DRIVE AXLE - FULL FLOATING

1988 Jeep Cherokee

Drive Axles - Dana Full-Floating Axles Jeep Front & Rear Drive Axles

DESCRIPTION

The axle assembly is an integral carrier type with hypoid gear ring and pinion. Stamped steel cover is removable for inspection and repair of differential. Vehicle loads are carried by axle housings. Axle shafts of "full-floating" rear assemblies may be removed without disturbing wheel bearings.

Drive pinion depth, pinion bearing preload and differential side bearing preload are all set by shims.

See LOCKING HUB and 4WD STEERING KNUCKLE articles in this section for removal and installation procedures for these front drive axle component parts.

AXLE RATIO & IDENTIFICATION

A metal tag on axle is stamped with gear ratio, part numbers and limited slip identification. To determine drive axle ratio, refer to MODEL IDENTIFICATION BY RING GEAR SIZE table.

MODEL IDENTIFICATION BY RING GEAR SIZE

Model Ring Gear Diameter

44 8.50"

9.75"

9.75"

70 10.50"

80 11.25"

FRONT HUB, BEARING, SPINDLE & AXLE SHAFT R & I

FRONT HUB BEARING ADJUSTING SPECIFICATIONS

Application (1) Ft. Lbs. (N.m)

Adjusting Nut

Step 1 50 (68)

Step 2 Back Off 20 °

Lock Nut 50 (68)

(1) - While Rotating Hub.

REMOVAL (CHEROKEE, COMANCHE & WAGONEER)

Raise and support vehicle. Remove tire and wheel assembly.

Remove disc brake caliper and support out of way.

Match mark disc rotor and hub and remove disc rotor.

Remove cotter pin, nut lock and axle hub nut. Remove hub-to-knuckle

bolts. Pull hub assembly off axle shaft. Pull axle shaft through

knuckle to remove. Inspect axle shaft "U" joint and shaft splines for

wear. Replace as necessary.

Press hub out of bearings. Remove seals and bearings.

Inspect bearings and races for wear and pitting. Replace bearing and race together.

INSTALLATION

Install axle shaft through knuckle and engage in axle gear

splines. Pack bearings with multi-purpose grease and fill cavities in

bearing hub. Install new seals.

Press hub into bearings. Install hub assembly on axle

shaft and install bolts. To complete installation, reverse removal

procedure. See TORQUE SPECIFICATIONS table at end of this article.

INTERMEDIATE AXLE SHAFT R & I

REMOVAL (DISCONNECT AXLE MODELS)

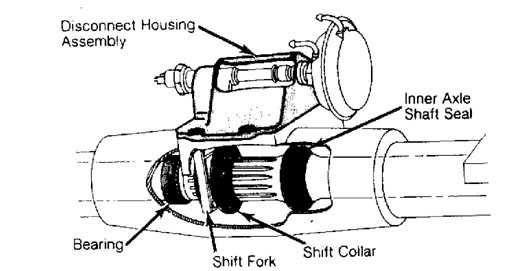

Fig. 1: View Of Axle Disconnect Assembly Courtesy of Chrysler Motors.

INSTALLATION

Remove outer axle. See FRONT HUB, BEARING, SPINDLE & AXLE

SHAFT in this article.

Remove axle assembly inspection cover and drain fluid.

Remove vacuum and electrical connections at disconnect housing

assembly. Remove bolts and pull disconnect housing from axle tube. See

Fig. 1.

Remove intermediate shaft retaining clip on inner end of

axle shaft. Carefully slide intermediate axle shaft through seal and

out end of axle tube. Remove shift collar.

Inspect intermediate shaft bearings and seals for wear. If

replacement of bearings or seal is necessary, use recommended tools.

On Jeep, use Tool Set (J-34659), Slide Adapter (J-34659-4)

and Over Rod (J-34659-3) to replace intermediate shaft bearings and

seal.

Coat intermediate shaft with lubricant and carefully slide

through seal and engage in drive axle splines. Install retaining clip.

Install shift collar on axle shaft. Install outer axle

shaft and check for smooth operation of shift collar.

Apply bead of silicone sealer to inspection cover and

install cover. Fill axle housing with 2.5 pts. (1.2L) of 75W 90 gear

oil. Pour a small amount of gear oil on shift collar and install

disconnect housing. Ensure shifting fork is properly positioned in

shift collar.

To complete installation, reverse removal procedure.

Tighten all bolts and nuts to specification. See TORQUE SPECIFICATIONS table at end of this article.

FRONT AXLE ASSEMBLY R & I

REMOVAL (CHEROKEE, COMANCHE, WAGONEER)

Raise and support vehicle. Remove tire and wheel assembly.

Remove hubs, spindles and axles. See FRONT HUB, BEARING, SPINDLE &

AXLE SHAFT in this article.

Disconnect vacuum hoses and electrical connections from

shift motor. Disconnect stabilizer bar, track bar and steering damper.

