DIFFERENTIAL - DANA TRAC-LOK & POWER-LOK

1988 Jeep Cherokee

1988 Positive Traction Differentials Trac-Lok

Jeep

- Dana Power-Lok &

DESCRIPTION

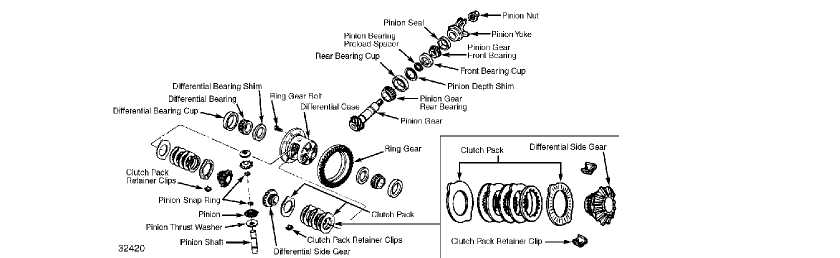

The limited slip differential uses 2 sets of multiple disc clutches to control differential action. Dana produces 2 types of positive traction differentials. The Power-Lok 4-pinion differential is a split-case type. The Trac-Loc 2-pinion differential is a single-case type.

OPERATION

When one or both wheels are on a low-traction surface such as snow, ice or mud, the friction between the clutch plates will transfer a portion of the usable torque to the wheel with the most traction. The wheel on ice or snow will have a tendency to operate with the opposite wheel in a combined driving effort.

AXLE RATIO & IDENTIFICATION

To determine axle ratio, see DRIVE AXLE RATIO IDENTIFICATION in this section.

LUBRICATION

NOTE: Always use special positive traction differential lubricant as specified by manufacturer.

DIAGNOSIS & TESTING

DANA 2-PINION TRAC-LOK

1) Drive vehicle to thoroughly warm up lubricant in rear axle. Place a piece of slick paper over a smooth formica board. Ensure formica board is on flat and level floor.

Fig. 1: Exploded View of Jeep Single-Case Dana Trac-Lok Differential

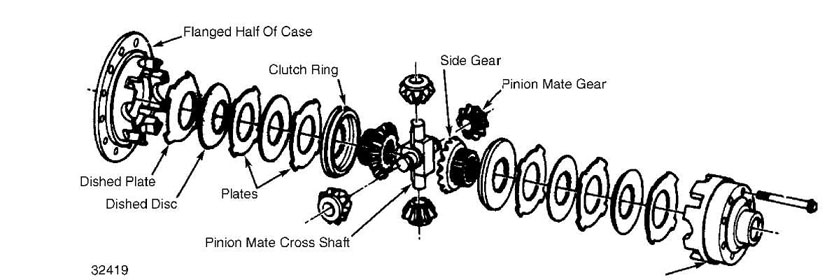

Fig. 2: Exploded View of Split Case (4-Pinion)

Bottom Half Of Case’

Drive vehicle over formica board until one rear wheel is

in the center of board and paper. Place a block of wood 2" high and a

minimum of 3" wide in front of one of the front wheels.

Open throttle gradually attempting to slowly drive vehicle

over block of wood. If paper slips out of position, reposition paper

and repeat test. If vehicle drives over block of wood, axle is

functioning properly.

DANA 4-PINION POWER-LOK

With engine off and transmission in "N", raise one wheel

off ground. Block both front and rear wheels of opposite side. Install

adapter tool across 2 wheel studs and attach torque wrench to center

of tool.

Observe torque required to continuously turn wheel

smoothly through several revolutions. Repeat test for opposite side.

If differential is okay, torque should be 40-200 ft. lbs. (54-272 N.

m). Disregard breakaway torque. Use rotating torque only.

NOTE: Exploded view of Chrysler Motors Trac-Lok differential was not available from manufacturer.

REMOVAL & INSTALLATION

See DANA SEMI-FLOATING or FULL-FLOATING AXLE article in this section.

OVERHAUL

DANA 2-PINION TRAC-LOK

NOTE: For front axle shaft and bearing removal, see articles on DANA FULL-FLOATING AXLES or 4WD STEERING KNUCKLES in this section. With the exception of ring gear and differential side bearings, Chrysler Motors does not recommend disassembly of differential. If repair is required, manufacturer recommends replacing entire unit as an assembly.

Disassembly (Jeep)

1) Using 2 screwdrivers, remove pinion snap rings. Using a brass drift and a hammer, remove pinion shaft from case. Install Step

Plate (J 23781-7) in bottom side gear. Install grease in centering hole of step plate. Position Rotating Tool (J 23781-3) on step plate tool. Coat threads of Forcing Screw (J 8646-2) with oil.

Insert forcing Screw (J 8646-2) through case and thread

into rotating tool. Thread screw through tool until it contacts

centering hole in step plate. Tighten forcing screw to relieve clutch

pack tension from pinions. Remove pinion thrust washers.

Tighten forcing screw until all clutch pack tension is

relieved from pinions. Slide rotating tool pawl so it engages with

side gear teeth. Rotate side gears with rotating tool until pinions

can be removed through case opening.

