STEERING GEAR - POWER

1988 Jeep Cherokee

1987-88 STEERING

Jeep Power Steering Gears - Saginaw Rotary Valve

Cherokee, Comanche, Grand Wagoneer, Pickup, Wagoneer, Wrangler

DESCRIPTION

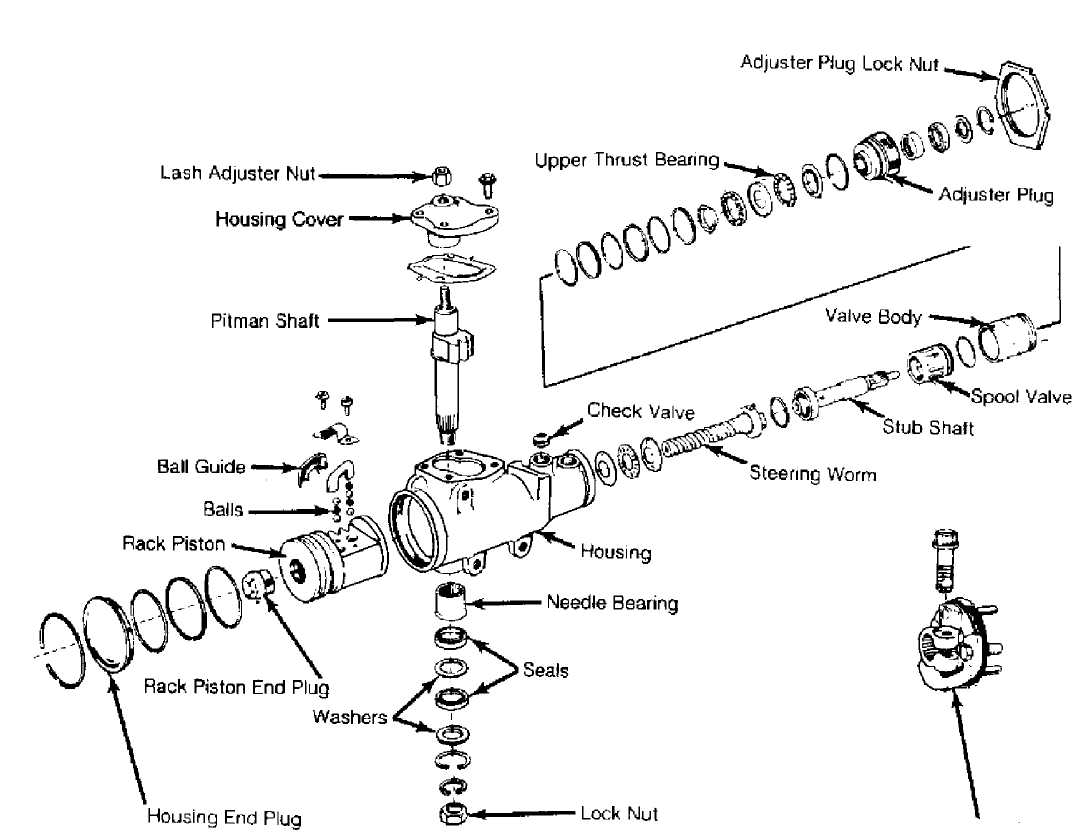

Steering gear is a recirculating ball-type, available in either a constant or a variable ratio design. Steel balls form a "rolling thread" between steering gear worm shaft and rack/piston nut. Worm shaft thrust is absorbed by a thrust bearing and two races at lower end, and by a bearing in adjuster plug at upper end.

This design puts spring pressure on worm shaft to ensure proper thrust bearing preload. Adjuster plug provides initial preload adjustment and service adjustment (when repairing gear). As worm shaft is turned right, rack/piston is moved upward in gear.

As worm shaft is turned left, rack/piston is moved downward in gear. The rack/piston teeth mesh with sector, which is forged as part of sector shaft. Rotating worm shaft moves sector shaft, which turns wheels through mechanical linkage. See Fig. 1.

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

LUBRICATION

See POWER STEERING GENERAL SERVICING article.

TESTING

See POWER STEERING GENERAL SERVICING article.

