TUNE-UP - 4-CYL

1988 Jeep Cherokee

1988 Jeep 4 Tune-Up TUNE-UP

All Models

IDENTIFICATION

ENGINE IDENTIFICATION

Engine can be identified by the 4th character of the Vehicle Identification Number (VIN). The VIN is stamped on a plate attached to top left corner of instrument panel.

ENGINE CODES

Engine Code

2.5L (150") TBI H

TUNE-UP NOTES

NOTE: When performing tune-up procedures described in this article, the following notes and precautions must be followed.

Due to late changes and corrections, always refer to Emission Control Label in engine compartment before attempting tune-up. If manual and label differ, always use label specifications.

EPA High Altitude emission standards apply to vehicles sold in certain areas outside California which have an elevation above 4000 feet.

When performing tune-up on vehicles equipped with catalytic converter, do not allow or create an engine misfire in one or more cylinders for an extended period of time. Damage to converter may occur due to loading converter with unburned fuel.

TESTING

ENGINE COMPRESSION

Test compression with all spark plugs removed, throttle plates and choke valve wide open and engine at normal operating temperature. Crank engine through at least 5 compression strokes before recording reading.

COMPRESSION SPECIFICATIONS

Application Specification

Compression Ratio 9.2:1

Compression Pressure 155-185 psi (10.9-13.0 kg/cm)

Max. Variation Between Cylinders 30 psi (2.1 kg/cm)

SPARK PLUGS

SPARK PLUG TYPE

Application

Champion No.

2

. 5L RC-12LYC

SPARK PLUG SPECIFICATIONS

Application Gap: In. (mm) Torque: Ft. Lbs. (N.m)

2.5L 035 (.89) 7-15 (9-20)

HIGH TENSION WIRE RESISTANCE

Do not puncture spark plug wires with any type of probe. Remove spark plug wire and check resistance with an ohmmeter.

ADJUSTMENTS

VALVE ARRANGEMENT

* E-I-I-E-E-I-I-E (Front-to-rear). VALVE CLEARANCE

All models are equipped with hydraulic lifters, which should be adjusted to zero lash.

IGNITION COIL WIRE

Remove ignition coil wire from coil and distributor cap. Check terminals for corrosion and clean if necessary. Check coil wire resistance. Replace wire if resistance is excessive.

HIGH TENSION WIRE RESISTANCE (OHMS)

