Ā

1993 Jeep Cherokee

1993 Drive Axles - Front Axles

Cherokee, Grand Cherokee, Grand Wagoneer, Wrangler

DESCRIPTION

Model 30 axle is used on all 4WD applications. Cherokee uses Selec-Trac 4WD system. Wrangler uses Command-Trac 4WD system. Grand Cherokee and Grand Wagoneer use a full-time 4WD system.

Command-Trac is a part-time system designed for off-road use. Command-Trac uses a vacuum operated axle disconnect mechanism to control 4WD operation.

Selec-Trac is a combination part-time/full-time system designed for both highway and off-road use. Transfer case shifter is used to control 4WD operation.

AXLE RATIO & IDENTIFICATION

Axle build date and manufacturerÆs number are stamped on passenger-side axle tube, near housing cover. Axle assembly part number, gear ratio and identification tag are attached to the left side of the housing cover. See AXLE RATIO & IDENTIFICATION table.

AXLE RATIO & IDENTIFICATION TABLE

Axle Pinion/Ring Gear Ring Gear

Ratio Tooth Combinations Diameter

Front Axle (1)

3.07:1 14/43 7 1/8" (181 mm)

3.55:1 11/39 7 1/8" (181 mm)

4.10:1 9/37 7 1/8" (181 mm)

(1) - Model 30 axle used on all models.

REMOVAL & INSTALLATION

NOTE: This article covers removal, installation and overhaul of

front axle components. For information on differential, see 7 1/8", 7 9/16" & 8 1/4" RING GEARS article.

AXLE ASSEMBLY

Removal (Except Wrangler)

Raise and support vehicle under frame. Remove wheels.

Remove disc brake calipers. Hang calipers aside with wire. Remove

rotors and brake shields.

Disconnect breather tube at axle. Remove vent hose from

differential housing. Remove stabilizer bar link, tie rod and drag

link. Remove front drive shaft. Disconnect shock absorbers and

steering damper. If equipped with Anti-Lock Brake System (ABS),

disconnect brake sensor.

Disconnect track bar. Position jack under axle. Disconnect

upper and lower control arms at axle. Lower and remove axle slowly to

release coil spring pressure.

Installation (Except Wrangler)

Raise axle into position while guiding coil springs into position. Connect upper and lower control arms to axle. To complete installation, reverse removal procedure.

Removal (Wrangler)

Raise vehicle. Position supports under frame rails at rear

of front springs. Remove wheels. Remove brake calipers and hang aside

with wire. Remove brake rotors. Disconnect Command-Trac vacuum

harness.

Mark front drive shaft and axle yoke for reassembly.

Disconnect front drive shaft at axle yoke. Secure shaft to frame with

wire. Disconnect tie rods at steering knuckles. Remove steering

damper. Remove shock absorbers. Remove retaining nuts and bolts from

track bars at axle shaft tube brackets. Disconnect breather tube at

axle. Disconnect stabilizer bar link bolts at spring brackets.

Support axle and raise jack slightly to relieve spring

tension. Remove spring "U" bolts and brackets. Loosen nuts attaching

spring rear shackles to springs. Remove bolts attaching spring front

shackles. Lower springs to floor. Remove axle assembly.

Installation (Wrangler)

To install, reverse removal procedure.

AXLE SHAFT

Removal

Raise and support vehicle. Remove wheels, caliper and

rotor. Remove cotter pin, lock nut and axle hub nut.

Remove hub-to-steering knuckle bolts. Remove hub and rotor

shield from steering knuckle. Remove left axle shaft from axle tube.

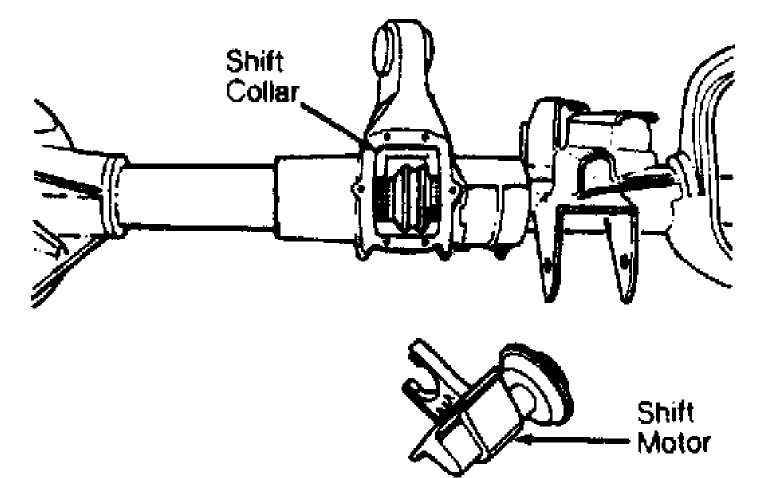

On models with Command-Trac, disconnect vacuum harness. Remove vacuum

motor housing. See Fig. 1.

