LOCKING HUBS - AUTOMATIC

1988 Jeep Cherokee

1988 Locking Hubs - Command-Trac & Selec-Trac Jeep

DESCRIPTION & OPERATION

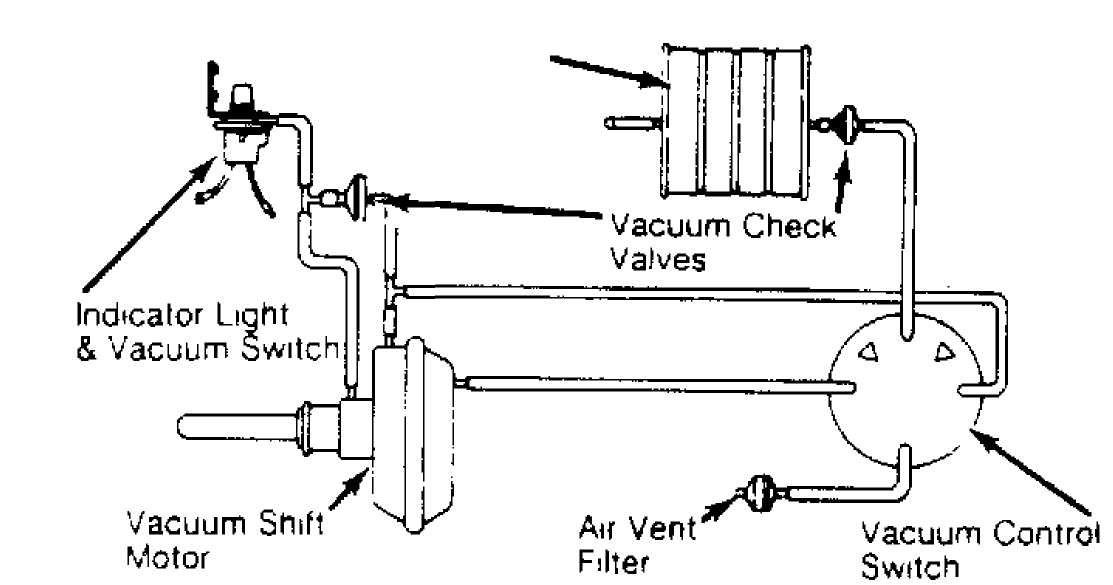

Command-Trac locking hub is used on Model 30 front axles. This system can be shifted between 2WD and 4WD high range while vehicle is moving. The only time vehicle must be stopped to shift into or out of 4WD is when shifter is in low range. See Fig. 1.

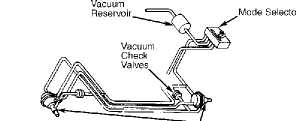

Selec-Trac locking hubs allow full or part time 4WD. Used on Model 30 front axles, system can be shifted into 2WD or 4WD modes only when vehicle is stopped. See Fig. 2.

Vacuum Reservoir

Fig. 1: Command-Trac Vacuum Control System

TROUBLE

SHOOTING

TROUBLE

SHOOTING

SELEC-TRAC SYSTEM

2WD To 4WD

Position mode select switch to "4WD" position while driving vehicle 2-3 MPH. Axle should ratchet and clunk into position. Transfer case should shift after axle shifts, accompanied by hissing sound from mode selector switch.

4WD To 2WD

1) Position mode select switch to "2WD" position. Transfer case should shift to 2WD and not allow shifting into 4WD or "LO" range. Axle should shift after transfer case shifts.

2) To determine if front axle has completed a shift out of 4WD into 2WD, position mode select switch back to "4WD" position while operating vehicle at slow speed. If vehicle shifts into 2WD, axle will ratchet. If shift is not completed, transfer case will shift into 4WD and hissing sound will come from mode select switch.

FRONT AXLE SHIFT MOTOR TEST

Disconnect

vacuum harness from front axle shift motor.

Connect

vacuum pump to shift motor front port. Apply 15 in.

Hg vacuum

to shift motor. Rotate right

front wheel to disengage axle.

Shift

motor should hold vacuum at least 30 seconds.

If

not, replace motor. If motor does hold vacuum, disconnect

vacuum pump

from shift motor front

port. Connect pump to shift motor rear port and

cap

transfer case connecting port. Apply 15 in.

Hg vacuum to motor.

Shift

motor should hold vacuum for at least 30 seconds.

If

not, replace motor. If motor does

hold vacuum, remove cap from shift

motor transfer case connecting

port and check for vacuum. If no vacuum

is present, rotate right

front wheel to ensure axle has shifted

completely. Axle must

completely shift to open shift motor connecting

port.

Recheck

vacuum at shift motor transfer case port. If

vacuum

is present, transfer case requires diagnosis. Command-Trac

uses

Model 207 transfer

case. Selec-Trac uses Model 228 transfer

case.

