TRANSMISSION OVERHAUL

OVERHAUL SERVICE TOOLS

The special tools needed to overhaul the AW 4 transmission are provided in tool kit 6294 (B.Vi.FM. 23). However, ptessure test port adapter 7554 is not in-cludedin this kit and will have to be ordered separately. The overhaul tool kit and test port adapter are available through the parts division and dealer special tool program.

TRANSMISSION DISASSEMBLY

(1) Remove torque converter.

(2) Remove dipstick and both halves of oil filler tube.

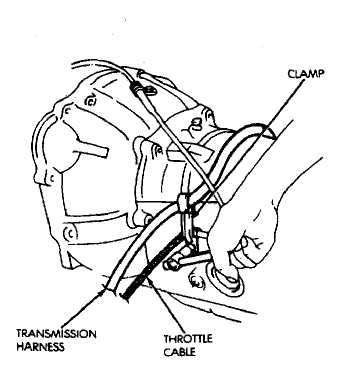

(3) Remove clamp attaching wire harness and throttle pressure cable (Fig. 1) to transmission.

(4) Remove shift lever from manual valve shaft at left side of transmission.

Remove neutral switch.

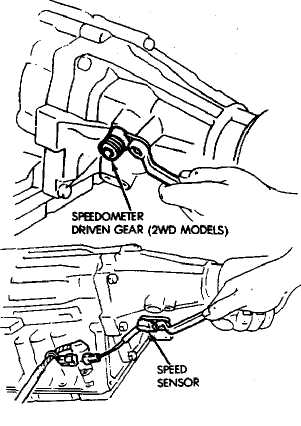

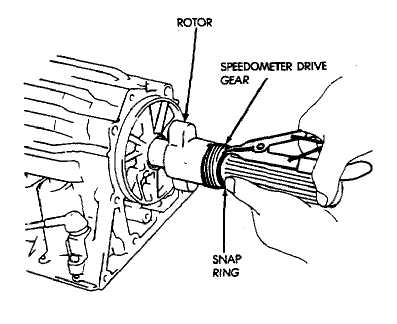

Remove speedometer driven gear (if equipped) and

remove speed sensor (Fig. 2).

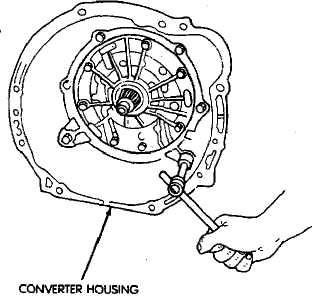

(7) Remuve converter housing bolts and remove housing (Fig. 3) from case.

(8) Remuve extension housing or adapter housing.

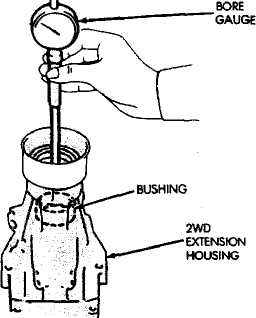

(9) On 2WD models, measure inside diameter of extension housing bushing with cylinder bore gauge or inside micrometer. Diameter should be 38.09 mm

Fig. 2 Removing/Installing Speedometer Driven Gear And Speed Sensor

Fig. 1 Remove Harness And Cable Clamp

Fig. 3 Removing/Installing Converter Housing

(1.4996 in) or less. Replace housing as assembly if inside diameter exceeds specified limit.

Remove the speedometer drive gear snap ring

and remove the gear and gear spacer if equipped (Fig.

5).

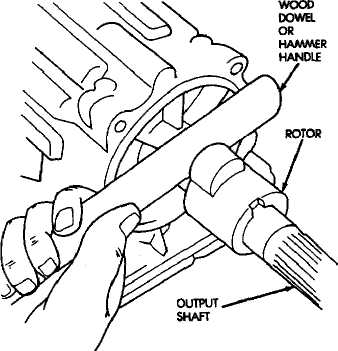

Remove speed sensor rotor and key. Use wood

dowel or hammer handle to loosen and remove rotor

(Fig. 6).

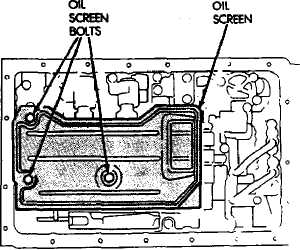

Remove transmission oil pan, oil screen and

screen gaskets'(Fig. 7). Then mount transmission in

holding fixture.

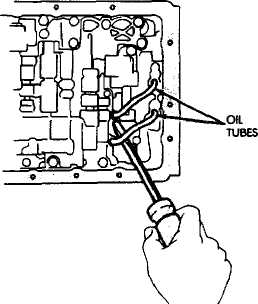

Remove valve body oil feed tubes (Fig. 8).

Disconnect solenoid wires (Fig. 9).