Disconnect drive shaft at pinion yoke and tie to frame.

Remove left and right tie rod ends from knuckles.

Support axle assembly on floor jack. Remove lower shock

mounts. Disconnect axle housing-to-frame control arms at axle. Lower

floor jack slowly and remove axle assembly. Remove coil spring lower

bracket and coil spring.

INSTALLATION

1) Place axle housing on floor jack and position under

vehicle. Install coil springs and raise assembly into position. Ensure top of coil springs seat in spring pocket.

2) Check all bushings and mounting hardware for wear or

damage. To complete installation, reverse removal procedure. Tighten

all bolts and nuts to specification. See TORQUE SPECIFICATIONS table

at end of this article. Fill axle assembly with gear oil. Check wheel

alignment.

REAR HUB, BEARINGS & AXLE SHAFTS R & I

Raise and support vehicle. Remove tire and wheel assembly.

Remove axle flange nuts or bolts. If nuts are used, rap center of axle

flange sharply with hammer to loosen tapered dowels. Remove bolts or

dowels and pull axle shaft out of hub.

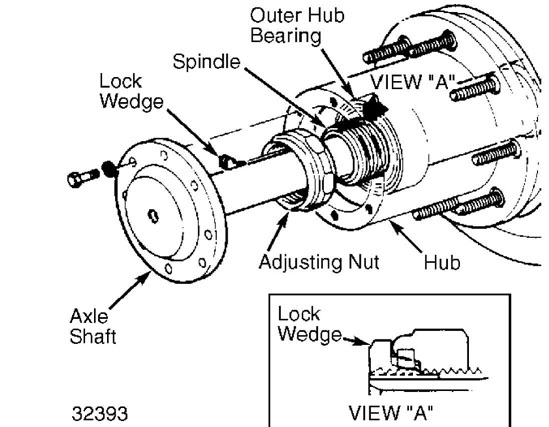

Depending on application, bend back ears of lock washer,

or remove locking wedge from nut, or remove snap ring and key. Remove

bearing adjusting nut(s) and remove hub assembly.

Remove inner hub seal and bearing. Inspect bearings and

races for wear. To replace bearing, drive outer race from bearing hub

using a punch and hammer. Install new race being careful not to chip

or dent race. Ensure new race is seated in hub.

Pack bearings with multi-purpose grease. Install new seal.

Carefully install hub on axle spindle to avoid damaging seal lip and

spindle threads.

Install outer bearing and adjusting nut. Tighten bearing

adjusting nut in steps. See REAR HUB BEARING ADJUSTING SPECIFICATIONS

table. Install lock ring if used. Install spindle lock nut if used and

tighten to proper specification. See REAR HUB BEARING ADJUSTING

SPECIFICATIONS table.

REAR HUB BEARING ADJUSTING SPECIFICATIONS

Application

(1) Ft. Lbs. (N.m)

Adjusting Nut

Step 1 50 (68)

Step 2 Back Off 45 °

Lock Nut 50 (68)

(1) - While rotating hub.

6) Install new axle flange gasket or apply silicone sealer. Install axle and tighten bolts or nuts to proper specification. See TORQUE SPECIFICATIONS table at end of this article.

Fig. 2: Rear Hub & Bearing Adjuster

REAR AXLE ASSEMBLY R & I

REMOVAL

Raise and support vehicle. Remove wheels, hubs and axles.

See REAR HUB, BEARINGS AND AXLE SHAFTS.

Remove lower shock mounts and stabilizer bar mount.

Disconnect drive shaft and tie up. Remove hydraulic brake line at

junction and plug.

Disconnect park brake cables and hydraulic brake lines to

wheel cylinders or calipers. Remove brake backing plate or caliper.

Support axle housing with floor jack and remove leaf

spring "U" bolts. Carefully lower axle housing and remove from

vehicle.

INSTALLATION

Place axle housing on floor jack. Raise axle and install "U" bolts and nuts. To complete installation, reverse removal procedure. Tighten all bolts and nuts to specification. See TORQUE SPECIFICATIONS table at the end of this article and REAR HUB BEARING ADJUSTING SPECIFICATIONS table.