Remove right axle shaft from axle tube. Ensure shift

collar remains on intermediate shaft.

Fig. 1: Removing Command-Trac Shift Motor Courtesy of Chrysler Corp.

Installation

1) Install right and left axle shafts in axle tubes. On

models with Command-Trac, ensure shift collar is correctly positioned on intermediate axle shaft.

Ensure outer axle shaft is completely engaged with shift

collar and joined with intermediate axle shaft. See Fig. 1. Install

shift motor. Ensure fork engages with shaft collar.

On all models, lubricate hub bore in steering knuckle with

wheel bearing grease. Install rotor shield. Install hub on axle. Slide

hub into steering knuckle hub bore. Tighten hub bolts. Install the

washer and the hub nut. Tighten hub nut to proper specification. See

TORQUE SPECIFICATIONS TABLE at the end of this article. Install

retainer and cotter pin. Install rotor, caliper and wheel. Lower

vehicle.

INTERMEDIATE AXLE SHAFT

Removal & Installation (Wrangler)

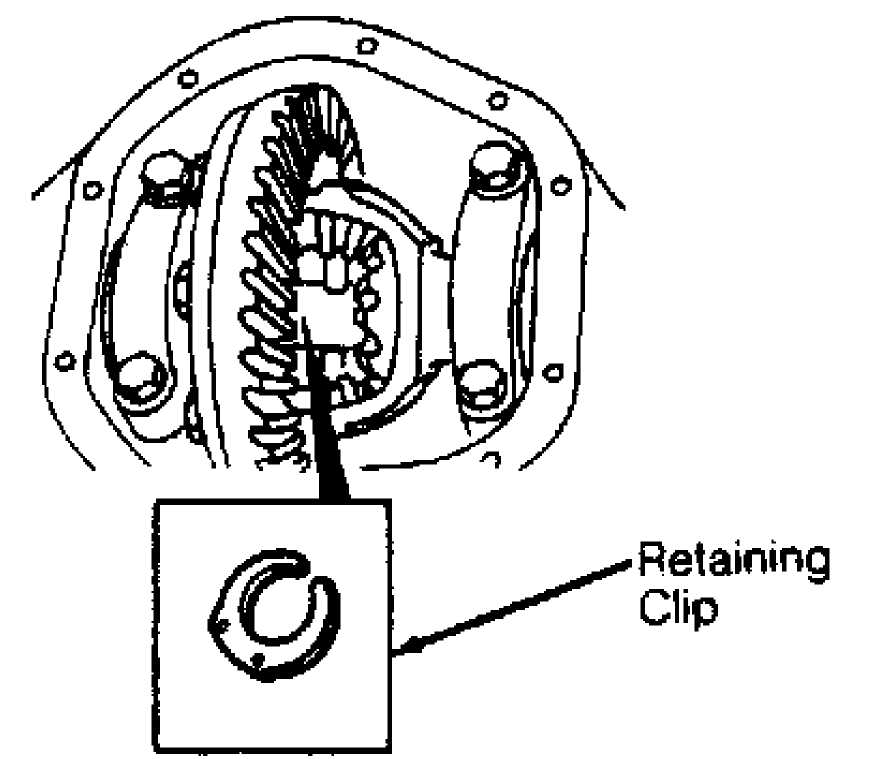

Fig. 2: Removing Intermediate Shaft Retaining Clip Courtesy of Chrysler Corp.

HUB & BEARING

Remove outer axle. Remove differential cover and drain fluid. Remove intermediate shaft retaining clip. See Fig. 2. Remove intermediate shaft. To install, reverse removal procedure. Fill differential housing with 2.5 pts. (1.2L) of SAE 75W-90 gear oil.

