A/C COMPRESSOR OVERHAUL

1993 Jeep Cherokee

1993 GENERAL SERVICING Compressor Servicing

REFRIGERANT OIL & REFRIGERANT SPECIFICATIONS

NOTE: Due to late changes, always refer to underhood A/C

Specification Label in engine compartment or A/C compressor label while servicing A/C system. If A/C Specification Label and specifications in table differ, use label specifications.

REFRIGERANT OIL & REFRIGERANT CAPACITY TABLE (CARS)

(1) Oil Refrigerant

Application Ounces Ounces

Chrysler Corp.

All FWD Cars (2) 7.3 32

Concorde, Intrepid

& Vision 5.0 28

Laser & Talon 5.0 33

- Total system capacity, unless otherwise noted.

- With fixed displacement compressor. Use 8.7 ounces with

variable displacement compressor.

REFRIGERANT OIL & REFRIGERANT CAPACITY TABLE (LIGHT TRUCKS/VANS)

(1) Oil Refrigerant

Application Ounces Ounces

Chrysler Corp. (Except Jeep)

Dakota 4.6 44

FWD Vans (2)

With Rear Unit 13.4 50

Without Rear Unit 6.7 36

Pickup & Ramcharger 4.6 44

RWD Vans

With Rear Unit 9.3 65

Without Rear Unit 7.3 45

Jeep

Cherokee 4.6 38

Grand Cherokee (2) 8.0 28

Wrangler 4.6 32

- Total system capacity, unless otherwise noted.

- Models use R-134a refrigerant and PAG (ND8) Refrigerant Oil

(Part No. 82300102).

COMPRESSOR APPLICATIONS

NOTE: Due to late changes, always refer to underhood A/C

Specification Label in engine compartment or A/C compressor label while servicing A/C system. If A/C Specification Label and specifications differ, use label specifications.

COMPRESSOR APPLICATIONS TABLE (CARS)

Application Compressor

Chrysler Corp.

Concorde, Intrepid, Laser,

Talon & Vision Nippondenso 10PA17 10-Cyl.

Except Concorde, Intrepid,

Laser, Talon & Vision Nippondenso 6C-17 6-Cyl.,

Nippondenso 10PA17 10-Cyl.,

Sanden TR-105 10-Cyl.,

Sanden SD-709P 7-Cyl.

COMPRESSOR APPLICATIONS TABLE (LIGHT TRUCKS & VANS)

Application Compressor

Chrysler Corp. (Except Jeep)

Dakota, Pickup & Ramcharger Sanden SD-709 7-Cyl.

FWD Vans Nippondenso 10PA17 10-Cyl.

RWD Vans Sanden TR-105 10-Cyl.

(1) - Series codes are determined by fifth character of VIN code.

BODY DESIGNATIONS

BODY DESIGNATIONS TABLE (CHRYSLER CORP. CARS)

Body Designation (1) Model

"A" Body Acclaim, LeBaron Sedan & Spirit

"C" Body Dynasty & New Yorker

"G" Body Daytona

"J" Body LeBaron Convertible/Coupe

"LH" Body Concorde, Intrepid & Vision

"P" Body Shadow & Sundance

"S" Body Laser & Talon

"Y" Body Fifth Avenue & Imperial

(1) - Body codes are determined by fifth character of VIN code.

BODY

DESIGNATIONS TABLE (CHRYSLER CORP. LIGHT TRUCKS &

VANS)

Model Designation

Caravan "D" & "K" Series

Dakota "N" Series

Pickups (Full Size) "D" & "W" Series

Ramcharger "AD" & "AW" Series

Town & Country "Y" Series

Vans (Full Size) "B" Series

Voyager "H" & "P" Series

NIPPONDENSO 6C-17 6-CYLINDER

CLUTCH ASSEMBLY

Removal

1) Disconnect negative battery cable. Loosen and remove

compressor drive belt. Disconnect clutch coil lead. With refrigerant lines attached, remove compressor mounting bolts and position compressor for service.

Using

Clutch Hub Holder (6355), remove

crankshaft nut.

Using Clutch Hub Puller (6354), remove

clutch hub and hub clearance

shims.

Remove

snap ring and pulley assembly. Remove snap ring and

clutch coil

assembly.

Installation

Align hole

in back of clutch coil with pin in compressor

housing. Ensure

clutch coil lead is properly routed. To complete

installation,

reverse removal procedure.

