CLUTCH

1988 Jeep Cherokee

1988 Clutch Hydraulic

Cherokee, Comanche, Wagoneer, Wrangler

DESCRIPTION

The clutch assembly consists of a single dry-disc driven plate and a one-piece diaphragm spring-type clutch cover. On Wrangler 4-cylinder models, the clutch cover and driven plate diameter is 9.28"

(232 mm). On Wrangler 6-cylinder models, the clutch cover and driven plate diameter is 10.5" (266 mm). On all other 4 and 6-cylinder models, the clutch cover and driven plate diameter is 9.7"

(246 mm). The clutch is actuated through a hydraulic master cylinder and slave cylinder.

On Wrangler models, the slave cylinder is mounted inside the clutch housing. The bearing is permanently attached to the cylinder piston.

TRANSMISSION APPLICATION

Vehicle Model Transmission Model

Cherokee, Comanche, Wagoneer Aisin AX4 4-Speed

Aisin AX5 5-Speed O/D

Wrangler Aisin AX5 5-Speed O/D

Peugeot BA 10/5 5-Speed O/D

REMOVAL & INSTALLATION

TRANSMISSION

Removal

1) Remove the shift knob and lock nut from transmission and

transfer case shift levers (if equipped). On Wrangler models, remove

screws attaching transmission and transfer case shift lever boots and

remove both boots.

2) On all other models, raise outer gearshift lever boot and

remove upper part on center console. Remove lower part of console,

remove inner boot and gearshift lever.

On Wrangler models, remove transmission shift tower dust

cover. Remove transmission shift lever and stub shaft. DO NOT remove

shift lever from stub shaft.

On all models, raise and support vehicle. Drain

transmission lubricant. Mark rear drive shaft for reassembly and

remove rear drive shaft. Support transmission assembly and remove

crossmember. Disconnect speedometer cable and wiring from back-up

light switch.

On 4WD models, drain transfer case lubricant. Disconnect

transfer case vacuum hoses and linkage. Tag vacuum hoses for

reassembly. Disconnect front drive shaft and secure out of way.

On all models, remove clutch slave cylinder. Position

transmission jack under transmission assembly. Remove bolts securing

clutch housing to engine and remove transmission assembly. Remove

throw-out lever, bearing, and pivot ball from clutch housing.

Installation

To install, reverse removal procedure.

CLUTCH

Removal

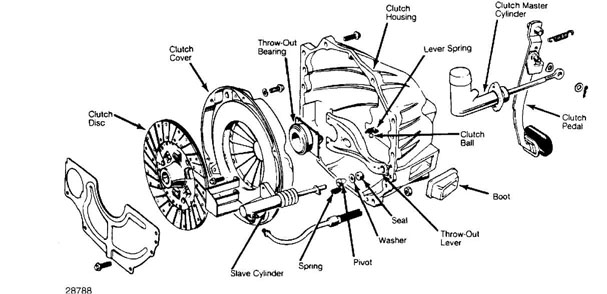

Remove transmission assembly. Mark position of clutch cover on flywheel for reassembly reference. Evenly loosen clutch cover bolts one or 2 turns at a time until clutch cover spring tension is released. Remove cover bolts, clutch cover, and disc. See Fig. 1.

Installation

Check all components for wear or damage and replace as

necessary. Using clutch alignment tool, align clutch disc and loosely

install clutch cover. Be sure marks made during removal are aligned.

To avoid warping clutch cover, tighten each cover bolt a

few turns at a time. To complete installation, reverse removal

procedure.

Fig. 1: Exploded View Of Cherokee, Comanche & Wagoneer Hydraulic

Clutch Assembly

Wrangler has a one-piece slave cylinder.

CLUTCH MASTER CYLINDER

Removal system.

Disconnect hydraulic line at master cylinder. Plug

openings to prevent dirt from entering system. Remove cotter pin and

washer holding cylinder push rod on clutch pedal.

Slide push rod off pedal pivot. Remove nuts attaching

clutch master cylinder to studs on dash panel and remove cylinder.

Installation

To install, reverse removal procedure. Bleed hydraulic

CLUTCH SLAVE CYLINDER

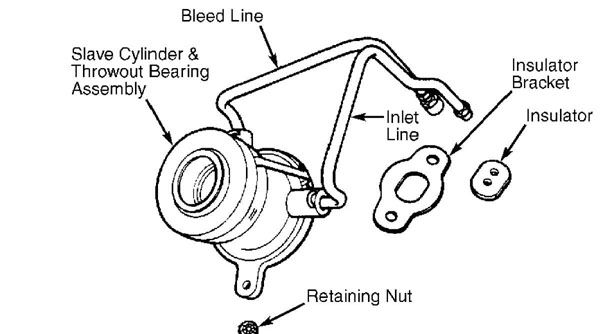

Removal (Wrangler) system.

Disconnect slave cylinder inlet line. Remove transmission

and transfer case. Slide rubber insulator off slave cylinder lines.

Remove bolts attaching insulator bracket to clutch housing. Slide

bracket off cylinder lines.

Remove slave cylinder and bearing retaining nut. Pry nut

up and off mounting pin on transmission front case. Remove slave

cylinder and bearing by sliding assembly off transmission input shaft.

See Fig. 2.

Installation

To install, reverse removal procedure. Bleed hydraulic

32327

Fig. 2: Wrangler Clutch Slave Cylinder Courtesy of Chrysler Motors.

Removal (Cherokee, Comanche & Wagoneer)

Disconnect hydraulic line at clutch slave cylinder. Cap line to prevent fluid loss. Remove spring holding clutch fork lever to cylinder push rod. Remove bolts attaching slave cylinder to clutch housing. Remove slave cylinder, heat shield, clutch fork pivot, washer and seal.