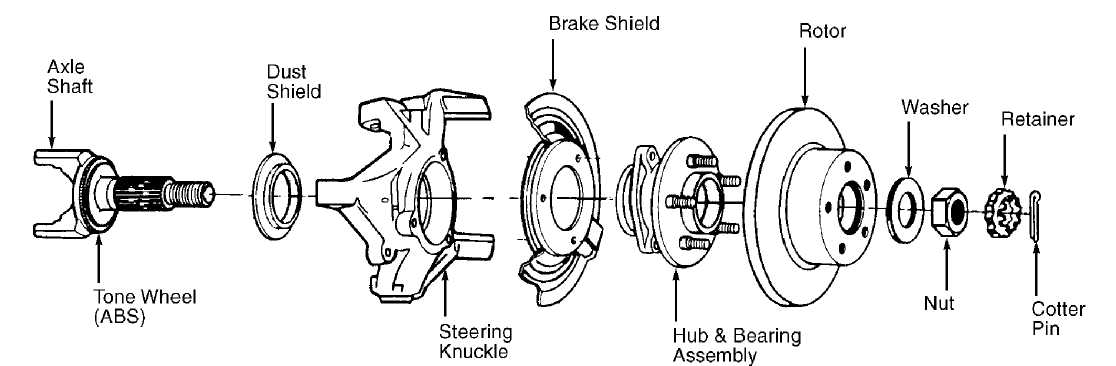

Removal

Raise and support vehicle. Remove wheel, caliper and rotor. Remove cotter pin, nut retainer, hub nut and washer. Remove hub-to-knuckle bolts. Remove hub from steering knuckle. See Fig. 3.

Installation

Apply wheel bearing grease to hub bore in steering knuckle and install hub and bearings. To complete installation, reverse removal procedure.

NOTE:

Hub bearings cannot be serviced. If defective, replace complete hub assembly.

92D21835

Fig. 3: Exploded View Of Hub Assembly Courtesy of Chrysler Corp.

OVERHAUL

AXLE SHAFT OUTER "U" JOINT

Remove axle shaft. Remove bearing cap and snap rings. Press out bearings caps from yoke. To install, reverse removal procedure. Pack replacement bearing caps 1/3 full of bearing grease.

AXLE SHAFT CV JOINT

NOTE: If worn or damaged, assembly.

CV joint MUST be replaced as a complete

Disassembly

Remove boot clamps. Carefully slide boot down axle shaft.

Remove lubricant to expose CV joint components. Place joint in soft-

jawed vise. Remove internal circlip and slide CV joint from shaft.

Using paint, mark hub, bearing cage and housing for reassembly

reference.

Press down on one side of bearing cage to access bearing

balls. If CV joint is tight, use a hammer and brass drift to loosen

hub. DO NOT strike cage or ball. Remove balls. Remove hub and cage

from housing. Align hub lands with cage windows. Rotate hub 90 degrees

and remove hub from cage. Inspect components for wear and damage.

Replace joint, if necessary.

marks.

Reassembly

1) Lightly oil components before reassembly. Align reference Install hub into cage. Install hub/cage into housing. Tilt cage

and insert balls into hub raceways. Push high side of hub/cage assembly into housing. Ensure assembly rotates freely in housing. Install shaft and circlip.

2) Pack bearing assembly with molybdenum base CV joint

grease. Slide boot over CV joint. Install NEW boot clamps. Check shaft and joint for smooth movement.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Applications

Ft. Lbs. (N.m)

Cherokee

Axle Yoke Nut 210 (285)

Hub Bolt 75 (102)

Hub Nut 175 (237)

Lower Control Arm Bolt 85 (115)

Track Bar Axle Bracket Nut 74 (100)

Track Bar Frame Nut 31 (42)

"U" Joint Strap Bolt 14 (19)

Upper Control Arm Bolt 55 (75)

Grand Cherokee & Grand Wagoneer

Hub Bolt 75 (102)

Hub Nut 175 (237)

Spring Pivot Bolt 100 (136)

Track Bar Axle Bracket Nut 74 (100)

Track Bar Ball Stud Nut 60 (81)

Upper Control Arm Bolt 55 (75)

Wrangler

Axle Yoke Nut 210 (285)

Frame Bracket 105 (142)

Hub Bolt 75 (102)

Hub Nut 175 (237)

Shackle Bolt 95 (129)

Track Bar Axle Nut 74 (100)

Track Bar Frame Nut/Bolt 125 (169)

"U" Bolt At Axle Tube Retaining Nut 90 (122)

"U" Joint Strap Bolt 14 (19)

INCH Lbs. (N.m)

Vacuum Shift Motor Bolt 98 (11)