Steering Shaft

30538

Fig. 1: Exploded View of Saginaw Rotary Valve Power Steering Gear

ADJUSTMENTS

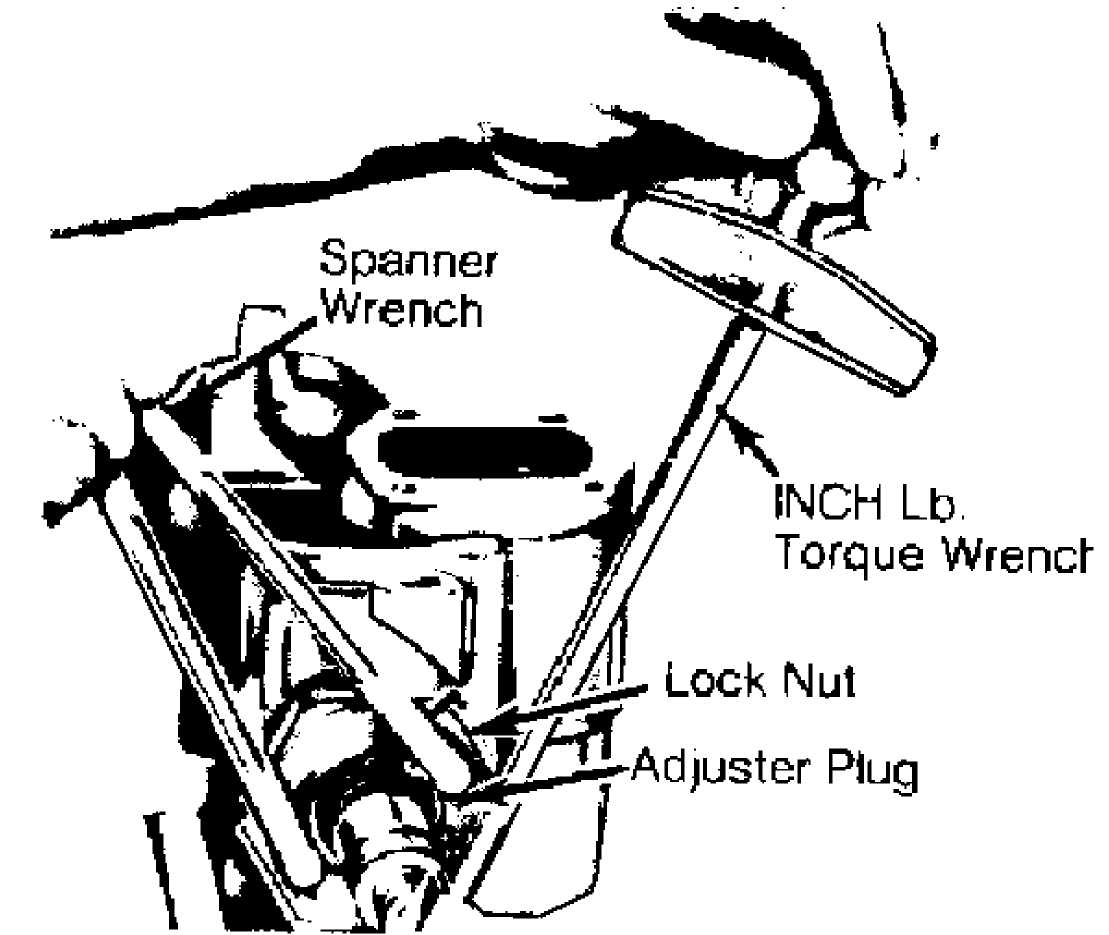

THRUST BEARING PRELOAD ADJUSTMENT

Remove

steering gear from vehicle. Remove adjuster plug

lock nut. Turn

adjuster plug clockwise with a spanner wrench until

plug

is seated in housing. This will require 20-30 ft.

lbs. (27-41 N.

m) of torque.

Place

an index mark on housing opposite one spanner wrench

hole in

adjuster plug. Measure 1/2" (13 mm)

counterclockwise from mark

and again

mark housing. Rotate plug counterclockwise until hole in

adjuster

lines up with second mark.

Tighten

lock nut. Ensure adjuster remains in position.

Attach an INCH

lb. torque wrench to end of input shaft. Turn input

shaft to

right stop, then back 1/4 turn.

Using

torque wrench measure rotational torque required to

turn

shaft. Reading should be taken with beam of torque wrench

near

vertical while turning it counterclockwise at an even rate.

Torque

reading should be 4-10 INCH

lbs. (.4-1.1 N.m). See. Fig. 2.

NOTE: If reading does not fall within this range, adjuster plug

may have turned while lock nut was being tightened. Steering gear may be incorrectly assembled or worm shaft thrust bearings and races may be defective. Repair as required and readjust preload.

30539

Fig. 2: Measuring Thrust Bearing Preload

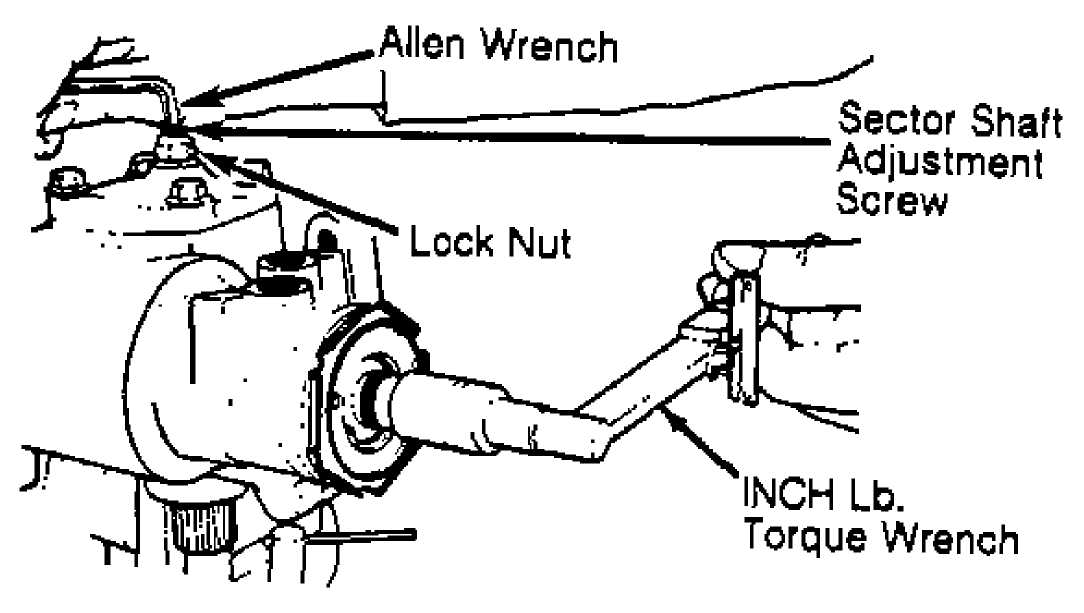

OVER-CENTER PRELOAD TORQUE ADJUSTMENT

Loosen

adjuster screw lock nut. Back off adjuster screw

until

stopped, then turn in 1 full turn. Rotate

input shaft from stop

to stop counting

number of turns. Turn shaft half way back to center

position.

Attach an INCH lb. torque wrench to input shaft. Turn

shaft from side to side through specified arc on each side of center. See OVER-CENTER PRELOAD chart. Note torque reading going over center. Adjust thrust bearing preload before over-center preload. See Fig. 3.

OVER-CENTER PRELOAD SPECIFICATIONS - INCH LBS. (N.m)

Application

Application

New Gears .. . Used Gears (2)

Arc

45. 45.

Over-Center

4-8 (.4-.9) 4-5 (.5-.6)

(1) Total

14 (1.5) 14 (1.5)

- Total preload is sum of thrust bearing and over-center preload.

- In service for more than 400 miles (640 km.).