Tighten

crankshaft nut. Using a feeler gauge, check clutch

plate-to-pulley

clearance. Clearance should be .020-.035" (.51-.89

mm). If clearance is incorrect, add or remove shims as necessary.

SHAFT SEAL

Removal

Discharge

A/C system using approved refrigerant

recovery/recycling

equipment. Remove compressor. Drain oil from

compressor, and

measure amount of oil drained. Remove compressor

clutch assembly.

Remove

compressor crankshaft key. Remove felt packing from

nose of front

cover. Clean area around seal.

3) Remove

shaft seal snap ring. Using Seal Remover/Installer

(6429),

remove seal from compressor.

Installation

Lubricate

NEW shaft seal with refrigerant oil. Install

Seal

Protector (6231) over compressor shaft.

Using flat end of Seal

Remover/Installer

(6429), install shaft seal until seal

seats in

housing.

Install

NEW shaft seal snap ring. Install clutch assembly.

Using

new refrigerant oil, add same amount of oil to compressor as

was

drained from it. Install compressor. Evacuate and recharge

system.

Perform leak test. See LEAK

TESTING in A/C GENERAL SERVICING

PROCEDURES

article in the AIR CONDITIONING & HEAT

Section.

NIPPONDENSO 10PA17 & 10PA17A 10-CYLINDER

CLUTCH ASSEMBLY

Removal

Remove

and discard compressor shaft bolt. Remove clutch

plate

and shims. Tap on clutch plate using a soft-faced hammer

(if

necessary).

Remove

pulley assembly snap ring. Remove pulley assembly.

Remove snap

ring, and disconnect clutch coil lead. Remove clutch coil.

Installation (Chrysler)

Install

clutch coil so pin in back of coil aligns with

hole in front

housing. Install snap ring with beveled side away from

compressor.

Install

pulley assembly. Install snap ring with beveled

side away from

compressor. If reusing original clutch plate and

pulley, old

shims can be used.

If

using new components, install several shims so shim

pack

thickness is .10" (2.5 mm).

Install clutch plate and hold it

tightly

against shims.

Using feeler gauge, measure air gap between clutch plate

and pulley surface. On Laser and Talon, clearance should be .014-.026" (.36-.66 mm). On all models except Laser and Talon, clearance should be .020-.035" (.51-.89 mm). Adjust shim thickness to obtain correct clearance. Install NEW compressor shaft bolt and tighten it to 13 ft. lbs. (18 N.m).

5) Once compressor shaft bolt is tightened, recheck clearance between clutch plate and pulley surface in 4 places. Readjust clearance if necessary.

NOTE: On Chrysler models, ensure voltage is correct after

installing new clutch. Cycle clutch on for 5 seconds and off for 5 seconds. Repeat cycle 20 times with A/C on, blower fan on high speed and engine speed at 1500-2000 RPM.

SHAFT SEAL

Removal

Discharge

A/C system using approved refrigerant

recovery/recycling

equipment. Remove compressor. Drain oil from

compressor, and

measure amount drained. Remove clutch assembly.