REMOVAL & INSTALLATION

LOCKING HUB

Removal

Remove

cover to outer clutch housing. Remove bearing race

spring

assembly. Remove sealing ring and seal bridge retainer.

Remove

bearing components.

Squeeze

tangs of wire retaining ring together with needle-

nose pliers.

Pull remaining components of automatic hub from wheel.

Installation

1) Ensure

lock ring is in position. Using Bearing Nut Wrench

(J-6893-D),

tighten wheel bearing adjusting nut to 50 ft.

lbs. (60 N.

m) to seat bearings.

32466 Vanuum Shift Motors

Fig. 2: Selec-Trac Vacuum Control System

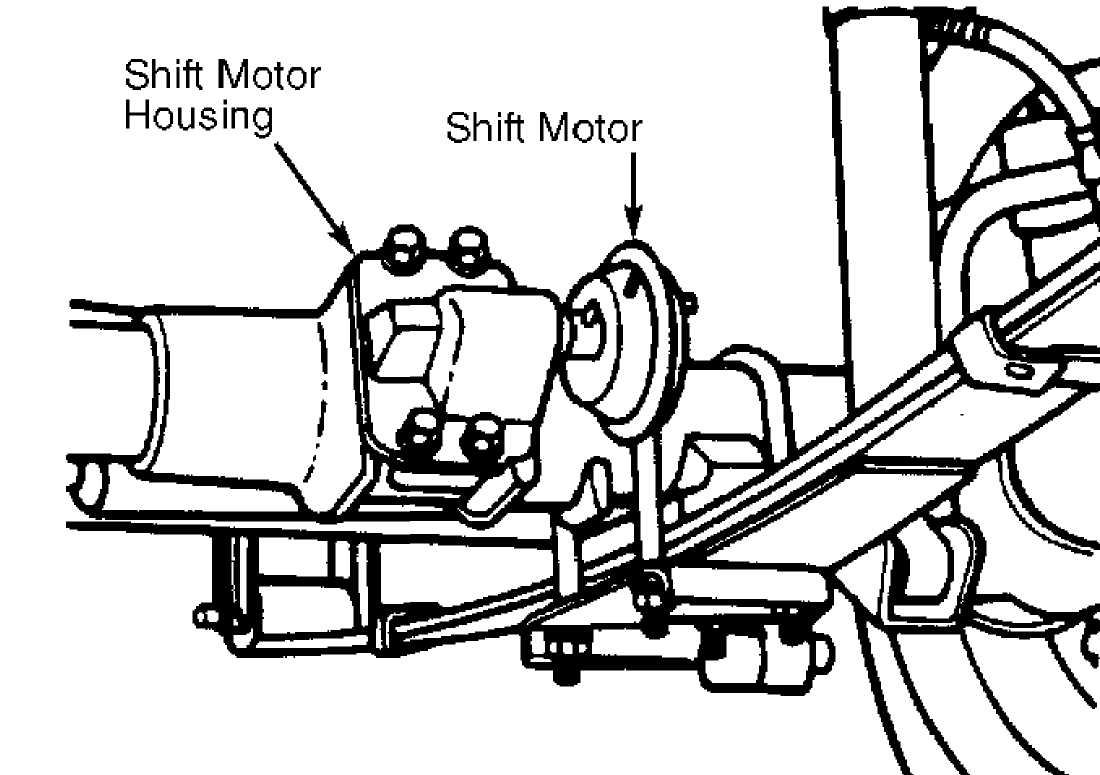

AXLE SHIFT MOTOR & HOUSING

Back

off nut and tighten to 35 ft. lbs. (47

N.m) while

rotating

hub. Finally, back off nut a maximum of 3/8 turn.

Assemble

lock ring (with tab in keyway)

over axle shaft, against bearing

adjustment

nut.

Adjustment

nut pin must pass through one of the washer

holes.

Tighten outer adjusting nut to 183 ft.

lbs. (248 N.m). Align

outer

clutch housing splines with splines of wheel hub.

Loosen

cover screws 3 or 4 turns,

and push in on cover to

allow retaining

ring to expand into rotor hub groove. Tighten cover

cap

screws to 40-50 INCH lbs. (4.5-5.6

N.m).

Removal

Raise

and support vehicle. Drain shift housing fluid.

Disconnect vacuum

harness. Remove housing bolts. Remove motor and

housing.

Mark shift fork and housing for reassembly. See Fig. 3.

Rotate

shift motor. Remove shift fork and motor snap

rings.

Remove shift motor from housing. Remove "O" ring

from motor.

Always use a new "O"

ring for reassembly.

Installation

Install new "O" ring on motor shaft. Install motor into

housing and slide shift fork onto shaft. Position motor and housing on axle. Add axle lubricant to shift motor housing. Install shift fork in shift collar and install housing bolts. Connect all vacuum harnesses to motor.

32464

Fig. 3: Shift Motor & Housing