30540

Fig. 3: Adjusting Over-Center Preload

REMOVAL & INSTALLATION

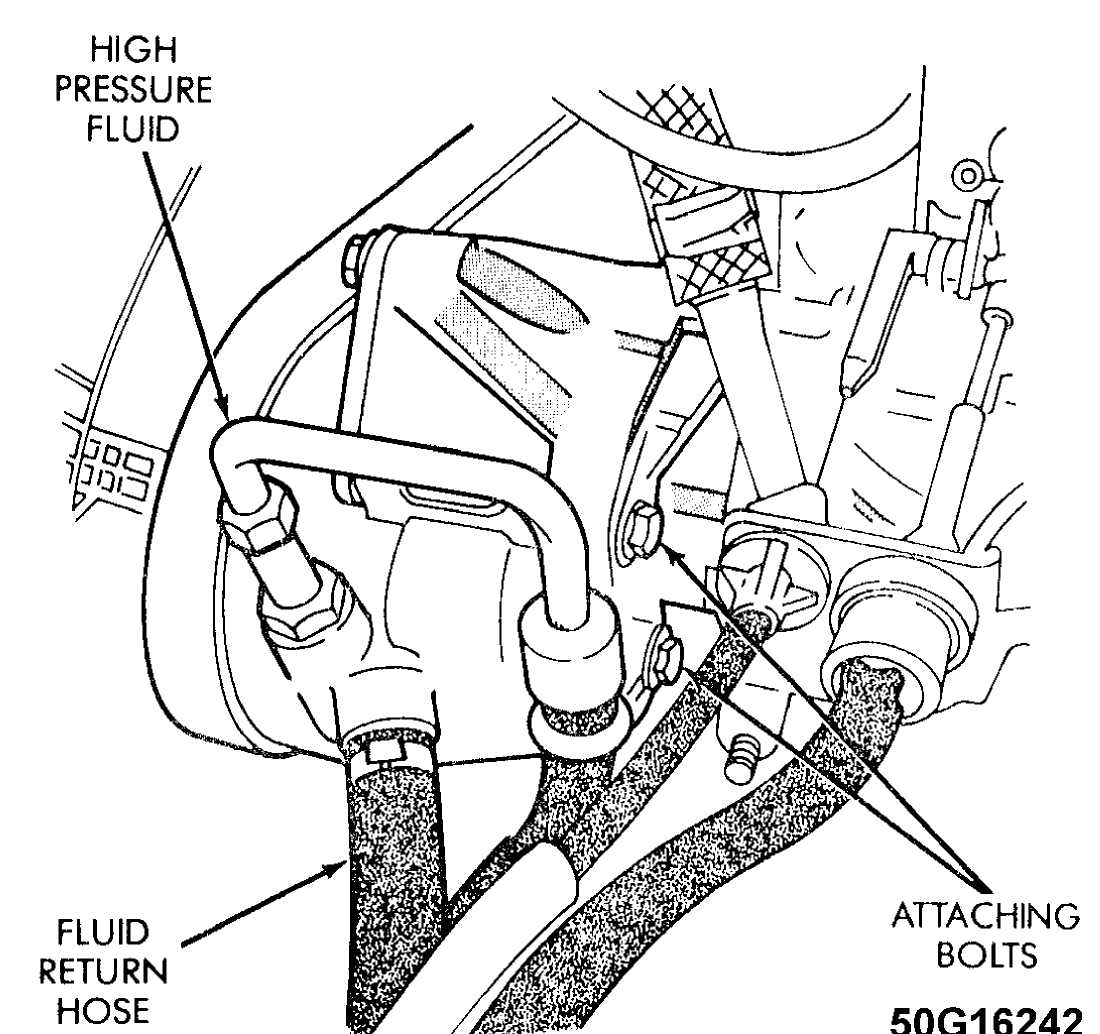

POWER STEERING PUMP

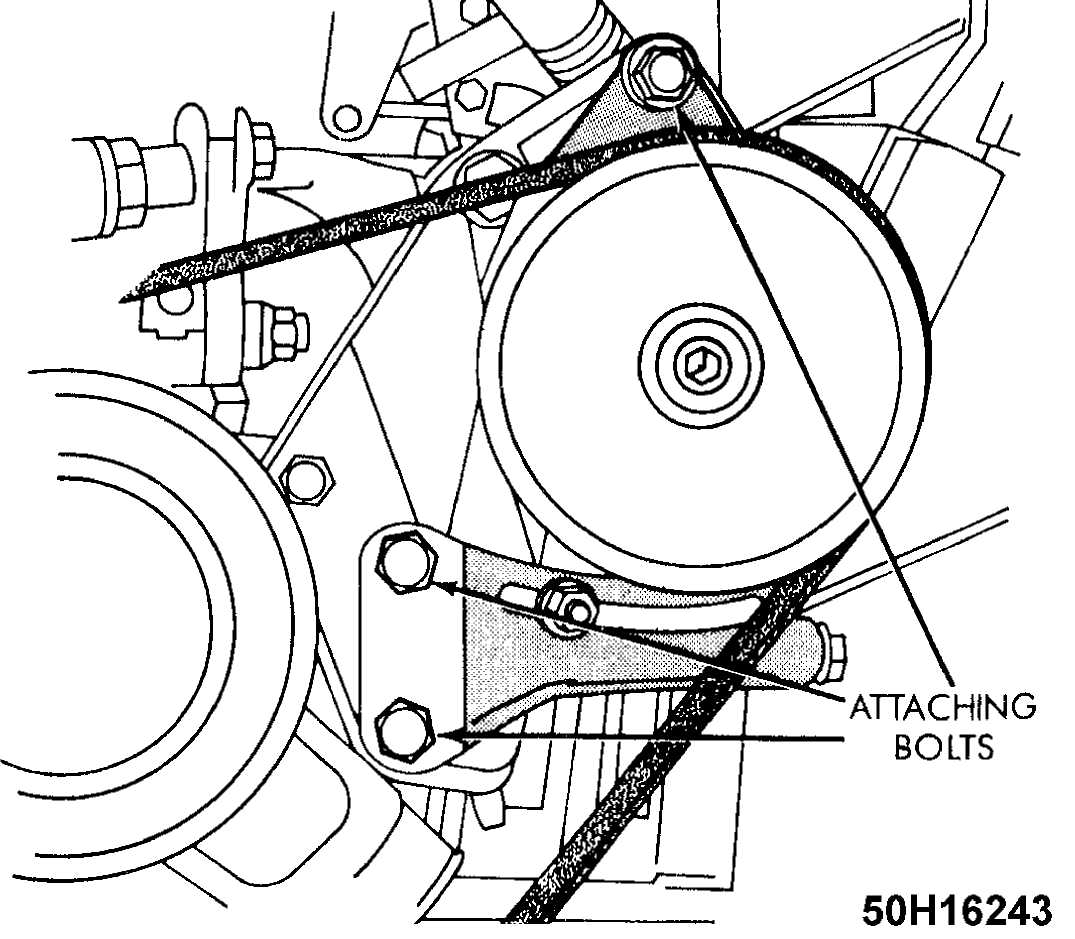

Removal & Installation

Loosen

and remove pump drive belt. Disconnect pressure and

return

hoses from pump. Cap ends to prevent loss of fluid

or

contamination.