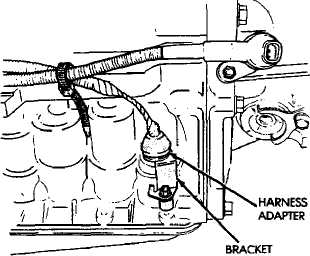

Remove harness bracket bolt and remove harness

and bracket Fig. 10).

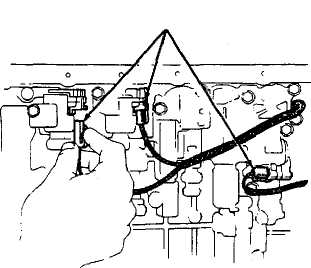

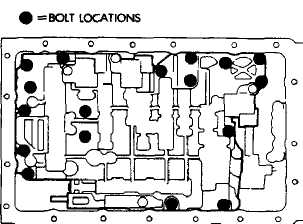

Remove valve body bolts (Fig. 11).

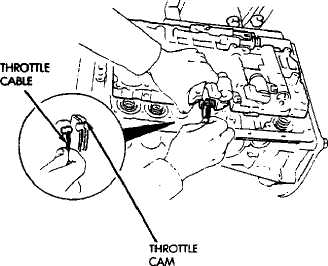

Disconnect throttle cable from throttle cam (Fig.

12).

Fig. 4 Checking Bushing Diameter—2WD Extension Housing

Fig. 6 Removing Speed Sensor Rotor

Fig. 6 Removing Speed Sensor And Speedometer Drive Gear

Fig. 7 Removing Oil Screen

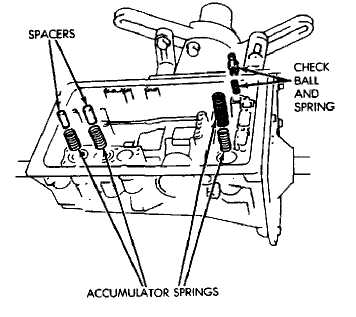

Remove valve body from case. Then remove ac

cumulator springs, spacers and check ball and spring

(Fig. 13).

Remove second brake and clutch accumulator

pistons with compressed air (Fig. 14). Apply air pres

sure through feed port and ease the pistons out of the

bore.

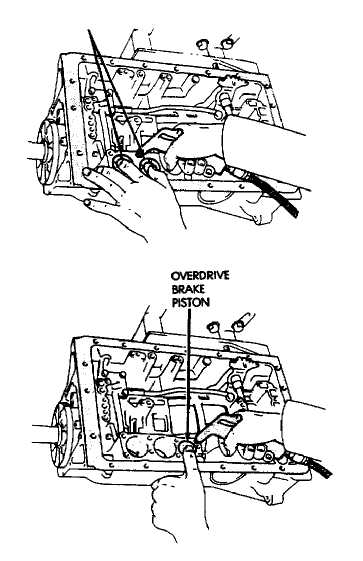

Remove overdrive brake accumulator piston with

compressed air (Fig. 14).

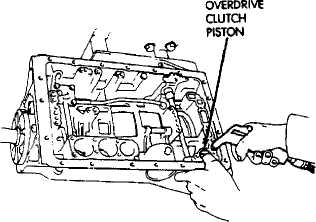

Remove overdrive clutch accumulator piston

with compressed air (Fig. 14).

Remove throttle cable.

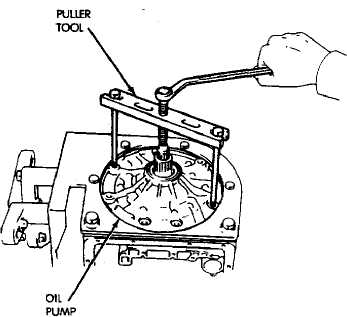

Remove oil pump bolts and remove pump with

bridge-type puller B.Vi. FM. 25 (Fig. 15).

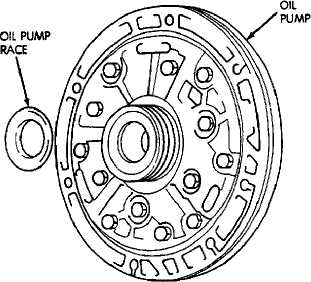

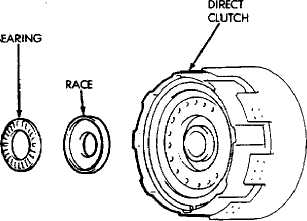

Remove race from oil pump (Fig. 16).

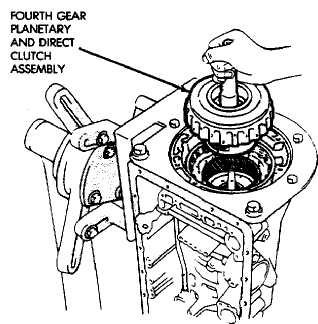

Remove fourth gear overdrive planetary gear and

overdrive direct clutch assembly (Fig. 17).

