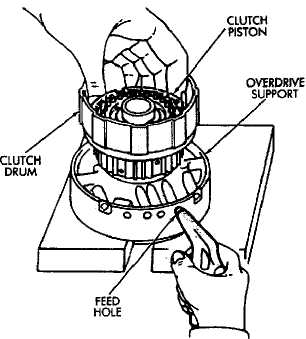

Remount forward clutch drum on overdrive sup

port (Fig. 6).

Apply compressed air through feed hole in sup

port to remove piston (Fig. 6). Use only enough air

pressure to ease piston out of drum.

Remove and discard clutch piston O-rings.

Remove clutch drum O-ring from rear hub (16) of

the drum.

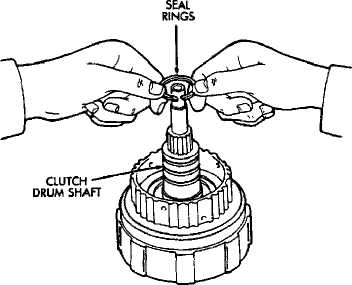

Remove three seal rings from clutch drum shaft

(Fig. 8).

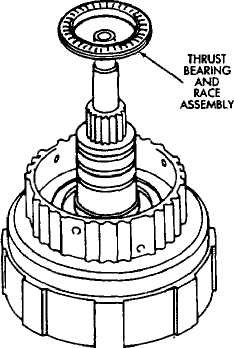

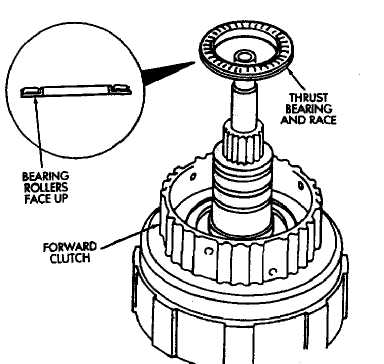

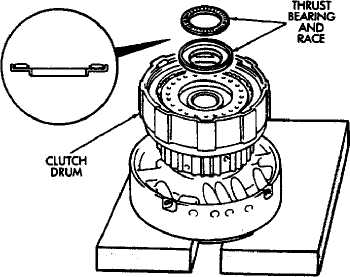

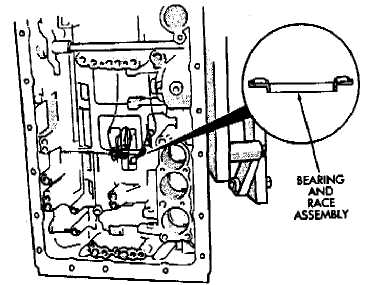

Remove thrust bearing and race assembly from

clutch drum (Fig. 9).

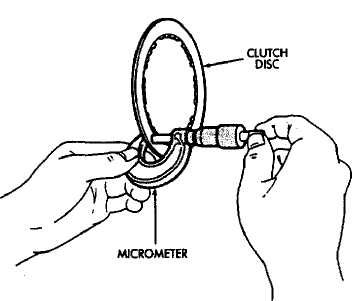

Measure clutch disc thickness (Fig. 10). Mini

mum allowable thickness is: 1.84 mm (.0724 in) on

4-cyl. transmissions and 1.51 mm (.0595 in) on 6-cyl.

transmissions.

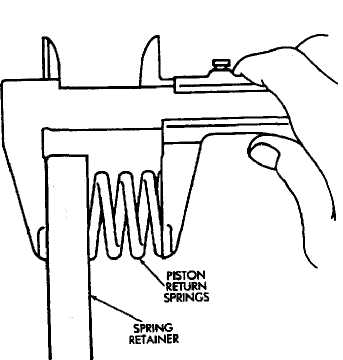

Measure free length of piston return springs with

springs mounted in retainer (Fig. 11). Length should be

19.47 mm (.767 in). Replace springs and retainer if

length is incorrect.

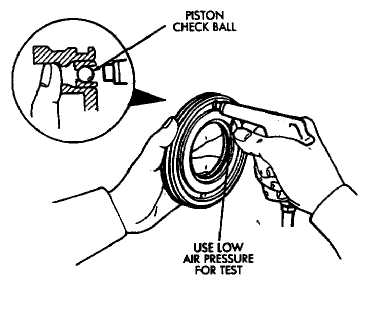

Inspect clutch piston check ball (Fig. 12). Ball

should move freely within piston. Check ball seating by

Fig. 8 Removing Clutch Drum Seal Rings

Fig. 7 Removing/Installing Clutch Drum O-Ring

Fig. 9 Removing Clutch Drum Thrust Bearing Assembly

applying low pressure compressed air to ball feed hole. Ball should seat firmly and not leak air.

(21) Measure inside diameter of bushing in clutch drum hub. Maximum allowable diameter is 24.08 mm (.9480 in). Replace clutch drum if bushing inside diameter is greater than specified.

Forward Clutch Assembly

(1) Lubricate bearing and race assembly with petroleum jelly and install it in clutch drum (Fig. 13). Race side of assembly faces downward and toward drum. Bearing rollers face up (Fig. 13)

Coat new clutch drum shaft seal rings with pe

troleum jelly.Before installing drum shaft seal rings,

squeeze (contract) each ring so ring ends overlap (Fig.

14). This tightens ring making clutch installation eas

ier.

Install seal rings on shaft. Keep rings closed as

tightly as possible during installation. Avoid over

spreading them.

Mount clutch drum on overdrive support.

Lubricate and install new O-ring on clutch drum

hub (Fig. 7).