Remove

bracket-to-engine bolts. Remove pump and mounting

bracket as an

assembly. To install, reverse removal procedure. Fill

and bleed

system.

Fig. 4: Power Steering Pump (Cherokee & Commanche)

Fig. 5: Front Bracket Boltsp (Cherokee & Commanche)

STEERING GEAR

Removal

Remove

collapsible steering column. Raise and support

vehicle. Place

drain pan under steering gear assembly. Center steering

gear.

Disconnect hydraulic hoses from gear and cap ends.

Disconnect

steering linkage from pitman arm. Remove pitman arm

from gear.

Remove

flexible coupling clamp bolt and bolts retaining

steering gear to

frame. Disconnect gear from flexible coupling and

remove gear

from vehicle. On Jeep CJ7 and Scrambler models, remove

steering

gear and mounting bracket as an assembly.

Installation

To install, reverse removal procedure. Fill pump reservoir. Bleed air from system. See POWER STEERING GENERAL SERVICING article.

OVERHAUL

SUBMERGED VANE POWER STEERING PUMP

Disassembly

1) Drain pump reservoir. Clean exterior of unit. Measure distance shaft protrudes from pulley, and record for assembly reference. Using pulley remover, remove pulley from shaft. Clamp pump in vise; DO NOT overtighten vise. Remove pressure line union, reservoir mounting stud and reservoir. See Fig. 6. Remove and discard pressure line union "O" rings.

"O"

Ring

"O"

Ring

Cap/Dtpstick

Reservoir

End Plate

Pressure Plate Spring

Pressure Pfate

Pump Ring

8 Retaining Ring 9. Vane

Rotor

Thrust Plate

Dowel Pin

Drive Shaft

"O"

Ring

15- "Î" Ring

"O" Ring

Plug

Plug

Housing

20 Drive Shaft Seal

Bushing

Plug

23. "O" Ring 24 "O" Ring

Dowel Pin

Flow Conirol Valve

Spfing

"O" Ring

End Plate Retaining Ring

Reservoir Mounting Stud

Pressure Line Union

Fig.

6: Exploded

View of Pump Assembly (Grand Wagoneer &

Wrangler) Courtesy

of Chrysler Motors

Fig.

6: Exploded

View of Pump Assembly (Grand Wagoneer &

Wrangler) Courtesy

of Chrysler Motors

Using

punch and screwdriver, remove end plate retaining

ring. Remove

end plate and pressure plate spring. Remove "O"

ring,

flow control valve and spring. Note direction of pump

ring

installation for reassembly reference.

Using

soft-faced hammer, tap end of drive shaft to loosen

pressure

plate. Remove pressure plate, pump ring, vanes, retaining

ring,

rotor and thrust plate assembly from body. Remove drive

shaft.

Using a screwdriver, pry drive shaft oil seal from

housing. Remove

dowel pins and seals.

Cleaning & Inspection

1) Clean all pump components in solvent, and blow dry.

Inspect flow control valve assembly for wear, scoring, burrs and other damage. Inspect seal bore for burrs, nicks and score marks.

Inspect

machined surfaces of body for scratches and burrs.

Check

"O" ring mating surfaces.

Inspect drive shaft for excessive

wear.

Inspect

pump ring for roughness. Check thrust plate and

pressure

plate for scoring and wear. Ensure vanes slide freely but

fit

snugly into slots. If vanes are

loose in slots, replace rotor and/or

vanes.

Reassembly

1) Before installation, coat all "O" rings, rotor, pressure

plate and end plate with petroleum jelly. Install new drive shaft seal in housing. Install "O" ring in third groove of housing. Install dowel pins in thrust plate. Install drive shaft through thrust plate and rotor. Install NEW retaining ring. Ensure rotor slides freely on drive shaft splines.

Install

drive shaft in pump housing. Ensure thrust plate

engages with

dowel pins. Install pump ring on dowel pins with rotation

arrow

facing upward. Install vanes with rounded edges toward pump

ring.

Lubricate

outer chamfered edge of pressure plate with

petroleum

jelly. Install pressure plate with spring groove facing

upward.

To seat pressure plate, place large socket on pressure plate

and

press downward approximately 1/16".

Install

end plate "O" ring in second

groove of housing.

Install pressure

plate spring and end plate in housing. Press end

plate downward,

and install retaining ring. Install "O" ring,

flow

control valve and spring.

Install

mounting stud and pressure line union "O" rings

in

rear of pump housing. Lubricate inner edge of reservoir with

petroleum

jelly, and install. Install

mounting stud. Tighten stud to

specification. Install pressure

line union, and tighten to

specification. See appropriate table

under TORQUE SPECIFICATIONS.

Using

Pump Pulley Installer (J-25033-B), install

pulley on

pump shaft. Ensure shaft

protrudes distance measured in disassembly

procedure.

When

replacing plastic pulley with metal pulley, install

pulley flush

with end of shaft. Install pump on engine, and compare

alignment

with adjacent pulleys. If necessary, correct alignment by

using

pump pulley installer to adjust shaft protrusion.

NON-SUBMERGED VANE POWER STEERING PUMP

Disassembly

Remove

return tube. Clean exterior of unit. Measure

distance

shaft protrudes through pulley, and record for reassembly

reference.

Using pulley remover, remove pulley from shaft. Remove

fitting,

"O" ring, flow control valve and

spring. See Fig. 7.

Remove

snap ring, drive shaft and bearing. Note direction

of snap ring

installation for reassembly reference. Support drive

shaft

bearing on inner race, and press drive shaft from bearing.

Using

screwdriver, remove drive shaft seal from housing.