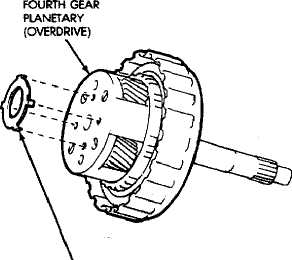

Remove race from fourth gear overdrive plane

tary (Fig. 18).

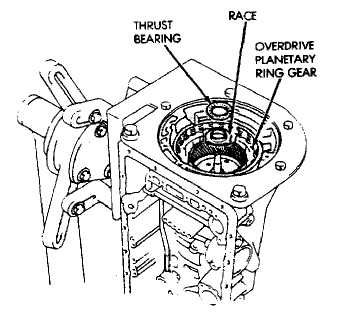

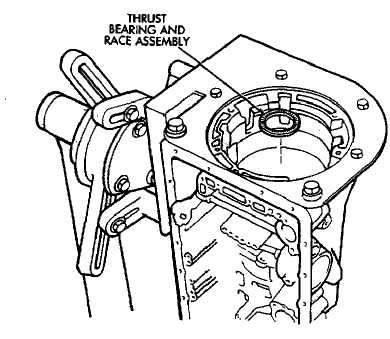

Remove thrust bearing, race and overdrive plan

etary ring gear (Fig. 19).

Measure stroke length of overdrive brake piston

as follows:

Mount dial indicator on case (Fig. 20).

Mount gauge tool B.Vi. FM. 35 so it contacts

piston (Fig. 20).

Fig. 8 Removing Valve Body Oil Tubes

SOLENOID WIRE CONNECTORS

Fig. 10 Removing Bracket And Harness

Fig. 9 Solenoid Wires

Fig. 11 Valve Body Bolt Locations

Apply 57-114 psi air pressure through piston

apply port and note piston stroke on dial indicator.

Stroke length should be: 1.40 -1.70 mm (.055 to .0699

in) on 6-tylinder models and 1.32 -1.62 mm (.0520 to

.0638 in) on 4-cylinder models.

If stroke is not within limits, replace brake

pack retainer. Select required retainer from Over

drive Brake Retainer Selection chart in Specifications

section.

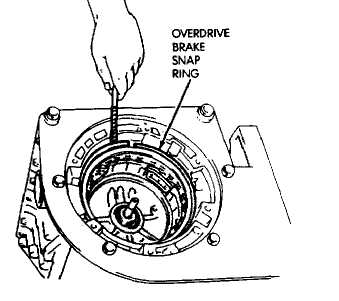

Remove overdrive brake snap ring (Fig. 21).

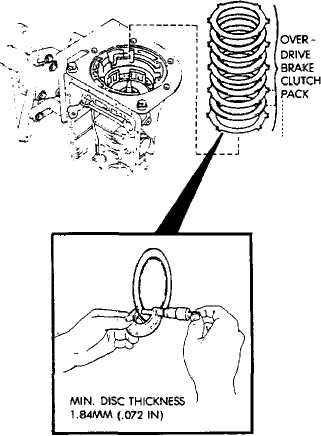

Remove overdrive brake discs and plates (Fig.

221. Then measure disc thickness with a micrometer.

Minimum disc thickness is 1.84 mm (.0724 in). Replace

discs if thickness is less than specified.

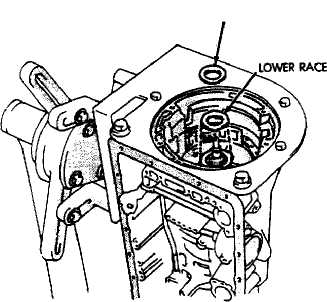

Remove overdrive support lower race (43) and

upper bearing and race assembly (Fig. 23).

Fig. 12 Removing Throttle Cable

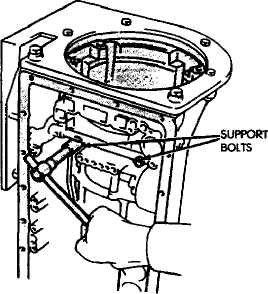

Remove overdrive support bolts (Fig. 24).

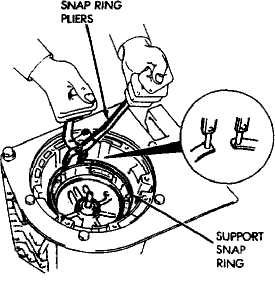

Remove overdrive support snap ring with tool

B.Vi. FM. 29 (Fig. 25).