Fig. 10 Measuring Clutch Disc Thickness

Fig. 11 Checking Return Spring Length 62 Fig- 13 Installing Thrust Bearing And Race

Lubricate and install new O-rings on clutch piston

and install piston in drum.

Install piston return springs.

Compress piston return springs with tool B.Vi.

FM-27 and shop press and install piston snap ring. Be

sure snap ring end gap is not aligned with any notches

in drum.

Install cushion plate in drum. Concave side of plate

faces downward (Fig. 5).

Fig. 14 Installing Clutch Drum Shaft Seal Rings

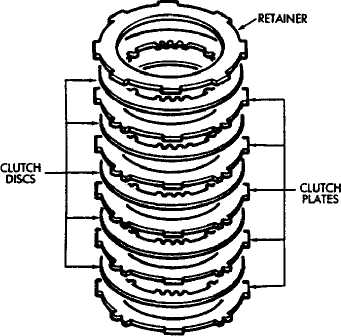

Install clutch discs, plates and retainer (Fig. 15).

Install tabbed plate followed by disc until required

number of plates and discs are installed. Use six plates

and discs in a 6-cyl. transmission and five plates

and discs in a 4-cyl. transmission.

Install clutch pack snap ring.

Recheck clutch piston stroke length using same

method outlined at beginning of disassembly procedure.

If stroke length is not within specified limits, replace

clutch discs.

Lubricate race and bearing with petroleum jelly

and install them in clutch drum (Fig. 16). Be sure bear-

ng rollers face up and race lip seats in drum as shown.

Verify bearing and race size. Outer diameter of

bearing is 46.7 mm (1.839 in). Outer diameter of race is

48.9 mm (1.925 in). Inner diameter of bearing and race

is 26.0 mm (1.024 in).

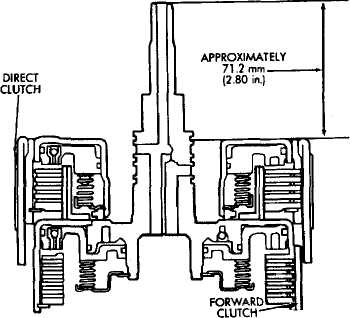

Mount forward clutch on direct clutch and check

assembled height (Fig. 17). Height should be 70.3 to

71.5 mm (2.767 to 2.815 in).

Fig. IS Installing Forward Clutch Discs And Plates

Fig. 16 Installing Thrust Bearing And Pace

Fig. 17 Checking Forward Clutch Assembled Height

FRONT PLANETARY GEAR OVERHAUL

Front Planetary Disassembly

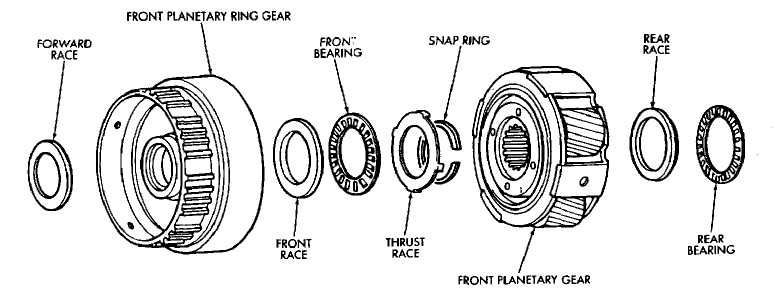

Remove ring gear from planetary gear (Fig. 1).

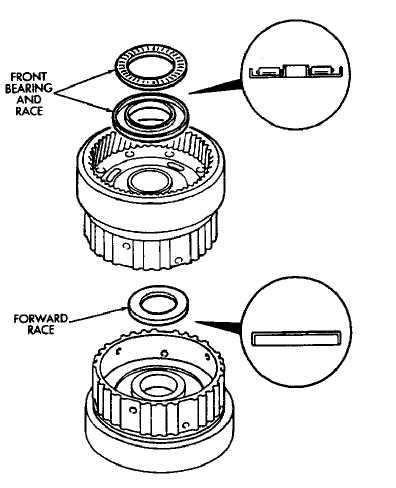

Remove front bearing and the two races from ring

gear (Fig. 1).

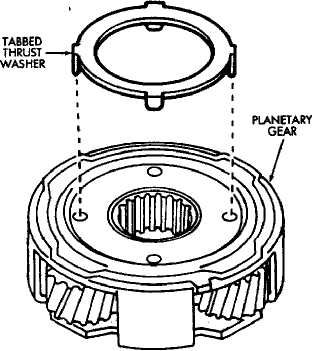

Remove tabbed thrust race from planetary gear

(Fig. 1).

Remove snap ring attaching planetary gear to

shaft and remove gear.

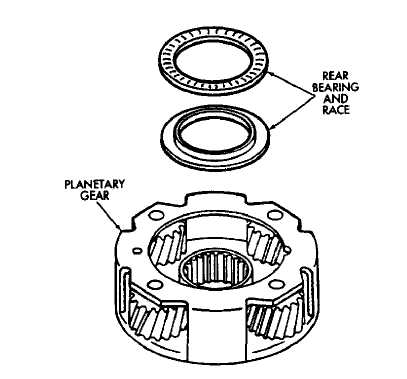

Remove rear bearing and race from planetary

gear.

Measure inside diameter of ring gear bushing.

Maximum allowable diameter is 24.08 mm (.9480 in). Replace ring gear if bushing inside diameter is greater than specified.

Front Planetary Assembly

Lubricate planetary and ring gear bearings and

races with petroleum jelly.