Remove

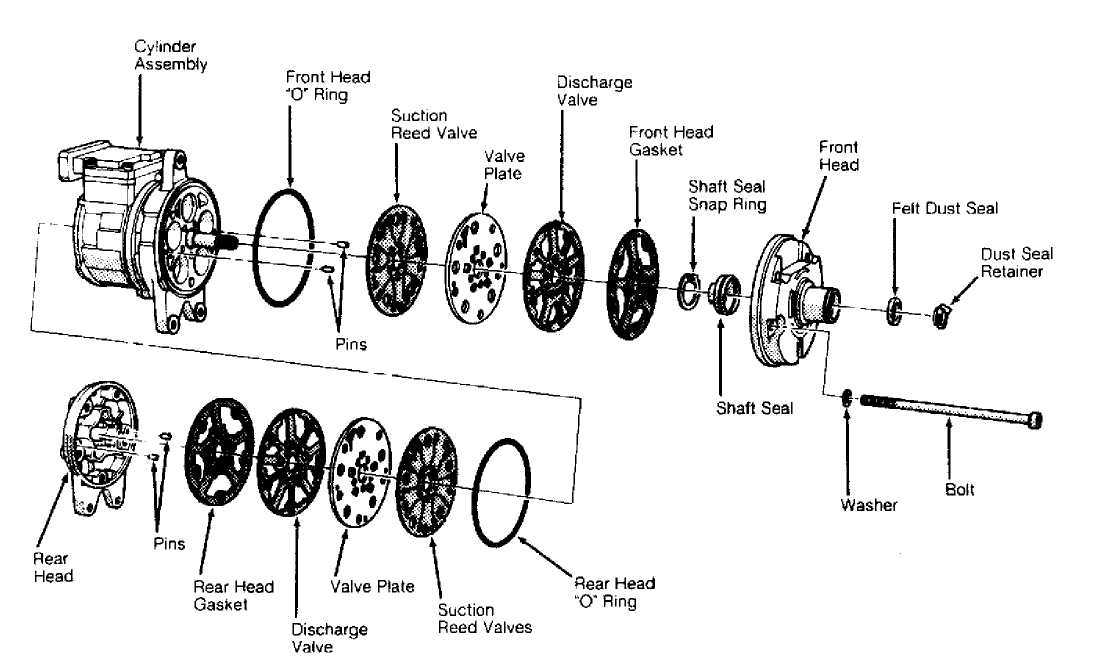

felt dust seal and dust seal retainer from front

head.

See Fig. 1. Remove shaft seal snap ring.

Position front head

(nose up) on cardboard placed on a flat surface. Using brass drift, press shaft seal from front head.

Installation

Lubricate

new shaft seal with refrigerant oil. DO NOT

touch sealing

surfaces. Press seal into front head, and install snap

ring.

Install felt dust seal and dust seal retainer.

Lubricate

Shaft Seal Protector (J-34614) and front head

"O"

ring with refrigerant oil. Install shaft seal

protector on

crankshaft. Install a new

front head "O" ring on cylinder

assembly.

Install

front head on cylinder assembly. Ensure dowel pins

are aligned.

Use care when guiding shaft seal protector through seal

opening.

Remove shaft seal protector.

Install

through bolts using NEW brass washers. Diagonally

tighten

bolts to 19 ft. lbs. (26 N.m).

Using INCH-lb. torque wrench,

check compressor shaft rotating

torque. Rotating torque should be 26

INCH

lbs. (3 N.m). Install clutch assembly.

Using

new refrigerant oil, add same amount of oil to

compressor as was

drained from it. Install compressor. Evacuate and

recharge

system. Perform leak test. See LEAK TESTING in A/C GENERAL

SERVICING

PROCEDURES article in the AIR CONDITIONING & HEAT

Section.

Fig. 1: Exploded View Of Compressor (Nippondenso 10PA17, 10PA17A & 10PA20 10-Cylinder) Courtesy of Ford Motor Co.

SANDEN SD-709 & SD-709P 7-CYLINDER

CLUTCH ASSEMBLY

Removal

Using

Spanner (6462), hold clutch and remove

compressor

shaft nut. Using Puller

(6461), remove clutch plate. Remove key

from

compressor shaft.

Remove

pulley snap ring. Install jaws of Puller (6141-1)

in

snap ring groove on pulley. Place Shaft Protector (6141-2)

on

compressor shaft.

Install

puller plate on jaws. Thread 2 bolts

through

puller plate into jaws. Remove

pulley from compressor. Remove snap

ring

and clutch coil.

Installation

Install

clutch coil and snap ring on compressor. Support

compressor on

rear mounting ears.

Using

hammer, Handle (6464) and Driver (6143),

install

pulley assembly. Ensure driver rests

on inner race of bearing when

installing pulley assembly. Install

snap ring.

Install

shims. Install key in compressor shaft. Using

hammer and Shaft

Protector (6141-2), install clutch plate

on

compressor shaft. Tighten compressor

shaft nut to 25-30 ft. lbs. (34-

41

N.m).

Using

feeler gauge, measure clearance between clutch plate

and

pulley assembly in several areas. Clearance should be .016-.031"

(.41-.79 mm). If clearance is not within specification, adjust shim thickness to obtain correct clearance.

SHAFT SEAL

Removal

Discharge

A/C system using approved refrigerant

recovery/recycling

equipment. Remove compressor. Drain oil from

compressor, and

measure amount drained. Remove clutch assembly.

Remove key

from shaft. Remove felt ring metal retainer and

felt ring. Using

small screwdriver, remove shims for clutch plate.

Ensure

area around seal is clean. Remove shaft seal snap

ring.

Using Shaft Seal Remover/Installer (6142), remove

shaft seal.

Install

Shaft Seal Remover/Installer (6144) into

shaft

seal. Press downward on shaft

seal remover/installer and rotate it to

engage

tangs with slots of shaft seal. Pull shaft seal from

compressor.

Installation

Install

Shaft Protector (6141-2) over compressor

shaft.