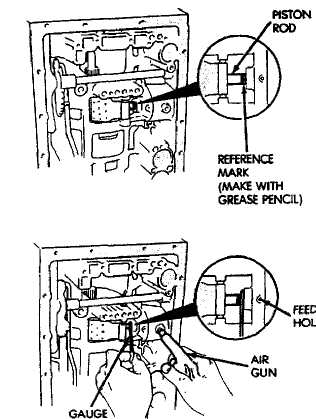

SECOND BRAKE AND CLUTCH PISTONS

Fig. 13 Removing Accumulator Springs-Spacers-Check Ball

31 Fig. 14 Removing Accumulator Pistons

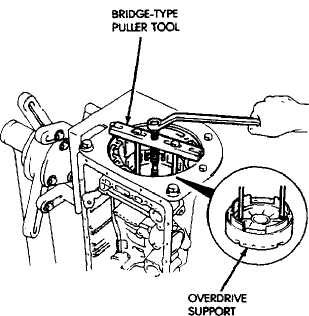

(34i Remove overdrive support (Fig. 261 with bridge-type puller tool B.Vi. FM. 25.

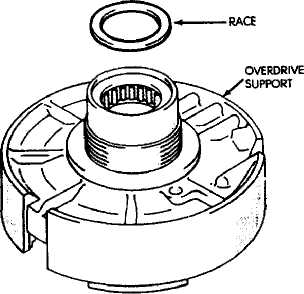

(35»Remove race from hub of overdrive support (Fig. 27).

(36) Measure stroke length of second coast brake piston rod as follows:

Fig. 15 Removing Oil Pump

Make reference mark on piston rod (Fig. 28) as

shown.

Apply 57-114 psi air pressure through piston

feed hole and check stroke length with gauge B.Vi.

FM. 40/41 (Fig. 28).

Stroke length should be 1.5-tc-3.0 mm (.059 to

.118 in).

If stroke length is incorrect, install new piston

rod and recheck stroke. If stroke is still incorrect,

replace second coast brake band.

Replacement piston rods are available in two

different lengths which are: 71.4 mm (2.811 in) and

72.9 mm (2.870 in).

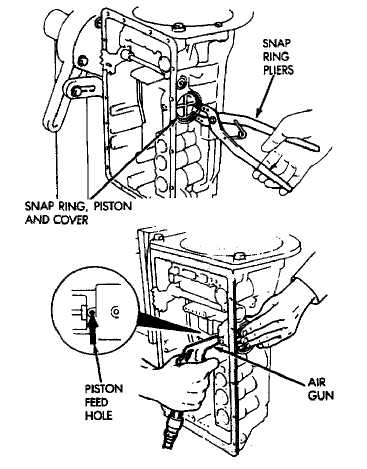

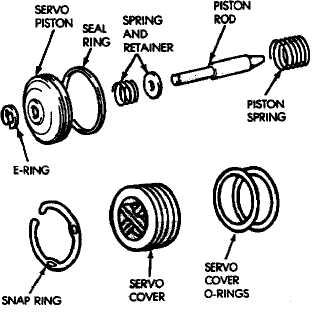

(37) Remove second coast brake piston snap ring with tool B.Vi. FM. 29. Then remove piston cover and piston assembly with compressed air applied through piston feed hole (Fig. 29).

Fig. 17 Removing Fourth Gear Planetary And Direct Clutch Assembly

Fig. 16 Removing Oil Pump Race

32 Fig. 18 Remove Fourth Gear Planetary Race

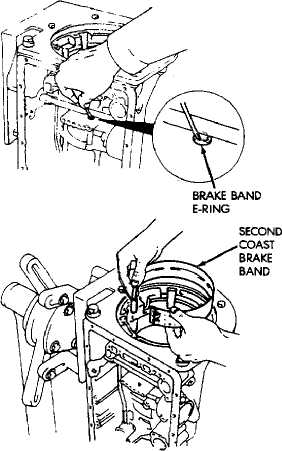

(38) Disassemble second coast brake piston (Fig. 30). (41) Remove the second coast brake band E-ring from

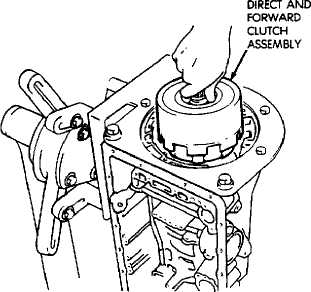

i39l Remove direct and forward clutch assembly (Fig. band pin and remove brake band «Fig. 33).

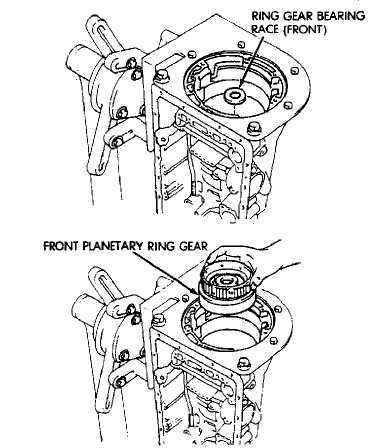

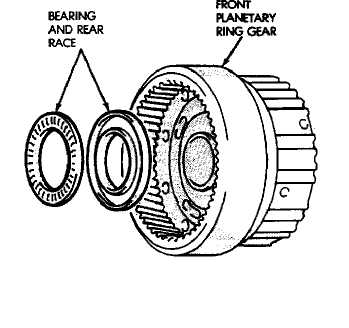

.Ä1 (42) Remove front planetary ring gear front bearing

(40) Remove thrust bearing and race from clutch hub race and remove front planetary ring gear (Fig. 34).