PINION SEAL & YOKE R & I

REMOVAL

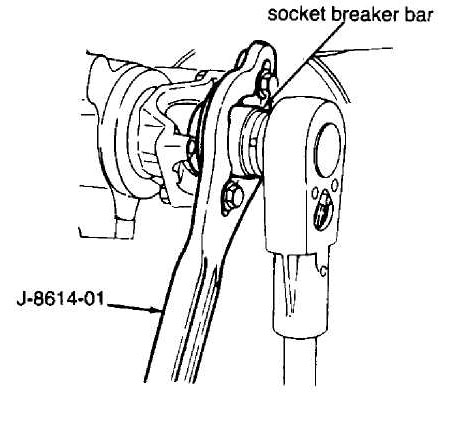

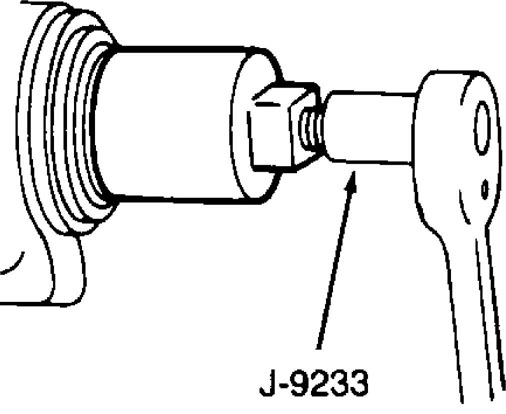

Fig. 3: Removing Pinion Nut & Washer

Raise and support vehicle. Mark drive shaft-to-yoke

contact area for reassembly reference. Remove drive shaft-to-yoke

attaching nuts/strap bolts. Discard used strap bolts. Remove drive

shaft.

Using a breaker bar and Pinion Nut Remover (8614-01),

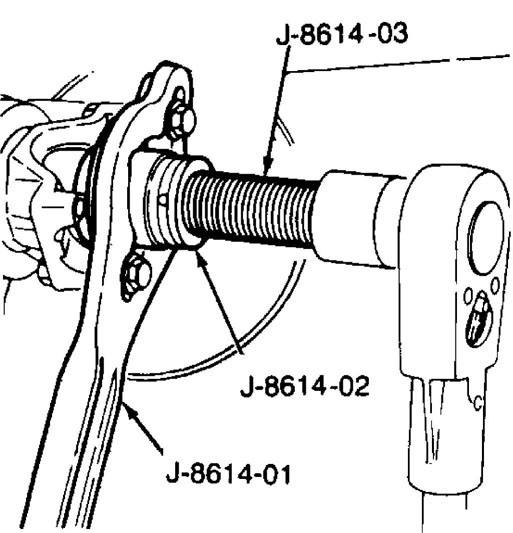

remove pinion nut and washer. See Fig. 3. Using Yoke Pullers (8614-

01), (8614-02) and (8614-03), remove yoke. See Fig. 4. Using Pinion

Seal Remover (J-9233 or J-7583) , remove pinion seal from front

differential housing. See Fig. 5.

Fig. 4: Removing Front Drive Axle Yoke

Fig. 5: Removing Pinion Seal

INSTALLATION

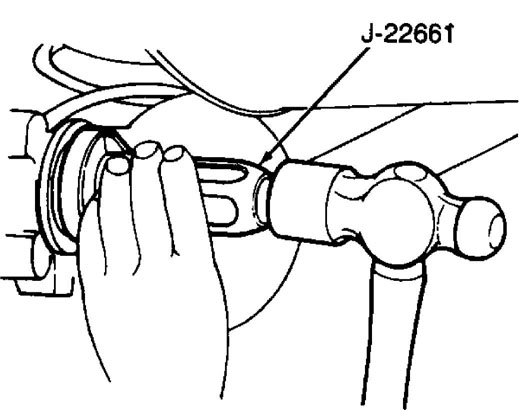

Using Seal Installer (J22661), drive new seal into front differential housing. See Fig. 6. Tighten yoke attaching nut to 210 ft. lbs. (285 N.m). Using NEW strap bolts, align and install drive shaft. Tighten strap bolts to 14 ft. lbs. (19 N.m). Fill differential with SAE 75W-90 gear lubricant.

Fig. 6: Installing New Front Axle Shaft Seal

AXLE SHAFT OVERHAUL

NOTE: All front axle shafts except (Select-Trac) use Cardan "U"

joints and should be overhauled in same manner as drive shaft "U" joints.

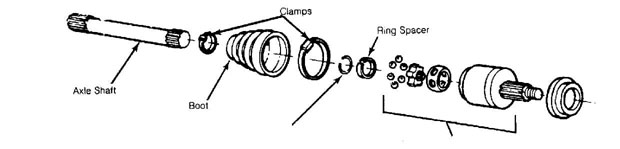

DISASSEMBLY (SELECT-TRAC)

Cut and remove both outer boot clamps. Slide boot off

outer CV joint.

Using a block of wood seated on inner race, tap joint from

shaft. If shaft is clamped in a vise, be sure to use protective vise

jaws.

Tap outer CV cage with a brass punch until cage is tilted

out far enough to remove first ball bearing. Remove remaining ball bearings in same manner.

Rotate outer CV joint cage outward until it is at a 90

degree angle to installed position. Align 2 oblong holes in outer

joint cage with slots in interior wall of spindle housing and remove

cage and inner race.

Remove inner race from cage by aligning shoulder between

race grooves with inside of oblong cage holes. Rotate inner race out

of cage using larger of 2 openings in cage. Remove retaining ring,

spacer ring and outer boot.