Insert

punch into access hole to disengage and remove

retaining

ring. Using a brass drift, tap on thrust plate, and remove.

Remove

"O" ring, pump ring, rotor and

vanes. Remove dowel pins,

pressure plate, "O"

ring and pressure plate spring. Remove "O"

ring,

dowel pin and

sleeve.

9.

Pump Housing

9.

Pump Housing

Return Tube

Dowel Pin

Sleeve

"O- Ring

Pressure

Plate Spring

15.-Î’Ring

1 Snap Ring

Drive Shaft Bearing

Drive Shaft

Drive Shaft Seal

Fitting

"0n Ring

Flow Control Valve

Pressure Plate

Dowel Pins

Vanes

Rotor

Pump Ring

-Î" Ring

Thrust Plate

8, Flow Control Valve Spring 23. Retaining Ring

Fig.

7: Exploded

View of Cherokee & Comanche

Pump Assembly Courtesy of Chrysler Motors

Fig.

7: Exploded

View of Cherokee & Comanche

Pump Assembly Courtesy of Chrysler Motors

Cleaning & Inspection

1) Clean all pump components in solvent, and blow dry.

Inspect flow control valve assembly for wear, scoring, burrs and other damage. Inspect seal bore for burrs, nicks and score marks.

Inspect

machined surfaces of body for scratches and burrs.

Check

"O" ring mating surfaces.

Inspect drive shaft and sleeve for

wear.

Inspect

pump ring for roughness. Check thrust plate and

pressure

plate for scoring and wear. Ensure vanes slide freely but fit

snugly

into slots. If vanes are loose in slots, replace rotor and/or

vanes.

Reassembly

Lubricate

all "O" rings, seals, pump ring,

rotor and vanes

with petroleum jelly.

Install sleeve. Ensure sleeve is fully seated.

Install

"O" ring in sleeve seat. Install

small dowel pin

in pump housing. Install pressure plate spring

and "O" ring. Install

pressure

plate with dowel pin hole aligned with dowel pin holes.

Install

dowel pins.

Install pump ring with identification marks located

adjacent to one dowel pin. Install rotor with counterbore toward drive shaft end of housing.

4) Install

vanes with rounded edges toward pump ring. Install

thrust

plate "O" ring. Install thrust

plate with indentations aligned

with bolt holes of housing.

Install retaining ring.

CAUTION: Pump ring must be installed with identification marks located adjacent to dowel pins. Thrust plate must be installed so indentations in thrust plate align with bolt holes of housing and thrust plate engages with pump ring dowel pins.

Using a

socket, install drive shaft seal in housing until

seal bottoms.

Support drive shaft bearing on inner race, and press

drive shaft

into bearing. Install drive shaft and bearing in pump

housing.

Rotate

drive shaft during installation to align with rotor

serrations.

Ensure bearing is fully seated in pump housing. Snap ring

should

be installed with large lug area (near snap ring pliers

hole)

positioned right of small lug

(near snap ring pliers hole), ensuring

beveled

area of snap ring is properly positioned.

Install

spring, flow control valve and "O" rings.

Install

return tube with new "O" ring.

Install pulley.

STEERING GEAR

Disassembly

Cap all

openings in gear. Clean gear exterior thoroughly.

Mount gear in

vise so that pitman shaft points downward. Rotate

housing end

plug retainer ring until one end of plug is over the hole

in the

housing.

Force

end of ring from groove in housing and remove.

Rotate

input shaft counterclockwise to force housing end plug out

of

housing. Rotate input shaft

clockwise 1/2 turn to draw

rack/piston

inward. Remove piston end

plug.

CAUTION: DO NOT rotate shaft more than is necessary to remove plug as ball bearings will fall out of worm and rack piston assembly.

3) Remove

lock nut from sector shaft adjuster. Remove sector

shaft cover.

Remove and discard "O" ring from

cover. Turn input shaft

until sector

shaft teeth are centered in housing.

Tap end of

sector shaft with a soft-faced hammer to free

shaft from housing,

then remove sector shaft. Remove adjuster plug

lock nut. Remove

adjuster plug with a spanner wrench.

Insert a

rack/piston arbor into end of rack/piston until

arbor just

contacts worm shaft. Turn stub shaft counterclockwise to

force

rack/piston onto arbor. Remove rack/piston and arbor as an

assembly.

Take care

to keep arbor fully inserted so ball bearings

will not fall out.

Remove input shaft and control valve assembly from

housing.

Remove worm, wormshaft lower thrust bearing, and races from

housing.