.Fig- 32).

Fig. 21 Remove Overdrive Brake Snap Ring

Fig. 19 Remove Bearing, Race And Planetary Ring Gear

Fig. 22 Remove/Measure Overdrive Brake Disc Thickness

Fig. 22 Remove/Measure Overdrive Brake Disc

Fig. 20 Measuring Overdrive Brake Piston Stroke 33 Thickness

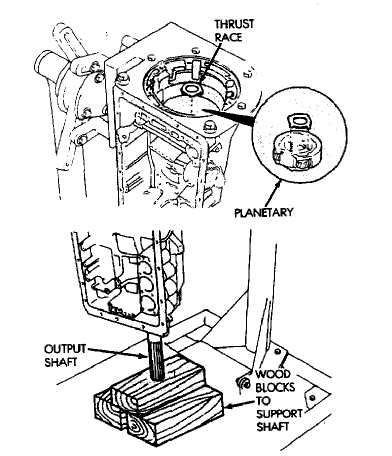

Remove thrust bearing and rear race from ring

gear (Fig. 35).

Remove planetary thrust race (Fig. 36).

Relieve load on planetary snap ring as follows:

Loosen transmission holding fixture. Turn transmis

sion over and allow output shaft to support transmis

sion weight. Place wood blocks under shaft to protect

splines (Fig. 36).

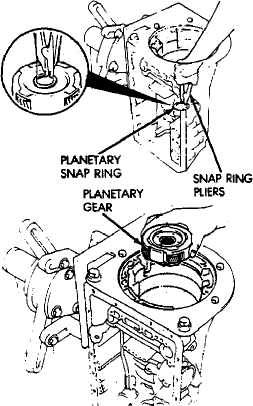

Remove planetary snap ring and remove plane

tary gear (Fig. 37).

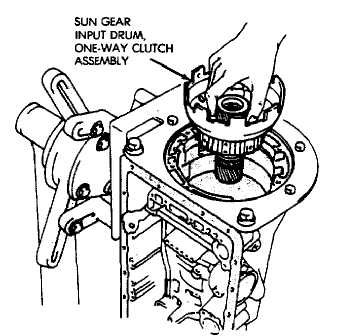

Remove sun gear, input drum and one-way clutch

as assembly (Fig. 38).

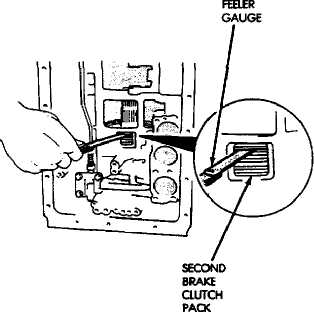

Measure second brake clutch pack clearance (Fig.

39). Clearance should be: .62 to 1.98 mm (.0244 to .0780

in) on six-cyl. transmissions and .89 to 2.15 mm (.0350

UPPER BEARING AND RACE

to .0846 in) on four-cyl. transmissions. Replace discs if clearance is not within specifications.

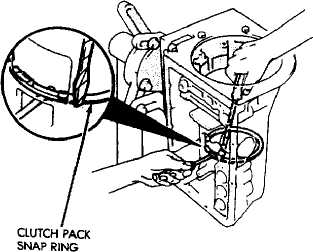

Remove second brake clutch pack snap ring (Fig.

40).

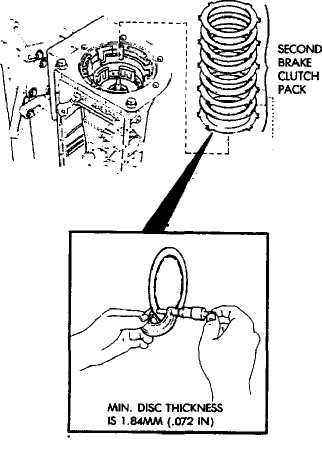

Remove second brake clutch pack (Fig. 41). Mea

sure disc thickness with micrometer. Minimum thick

ness should be 1.84 mm (.0724 in). Replace discs if not

within specfications.

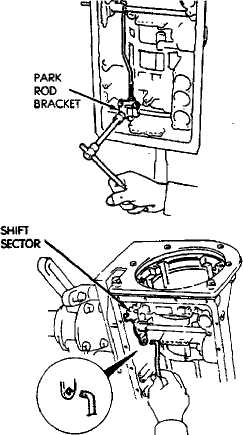

Remove bolts attaching park rod bracket to case.