Retaining Ring

Constant Velocity {CV) Joint

Fig. 7: Exploded View of Jeep (Select-Trac) Drive Axle Courtesy of Chrysler Motors.

CLEANING & INSPECTION

Wash all parts in solvent and dry. Inspect inner and outer

ball races for damage. Inspect splined stub shaft for wear, cracks and

twisted splines.

Inspect all 6 balls for pitting, cracking or scoring.

Dulling of surface is normal. If any damage is found, replace entire

CV joint assembly. Polished areas in races and on cage spheres are

normal and DO NOT require joint replacement.

REASSEMBLY

Apply a light coat of CV grease on ball grooves of inner

and outer races. Install inner race into cage using a rotating action

opposite of removal. Inner race snap ring should face axle side.

Be sure ball bearing retaining ring is installed on inner

race side facing small end of cage. Align windows of cage with outer

race lands, and pivot cage with inner race into tilted position

(opposite of removal).

Install ball bearings one at a time into outer CV joint as

cage is tilted and rotated. After balls are installed into cage, pivot

cage and inner race into installed position.

Slide new seal clamp for small end of boot seal, boot seal

and seal retainer onto axle shaft. Coat inside lip (large diameter end

of seal) with CV grease. Slide seal retainer on end of seal.

Spread ears of bearing race snap ring, and slide CV joint

onto axle shaft until snap ring seats in groove. Pack joint with

approximately 1/2 of grease provided in seal kit. Apply remaining

grease inside seal.

Slide seal toward joint until small end of seal is in

groove in axle shaft. Position small clamp over small end of seal and

into groove and tighten.

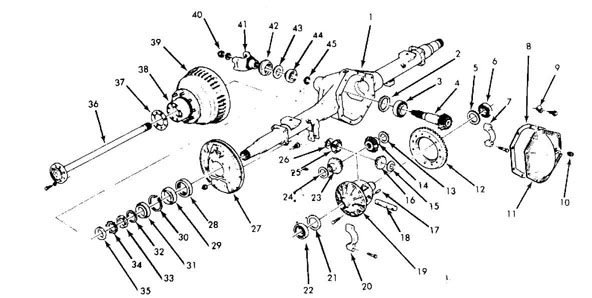

Carrier Housing

Shim Pack

Inner Pinion Bearing

Orive Pinion

Shim Pack

Side Bearing

Bearing Cap

8 Cover Gasket

9. Clip

Plug

Cover

Ring Gear

Thrust Washer

Side Gear

Thrust Washer

16 Pinion Gear

Lock Pin

Pinion Shaft

Differential Case

Bearing Cap

21 Shim Pack

Side Bearing

Side Gear

Thrust Washer

Pinion Gear

Thrust Washer

27 Backing Plate

Seal

Inner Hub Bearing

Snap Ring

Outer Hub Bearing

Adjusting Washer

Adjusting Nut

Lock Washer

Lock Nut

Axle Shaft

Axle Flange Gasket

Hub

Brake Drum

40 Flange Nut

41. Pinion Flange

42 Pinion Seat

Slinger

Outer Pinion Bearing

Shim Pack

Fig. 8: Exploded View Of Dana Full-Floating Axle Assembly

AXLE ASSEMBLY OVERHAUL

DISASSEMBLY

Drain lubricant. Remove axle shafts and housing cover. If

no side play is found in the differential case assembly, mount dial

indicator on pilot stud with tip against back of ring gear. Measure

runout of ring gear, marking ring gear and case at point of maximum

runout.

If runout total exceeds .006" (.15 mm), ring gear could be

loose or case could be damaged. Using .003" (.08 mm) feeler gauge, try

to force feeler gauge between cap and race. If it does, bearing race

may have been turning in carrier.

If race has been turning, carrier could be damaged.

Observe identifying letters stamped into bearing caps and face of

carrier sealing surface. Use these matched letters for reassembly

reference.

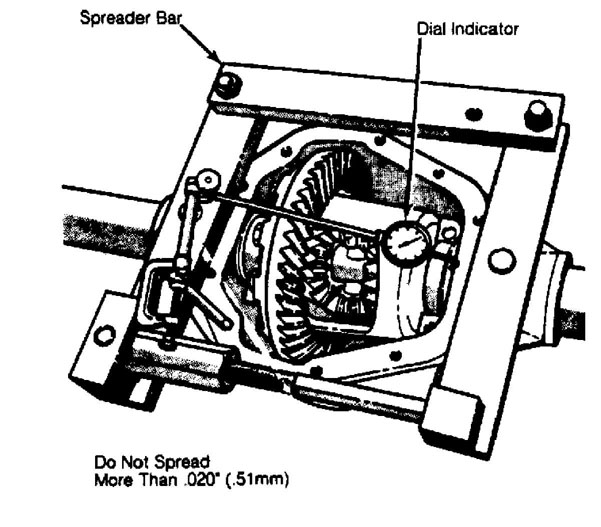

Remove side bearing caps. Use Housing Spreader (W-129-A on

Model 44; D-167 on Models 60, 61, 70 and housing to .015" (.38 mm). See Fig. 9.

to spread differential

CAUTION: DO NOT spread housing more than .020" (.51 mm). Permanent damage to housing could result.

