutes indicates pressure is bleeding past fuel pressure

regulator. Replace fuel pressure regulator.

Fuel Pump Capacity Test

1) Release fuel system pressure. See FUEL SYSTEM PRESSURE

RELEASE PROCEDURE heading above. Disconnect fuel supply line at fuel

rail near fuel pressure regulator. Connect 3/8" fuel hose to

disconnected fuel supply line. Insert other end of hose into approved

gasoline container. Start engine. Check fuel pump flow rate

(capacity).

2) A good fuel pump will deliver at least 1.05 qts. (1.0L) of

fuel per minute with return line hose pinched off. If fuel pump

capacity is incorrect, inspect fuel supply system for a plugged filter

or plugged fuel pump inlet filter.

Fuel Pump Relay

Some relays have battery voltage connected to terminal No. 30. Others have battery voltage connected to terminals No. 87 or 87A. See Fig. 2. In de-energized position, relay should have continuity between terminals No. 87A and No. 30. Resistance value between terminals No. 85 and No. 86 should be 70-80 ohms for resistor type relays, or 81-91 ohms for diode type relays.

FUEL CONTROL

Fuel Injectors

Disconnect injector from wiring harness. Connect ohmmeter on injector terminals. Resistance should be about 13.3-15.7 ohms at 68F (20C).

Oxygen (O2) Sensor

See OXYGEN (O2) SENSOR (HEATING ELEMENT) under ENGINE SENSORS & SWITCHES.

IDLE CONTROL SYSTEM

Idle Air Control (IAC) Motor

Set parking brake and block drive wheels. Route all

Exerciser Tester (7558) cables away from cooling fans, drive belt,

pulleys, and exhaust components. Return engine idle speed to normal

before disconnecting exerciser.

With ignition off, disconnect IAC motor connector at

throttle body. Plug in exerciser tester harness connector into IAC

motor. Connect Red clip of exerciser to battery positive terminal.

Connect Black clip to battery negative terminal. Red light

on exerciser will flash if exerciser is properly connected. Start

engine. Move exerciser switch to HIGH position. Engine speed should

increase. Move switch to LOW position. Engine speed should decrease.

If engine idle speed changes while using exerciser, IAC

motor is working properly. Return engine speed to normal idle and

disconnect exerciser from IAC motor.

If engine idle did not change, turn ignition off. DO NOT

disconnect exerciser from IAC motor. Remove IAC motor from throttle

body. With ignition off, cycle the exerciser switch between HIGH and

LOW positions. Pintle should move in and out of motor.

CAUTION: When checking IAC motor operation with motor removed from throttle body, DO NOT extend pintle more than 1/4" (6.35 mm), as pintle may separate from motor. The IAC motor must be replaced if pintle separates from motor.

6) If pintle still does not move, replace IAC motor. Start

engine and test replacement motor. If pintle now operates properly,

check IAC motor bore in throttle body and clean if necessary. Reinstall IAC motor and retest.

7) If throttle body is clear of obstructions, USE A Chrysler Corp. Diagnostic Readout Box II (DRB-II) tester and refer to appropriate IAC motor tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.

IGNITION SYSTEM

TIMING CONTROL SYSTEMS

Ignition timing is electronically controlled by Powertrain Control Module (PCM). Base ignition timing is NOT adjustable with this system. PCM controlled ignition system consists of coolant temperature sensor, crankshaft position sensor, distributor (includes rotor and camshaft position sensor), ignition coil, manifold absolute pressure sensor and throttle position sensor. See ENGINE SENSORS & SWITCHES for component testing.

EMISSION SYSTEMS & SUB-SYSTEMS

CRANKCASE VENTILATION SYSTEM

System and component testing information is not available from manufacturer.

FUEL EVAPORATION

System and component testing information is not available from manufacturer.

MISCELLANEOUS CONTROLS

A/C COMPRESSOR CLUTCH

A/C Compressor Clutch Relay

Some relays have battery voltage supplied to terminal No. 30. Other haves battery voltage supplied to terminals No. 87 or No. 87A. See Fig. 2. In de-energized position, relay should have continuity between terminals No. 87A and No. 30. Resistance value between terminals No. 85 and No. 86 should be 70-80 ohms for resistor type relays, or 81-91 ohms for diode type relays.

NOTE: Also see appropriate A/C clutch relay circuits tests in G - 2.5L & 4.0L TESTS W/ CODES article in the ENGINE PERFORMANCE Section.

RADIATOR (COOLING) FAN

Radiator (Cooling) Fan Relay

Some relays have battery voltage connected to terminal No. 30. Other haves battery voltage supplied to terminals No. 87 or No. 87A. See Fig. 2. In de-energized position, relay should have continuity between terminals No. 87A and No. 30. Resistance value between terminals No. 85 and No. 86 should be 70-80 ohms for resistor type relays, or 81-91 ohms for diode type relays.

NOTE: Also see appropriate radiator (cooling) fan relay circuit tests in G - 2.5L & 4.0L TESTS W/ CODES article in this section.