Then disconnect park rod from manual shaft lever and

remove rod and bracket (Fig. 42).

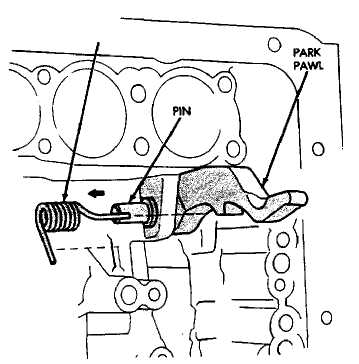

Remove park pawl spring, pin and pawl (Fig. 43).

Fig. 25 Removing/Installing Overdrive Support Snap Ring

Fig. 23 Remove Overdrive Support Bearing/Races

Fig. 23 Remove Overdrive Support Bearing/Races

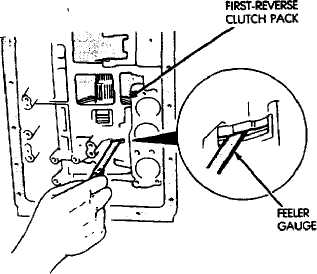

Fig. 26 Removing Overdrive Support

Fig. 24 Remove Overdrive Support Bolts 34 Fig. 26 Removing Overdrive Support(53) Measure clearance of first-reverse brake clutch pack (Fig. 44). Clearance should be: .70 to 2.00 mm (.0276 to .0787 in) îïá-cyl. transmissions and .60 to 1.74 mm (.0236 to .0685 in) on 4-cyl. transmissions. Replace discs if clearance is not as specified.

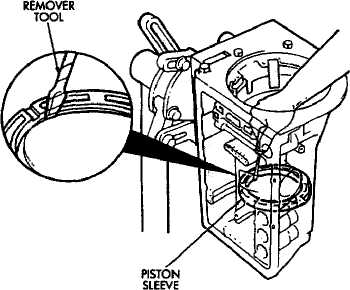

Remove second brake piston sleeve (Fig. 45).

Cover remover tool with tape to avoid damaging case.

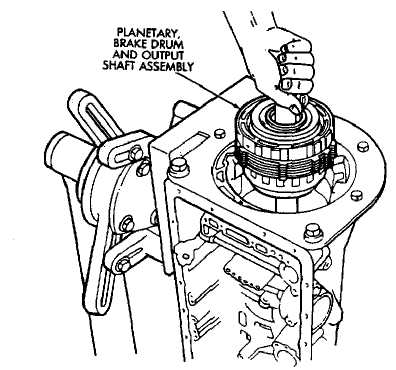

Remove rear planetary gear, second brake drum

and output shaft as an assembly (Fig. 46).

Remove planetary and brake drum thrust bear

ing and race assembly (Fig. 47).

Fig. 27 Remove Overdrive Support Race

Fig. 28 Measuring Second Coast Brake Piston Rod Stroke

Fig. 29 Removing Second Coast Brake Cover And Piston

Fig. 30 Second Coast Brake Piston Components

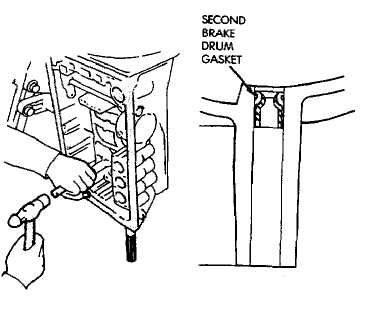

(57) Remove second brake drum gasket from case with

gasket scraper or screwdriver (Fig. 48).

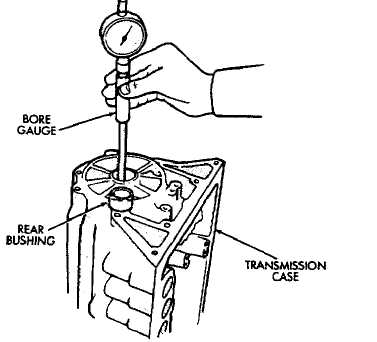

(58) Measure inside diameter of transmission case

rear bushing with bore gauge or inside micrometer (Fig.

49). Maximum allowable diameter is 38.18 mm (1.5031

inl. Replace transmission case if bushing I.D. is

greater than specified. Bushing is not serviceable.

CLEANING-INSPECTION

Clean the transmission components with solvent and dry them with compressed air only. Do not use shop towels or rags.

Blow compressed air through all oil feed passages and channels to be sure they are clear. Inspect the transmission components for wear and damage. Replace components that are damaged or worn beyond the limits specified in the individual overhaul procedures.

Replace all O-rings, gaskets and seals. These compo nents are not reusable. Also replace any snap ring that is distorted or damaged.