29259

Fig. 9: Correct Procedure for Spreading Housing

Pry differential case out of housing. Remove spreader to

prevent carrier taking set. On models with side bearing shims between

carrier and side bearing outer race, record sizes and positions of

shims. Be careful not to damage machined surfaces of housing.

Put case in soft-jawed vise and remove ring gear bolts and

discard. Tap ring gear loose with soft mallet. If ring gear runout measured earlier exceeded .006" (.15 mm), repeat runout measurement of case without ring gear. Total runout of case should not exceed .003" (.08 mm).

Using Flange Holder Wrench (C-3281), remove drive pinion

nut and washer. Using holder wrench and Flange Puller (C-452), remove

drive pinion flange. Using Pinion Seal Puller (C0748), remove pinion

oil seal. Remove slinger, gasket, outer pinion bearing and preload

shim pack.

Remove drive pinion with inner bearing. Remove inner and

outer pinion bearing races. Remove and note thickness of shim pack

behind inner bearing race. Remove inner pinion bearing from pinion

shaft using Puller Press (DD-914-P) with Adapter Ring (DD-914-9) and

Pinion Bearing Puller Plates (C-293-39 on Model 44; DD-914-37 on Model

60 and 61; DD-914-95 on Models 70 and 80) .

NOTE: Pinion bearing adjusting shims may remain on pinion shaft, stick to bearing or fall loose. Collect and save them for reassembly.

9) Remove side bearings with Bearing Puller (C-293-PA),

Extension Plug (C-293-3 on Model 44; DD-914-7 on Models 60, 61, 70 and 80) and Puller Plates (C-293-18 on Model 44; DD-914-62 on Models 60, 61, 70 and 80). Record shim thickness and location for reassembly reference.

If differential case is a one-piece unit, drive out lock

pin holding differential pinion shaft to case. Remove differential

pinion shaft, gears and thrust washers (one for each gear).

If differential case is a 2-piece unit, mark both

differential case halves to aid reassembly in correct position. Remove bolts holding case halves together. Tap on top half of case to break it loose from lower half. Remove top half of case. Remove pinion gear spider, pinion gears, side gears and all thrust washers.

INSPECTION

Use cleaning solvent to rinse gears and bearings. Check

large end of bearing rollers where wear, if any, is evident. Check

pinion and flange splines for excessive wear. Ensure ring gear teeth

are in good condition.

Check differential case for cracks, scoring of side gears,

thrust washers and pinion thrust faces. Check fit of side gears to

case and to axle shaft splines. Look at pinion shaft and spacer for

scoring or excessive wear.

REASSEMBLY & ADJUSTMENTS

When reassembling and adjusting ring and pinion assembly,

pinion depth, pinion bearing preload, side bearing preload and

backlash between ring and pinion must be adjusted.

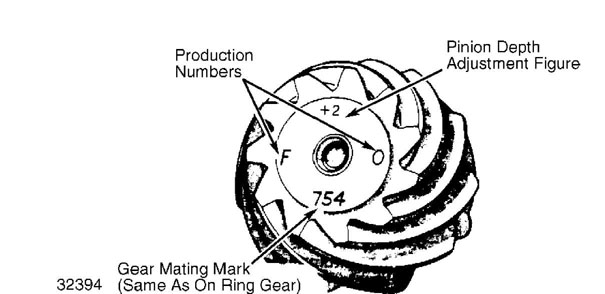

If only pinion shaft and ring gear are to be replaced and

carrier housing can be reused, compare pinion depth adjustment numbers

etched in faces of old and new pinion heads. See Fig. 10. Using

PINION DEPTH SHIM ADJUSTMENT SPECS table, correct shims can be

selected for new pinion shaft depth adjustment.

Fig. 10: Location of Pinion Gear Markings W/ Depth Adjustment Figures

NOTE: In order to use PINION DEPTH SHIM ADJUSTMENT SPECS table, old pinion shaft shim pack dimensions MUST be determined accurately. If original pinion shaft shim pack dimension cannot be determined accurately, Pinion Depth Gauge Set (D-271) must be used to properly determine pinion depth setting. Depth gauge set must also be used if new carrier housing is to be used.

