1993 Jeep Cherokee

1993 Drive Axles - Drive Shafts & Universal Joints Cherokee, Grand Cherokee, Grand Wagoneer, Wrangler

DESCRIPTION

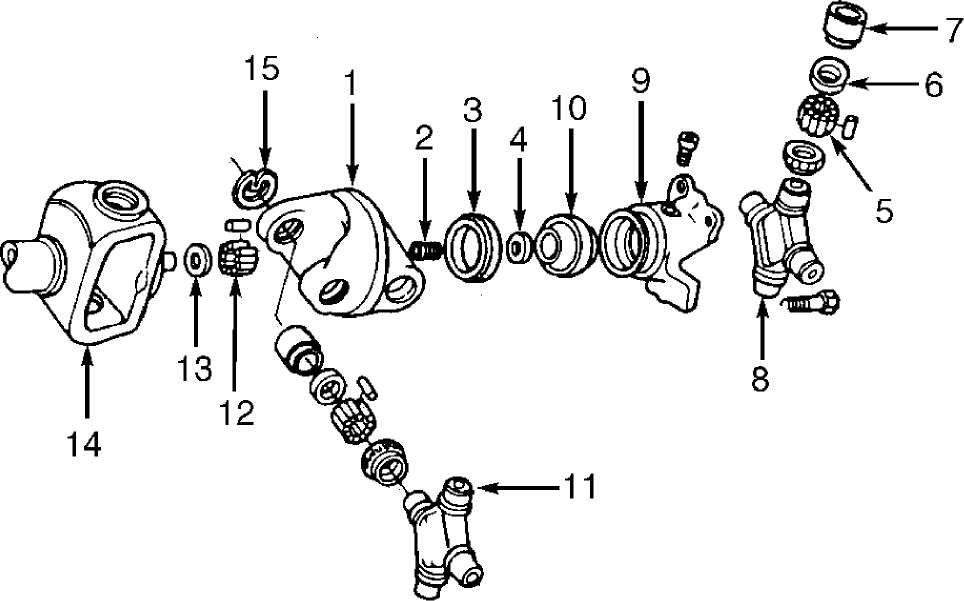

Drive shafts are balanced, one-piece, tubular steel shafts with universal joints at each end. Single Cardan universal joints contain a spider, 4 bearing caps with needle bearings, seals and clips. Double Cardan universal joints contains 2 spiders joined together, 8 bearing caps with needle bearings, seals and clips. See Fig. 1.

Link Yoke

Socket Spring

Socket Ball Retainer

Thrust Washer

Needle Bearings

Seal

Bearing Cap

Rear Spider

Socket Yoke

10. Socket Ball

Front Spider

Needle Bearings

Thrust Washer

Drive Shaft Yoke

Retaining Clip

92A21840

Fig. 1: Exploded View Of Double Cardan Universal Joint Courtesy of Chrysler Corp.

INSPECTION

VIBRATION

Tires & Wheels

Check tire inflation and wheel balance. Check for foreign objects in tread, damaged tread, mismatched treads or tire sizes. Check for tires that are out of round. Replace or repair as necessary.

Engine & Transmission Mounts

Tighten mounting bolts. Replace mounts if soft or separated.

Drive Shaft

Check shaft for damage or dents. Check for undercoating on shaft. If present, clean shaft.

Universal Joints

Check for defective or damaged "U" joints. Check for loose bolts and worn bearings.

DRIVE SHAFT RUNOUT

Remove any dirt from area around shaft where dial indicator is placed. Measure shaft runout about 3" from weld-seam on each end of shaft. With dial indicator mounted perpendicular to drive shaft, rotate shaft several times. Record runout measurement. Repeat the procedure at the opposite end and center of the drive shaft. See DRIVE SHAFT RUNOUT table. If runout is not equal to or less than specification, replace drive shaft.

DRIVE SHAFT RUNOUT TABLE

Application In. (mm)

Front & Rear of Shaft 010 (.25)

Center of Shaft 015 (.38)

DRIVE SHAFT ANGLE

NOTE: If drive shaft angle is excessive, vibration may result.

Check condition of springs, engine and transmission

mounts. Ensure all mounting fasteners are tight. To ensure proper

riding height, fuel tank should be full and vehicle should be empty of

cargo. Raise and support vehicle so suspension bears weight of vehicle

and wheels can rotate freely.