Identify planetary bearings and races before in

stallation. (Fig. 1). Bearings and races can be identified

by following dimensions:

• Outer diameter of rear bearing is 47.7 mm (1.878 in); inner diameter is 35.5 mm (1.398).

Fig. 1 Front Planetary Gear Components

Outer diameter of rear race 47.6 mm (1.874 in); inner

diameter is 33.7 mm (1.327 in).

Outer diameter of front race is 53.6 mm (2.110 in);

inner diameter is 30.5 mm (1.201 in).

Outer diameter of front bearing is 47.7 mm (1.878 in);

inner diameter is 32.6 (1.283 in).

Outer diameter of forward race is 47.0 mm (1.850 in);

inner diameter is 26.5 mm 1.043 in).

Install rear race and bearing in gear (Fig. 2).

Turn planetary over and install race thrust race

(Fig. 3).

Install front race and bearing and forward race in

ring gear (Fig. 4).

Set planetary gear assembly aside for final as

sembly.

Fig. 2 Installing Front Planetary Rear Bearing and Race

Fig. 3 Installing Front Planetary Thrust Race

Fig. 4 Installing Front Planetary Front Bearing And Races ’

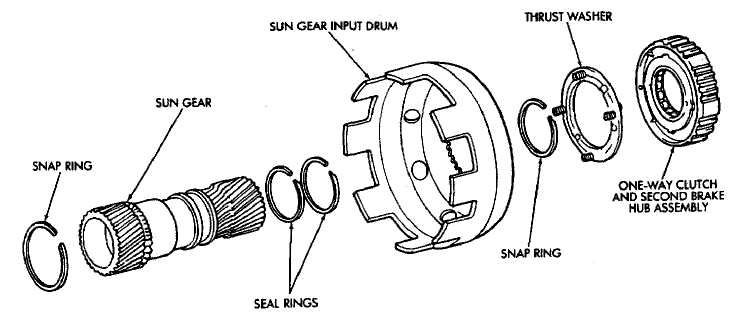

SUN GEAR AND NO. 1 ONE-WAY CLUTCH OVERHAUL

Sun Gear-Clutch Disassembly

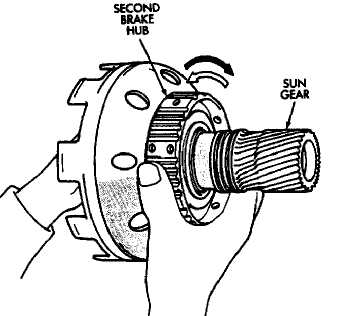

Hold sun gear and turn second brake hub clock

wise and counterclockwise (Fig. 2). Hub should rotate

freely clockwise, but lock when turned counterclock

wise. Replace one-way clutch and hub if it does not

operate properly.

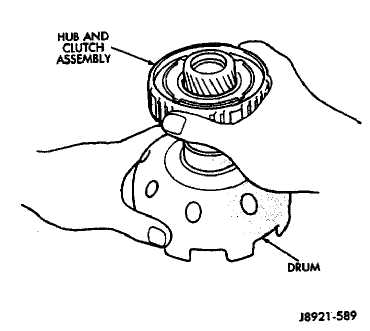

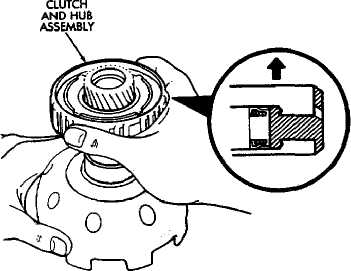

Remove one-way clutch/second brake hub assem

bly from drum (Fig. 3).

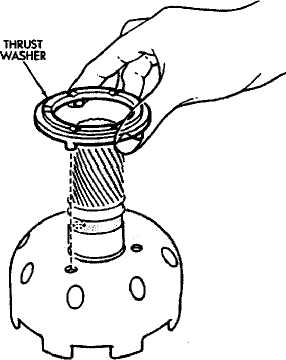

Remove thrust washer from drum (Fig. 4).

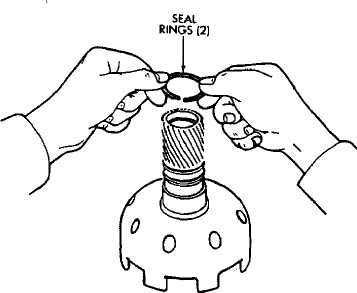

Remove two seal rings from sun gear (Fig. 5).

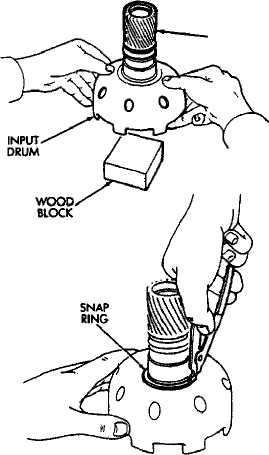

Support sun gear on wood block (Fig. 6). Then

remove first sun gear snap ring and separate drum from

gear.

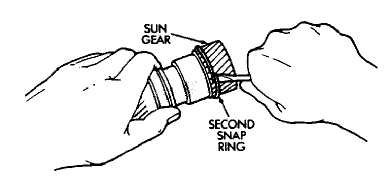

Remove remaining snap ring from sun gear (Fig.

7).

Measure inside diameter of sun gear bushings

with bore gauge or inside micrometer (Fig. 8). Maxi

mum allowable diameter is 27.08 mm (1.0661 in). Re

place sun gear if bushing inside diameter is greater

than specified.