PINION DEPTH SHIM ADJUSTMENT SPECS

PINION DEPTH SHIM ADJUSTMENT CHART (INCHES)

Old Pinion Marking | New Pinion Marking | ||||||||

-4 | -3 | -2 | -1 | 0 | + 1 | +2 | + 3 | + 4 | |

+ 4 | +0.008 | +0.007 | +0.006 | +0.005 | +0.004 | +0.003 | +0.002 | +0.001 | 0 |

+ 3 | +0.007 | +0.006 | +0.005 | +0.004 | +0.003 | +0.002 | +0.001 | 0 | -0.001 |

+2 | +0.006 | +0.005 | +0.004 | +0.003 | +0.002 | +0.001 | 0 | -0.001 | -0.002 |

+ 1 | +0.005 | +0.004 | +0.003 | +0.002 | +0.001 | 0 | -0.001 | -0.002 | -0.003 |

0 | +0.004 | +0.003 | +0.002 | +0.001 | 0 | -0.001 | -0.002 | -0.003 | -0.004 |

-1 | +0.003 | +0.002 | +0.001 | 0 | -0.001 | -0.002 | -0.003 | -0.004 | -0.005 |

-2 | +0.002 | +0.001 | 0 | -0.001 | -0.002 | -0.003 | -0.004 | -0.005 | -0.006 |

-3 | +0.001 | 0 | -0.001 | -0.002 | -0.003 | -0.004 | -0.005 | -0.006 | -0.007 |

-4 | 0 | -0.001 | -0.002 | -0.003 | -0.004 | -0.005 | -0.006 | -0.007 | -0.008 |

PINION DEPTH SHIM ADJUSTMENT CHART (MILLIMETERS)

Old Pinion Marking | New Pinion Marking | ||||||||

-10 | -8 | -5 | -3 | 0 | + 3 | + 5 | + 8 | + 10 | |

+ 10 | + 0.20 | + 0.18 | + 0.15 | + 0.13 | + 0.10 | + 0.08 | + 0.05 | + 0.03 | 0 |

+ 8 | + 0.18 | + 0.15 | + 0.13 | + 0.10 | + 0.08 | + 0.05 | + 0.03 | 0 | -0.03 |

+ 5 | + 0.15 | + 0.13 | + 0.10 | + 0.08 | + 0.05 | + 0.03 | 0 | -0.03 | -0.05 |

+ 3 | + 0.13 | + 0.10 | + 0.08 | + 0.05 | + 0.03 | 0 | -0.03 | -0.05 | -0.08 |

0 | + 0.10 | + 0.08 | + 0.05 | + 0.03 | 0 | -0.03 | -0.05 | -0.08 | -0.10 |

-3 | + 0.08 | + 0.05 | + 0.03 | 0 | -0.03 | -0.05 | -0.08 | -0.10 | -0.13 |

-5 | + 0.05 | + 0.03 | 0 | -0.03 | -0.05 | -0.08 | -0.10 | -0.13 | -0.15 |

-8 | + 0.03 | 0 | -0.03 | -0.05 | -0.08 | -0.10 | -0.13 | -0.15 | -0.18 |

-10 | 0 | -0.03 | -0.05 | -0.08 | -0.10 | -0.13 | -0.15 | -0.18 | -0.20 |

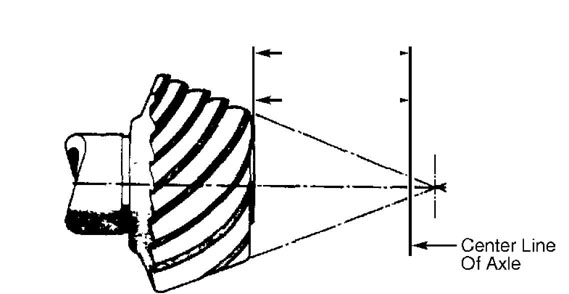

3) The pinion depth adjustment number is determined by manufacturer at time of assembly. Number represents distance best running position of pinion shaft deviates from "nominal" or standard distance between pinion gear face and center line of axle. See Fig. 11.

Axle Pinion Model Setting

60 — 3.125"-» (79.4mm)

70 — 3.500"-» (88.9mm)

32395

Fig. 11: Pinion Setting Standard Dimension

NOTE: Dimensions for Models 44, 61 and 80 not available.

NOTE: These are "nominal" distances from center of ring gear to

face of pinion shaft. Deviations are noted on pinion face.

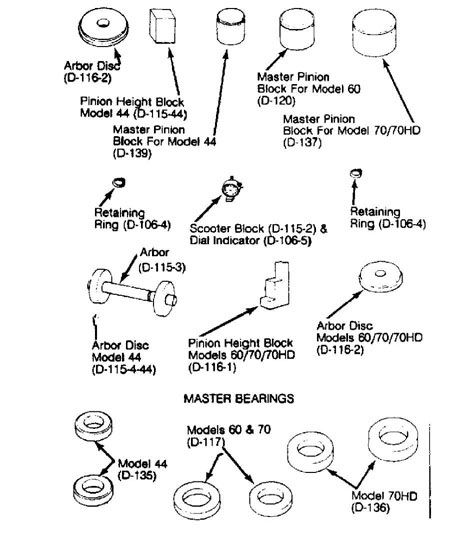

4) Pinion Depth Gauge Set (D-271) allows shim pack adjustments to be made without having to remove and replace differential bearings. See Fig. 12.