Remove clips from "U" joint cap bore. Ensure bearing caps

are clean. Joint bearing cap to be measured must be straight down.

Place Inclinometer (J-23498-A) on bearing cap. Center bubble in sight

glass. Record measurement. Rotate drive shaft 90 degrees. Repeat

procedure. Subtract smaller figure from larger figure to obtain "U"

joint angle.

Repeat procedure outlined in step 2) at opposite end of

drive shaft. Compare "U" joint angle measurements. Difference of "U"

joint angles MUST be within specification. See UNIVERSAL JOINT ANGLE

table. If not with specification, adjust "U" joint angle. See

SHAFT ANGLE under ADJUSTMENTS.

UNIVERSAL JOINT ANGLE TABLE

Application Specification

Double Cardan Universal Joint 0-2.5 ┬░

Single Cardan "U" Joint 0-1.5

ADJUSTMENTS

SHAFT ANGLE

Front - Except Wrangler

Adjust drive pinion gear shaft angle "A" at the lower

suspension arms with shims. Adding shims will decrease pinion gear

shaft angle "A" but will increase caster angle. See Fig. 2.

Adjustment of angle "A" is more important than caster

angle. When angle "A", angle "B" and vehicle height are correct, angle

"C" will also be correct.

90B04353

90B04353

Fig. 2: Front Drive Shaft Angle Courtesy of Chrysler Corp.

(Except Wrangler)

Front - Wrangler

Raise vehicle and place jack stands under frame. Place a

hydraulic jack under differential housing. Raise jack to support

weight of axle.

Loosen spring "U" bolt nuts, and install tapered shims

between springs and axle spring bracket to correct angle. Tighten

spring "U" bolt nuts to 52 ft. lbs. (70 N.m) for Cherokee or 100 ft.

lbs. (136 N.m) for all others.

NOTE: Adjustment procedure for rear shaft angle not available from manufacturer.

OVERHAUL

NOTE: If joints are rusted or corroded, before disassembly.

apply penetrating oil

SINGLE CARDAN UNIVERSAL JOINT

Disassembly

Scribe or paint marks on yokes and drive shaft for reassembly reference. Remove bearing cap retainer clips. Using sockets and vise as a press, remove bearing caps retaining spider to drive shaft and yoke. Remove spider. Inspect caps for cracks or defective needle bearings. Check spider for scoring or excessive wear. If defective, replace complete unit.

CAUTION: DO NOT place shaft or slip yoke tube in vise. Clamp only the forged portions in vise.

Reassembly

Clean universal joint bores and yoke. Apply grease to yoke

bores, bearing caps, bearings and spider contact surfaces.

Place spider into yoke and tap bearing cap, seal and

bearings into yoke far enough to hold spider. Place a socket (smaller

than cap) on side cap and place in vise.

Tighten vise until caps are seated in yoke. Rotate spider

to make sure no binding occurs. Install cap clips and repeat procedure

on remaining caps.

DOUBLE CARDAN UNIVERSAL JOINT

NOTE: Double cardan universal joints are not serviceable. If defective, replace as an assembly.

Disassembly

1) Scribe or paint marks on yokes and drive shaft for

reassembly reference. Remove bearing cap retainer clips. Using sockets and vise as a press, remove bearing caps retaining front spider to link yoke. Remove drive shaft yoke from link yoke. See Fig. 1.

2) Remove bearing caps retaining rear spider in link yoke.

Remove rear spider and socket yoke from link yoke. Remove bearing caps

retaining front spider in drive shaft yoke. Remove front spider from

drive shaft yoke.

Inspection

Check all component for cracks, scores and excessive looseness. If any defect is found, replace complete "U" joint assembly.

Reassembly

Ensure alignment of reference marks made during

disassembly. Use extreme pressure (EP) lithium grease to aid in

assembly. Place bearing caps on both ends of rear spider and secure

with tape. Spider will mate with transfer case yoke. Assemble socket

yoke and rear spider.

Install rear spider and socket yoke in link yoke. Insert

bearing caps in yoke bores. Using sockets and a vise, press caps into

bores Install retaining clips. Install front spider in drive shaft

yoke. Insert bearing caps in yoke bores. Press caps into bores.

Install retaining clips.

Install thrust washer on drive shaft yoke. Align and

install ball socket on drive shaft yoke. Install front spider in link

yoke. Insert bearing caps in yoke bores. Press caps into bores.

Install retaining clips. Check "U" joint for binding. Install drive

shaft.