During overhaul assembly operations, lubricate the transmission components with Jeep or Mopar Mercon " automatic transmission fluid or petroleum jelly as indicated. Petroleum jelly should be used to prelubricate thrust bearings, washers and races. It can also be used to hold parts in position during assembly.

Soak replacement clutch and brake pack components in transmission fluid for at least 30 minutes before installation.

Fig. 32 Remove Bearing And Race From Clutch Hub

Fig. 33 Removing Second Coast Brake Band

Fig. 31 Removing Direct And Forward Clutch As

sembly 36

Fia. 36 Relieving Load On Planetary Snap Ring

Fig. 34 Removing Front Planetary Ring Gear Fig. 36 Relieving Load On Planetary Snap Ring

Fig. 35 Removing Ring Gear Bearing And Rear Race

Fig. 37 Removing Planetary Snap Ring And Gear

Fig. 40 Removing Second Brake Clutch Pack Snap Ring

Fig. 38 Removing Sun Gear, Input Drum And One-Way Clutch

Fig. 39 Checking Second Brake Clutch Pack Clearance

38

Fig. 41 Remove/Measure Second Brake Clutch Disc Thickness

Fig. 42 Removing Park Rod And Bracket

Fig. 42 Removing Park Rod And Bracket

SPRING 0

Fig. 44 Checking First-Reverse Brake Clutch Pack Clearance

Fig. 45 Removing Second Brake Piston Sleeve

Fig. 43 Removing Park Pawl, Pin And Spring

Fig. 48 Removing Brake Drum Gasket

Fig. 46 Removing Rear Planetary, Second Brake Drum And Output Shaft

Fig. 49 Checking Rear Bushing Inside Diameter

Fig. 47 Removing Planetary And Brake Drum Thrust Bearing And Race Assembly

SUBASSEMBLY OVERHAUL AND TRANSMISSION ASSEMBLY

MANUAL VALVE SHAFT OVERHAUL

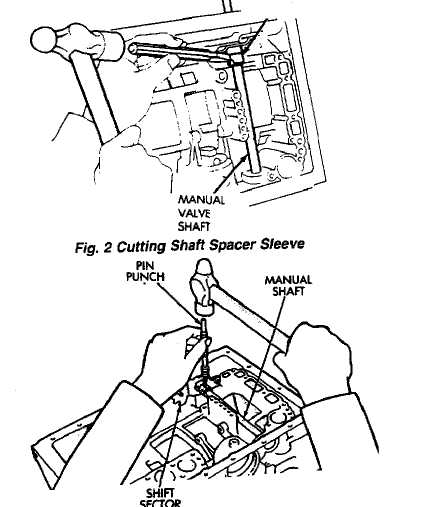

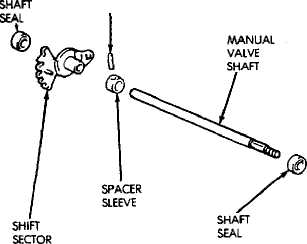

1 11 Remove shaft spacer sleeve in half with chisel and remove it from lever and shaft (Fig. 2).

(2) Remove shift sector retaining pin with pin punch

(Fig. 3).

(3) Pull shaft out of case and remove manual lever.

14) Carefully pry shaft seals from case.

PIN

Fig. 1 Manual Valve Shaft Components

SPACER

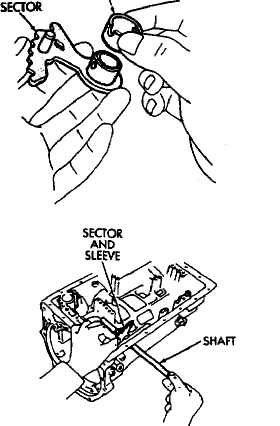

Lubricate new seals with petroleum jelly and in

stall them in case (Fig. 4).

Install new spacer sleeve on shift sector (Fig. 5).

Install sector and sleeve on shaft and install shaft

in case.

Align sector and sleeve and install new retaining

pin.

Align notch in sleeve with depression in sector and

stake sleeve in two places. Be sure lever and shaft rotate

smoothly.

SEAL INSTALLER TOOL

Fig- 4 Installing Manual Shaft Seals

SLEEVE

Fig. 3 Removing/Installing Sector Retaining Pin 41

Fig. 5 Installing Manual Shaft And Sector

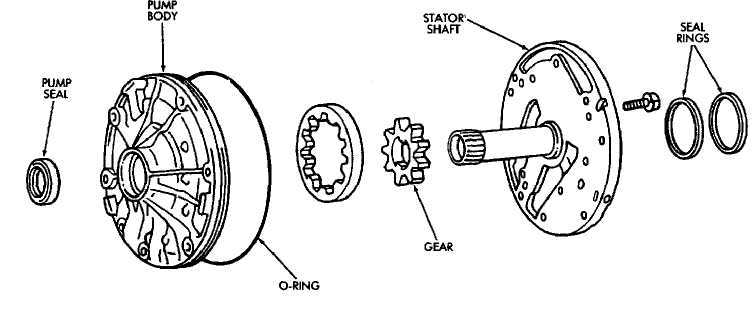

Fig. 1 Oil Pump Components

OIL PUMP OVERHAUL

Remove pump body O-ring (Fig. 1).