Reassembly

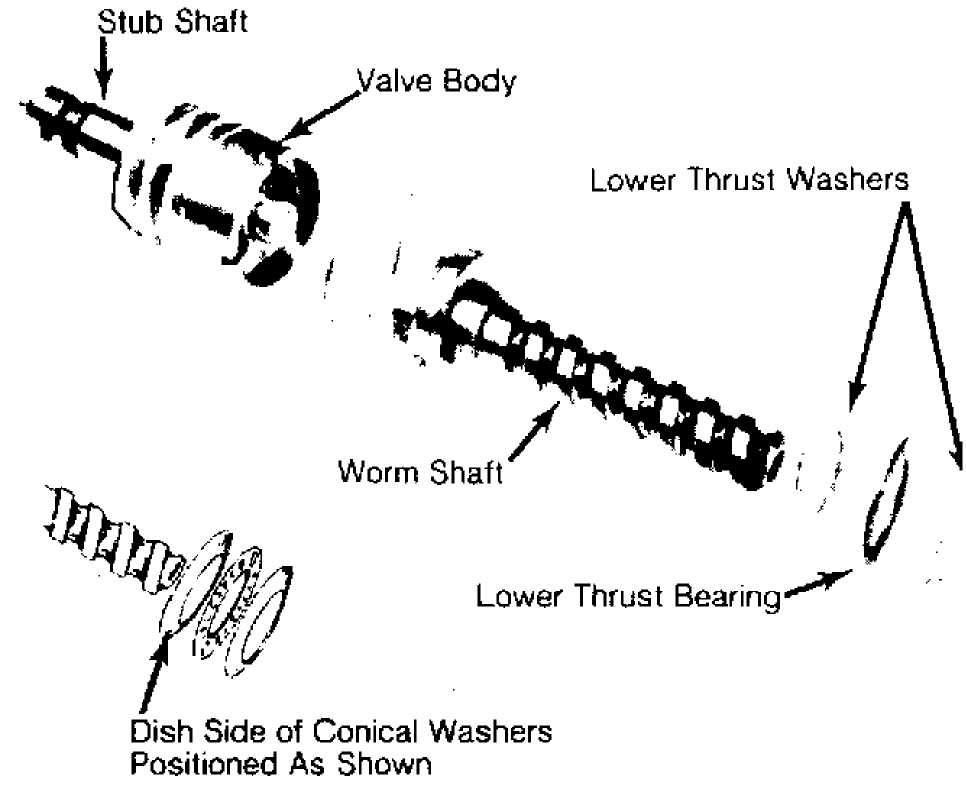

1) Lubricate all parts with clean power steering fluid before reassembly. Install the lower thrust bearing and races onto the worm. Cupped side of thrust washers must face toward stub shaft. See Fig. 8.

30541

Fig. 8: Reassembly of Valve Body & Worm Shaft Assembly

NOTE: If conical thrust races are used, ensure tapered surfaces

are parallel to each other and that cupped sides face toward stub shaft.

Install

stub shaft cap "O" ring in valve

body. Align valve

body drive pin on

worm with narrow pin slot in valve body. Worm drive

lugs

must engage in stub shaft cap.

Install

valve body and worm assembly into housing. Perform

installation

by pressing directly on valve body only. This will

prevent stub

shaft "O" ring from disengaging

from valve body.

Valve

body is correctly seated when fluid return port in

housing

is fully visible. Ensure worm locating pin is fully engaged in

valve

body. Place seal protector over input shaft, install a new

adjuster

plug "O" ring, then install

adjuster plug.

Remove

seal protector from housing and loosely install

adjuster plug

lock nut. Insert arbor and rack/piston into housing.

Align worm

and rack/piston and turn stub shaft clockwise to engage

worm.

Maintain pressure on arbor until worm is fully engaged.

Turn input

shaft clockwise until middle rack groove in

rack/piston is

aligned with center of sector shaft roller bearing.

Remove arbor.

Install a new sector shaft cover gasket.

Thread

sector shaft cover onto adjuster screw until

bottomed.

Back off 1 1/2 turns. Install sector shaft

so that center

gear tooth meshes with

center groove in rack/piston. Install cover

attaching

bolts.

Install

adjuster lock nut halfway onto sector shaft.

Install piston and

plug in rack/piston. Install housing end plug "O"

ring,

end plug and retainer ring. Adjust worm bearing preload

and

over-center preload at this time.

ADJUSTER PLUG

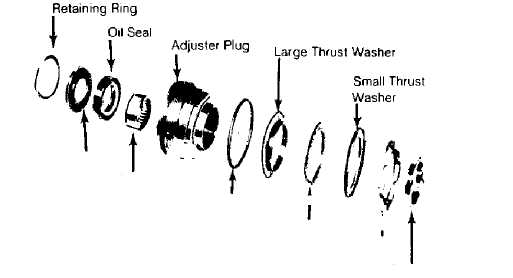

Disassembly

Remove

thrust bearing retainer ring with a screwdriver,

taking care not

to score needle bearing bore. Discard retainer ring.

Remove

thrust bearing spacer, thrust bearing and bearing races.

Remove

and discard adjuster plug "O" ring,

then remove

input shaft seal retainer. Remove and discard dust

seal. Pry input

shaft seal from adjuster plug.

Inspect

needle bearing in adjuster plug. If necessary,

remove

bearing by pressing out from spacer end. See Fig. 9.

Inspection

Inspect thrust bearing for cracks and rollers for pitting, scoring, or cracking. Check thrust races and spacer for damage or damage. Replace parts as necessary.

Dust

Seal

Dust

Seal

Needle Bearing

"0" Ring ò

Thrust Bearing i

Spacer

Retainer 30542

Fig. 9: Exploded View of Adjuster Plug Assembly

Reassembly

1) Press roller bearing into adjuster plug (identification end facing arbor) until bearing bottoms on input shaft seal bore.

Install input shaft seal with spring in seal facing adjuster plug.

Install

dust seal into adjuster plug. Rubber face of seal

must face away

from plug. Install retainer ring. Install adjuster plug

"O"

ring.

Assemble

thrust bearing, thrust bearing race, and thrust

bearing spacer on

adjuster plug. Using a brass or wooden dowel, press

bearing

retainer into needle bearing bore.