Installation

To install, reverse removal procedure. Bleed hydraulic system.

PILOT BUSHING

Removal (Cherokee, Comanche & Wagoneer)

Remove clutch assembly. Remove pilot bushing using Slide Hammer (J-2619-01) and Bushing Remover (J-5822).

Installation

Lubricate replacement bushing with engine oil. Remove pilot bushing lubricating wick and soak wick in engine oil. Install wick in bushing bore. Install bushing using Clutch Pilot Shaft (J-33169) . Keep pilot shaft parallel with crankshaft center line to prevent damage to bushing. Reverse removal procedure to complete installation.

OVERHAUL

CLUTCH MASTER CYLINDER

Disassembly

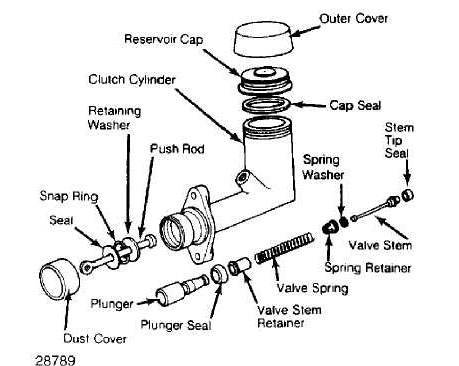

Remove reservoir cap and cover. Remove push rod dust

cover. Remove snap ring holding push rod in cylinder bore. Discard

dust cover and snap ring.

Remove push rod, retaining washer, and seal as an assembly. Discard seal. Remove plunger, valve spring, and valve stem assembly from cylinder bore by tapping cylinder body on wood block.

NOTE: Retainer tab is located in rectangular slot in side of stem retainer.

Remove valve stem from retainer. Remove spring washer and

stem tip seal from end of valve stem. See Fig. 3. Discard stem tip

seal and spring washer. Clean parts with brake fluid or brake cleaning

solvent.

Inspect cylinder bore for wear, nicks or scores. Master

cylinder bore must be clean and smooth. Light discoloration is

acceptable. Replace if necessary. Clutch master cylinder must not be

honed under any circumstances.

Fig. 3: Exploded View Of Clutch Master Cylinder Courtesy of Chrysler Motors.

Reassembly

1) Lubricate cylinder bore with brake fluid. Make sure lip of

plunger seal faces stem end of plunger. Install stem tip seal so seal shoulder fits in undercut at end of valve stem.

2) End of valve stem should pass through stem retainer and seat in small bore in end of plunger. Bend retainer tab downward to lock stem and retainer on plunger. To complete assembly, reverse disassembly procedures.

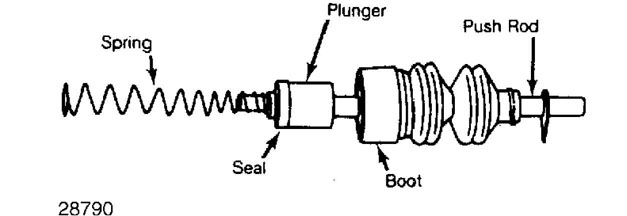

CLUTCH SLAVE CYLINDER

Disassembly

NOTE: On Wrangler models, the integral slave cylinder and throw out bearing assembly is not serviceable. If cylinder, bearing or lines become damaged the entire assembly must be replaced.

Clean cylinder exterior. Remove dust boot from cylinder.

Remove cylinder push rod, plunger and spring as an assembly. Remove

spring seal from plunger.

Remove snap ring holding push rod in plunger. Remove push

rod and boot. Remove boot from push rod. See Fig. 4. Clean parts with

brake fluid or brake cleaning solvent. Inspect cylinder bore for wear,

nicks or scores. Replace if necessary.

Fig. 4: Exploded View Of Clutch Slave Cylinder Courtesy of Chrysler Motors.

Reassembly

Reverse disassembly procedure. Lubricate cylinder bore and seal with brake fluid before reassembly.

HYDRAULIC SYSTEM BLEEDING

Fill master cylinder reservoir with DOT 3 brake fluid. On

all models except Wrangler, compress slave cylinder plunger by pushing

release lever as far forward as possible.

Attach rubber hose to slave cylinder bleeder screw.

Immerse other end of hose in glass container 1/2 full of brake fluid.

Loosen bleeder screw and have an assistant depress clutch pedal.

Tighten bleeder screw and release pedal.

Repeat bleeding procedure until fluid entering container

is free of bubbles. DO NOT allow reservoir to run out of fluid during bleeding. Refill clutch master cylinder to level mark on reservoir.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft. Lbs. (N.m)

Cherokee, Comanche & Wagoneer

Bellhousing-to-Engine Bolts 28 (38)

Clutch Cover Bolts 23 (31)

Crossmember-to-Sill Bolts 30 (41)

Flywheel Bolts

4-Cylinder (1) 50 (68)

6-Cylinder 61-75 (83-102)

Master Cylinder Attaching Nuts 19 (26)

Rear Support-to-Engine Bolt 33 (45)

Slave Cylinder-to-Clutch

Housing Bolts 16 (22)

Transmission Drain Plug 27 (37)

Wrangler

Bellhousing-to-Engine Bolts 28 (38)

Clutch Cover Bolts

4-Cylinder 23 (31)

6-Cylinder 40 (54)

Crossmember-to-Sill Bolts 30 (41)

Master Cylinder Attaching Nuts 19 (26)

Rear Support-to-Crossmember Bolts 33 (45)

Transmission Drain Plug 27 (37)

(1) - Plus additional 60 degrees turn after reaching torque specification.