Remove pump seal rings (Fig. 1).

Remove bolts attaching stator shaft to pump body

and separate components.

Remove drive gear and driven gear from pump

body (Fig. 1).

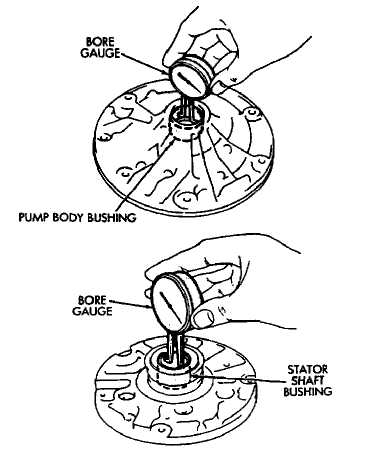

Measure inside diameter of pump body bushing

with bore gauge (Fig. 2). Diameter should be maximum

of 38.19 mm (1.5035 in). Replace pump body if bushing

I.D.- is greater than specified.

Measure inside diameter of stator shaft bushing

(Fig. 2). Take measurements at front and rear of bush

ing. Diameter should be maximum of 21.58 mm (.08496

in) at front and 27.08 mm (1.0661 in) at rear. Replace

stator shaft if bushing diameter is greater than speci

fied.

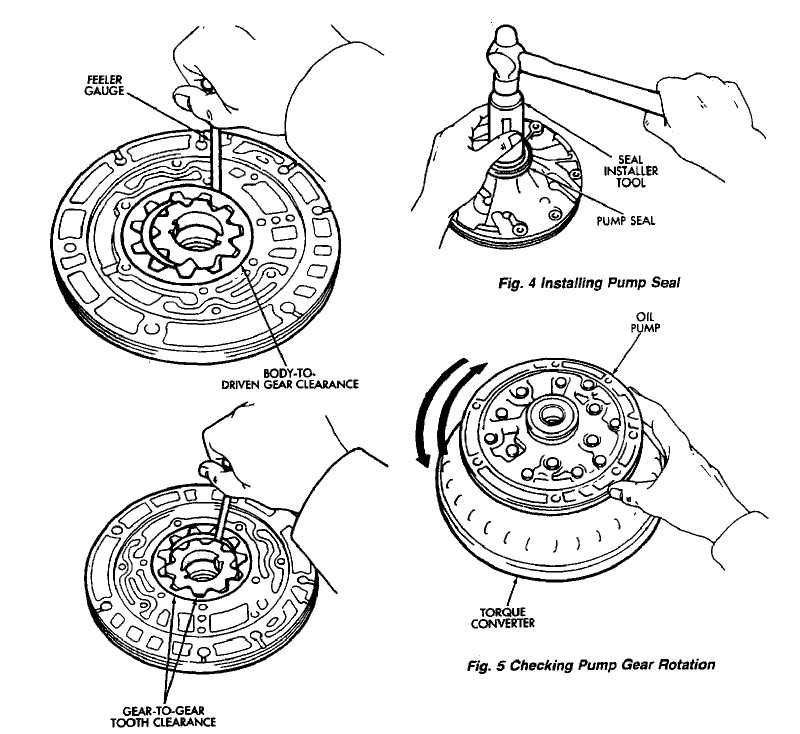

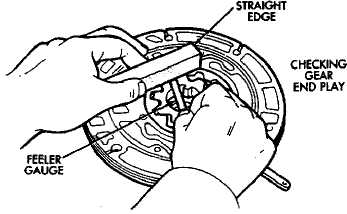

Measure oil pump clearances (Fig. 3).

Clearance between pump driven gear and pump body

should be maximum of .3 mm (.012 in).

Clearance between tips of pump gear teeth should be

maximum of .3 mm (.012 in).

Clearance between rear surface of pump housing and

pump gears should be maximum of 0.1 mm (.004 in).

Replace pump body and gears if any clearance is

greater than specified.

Remove old pump seal. Install new seal with in

staller tool B.Vi. FM. 38 (Fig. 4).

Lubricate and install gears in pump body.

Assemble stator shaft and pump body. Tighten

shaft-to-body bolts to 10 ¹m (7 ft-lbs) torque.

Install new O-ring on pump body and new seal

rings on stator shaft.

Install pump in torque converter and check pump

gear rotation. Gears must rotate smoothly when turned

clockwise and counterclockwise.

Lubricate pump O-ring and seal rings with pe

troleum jelly.

Fig. 2 Checking Pump/Stator Shaft Bushings

Fig.

3 Checking Pump Gear

Clearances 43