RACK/PISTON & WORM

Disassembly

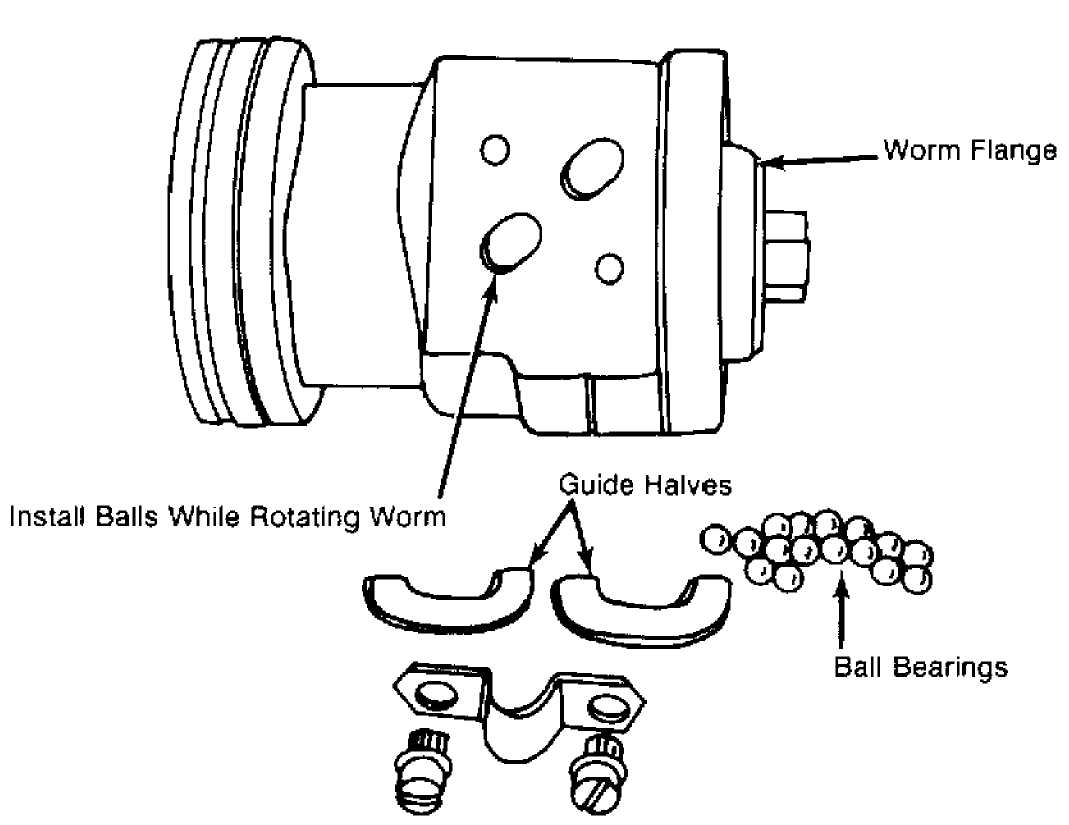

Remove worm, lower thrust bearing and bearing races from rack piston. Remove piston ring and back-up "O" ring from rack/piston. Remove ball return guide clamp, ball return guide and all ball bearings from rack/piston.

Inspection

Clean and

dry all parts. Inspect worm and rack/piston

grooves for scoring.

Inspect ball bearings for damage. If any ball

bearings are

damaged, replace entire set. Check ball guides for

pinching of

ends.

Inspect

lower thrust bearing races for cracking, scoring,

or pitting.

Replace wormshaft and rack/piston as an assembly if either

part

is damaged. Inspect rack/piston teeth for chips, cracks, dents

or

scoring.

Reassembly

1) Install

"O" ring and piston ring onto

rack/piston using

care not to twist them. Install worm into

rack/piston until worm is

against piston

shoulder. Install ball bearings into rack/piston while

slowly

rotating worm counterclockwise.

NOTE: See RACK PISTON & WORM ASSEMBLY BALL BEARINGS table for

number of balls to be installed. BE SURE to install light and dark colored balls alternately, as Black balls are .0005" smaller than Silver balls.

Install

correct number of balls in ball guide. Bearings in

guide must be

in sequence with bearings in rack/piston. Hold balls in

place

with chassis lubricant and install return ball guide assembly

into

position.

Install

clamp and tighten attaching bolts. Alternate light

and

dark colored balls when installing. See Fig. 10.

Insert

rack/piston

arbor into rack/piston until it contacts worm. Maintain

pressure

on arbor, and back worm out of rack/piston. DO NOT allow

ball

bearings to drop out of circuits.

RACK PISTON & WORM ASSEMBLY BALL BEARINGS TABLE

Application Rack/Piston Guide

Application Rack/Piston Guide

Jeep 18 6

30543

Fig. 10: Installing Ball Bearing into Rack/Piston Assembly

ROTARY VALVE

NOTE: Complete valve assembly is balanced during assembly. If replacement of any part other than rings or seals is necessary, replace complete assembly.

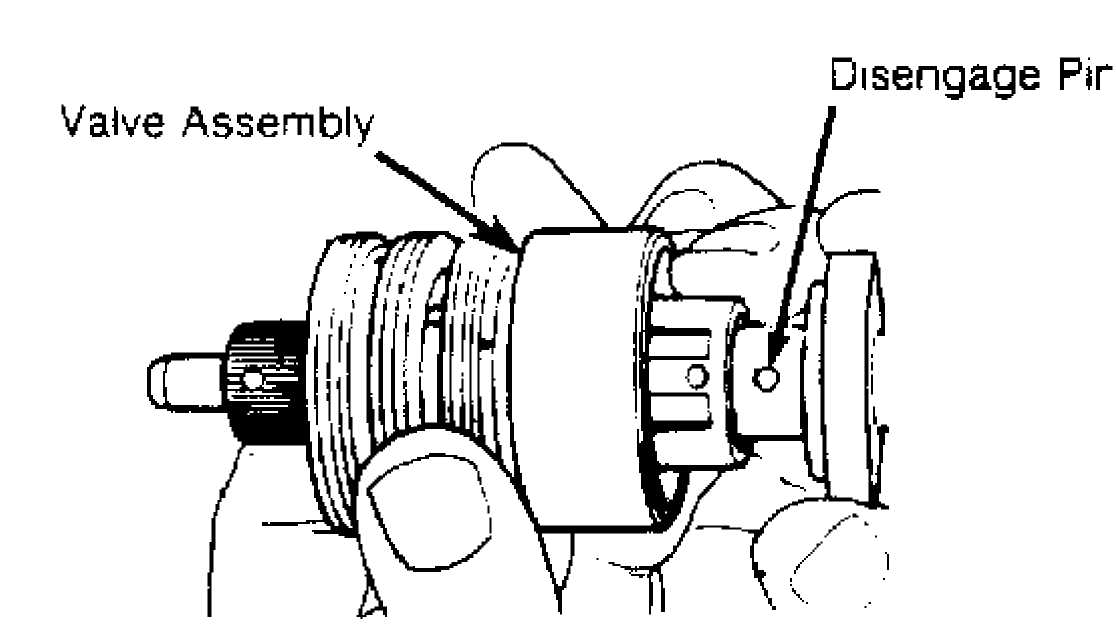

Disassembly

1) Remove and discard stub shaft cap "O" ring. Invert valve and lightly tap end of stub shaft against wood block until shaft cap is free of valve body. Pull stub shaft outward until drive pin hole is visible. Depress the pin to remove the stub shaft from the valve body. See Fig. 11.

NOTE: DO NOT pull shaft any further than 1/4" (6 mm) or spool valve may become cocked in valve body.

30335

Fig. 11: Pulling Shaft from Valve Assembly

2) Disengage

drive pin and carefully remove stub shaft from

valve

body and spool assembly with a twisting motion. If binding

occurs,

realign valve and try removal again.

CAUTION: DO NOT force stub shaft or spool out of valve body.

3) Remove

spool valve from valve body with twisting motion.