Wire Length (In.) Minimum Maximum

0-15 3000 10,000

15-25 4000 15,000

25-35 6000 20,000

Over 35 8000 25,000

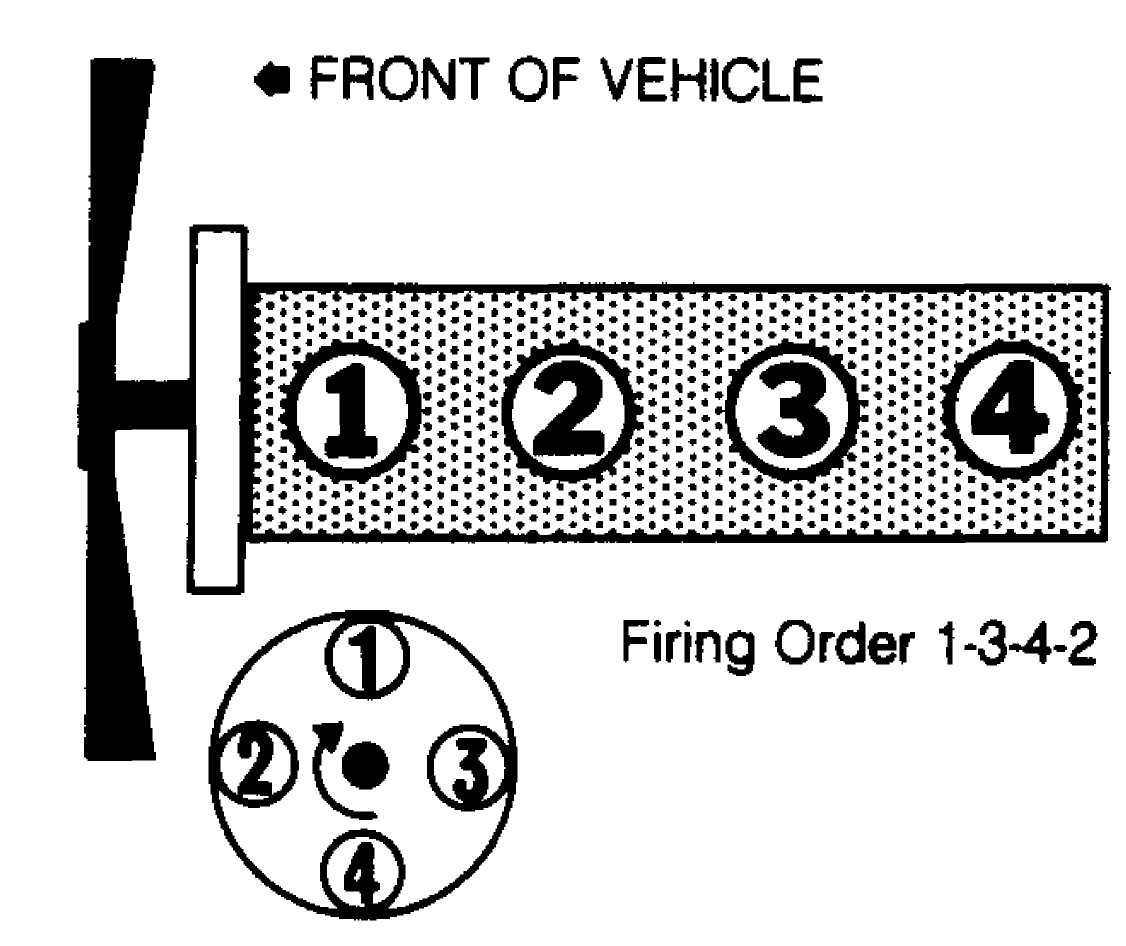

DISTRIBUTOR

All models are equipped with a Renix solid state ignition module. Renix system uses a TDC sensor mounted near the flywheel. The distributor consists of a cap and rotor. Its only function is to distribute high voltage to appropriate spark plug. No adjustments are required on either system.

9087

9087

Fig. 1: 2 . 5L Firing Order & Distributor Rotation

IGNITION TIMING

NOTE: No adjustment is possible on models with Renix ignition.

HOT (SLOW) IDLE RPM

NOTE: Adjust ISC motor plunger only after replacing ISC motor.