Remove forcing screw, rotating tool, upper side gear and

clutch pack. Remove differential case from axle shaft. Remove

remaining side gear, clutch pack and step plate tool. Remove retainer

clips from clutch packs. Mark clutch packs for reassembly reference.

Using a press, remove differential bearings.

Cleaning & Inspection

Clean all parts and dry with compressed air. If any clutch plates or discs require replacement, all plates and discs should be replaced. Replace any worn or damaged components.

NOTE: For adjustment procedures, see DANA SEMI-FLOATING or FULL FLOATING AXLE articles in this section

Reassembly

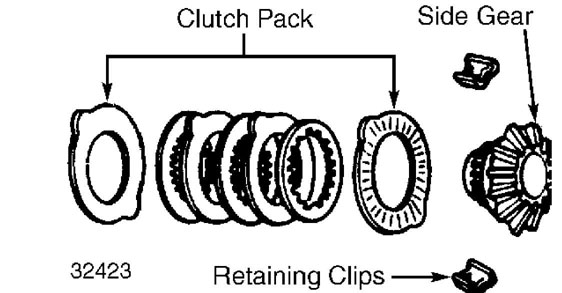

1) Lightly lubricate clutch pack discs with axle lubricant. Assemble clutch pack discs and install retaining clips on ears of discs. See Fig. 3. Install assembled clutch packs on side gears.

Fig. 3: Typical Clutch Pack Assembly

2) Mount differential case on axle shaft. Install first clutch pack and side gear in bottom bore of case. Ensure retaining clips remain seated in case pockets. Install Step Plate (J 8646-2) in

clutch pack just installed.

Install remaining side gear and clutch pack in case. Hold

assembly in position and install rotating tool and forcing screw.

Tighten forcing screw and compress clutch packs. Install pinions.

Rotate side gear with tool pawl until each pinion is aligned with

pinion shaft bore.

Install pinion thrust washers and pinion shaft. Install

pinion thrust washers and pinion shaft. Install snap rings on pinion

shaft. Remove differential from axle shaft. Remove shaft from vise.

Using Remover (J 22912-01), remove differential bearings. Install end

play shims on each side of case. Reinstall differential bearings.

Position ring gear on differential case. Install NEW ring

gear bolts and tighten to 52 ft. lbs. (70 N.m).

DANA 4-PINION POWER-LOK

NOTE: Differential bearings do not need to be removed to overhaul.

Disassembly

Mark case halves, pinion mate shafts and ramps for

reassembly reference. Clamp differential assembly in soft-jawed vise

and loosen case half bolts (DO NOT remove bolts). Position

differential assembly on bench with ring half of case down. Remove

case attaching bolts. Remove cover half of case.

Remove pinion mate gear, side gear ring and clutch pack.

Keep parts together for reassembly reference. Remove parts from drive

gear half of case.

Cleaning & Inspection

Clean all parts and dry with compressed air. If any clutch plates or discs require replacement, it is recommended that all plates and discs be replaced. Replace any part that is worn or damaged.

Reassembly

NOTE: For adjustment procedures, see DANA SEMI-FLOATING or FULL FLOATING AXLE articles in this section.

Position side gear ring from drive gear half of case on a

pinion flange. Coat clutch plates with Hypoid Gear Lubricant (C6A-Z-

19580-E). Reassemble parts in correct order. See Fig. 1. Install ring

gear half of case over clutch pack and side gear ring. Ensure clutch

plate lugs enter slots in case and case bottoms on clutch pack.

Hold assembly together and turn case half upside down.

Install gear in side gear ring. Install mate shaft and pinions on side

gear ring. Align mate shaft and case markings. Install cover half mate

shaft and pinions. Align markings.

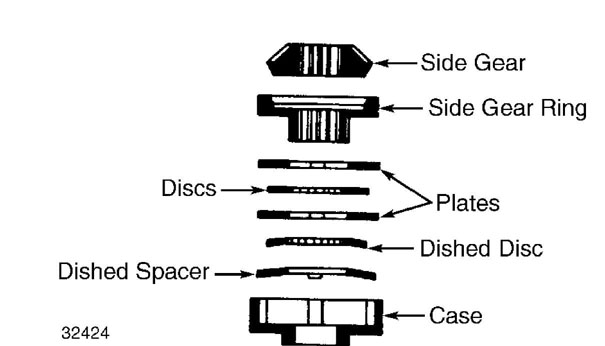

Install side gear on pinions. Position side gear ring on

side gear and pinions. Assemble clutch pack on side gear. See Fig. 4.

Align clutch plate lugs and install all parts in case. Position cover

half of case over assembly. Align case marks made during disassembly.

Lubricate bolt threads with axle lube and install case

bolts. Using both axle shafts, align splines of side gear and side

gear ring. Tighten case bolts to 65-70 ft. lbs. (89-94 N.m).

Remove axle shafts. If properly assembled, each pinion

mate cross shaft should be tight on its ramp. If clearance is present,

it should not exceed .010" (.254 mm).

Fig. 4: Power-Lok Differential Clutch Pack Assembly Courtesy of Ford Motor Co.