Sun Gear-Clutch Assembly

(1) Install first snap ring on sun gear.

Fig. 1 Sun Gear And One-Way Clutch Components

Fig. 3 Removing/Installing Brake Hub And Clutch Assembly

Fig. 2 Checking One-Way Clutch Operation

I

(2) Install sun gear in drum and install remaining snap ring.

C3) Coat replacement seal rings with petroleum jelly and install them on sun gear. Be sure seal ring ends are interlocked.

Install thrust washer. Be sure washer tabs are

seated in drum slots.

Install one-way clutch/second brake hub assembly

on sun gear. Deep side of hub flange faces upward (Fig

9).

Check one-way clutch operation again (Fig. 2).

Hold sun gear and turn second brake hub clockwise and

counterclockwise. Hub should turn clockwise freely, but

lock when turned counterclockwise.

Set sun gear/clutch assembly aside for final as

sembly.

Fig. 4 Removing/Installing Thrust Washer

SUN GEAR

Fig. 6 Removing/Installing Sun Gear

Fig. 7 Removing/Installing Second Snap Ring

Fig. 9 Installing Clutch And Hub Assembly

Fig. 8 Checking Sun Gear Bushings

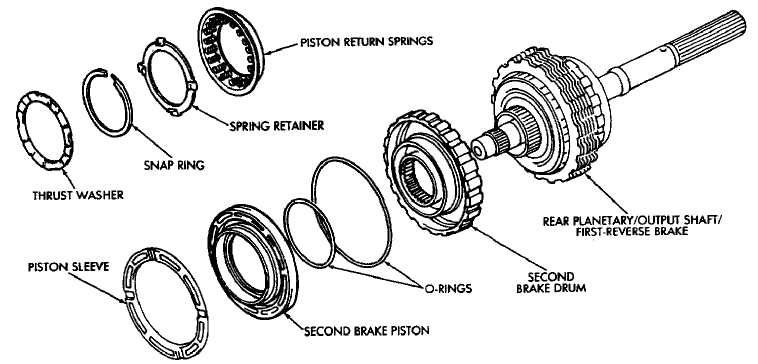

SECOND BRAKE OVERHAUL

Brake Disassembly

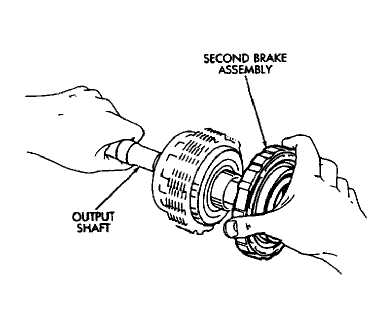

Remove second brake drum from output shaft (Fig.

2).

Set output shaft assembly aside for overhaul. Refer

to Rear Planetary Gear and Output Shaft Overhaul

procedures.

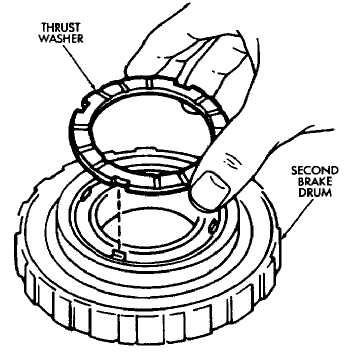

Remove thrust washer from second brake drum

(Fig. 3).

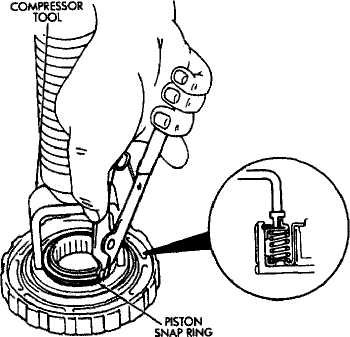

Compress piston return springs with tool B.Vi.

FM-27 and shop press. Then remove piston snap ring

(Fig. 4).

Remove compressor tool and remove spring re

tainer and return springs.

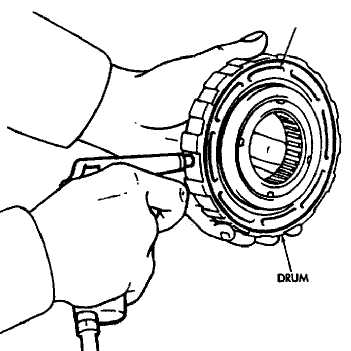

Remove second brake piston and sleeve from drum

with compressed air (Fig. 5). Use only enough air pres

sure to ease piston out of drum.

Remove and discard brake piston O-rings.

Fig. 1 Second Brake Components

Fig. 2 Removing/Installing Second Brake Assembly

Fig. 3 Removing/Installing Drum Thrust Washer

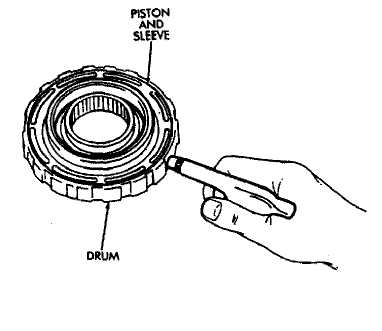

(4) Check brake piston operation with low pressure compressed air (Fig. 7). Apply air pressure through feed hole in drum. Piston should move smoothly when ap-plying-releasing air pressure.