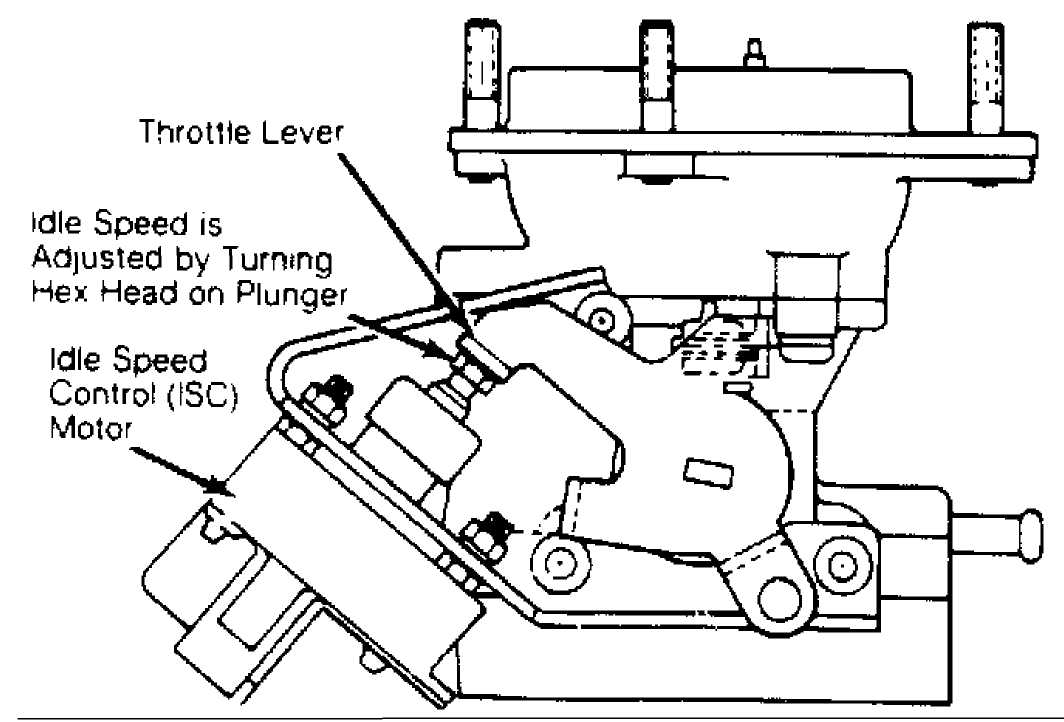

Idle Speed Control (ISC) Motor Plunger

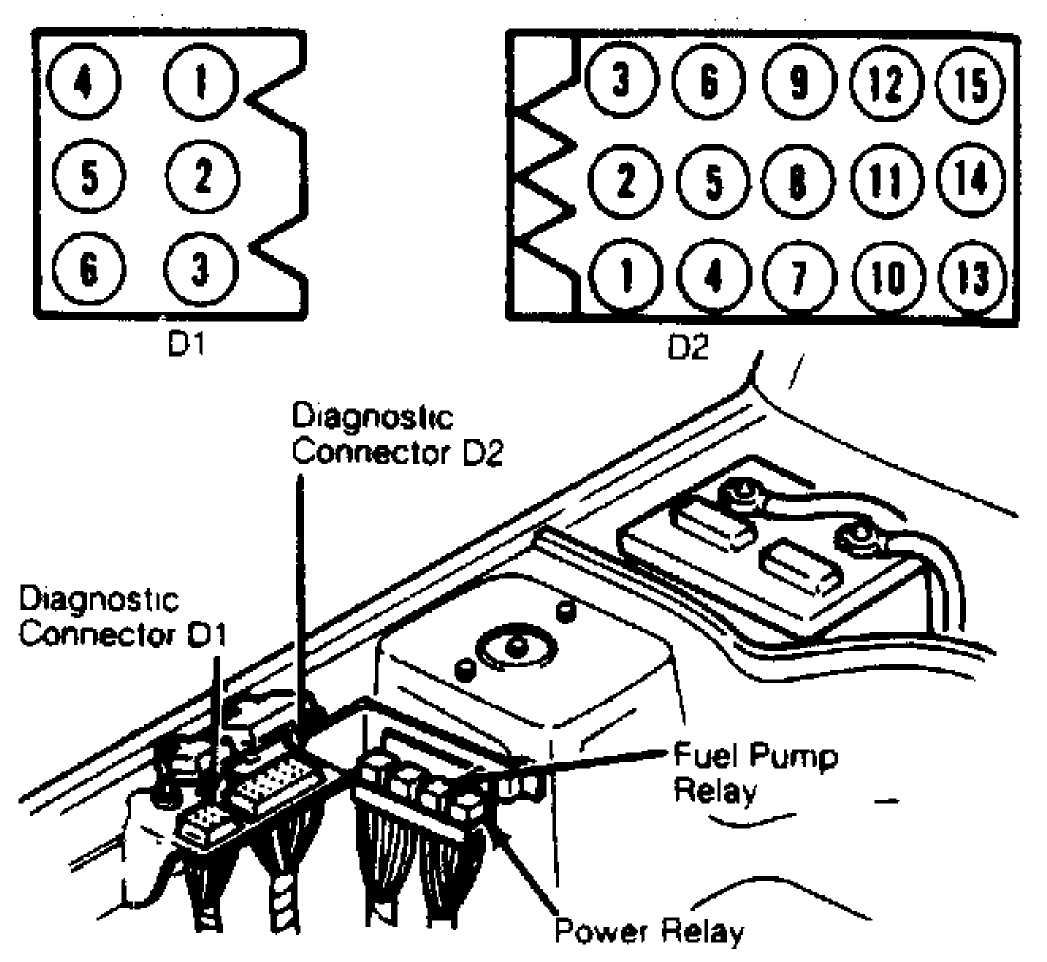

1) Remove air cleaner, turn off A/C (if equipped) and warm engine to normal operating temperature. Connect tachometer negative lead to diagnostic connector terminal "D1-3" and positive lead to connector terminal "D1-1". See Fig. 2. Turn ignition off. ISC plunger should fully extend.

