1993 Jeep Cherokee

1993 Drive Axles - Differentials - Spicer (Dana) Trac-Lok Cherokee, Grand Cherokee, Grand Wagoneer, Wrangler

DESCRIPTION

The Trac-Lok positive traction differential is a 2-pinion, single-case type. Under normal conditions, torque to each rear wheel is divided evenly. When vehicle is driven on snow, ice or mud, torque will transfer to the wheel with the greatest traction.

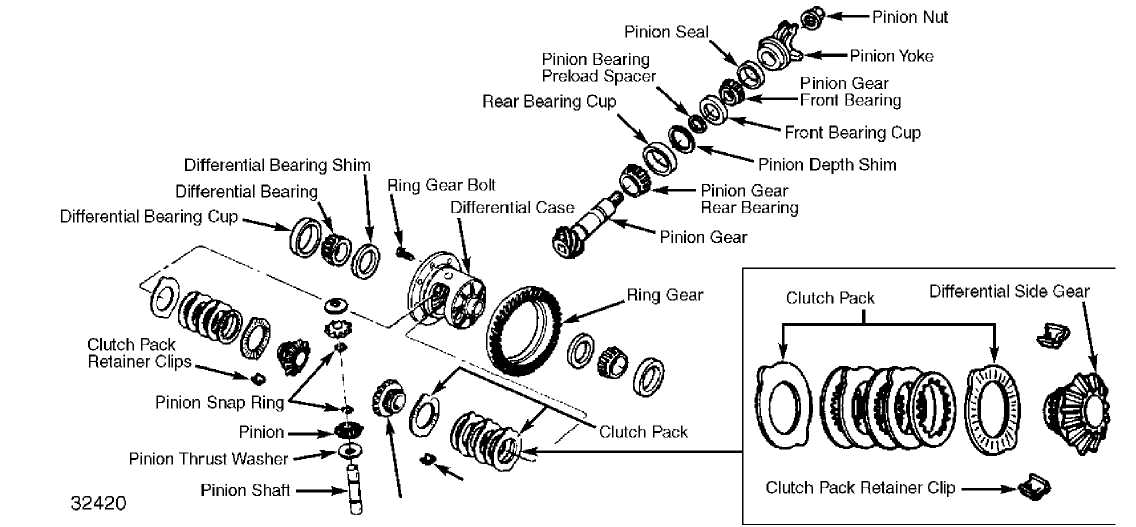

Clutch Pack Retainer Clips Differential Side Gear

Fig. 1: Exploded View Of Trac-Lok Differential Courtesy of Chrysler Corp.

LUBRICATION

NOTE: Use 75W-90 GL-5 plus Trac-Lok additive (friction modifier).

DIAGNOSIS & TESTING

Most common Trac-Lok condition is chatter when turning corners. Incorrect or contaminated oil is usual cause.

Changing axle oil (with Trac-Lok additive) should correct the condition. After changing Trac-Lok differential oil, make 10 or 12 slow figure 8 turns. If chatter persists, clutch packs must be inspected for damage.

REMOVAL & INSTALLATION

NOTE: This article covers overhaul of Trac-Lok (positive traction) unit. For other information, see 7 1/8", 7 9/16" & 8 1/4" RING GEARS article in this section.

OVERHAUL

Disassembly

Using 2 screwdrivers, remove pinion snap rings. Using a

brass drift and a hammer, remove pinion shaft from case. See Fig. 1.

Install Step Plate (C-4487-1) in side gear. Grease centering hole of

step plate. Position Gear Rotator (C-4487-4) in pinion shaft hole.

Coat threads of Forcing Screw (C-4487-2) with oil.

Insert Threaded Adapter (C-4487-3) into side gear opposite

step plate. Insert Forcing Screw (C-4487-2) through threaded adapter.

Thread screw through adapter until it contacts centering hole in step

plate. Tighten forcing screw sufficiently to relieve clutch pack

tension. Remove pinion thrust washers.

Loosen forcing screw until all clutch pack tension is

relieved. Using gear rotator, engage side gear teeth and rotate side

gears until pinions can be removed.

Remove step plate, threaded adapter, gear rotator, forcing

screw, side gears and clutch packs. Remove clutch pack retainer clips.

Mark clutch packs for reassembly reference.

Fig.

Reassembly

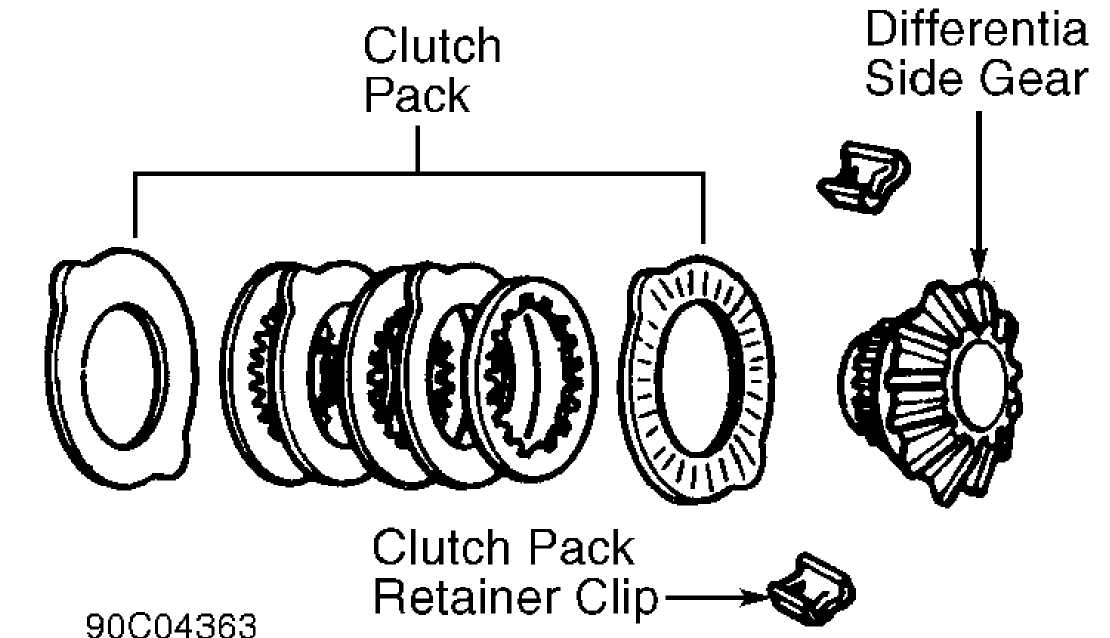

1) Lightly oil clutch discs. Assemble clutch pack discs. See 2. Assemble clutch packs on side gears.

Fig. 2: Identifying Trac-Lok Clutch Pack Assembly Courtesy of Chrysler Corp.

Install clutch pack and side gear in side of case. Ensure

retaining clips remain seated in case pockets. Install step plate in

clutch pack just installed.

Install remaining side gear and clutch pack in case. Hold

assembly in position. Install rotating tool and forcing screw.

Tighten forcing screw and compress clutch packs. Install

pinions. Rotate side gear with tool pawl until each pinion is aligned

with pinion shaft bore.

Install pinion thrust washers. Remove tools. Install

pinion shaft. Install snap rings on pinion shaft. Position ring gear

on differential case. Install NEW ring gear bolts and tighten to 45-60

ft. lbs. (61-81 N.m).