Coat shaft protector, new shaft

seal and shaft seal seat with

refrigerant oil. DO NOT touch

sealing surfaces of seal.

Place seal

on seal remover/installer, and twist tool to

hold seal. Install

seal in compressor, and twist tool in opposite

direction to

release seal. Remove seal remover/installer. Using shaft

seat

remover/installer, install shaft seat.

Install

snap ring. Tap on snap ring to ensure it seats in

groove (if

necessary). Install shims and new felt. To

install

remaining components, reverse

removal procedure. Using new refrigerant

oil,

fill compressor with the same amount of oil drained from it.

Install

compressor. Evacuate and recharge system. Perform leak test.

See

LEAK TESTING in A/C GENERAL SERVICING PROCEDURES article in the

AIR

CONDITIONING & HEAT Section.

SANDEN TR-105 10-CYLINDER

CLUTCH ASSEMBLY

Removal

1) Discharge A/C system using approved refrigerant

recovery/recycling equipment. Remove compressor. Install two6-mm bolts in holes of clutch plate. Hold 6-mm bolts while removing nut from end of compressor shaft.

Remove

clutch plate and shims. Tap clutch plate from

compressor

(if necessary). DO NOT pry between clutch

plate and pulley

to remove clutch

plate.

Remove

pulley assembly snap ring. Remove pulley assembly.

Disconnect

clutch coil lead. Scribe marks on clutch coil and

compressor for

installation reference. Remove snap ring and clutch

coil.

Installation

Install

clutch coil on compressor so locating pin engages

hole in clutch

coil. Install snap ring with beveled side away from

compressor.

Install

pulley assembly. Install snap ring with beveled

side away from

compressor. If reusing original clutch plate and

pulley, old

shims can be used.

If

new components are used, install several shims so shim

pack

thickness is .10" (2.5 mm).

Install clutch plate and hold it

tightly

against shims.

Using feeler gauge, measure air gap between clutch plate

and pulley surface. Proper clearance is .013-.025" (.33-.64 mm). Adjust shim thickness to obtain correct clearance. Tighten compressor shaft nut to 13 ft. lbs. (18 N.m).

5) Once compressor shaft nut is tightened, recheck clearance between clutch plate and pulley surface in 4 places. Readjust clearance if necessary. Install compressor. Evacuate and recharge system. Perform leak test. See LEAK TESTING in A/C GENERAL SERVICING PROCEDURES article in the AIR CONDITIONING & HEAT Section.

NOTE: After installing new clutch, ensure voltage is correct.

Cycle clutch on for 5 seconds and off for 5 seconds. Repeat cycle 20 times with A/C on, blower fan on high speed and engine speed at 1500-2000 RPM.

SHAFT SEAL

Removal

1) Discharge A/C system using approved refrigerant

recovery/recycling equipment. Remove compressor. Install two 6-mm bolts in holes of clutch plate. Hold 6-mm bolts while removing nut from end of compressor shaft.

Remove

clutch plate and shims. Tap clutch plate from

compressor

(if necessary). DO NOT pry between clutch

plate and pulley

to remove clutch

plate.

Insert

2 jaws of Bearing Remover/Installer (6533)

into

bearing groove.

Install retainer over jaws of bearing

remover/installer.

Tighten

pressure screw of bearing remover/installer

against compressor

shaft until bearing is removed.

Remove

felt washer from compressor. Remove shaft seal snap

ring. Engage

Seal Remover/Installer (6551) in slots of

seal case. Lift

seal from compressor.

Installation

Place

Seal Sleeve Protector (6552) over

compressor shaft.

Coat seal sleeve

protector and seal lip with refrigerant oil. Using

seal

remover/installer, install seal. Remove seal sleeve protector.

Install

shaft seal snap ring. Install felt washer. Install

bearing in

pulley. Using hammer with jaws and retainer of

bearing

remover/installer, drive bearing into pulley.

If

reusing original clutch plate and pulley, old shims can

be

used. If using new components, install several shims so shim

pack

thickness is .10" (2.5 mm).

Install clutch plate and hold it tightly

against

shims.

Using

feeler gauge, measure air gap between clutch plate

and pulley

surface. Proper clearance is .013-.025" (.33-.64

mm).

Adjust shim

thickness to obtain correct clearance. Tighten compressor

shaft

nut to 13 ft. lbs. (18 N.m).

Once

compressor shaft nut is tightened, recheck clearance

between

clutch plate and pulley surface in 4 places.

Readjust

clearance if necessary.