Remove

and discard all "O" rings and

Teflon rings.

Spool

Valve ""’ "/J- °

R’nQ

Spool

Valve ""’ "/J- °

R’nQ

"0" Rings (3)

Stub Shaft

30334

Fig. 12: Exploded View of Valve Body Assembly

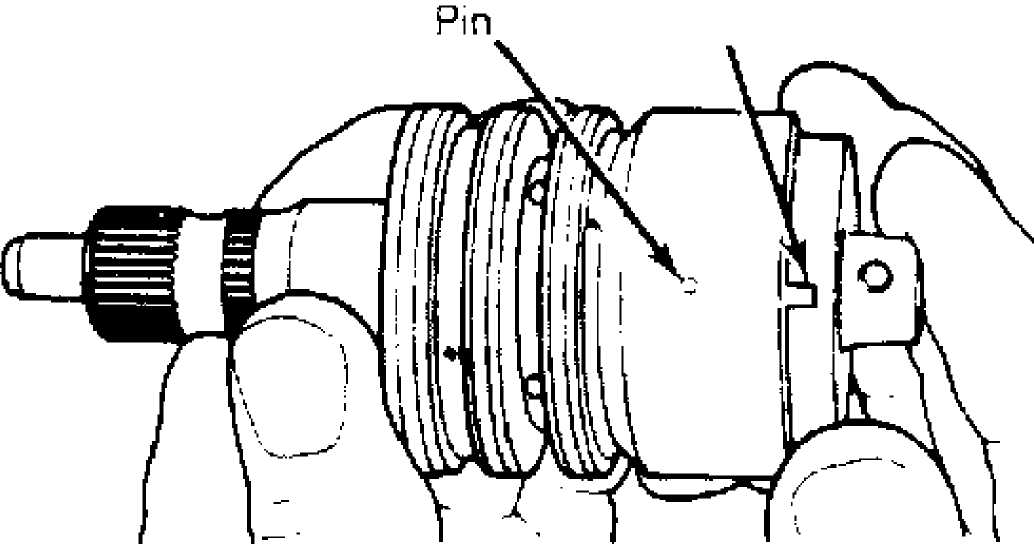

Reassembly

1) Lubricate all valve body components with power steering fluid. Install replacement back-up "O" rings in seal grooves and

install replacement seal rings over back-up rings. Take care not to damage seal rings during installation.

NOTE: Teflon seal rings may appear to be distorted after

installation. However, heat of operation will straighten them.

Lubricate

replacement spool valve damper "O" ring

with

petroleum jelly. Install on spool

valve. Carefully insert spool valve

into

valve body.

Push spool

valve through valve body until locating pin

hole is visible at

opposite end of valve body and spool valve is flush

with the

notched end of the valve. Install stub shaft in spool valve

and

valve body.

Be

sure stub shaft locating pin is aligned with spool

valve

locating hole. Align notch in stub shaft cap with stub

shaft

locating pin and press sub shaft

and spool valve into valve body.

Install stub shaft cap "O"

ring into valve body. See Fig. 13.

CAUTION: Before installing assembled valve body into gear housing, be sure valve body stub shaft locating pin is fully engaged in stub shaft cap notch. DO NOT allow stub shaft to disengage from valve body pin.

Notch

3Q336

Fig. 13: Aligning Pin & Notch for Input (Stub) Shaft

Stub shaft locating pin must align with spool valve locating hole.

STEERING GEAR HOUSING

Disassembly

Remove

sector shaft seal retaining ring and remove lower

steel washer.

Remove lower seal, spacer washer and upper seal from

housing.

Press sector shaft bearing out of housing from lower end.

To remove hose connector seat, tap out seat using a 5/16"-

18 thread tap. Thread connector seats ONLY 2-3 threads. Install a bolt with a flat washer and nut into seat.

3) Hold bolt from turning and tighten nut to extract seat from housing. Some steering gear units have metric thread fittings and hose fittings which use "O" ring seals instead of connector seats. Remove check valve and spring from inlet port and discard.

30337

Fig. 14: Gear Housing Seals & Bearing

Inspection

1) Replace housing if bore is severely worn, scored or pitted. Minor scratches may be removed with crocus cloth. Inspect

housing ball plug for fluid leakage. Seat ball plug with blunt punch.

Spray

ball area with Loctite Solvent 7559 and

dry with

compressed air. Cover ball

area with Loctite Sealant 290. Allow

sealant

to cure for 2 hours before assembling

gear.

Inspect

all retaining ring, bearing and seal surfaces in

housing. Replace

housing if any surface is worn or damaged.

Reassembly

Working

from upper end, press a new bearing into housing

until it is

seated .030" (.76 mm) below shoulder

in housing bore.

Lubricate new seal with power steering fluid.

Install

single lipped seal and spacer washer only far

enough to provide

clearance for next seal, washer and retaining ring.

DO NOT bottom

seal against housing counterbore.

Install

double lipped seal and steel washer. Install

retaining ring. DO

NOT allow seals to contact one another. To ensure

proper seal

action, be sure there is clearance between them.

If port

seat was removed, position new spring, check

valve, and a new

seat over opening in housing. Drive into place using

a brass

drift.

TORQUE SPECIFICATIONS

CHEROKEE, COMANCHE, WAGONEER & WRANGLER

TORQUE SPECIFICATIONS

(CHEROKEE, COMANCHE, WAGONEER & WRANGLER)

Application Ft.

Lbs. (N.m)

Adjuster Plug Lock Nut 80 (108)

Gear Housing-to-Frame Attaching Bolts 75 (102)

Pitman Arm Attaching Nut 185 (250)

Rack Piston End Plug 50 (68)

Sector Shaft Adjuster Lock Nut 33 (45)

Side Cover Bolts 45 (60)

GRAND WAGONEER & "J" TRUCK)

TORQUE SPECIFICATIONS (GRAND

WAGONEER & "J"

TRUCK)

Application Ft.

Lbs. (N.m)

Adjuster Plug Lock Nut 85 (116)

Gear Housing-to-Frame Attaching Bolts (95)

Pitman Arm Attaching Nut 185 (250)

Rack Piston End Plug 75 (102)

Sector Shaft Adjuster Lock Nut 33 (45)

Side Cover Bolts 40 (54)