STEERING KNUCKLES - 4WD

1988 Jeep Cherokee

1988 4WD Steering Knuckles ALL MANUFACTURERS

DESCRIPTION

Open type steering knuckles are used on all models. Open type knuckles provide sharper turning angle, which will decrease vehicle turning radius. Axle shafts are free floating. Depending upon vehicle model, steering knuckles can be attached to axle housing by either ball joints or roller bearings and king (pivot) pins.

OVERHAUL

BALL JOINT TYPE

Disassembly

Raise

vehicle and support securely. Remove wheels. Remove

brake caliper

and rotor. If equipped, remove locking hubs. See

appropriate

LOCKING HUBS article in DRIVE AXLE section.

Disconnect

tie rod end from steering knuckle. Remove

spindle nuts and

lightly tap spindle with soft face hammer to free it

from

steering knuckle. Pull out axle shaft assembly.

Clean all

components with solvent and dry with compressed

air. Inspect all

parts for burrs, chips, wear, flat spots or cracks.

Replace all

damaged or worn parts.

NOTE: When aligning upper ball joint nut to install cotter pin,

always tighten nut to align. Never loosen nut to align holes.

Reassembly

To reassemble, reverse disassembly procedure. Torque all fittings to specifications.

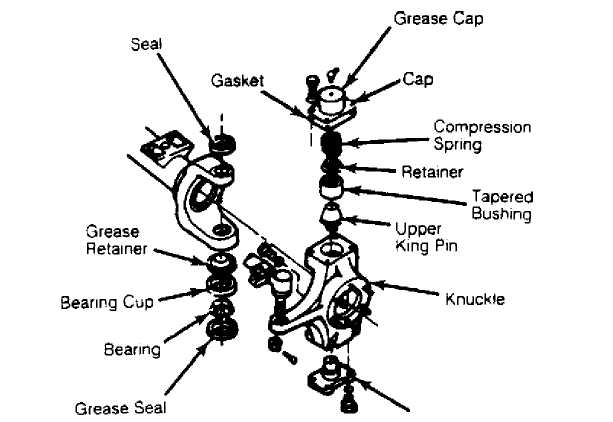

Lower King Pin & Retainer

Fig.

1: Exploded View of Steering Knuckle

Assembly

Fig.

1: Exploded View of Steering Knuckle

Assembly

ADJUSTMENT

NOTE: All other models are not adjustable. BALL JOINTS

Jeep, Truck & Wagoneer

1) Raise vehicle and remove front wheels. Disconnect

steering damper and connecting rod. Remove cotter pin from right side tie rod retaining nut. Rotate steering knuckles through complete arc several times.

Place

torque wrench on right side tie rod retaining nut.

Torque to turn

knuckles through complete arc should not be more than

25

ft. lbs. (34 N.m).

If

turning effort is excessive, disconnect tie rod ends

at

knuckles. Measure turning effort of right and left side

knuckles.

Individual turning effort

should not be more than 10 ft. lbs.

(14

N.m) .

If

individual turning effort is more than specified,

replace upper

ball joint split ring seat. If turning effort is more

than

10 ft. lbs. (14 N.m)

after split ring seat replacement, ball

joints

will have to be replaced.

TURNING ANGLE

Truck & Wagoneer

Turning

angle stop screws are located at rear of steering

knuckle, just

above axle centerline. To adjust, loosen lock nut on

turning

angle stop screw. Jeep turning angle is not adjustable.

Using

turntable to measure angle, adjust stop screw to

obtain specified

angle. Tighten lock nut without changing setting.

TURN ANGLE ADJUSTMENT

TURNING ANGLE ADJUSTMENT TABLE

Application Left Right

Application Left Right

Wheel Wheel

Jeep

Cherokee, Comanche,

& Wrangler (1) 32-33 (1) 32-33

Wagoneer 36-37 36-37

(1) - Angle stops are not adjustable. Parts must be replaced if angle is incorrect.

TORQUE

SPECIFICATIONS

TORQUE

SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft.

Lbs.(N.m)

Application Ft.

Lbs.(N.m)

Ball Joint Type

Lower Ball Joint Nut

Jeep 100 (136)

Upper Ball Joint Nut

Jeep 100 (136)

Upper Ball Joint Split Retaining Seat

Jeep 50 (68)

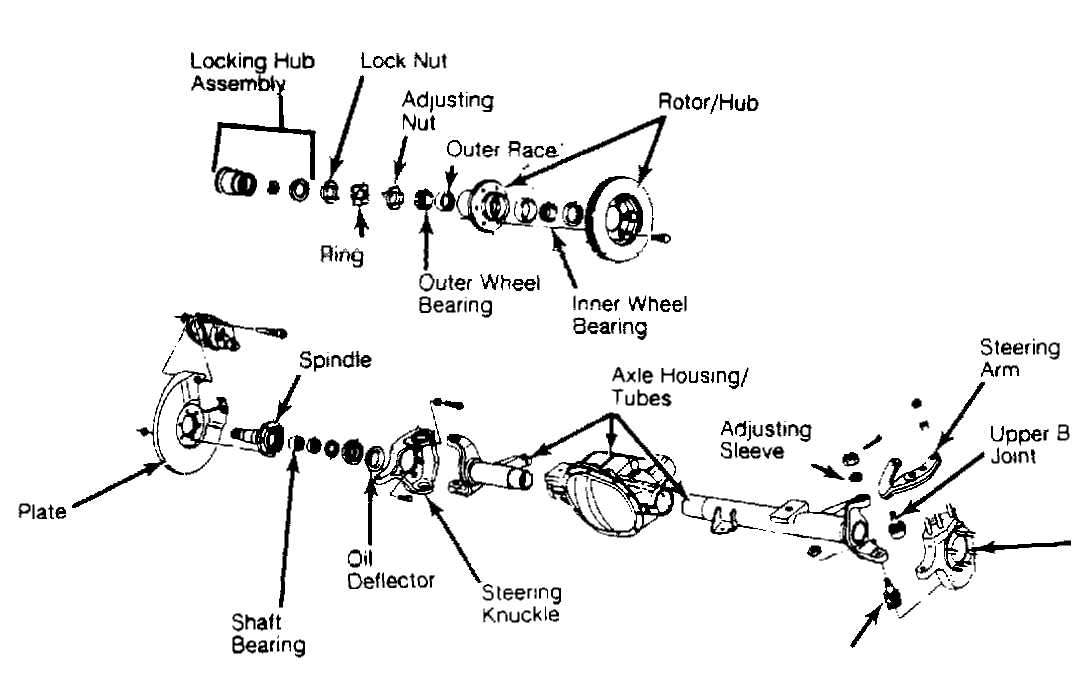

Fig.

2: Exploded View of Ball Joint Type

Steering Knuckle Assembly

Fig.

2: Exploded View of Ball Joint Type

Steering Knuckle Assembly

Lower Bali Joint