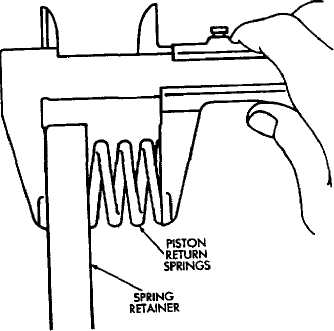

(8) Measure free length of piston return springs with (4) Check brake piston operation with low pressure

springs mounted in retainer (Fig. 6). Length should be compressed air (Fig. 7). Apply air pressure through feed

16 05 mm (.632 in). Replace return springs if length is hole in drum. Piston should move smoothly when ap-

less than specified. plying-releasmg a.r pressure.

Second Brake Assembly

Lubricate and install new O-rings on brake piston.

Then install brake piston in drum.

Install return springs and retainer on brake pis

ton.

Compress return springs with tool B.Vi. FM-27

and install piston snap ring.

Fig. 4 Removing/Installing Piston Snap Ring

Ïä. á Measuring Piston Return Springs

¹TON

Fig. 5 Removing/Installing Piston And Sleeve

Fig. 7 Checking Piston Operation

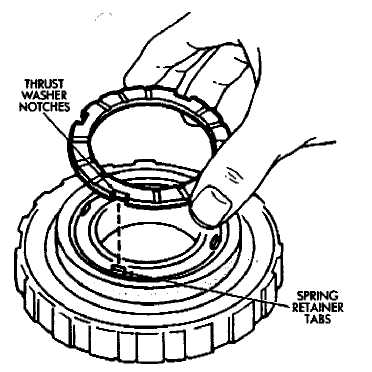

Coat thrust washer with petroleum jelly and in

stall it in drum. Be sure washer notches are aligned

with tabs on spring retainer (Fig. 8).

Set brake components aside for final assembly.

Fig. 8 Installing Thrust Washer

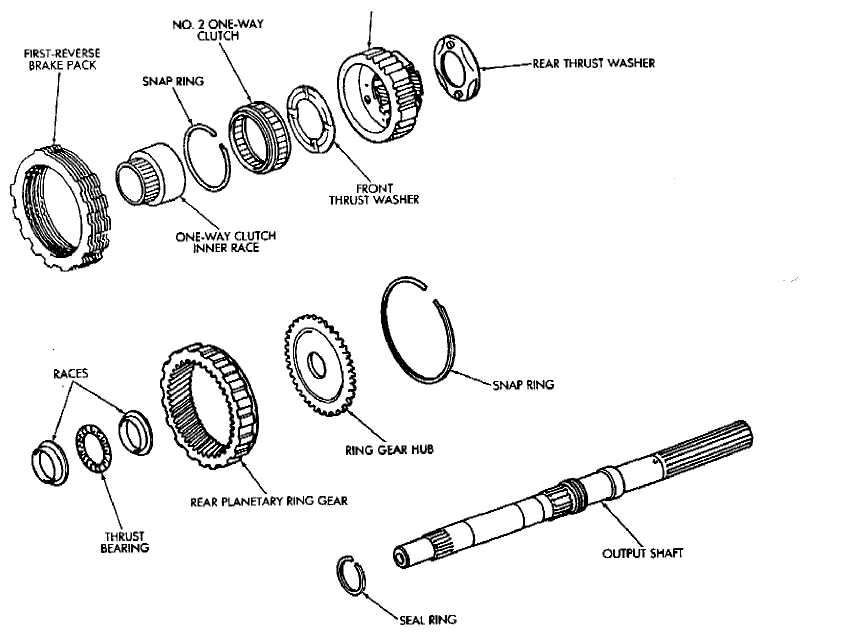

REAR PLANETARY, NO. 2 ONE-WAY CLUTCH AND OUTPUT SHAFT OVERHAUL

REAR PLANETARY GEAR

Fig, 1 Rear Planetary, Brake Peck, Clutch And Output Shaft Components

Planetary-Brake Pack-Shaft Disassembly

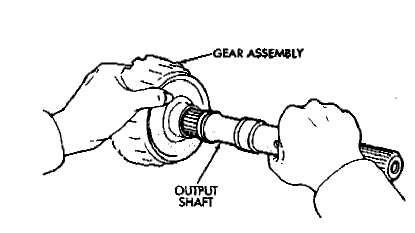

Remove output shaft from gear assembly (Fig. 2).

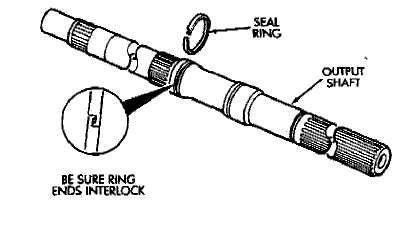

Remove and discard shaft seal ring (Fig. 4).

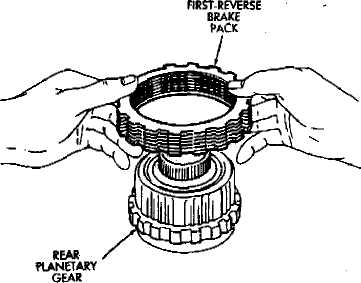

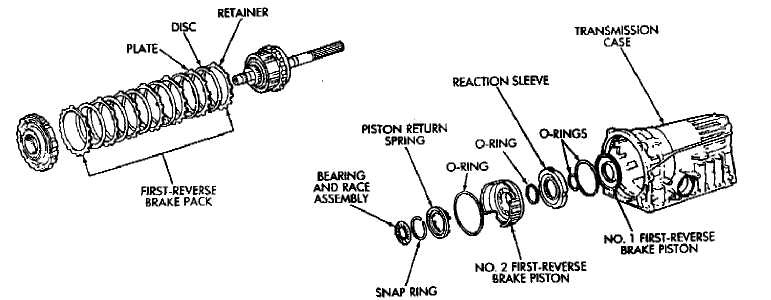

Remove brake pack from planetary gear (Fig. 4).