Fig. 2: TBI Diagnostic Connector & Terminal ID Courtesy of Chrysler Motors.

With

plunger extended, disconnect ISC motor electrical

connector.

Start engine. Engine idle speed should be 3300-3700 RPM.

If

not, turn plunger hex head to obtain

3500 RPM. See Fig. 3.

To fully

retract ISC motor, hold closed throttle switch

plunger inward

while opening throttle. Closed throttle switch plunger

should not

touch throttle lever when throttle is closed. If this

occurs,

check linkage and/or cable for binding.

Fig. 3: TBI Idle Speed Control (ISC) Motor Adjustment Courtesy of Chrysler Motors.

4) Connect ISC motor connector. Turn ignition off for 10 seconds. ISC motor should fully extend. Restart engine. Engine speed should momentarily be about 3500 RPM and return to idle speed. Turn ignition off and disconnect tachometer. Apply sealant to adjustment screw threads. Install air cleaner.

IDLE SPEED (RPM)

Application

2.5L TBI (ISC Plunger Extended)

Curb Idle

3500

NOTE: Holding plunger inward may create an intermittent trouble code in ECU memory. To clear ECU memory, turn ignition off and disconnect negative battery cable for 10 seconds.

THROTTLE POSITION SENSOR (TPS) ADJUSTMENT

NOTE: On some models, it may be necessary to remove throttle body from intake manifold, to access sensor wiring harness.

Automatic Transmission

Locate

the square TPS connector. Note connector terminal

identification

stamped on the back of the connector. Turn ignition on.

Connect voltmeter through back of wiring harness

connector. Connect negative voltmeter lead to terminal "D" and positive voltmeter lead to terminal "A" to check input voltage. DO NOT disconnect TPS connector.

Hold

throttle plate closed against idle stop and note

voltage. Input

voltage should be approximately 5 volts.

Disconnect

voltmeter positive lead and

connect to terminal "B" to measure output

voltage.

With

throttle plate closed, measure the output voltage.

The output

voltage should be approximately .2 volts.

If output voltage

is not within specification, loosen TPS

retaining screws.

Partially

tighten one retaining screw. Rotate TPS to

obtain correct output

voltage. Tighten retaining screws once correct

voltage is

obtained.

Manual Transmission

Turn

ignition on. Connect voltmeter through back of wiring

harness

connector. Connect negative voltmeter lead to terminal "B"

and

positive voltmeter lead to terminal

"C". DO NOT disconnect TPS

connector.

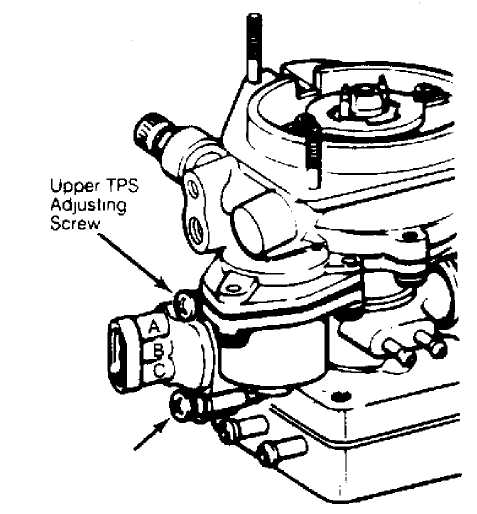

See Fig. 4.

Rotate

and hold throttle plate in wide open position.

Ensure throttle

linkage contacts stop. Note voltmeter reading. Voltage

reading

should be 5 volts at wide open throttle.

Return throttle plate

to closed

throttle position. Disconnect voltmeter positive lead from

sensor

terminal "C" and connect it to terminal "A".

Rotate

and hold throttle plate in wide open position.

Ensure throttle

linkage contacts stop. Note voltmeter reading. Output

voltage

should be 4.6-4.7 volts. If voltage is not

as specified,

loosen sensor mounting

screw. Loosen upper sensor mounting screw for

small

adjustments and lower screw for large adjustments.

Adjust

sensor. Tighten sensor mounting screws. Remove

voltmeter and

return throttle plate to closed position. Replace sensor

if

specified output voltage cannot be obtained.

