UNIVERSAL JOINTS

1988 Jeep Cherokee

1988 Drive Shafts - Universal Joints All Manufacturers

MAINTENANCE

Whenever drive shaft is removed from vehicle of if slip yoke sticks in extension housing seal, clean yoke with solvent. Lubricate inside diameter of seal with synthetic oil seal lubricant, and outside diameter of seal with transmission fluid.

OVERHAUL

NOTE: Universal joints should not be disassembled unless external leakage or damage has occurred.

Before disassembly, scribe alignment marks on yoke and shaft to allow reassembly in original position. If joints are rusted or corroded, apply penetrating oil before pressing out bearing cups or trunnion pin.

CROSS SHAFT & ROLLER TYPE UNIVERSAL JOINTS

There are 2 different retaining methods used for bearing cups, either snap rings or nylon retainers. Joints with snap rings may be taken apart and reassembled, using same cross shaft and bearings. Joints with nylon retainers are disassembled by breaking nylon retainers. Retainers must be replaced after service.

Removal & Disassembly

1) Disconnect yoke or flange attaching bolts and remove drive shaft from vehicle.

NOTE: DO NOT use a pry bar to hold drive shaft while loosening bolts. Damage to bearing seals may result.

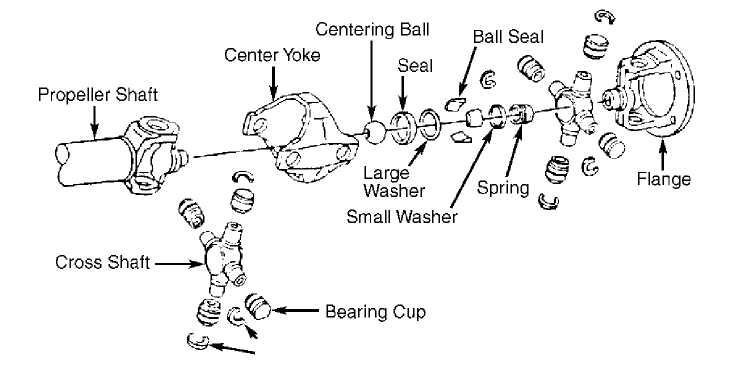

Fig.

Fig.

31767 ^Snap Rings

1: Exploded View of Jeep Constant Velocity Type Universal Joint

2) Remove retaining strap (if equipped). Remove bushing retainers from yoke. Press out rollers and bearings. Remove last roller and bushing assembly by pressing on end of cross shaft.

3) Remove cross shaft assembly from yoke. DO NOT remove seal retainers from cross shaft. Cross shaft and retainers are serviced as an assembly.

Reassembly

Coat

roller and bearing assemblies with lubricant, and

fill reservoirs

in ends of cross. Place cross assembly in drive shaft

yoke, and

place roller and bushing assemblies into position.

Press

both bushing assemblies into yoke until retainers

can

be installed, being careful to keep cross aligned in center

of

bushings. Install retainers, then

repeat procedure for remaining

bushings.

CONSTANT VELOCITY (CV) TYPE

NOTE: To prevent damage to constant velocity joints, center ball

when removing drive shaft assembly. When handling drive shaft after removal, support shafts on both sides of constant velocity joint if drive shaft is being moved horizontally. DO NOT allow one end to hang free or one shaft to bend at sharp angle. After removal, shaft may be carried vertically without damage.

Removal & Disassembly (Jeep)

Disconnect

yoke attaching bolts and flange attaching

bolts,

and remove drive shaft from vehicle. Mark joint so that center

yoke,

end yoke, and cross shafts will be installed in original

positions.

Pry out

all snap rings and press bearing out enough to

allow bearing end

to be clamped in vise. Tap on yoke until it is free

of bearing.

Repeat

procedure for remaining bearings. Remove remaining

parts from

center yoke assembly.

Reassembly

Pack all

bearings with specified grease. Assemble center

yoke components

in reverse order of disassembly.

Using

arbor press or vise, press 2 opposing

bearings into

osition at same time

until all bearings are installed. Be sure cross

shafts

and yokes remain aligned during this process.

Check

for free movement of joint. If bind exists, seat

bearings

by sharply rapping yokes with brass hammer. Never hammer

on

bearings.

Install

drive shaft in vehicle, making sure marks made

during disassembly

are aligned.

Installation (All Models)

NOTE: The drive shaft assembly, with cross and bearings installed, must have its yoke ears at each end of the shaft on same plane.

Before

installing drive shaft, clean yoke and inspect

machined surface

for scratches, nicks or burrs.

Provide

support for drive shaft during installation to

prevent damage to

universal joints. Position front end of shaft and

aligning marks

noted during removal.

Install

and attach 2 clamps to pinion yoke.

Install 4

screws and lock washer

assemblies on CV joint at transfer case. Use

press

bar to prevent assembly from rotating while attaching

screw

assemblies.