Measure thickness of each brake pack disc. Min

imum thickness is 1.51 mm (.0594 in). Replace all discs

if any disc is thinner than specified.

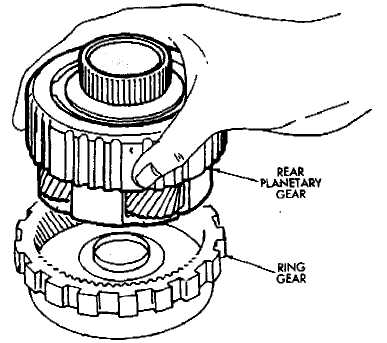

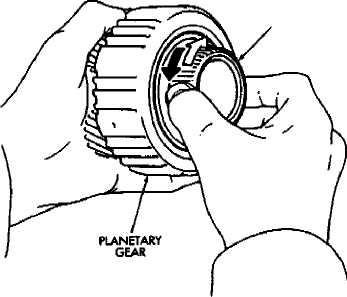

Remove planetary gear from ring gear (Fig. 5).

Check No. 2 one-way clutch. Hold planetary gear

and turn clutch inner race in both directions Race

should turn freely counterclockwise, but lock when

turned clockwise. Replace one-way clutch if necessary.

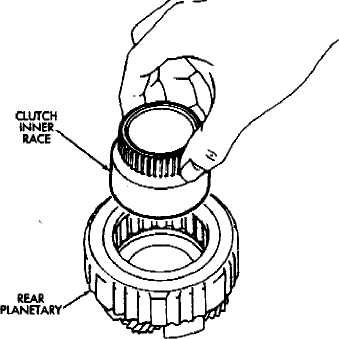

Remove clutch inner race from planetary gear

(Fig. 7).

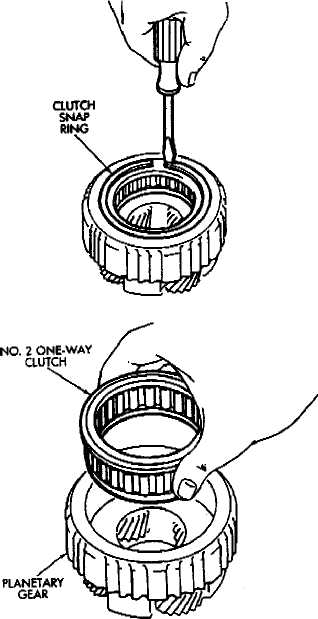

Remove clutch snap ring and remove No. 2 one

way clutch from planetary (Fig. 8).

Remove front and rear thrust washers from plan

etary gear (Fig. 9).

Fig. 2 Removing/Installing Output Shaft

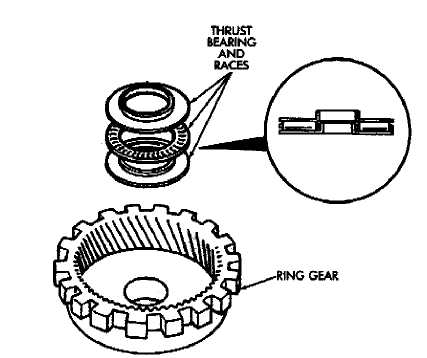

Remove thrust bearing and washers from ring

gear (Fig. 10).

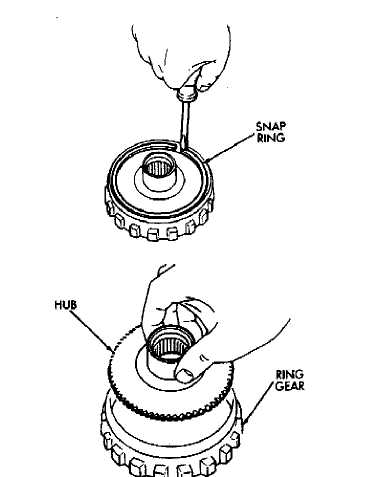

Remove ring gear snap ring and remove ring gear

hub (Fig. 11).

Inspect and replace any worn or damaged plan

etary gear components.

Assembling Rear Planetary, Brake Pack, Clutch And Shaft

Install hub and snap ring in ring gear (Fig. 11)

Identify ring gear thrust bearing and races races

by following dimensions:

Outer diameter of bottom race (Fig. 10) is 44.8 mm

(1.764 in); inner diameter is 27.6 mm (1.087 in).

Outer diameter of bearing (Fig. 10) is 44.7 mm (1.760

in); inner diameter is 30.1 mm (1.185 in).

Outer diameter of upper race Fig. 10) is 44.8 mm

(1.764 in); inner diameter is 28.8 mm (1.134 in).

Fig. 4 Removing/Installing First-Reverse Brake Pack

Fig. 3 Removing/Installing Shaft Seal Ring

Fig. Â Removing/Installing Rear Planetary

Coat planetary thrust washers with petroleum

jelly and install them in gear (Fig, 9).

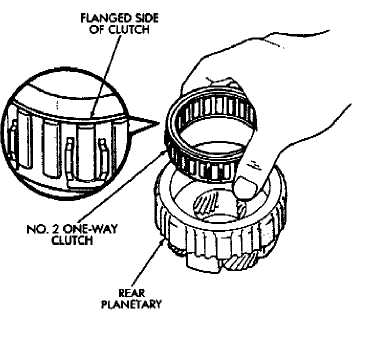

Install No. 2 one-way clutch in planetary gear. Be

sure flanged side of clutch faces upward (Fig. 12).