28624

Fig. 12: Pinion Depth Gauge Set (D-271)

NOTE: This set can be used on Models 44, 60, 61, 70 and 80. 5) Place differential case in holding fixture or vise.

Lubricate all parts with gear oil. On one-piece case, place side gears and new thrust washers in case. Place differential pinions and new thrust washers in case. Rotate side gears until holes in pinion gears and washers line up with holes in case. Install differential pinion shaft. Install lock pin after aligning hole in shaft with hole in case. Peen edge of hole to keep pin in place.

On 2-piece case, Install side gears and new washers with

pinion gears and cross shaft into half of case that is flanged. Put

top half of case on bottom half. Align scribe marks made before

disassembly. Tighten all bolts finger tight. Tighten bolts alternately

to 65-70 ft. lbs. (88-95 N.m).

On all one and 2-piece case units, inspect ring gear and

case for any burrs or nicks. Install ring gear and tighten NEW ring

gear bolts evenly in alternating pattern to specification.

Install Master Bearings into case. Use (D-135) for Model

44 or (D-117) for Models 60, 61, 70 and 80. Install differential case

in carrier. Install and tighten side bearing caps finger tight over

master bearings. Caps must be in same location as marked during

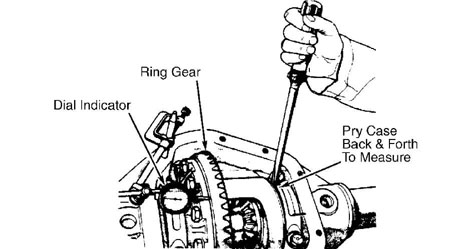

disassembly. Mount dial indicator on carrier with indicator tip

against back of ring gear.

Pry case assembly to one side of carrier. Zero dial

indicator and pry case in opposite direction. See Fig. 13. Record

reading. This indicates thickness of shim pack necessary to eliminate

clearance between case and side bearing races.

10) Actual placement of shim pack and necessary preload will

be calculated after drive pinion is installed and pinion depth has

been determined. Remove dial indicator. Remove bearing caps and

differential case from carrier.

NOTE:

If new differential side and pinion gears are used with new washers, gear backlash should be correct due to close machine tolerances. If old gears and/or washers are used, gear backlash must be checked.

32396

Fig. 13: Measuring Differential Case End Play

NOTE: If original ring and pinion is to be used, measure old shim packs and make up packs of same dimensions with new shims. Baffles are considered part of shim pack.

PINION DEPTH

Depth Gauge Set (D-271) is used to determine pinion depth.

Place Master Pinion Block (D-139 on Model 44; D-120 on Model 60 and

61; D-137 on Model 70; T80T-4020-F42 on Model 80) in pinion bore of

carrier. Put Arbor Discs (D-115-4-44 on Model 44; D-116-2 on Models

60,61 and 70; (T88T-4020-A) on Arbor (D-115-3). Install arbor in

carrier with discs riding in bearing bore.

Put Pinion Height Block (D-115-1-44 on Model 44; D-116-1

on Models 60, 61, 70 and 80) on top of master pinion block with side

against arbor. Place Scooter Block (115-2) with Dial Indicator (D-106-

5) on small step of pinion height block. Zero dial indicator with

scooter block flat on pinion height block.

Move scooter block so dial indicator tip touches arbor.

Move block back and forth (perpendicular to arbor) to get highest

reading. This reading, plus or minus value etched on pinion head, is

thickness of shim pack necessary for pinion bearing.

On Model 80, Use Gauge Tube (D81T-4020-F51) and Gauge

Block (D81T-4020-F56) to determine required thickness of shim pack.

On all models, measure shims separately with micrometer.

If baffle is used, its thickness must be included in shim pack. This

is also true if slinger is used between inner bearing and head of

pinion shaft. Place pinion height shim pack in carrier bore for inner

bearing race. Drive bearing race into carrier, making sure cup is

fully seated.

PINION BEARING PRELOAD

1) Drive outer pinion bearing into carrier housing. Press

inner pinion bearing onto pinion shaft using Press Tube (C-3095-A).

Ensure bearing seats fully. Insert pinion shaft into carrier. Install

outer bearing, slinger (if equipped), flange, washer and nut.

NOTE: Pinion preload shims and oil seal should NOT be installed at this time.

Using an INCH lb. torque wrench, tighten pinion nut until

10 INCH lbs. (1.13 N.m) rotational torque is required to move pinion

shaft. Recheck pinion depth with arbor and discs at this time. Place

pinion height block on face of pinion shaft.

Place dial indicator on small step of height block for

Model 44, 60 and 61 axles. Place dial indicator on high step of block

for Models 70 and 80 axles. Zero dial indicator and move it across

arbor to get highest reading. If reading is within .002" (.05 mm) of

etching on pinion face, pinion depth is correct.

NOTE: If pinion depth is not with .002" (.05 mm) of etched number on face of pinion, shim pack under inner bearing race must be changed before proceeding with differential settings.