Lower

TPS

Lower

TPS

Adjusting

Screw

Fig. 4: Adjusting Throttle Position Sensor (Man Trans) Courtesy of Chrysler Motors.

IDLE MIXTURE ADJUSTMENT

NOTE: Idle mixture adjustment is not possible on TBI models. COLD (FAST) IDLE RPM

NOTE: Fast idle is not adjustable on TBI models.

SERVICING

EMISSION CONTROL

See EMISSIONS section.

SPECIFICATIONS

IGNITION

Distributor

All models are equipped with Renix solid state ignition.

IGNITION COIL RESISTANCE - OHMS @ 75F (24C)

Application Primary Secondary

2.5L 4-.8 2500-4000

FUEL SYSTEM

FUEL INJECTION

Application Model

2. 5L Renix TBI

Fuel Pump

The 2.5L engine with TBI uses an electric fuel pump located in the tank.

FUEL PUMP SPECIFICATIONS

Application Pressure:

psi (kg/cm) Volume: Pts. (L)

Application Pressure:

psi (kg/cm) Volume: Pts. (L)

2.5L (TBI) 14.5 (1.0) N/A

BATTERY

BATTERY SPECIFICATIONS

Application Cold Cranking Reserve Capacity

** (1) Amps Minutes

Standard 421 75

Optional 452 81

(1) - At 0F (-18C).

STARTER

All 2 . 5L engines use a Bosch positive engagement starter. STARTER SPECIFICATIONS

Application

Volts Amps Test RPM

2.5L

12 75 2900

ALTERNATOR

All 2.5L engines use a Delco-Remy 10SI or 12SI alternator with integral regulator.

ALTERNATOR SPECIFICATIONS

Application Field Current Rated Amp

** Draw @ 12 Volts Output

Standard 4.0-5.0 Amps 56

Optional 4.0-5.0 Amps 66

Optional 4.0-5.0 Amps 78

ALTERNATOR REGULATOR

All 2.5L models use Delco-Remy nonadjustable regulators, integral with alternator.

REGULATOR OPERATING VOLTAGE @ 80F (27C)

Application Voltage

2.5L 13.9-14.9

BELT ADJUSTMENT

BELT ADJUSTMENT -

TENSION IN LBS. (KG) USING STRAND TENSION

GAUGE

Application New

Belt Used Belt

"V" Belts (1) 125-155 (57-70) 90-115 (41-52)

Serpentine 180-200 (82-91) 140-150 (64-68)

(1) - Adjust new P/S belt to 120-140 lbs. (54-64 kg).

SERVICE INTERVALS

REPLACEMENT INTERVALS

Component Interval (Miles)

Air Filter 30,000

Fuel Filter 30,000

Engine Oil & Filter 7500

PCV Valve 30,000

Spark Plugs 30,000

CAPACITIES

FLUID CAPACITIES

Application

Quantity

Auto. Trans. (Dexron II)

Wrangler 8.0 qts . (7 . 6L)

All Others 8.5 qts. (8.0L)

Cooling System

Wrangler 9.0 qts . (8 . 5L)

All Others 10.0 qts. (9.5L)

Crankcase (Includes Filter) 4.0 qts. (3.8L)

Drive Axle

Front 2.5 pts. (1.2L)

Rear

Commanche

Standard Capacity 2 . 5 pts. (1.2L)

Metric Ton Axle 4.8 pts . (2 . 3L)

All Others 2.5 pts. (1. 2L)

Fuel Tank

Cherokee & Wagoneer

Standard 13.5 gals. (51L)

Optional 20 gals. (76L)

Comanche

Standard 16 gals. (60L)

Optional 23.5 gals. (89L)

Wrangler

Standard 15 gals. (57L)

Optional 20 gals. (75L)

Manual Transmission

AX4 7.8 pts. (3.7L)

AX5 7.4 pts. (3.5L)

BA 10/5 3.5 pts. (1.6L)

Transfer Case (Dexron II)

Wrangler 3.2 5 pts. (1. 5L)

All Others

Command Trac 2.2 pts . (1. 0L)

Select Trac 3.0 pts. (1.4L)

SYSTEM REFRIGERANT CAPACITIES

Application Ozs.

All Models 36