CLUTCH INNER RACE

(6) Install clutch retaining snap ring and install

clutch inner race (Fig. 7). Turn race counterclockwise to

ease installation.

Fig. 6 Checking No. 2 One-way Clutch Operation

Verify one-way clutch operation. Hold gear and

turn inner race in both directions. Race should turn

freely counterclockwise, but lock when turned clock

wise.

Install planetary gear in ring gear.

Assemble clutch discs and clutch plates (Fig. 4>-

Sequence is disc first, then a plate. Use seven discs

and plates in a 6-cyl. transmission and six discs

and plates in a 4-cyl. transmission.

Install brake pack on planetary gear (Fig, 4).

Install new seal ring on output shaft (Fig. 3). Be

sure ring ends are interlocked as shown.

Set assembled components aside for final assem

bly.

Fig. 7 Removing/Installing Clutch Inner Race

Fig. Â RemovlngJnstellmg One-Way Clutch

Fig. 9 Removing/Installing Rear Planetary Thrust Washers

Fig. 10 Removing/Installing Ring Gear Thrust Bearing And Races

Fig. 11 Removing/installing Ring Gear Hub

Fig. 12 Installing No. 2 One-Way Clutch

FIRST-REVERSE BRAKE PISTON AND TRANSMISSION CASE OVERHAUL

Brake Disassembly-Inspection

Remove bearing and race assembly from trans

mission case (Fig. 2).

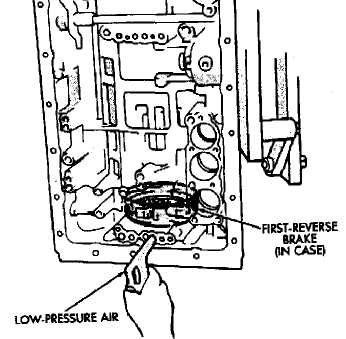

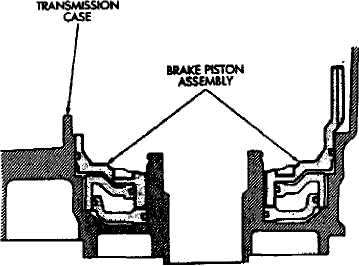

Check first/reverse brake piston operation with

compressed air (Fig. 3). Piston should move smoothly

and not bind or stick- If piston operation is incorrect,

case or piston may require replacement.

Compress piston return springs with tool B.Vi.

FM-28 and remove piston snap ring (Fig. 4).

Remove tool B.Vi. FM-28 and remove piston re

turn springs.

Remove No. 2 first-reverse brake piston with com

pressed air. Apply air through same transmission feed

hole used for checking piston operation.

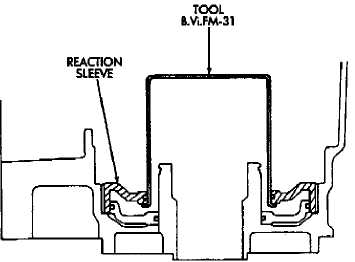

Remove reaction sleeve with tool B.Vi. FM-31 (Pig.

5). Insert tool flanges under sleeve and lift tool and

sleeve out of case.

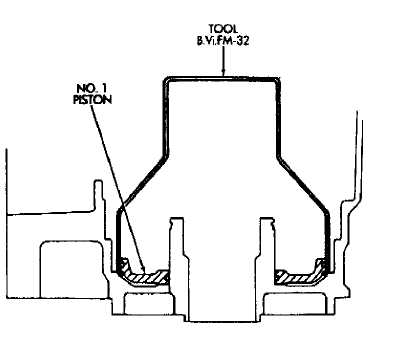

Remove No. 1 first/reverse brake piston with tool

B.Vi. FM- 32 (Fig. 6). Slip tool under piston and lift tool

and piston out of case.

Fig. 1 First-Reverse Brake Pistons And Transmission Case

Fig. 2 Removingflnstalling Bearing And Race Assembly

Fig. 3 Checking First-Reverse Brake Piston Operation

Measure free length of piston return springs with

Measure free length of piston return springs with

springs mounted in retainer. Length should be 18.332

mm (.724 in) Replace springs if length is less than this.

Clean transmission case thoroughly with solvent

and dry it with compressed air. Blow compressed air

through oil feed passages to remove solvent residue and

ensure that passages are clear. Inspect the case for wear

or damage. Replace case if necessary.

Assembling First/Reverse Brake Piston

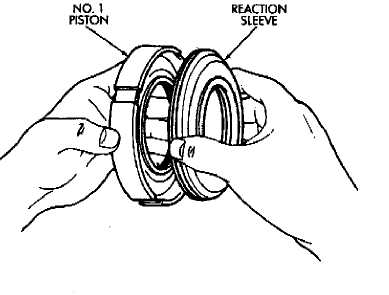

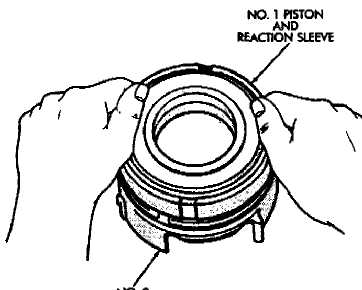

Lubricate and install new O-rings on No. 1 firsts

reverse brake piston and on reaction sleeve (Fig. 7).

Then install piston in sleeve.

Lubricate and install new O-ring on No. 2 brake

piston.