4) Remove pinion nut, washer, flange, slinger and outer

bearing. Place preload shims (removed during disassembly) on pinion.

Install bearing and slinger. After lightly coating lips with gear oil,

install pinion seal in carrier housing. Install flange, washer and NEW

pinion nut. Tighten nut to specification. See TORQUE SPECIFICATIONS

table at end of this article.

5) Using an INCH lb. torque wrench, measure preload

(rotational torque) of pinion shaft. Rotational torque required to

keep pinion shaft turning freely and smoothly should be 20-40 INCH lbs. (2.3-4.5 N.m). If preload needs to be increased, remove a few shims and recheck. To decrease preload, add a few shims and recheck. See Fig. 14.

Fig. 14: Carrier Housing Shim Positioning

DIFFERENTIAL BEARING PRELOAD

1) Install differential case in housing with master bearings

on case. Set up dial indicator in same position as when case end play was checked. See Fig. 13. Press ring gear toward pinion head while rocking ring gear so teeth mesh fully. Zero dial indicator while holding ring gear into pinion gear.

Press differential case (ring gear) away from pinion gear.

Repeat until dial indicator gives same reading each time. This figure

is shim pack thickness necessary between case and side bearing on ring

gear side. Remove dial indicator and differential from carrier. Remove

master bearings from case.

Put calculated shim pack on hub of case at ring gear side.

Place side bearing on hub. Use Bearing Installer (C-4025A) and Handle

(C-4171) to drive bearing onto case until it is seated. Take remaining shim pack as determined from case end play measurement and install pack on opposite side of case from ring gear.

4) Add .015" (.38 mm) thickness to shim pack opposite ring

gear to provide side bearing preload. Drive side bearing onto case

with installer and handle. Install spreader and dial indicator on

carrier housing. Spread housing .015" (.38 mm). Put side bearing races

onto side bearings. Install differential case into carrier.

RING & PINION BACKLASH

1) Install side bearing caps, making sure reference marks made on caps and carrier match. Tighten cap bolts to 80 ft. lbs. (108 N.m). Check backlash between ring and pinion gears at 3 points spaced equal distance on ring gear. See Fig. 15.

Fig. 15: Measuring Backlash Between Ring & Pinion Gears

2) Backlash reading between ring and pinion gears should be .004-.009" (.10-.23 mm). Maximum variation between readings at 3 points is .002" (.05 mm). If backlash is too high, move ring gear

closer to pinion gear. If backlash is too low, move ring gear away from pinion gear.

To change backlash readings, move shims from one side of

differential case to other. When backlash adjustment is completed,

check tooth contact pattern. See GEAR TOOTH CONTACT PATTERNS in this

section. Pattern should be correct if assembly and adjustments have

been done properly.

When differential is complete and correctly adjusted,

install new cover gasket and cover. Tighten cover bolts to 30-40 ft.

lbs. (41-54 N.m). Fill assembly with hypoid lubricant.

AXLE ASSEMBLY SPECIFICATIONS TABLE

Application Specifications In. (mm)

Pinion Gear Depth (Nominal Dimension)

Model 44 2.625 (66.68)

Model 60 & 61 3.125 (79.38)

Model 70 & 80 3.500 (88.90)

Ring Gear Backlash 004-.009 (.10-.23)

Side Bearing Preload 015 (.38)

INCH lbs. (N.m) Pinion Bearing Preload

New Bearings 20-40 (2.3-4.5)

Used Bearings 10-20 (1.1-2.3)

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Applications Ft. Lbs. (N.m)

Axle Flange-to-Hub Bolt

Model 44 35 (48)

Models 60 & 61 55 (75)

Model 70 & 80 85 (115)

Pinion Shaft Flange Nut

Models 44 & 70 210 (285)

Models 60 & 61 270 (367)

Model 80 440-500 (597-678)

Ring Gear-to-Case Bolt

Model 44 55 (75)

Models 60, 61, & 70 110 (149)

Model 80 145-165 (196-223)

Side Bearing Cap Bolt 80 (108)

Front Axle

Cherokee, Comanche, & Wagoneer

Axle Shaft Nut 175 (237)

Disconnect Housing Bolt 10 (14)

Hub-to-Knuckle Bolt 75 (102)

Lower Control Arm Bolt 133 (180)

Lower Shock Mount Bolt 14 (19)

Drive Shaft Bolt 14 (19)

Stabilizer Bar Link Bolt 70 (95)

Tie Rod Nut 25-45 (34-61)

Upper Control Arm Bolt 37 (50)

Wheel Lug Nut 75 (102)

Grand Wagoneer

Leaf Spring "U" Bolt Nut 100 (136)

Lower Shock Mount Bolt 45 (61)

Drive Shaft Bolt 16 (22)

Spindle Attaching Nut 65 (88)

Tie Rod Nut 60 (80)

Wheel Lug Nut 80 (108)