(31 Install assembled No. 1 piston and reaction sleeve on No. 2 piston (Fig. 8).

Lubricate and install piston assembly in case (Fig.

9). Align piston and case slots and press piston assembly

into case with hand pressure.

Position piston return springs on No. 2 piston.

Compress piston return springs with tool B.Vi.

FM-28 and install piston snap ring. Be sure snap ring

end gap is not aligned with any tangs on return spring

retainer.

(7) Verify piston operation with compressed air as

outlined in disassembly procedure.

Fig. 4 Removing/Installing Piston Snap Ring

Fig. 6 Removing/Installing First- Reverse Brake No.1 Piston

Fig. S Removing/Installing Reaction Sleeve

Fig. 7 Assembling Ho. 1 Piston And Sleeve

(8) Coat bearing and race assembly with petroleum jelly and install it in piston assembly (Fig. 2). Bearing

and race assembly outer diameter is 57.7 mm (2.272 in); inner diameter is 39.2 mm (1.543 in).

Fig, 8 Assembling First-Reverse Brake Pistons

Fig. 9 Installing First-Reverse Brake Piaton Assembly

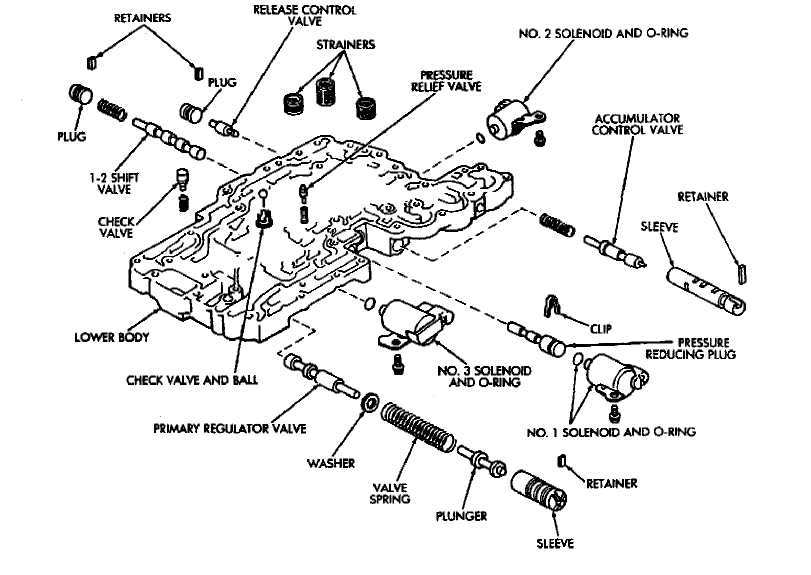

VALVE BODY OVERHAUL

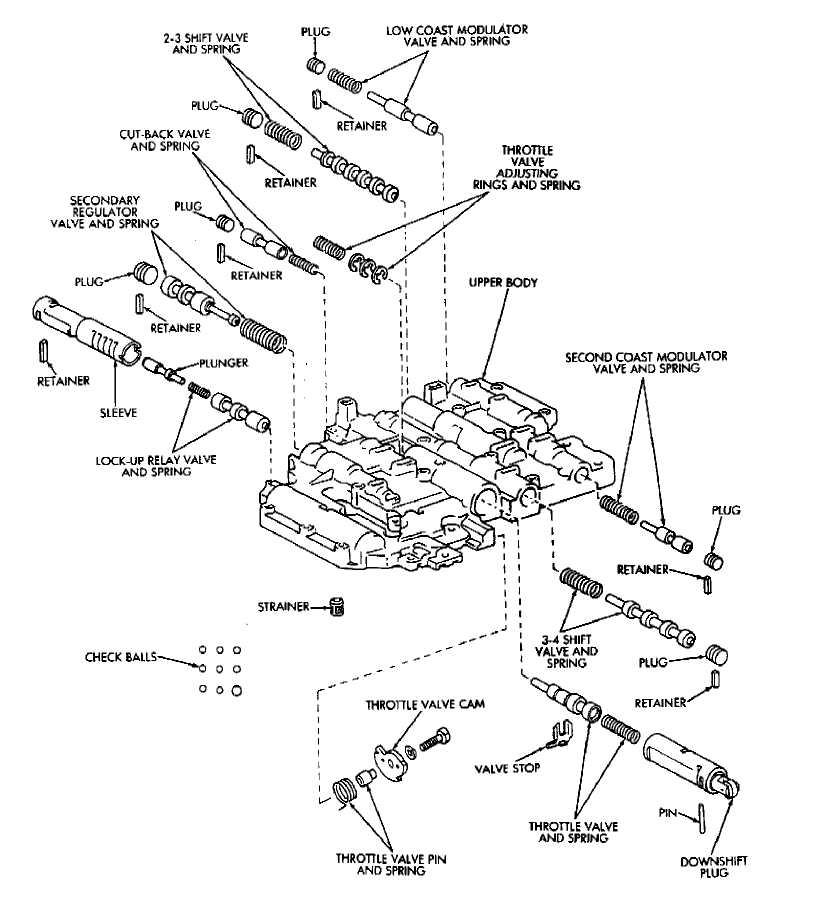

The valve body assembly consists of two sections which are the upper body and lower body (Figures 1 and

2). Disassembly, inspection and overhaul procedures for each section are outlined separately. Refer to the appropriate procedure as needed.

Fig, 1 Lower Body Components (Valve Body)

Fig. 2 Upper Body Components (Valve Body)