Ā

1993 Jeep Cherokee

1989-96 MAINTENANCE

Jeep Maintenance & Service Intervals

Jeep; Cherokee (1989-96), Wagoneer (1989-90)

* PLEASE READ THIS FIRST *

NOTE: All SERVICE SCHEDULES are listed for normal service

vehicles. If vehicle is operated under severe service conditions, see SEVERE SERVICE REQUIREMENTS (PERFORM W/SERVICE SCHEDULES) for items requiring additional maintenance.

NOTE: This article contains scheduled maintenance service

information. Fluid types and capacities listed with each service in this article are only those necessary to perform that scheduled service. For specifications pertaining to fluid capacities for the entire vehicle, fuse and circuit breaker identification, wheel and tire size, battery type, warranty information, or model identification refer to the MAINTENANCE INFORMATION article in this section.

CAUTIONS & WARNINGS

SUPPLEMENTAL RESTRAINT SYSTEM (AIR BAG) (1995-96 Models)

NOTE: See the AIR BAGS article in the ACCESSORIES/SAFETY EQUIPMENT Section.

Modifications or improper maintenance, including incorrect removal and installation of the Supplemental Restraint System (SRS), can adversely affect system performance. DO NOT cover, obstruct or change the steering wheel horn pad in any way, as such action could cause improper function of the system. Use only plain water when cleaning the horn pad. Solvents or cleaners could adversely affect the air bag cover and cause improper deployment of the system.

WARNING: To avoid injury from accidental air bag deployment, read and carefully follow all warnings and service precautions. See appropriate AIR BAGS article in ACCESSORIES/SAFETY EQUIPMENT.

WARNING: The Air Bag System installed on 1995 Cherokee models is a sensitive, complex MECHANICAL unit. Before attempting to remove or install the airbag system or related steering wheel and steering column components you MUST FIRST DISARM the AIR BAG firing mechanism. Failure to follow these procedures could result in accidental deployment and personal injury.

WARNING: The air bag module inflator/sensor assembly contains sodium azide and potassium nitrate. These materials are poisonous and extremely flammable. Contact with acid, water or heavy metals may produce harmful & irritating gases or combustible compounds. DO NOT attempt to dismantle the module or tamper with its arming lever. DO NOT attempt puncture, incinerate, or bring into contact with electricity. DO NOT store at temperatures exceeding 200 F.

WARNING: Replace airbag system components with parts specified in the

Chrysler Mopar parts catalog only. DO NOT mix components in this mechanically-fired airbag with components from ANY electrically-fired airbag system.

WARNING: The fasteners, screws and bolts used in this air bag system have a special coating on them and are specifically designed for use with this air bag system. DO NOT use any kind of substitute.

CAUTION: Disconnect negative battery cable before servicing any air bag system, steering column or passenger side dash component. After any repair, turn ignition key to the ON position from passengerÆs side of vehicle in case of accidental air bag inflation

AIR CONDITIONING MAINTENANCE

WARNING: NEVER add A/C refrigerant to correct a non-cooling problem unless pressure gauges are connected to the system by a certified technician. Lack of cooling may be caused by a restriction, therefore adding refrigerant can cause a dangerous pressure rise.

AIR CONDITIONING SERVICING (1994-96 Models)

CAUTION: Avoid breathing R-134a refrigerant and PAG lubricant vapors, exposure may irritate eyes, nose and throat. To remove R-134a from system use R-134a recycling equipment that meets SAE J2210 specifications. If accidental system discharge occurs, ventilate work area before resuming service.

WARNING: R-134a service equipment or vehicle A/C systems SHOULD NOT be pressure tested or leak tested with compressed air. Some mixtures of air/R134a have shown to be combustible at elevated pressures. These mixtures are dangerous and may cause fire and/or explosions. See AIR CONDITIONING SERVICE article in GENERAL INFORMATION section.

ANTI-LOCK BRAKE SYSTEM (If Equipped)

The anti-lock brake system contains electronic equipment that can be susceptible to interference caused by improperly installed or high output radio transmitting equipment. Since this interference could cause the possible loss of the anti-lock braking capability, such equipment should be installed by qualified professionals.

On models equipped with anti-lock brake systems, ALWAYS observe the following cautions:

DO NOT attempt to bleed hydraulic system without first

referring to the appropriate ANTI-LOCK BRAKE SYSTEM article

in the BRAKES Section.

DO NOT mix tire sizes. As long as tires remain close to the

original diameter, increasing the width is acceptable.

Rolling diameter must be identical for all 4 tires. Some

manufacturers recommend tires of the same brand, style and

type. Failure to follow this precaution may cause inaccurate

wheel speed readings.

Use ONLY recommended brake fluids. DO NOT use silicone brake

fluids in an ABS-equipped vehicle.

BATTERY WARNING

WARNING: When battery is disconnected, vehicles equipped with computers may lose memory data. When battery power is restored, driveability problems may exist on some vehicles. These vehicles may require a relearn procedure. See COMPUTER RELEARN PROCEDURES article in GENERAL INFORMATION section.

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off all lights and accessories to avoid damaging the electrical system. Be sure to use fuse with the correct indicated amperage rating. The use of an incorrect amperage rating fuse may result in a dangerous electrical system overload.

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning that brake pads need replacement.

BRAKE FLUID MAINTENANCE

CAUTION: Any time a hydraulic brake part is removed and/or replaced, the brake system MUST BE flushed. For more information regarding brake maintenance refer toBRAKE SYSTEM article.

BRAKE WARNING LIGHT

CAUTION: If BRAKE warning light is on with parking brake disengaged and engine running, there may be a problem in the hydraulic brake system. Braking effort, brake pedal travel and stopping distances may increase.

CATALYTIC CONVERTER

To prevent catalytic converter overheating, DO NOT allow engine to idle for more than 20 minutes.

COOLANT (PROPYLENE-GLYCOL FORMULATIONS)

To avoid possible damage to vehicle use only ethylene-glycol based coolants with a mixture ratio from 44-68% anti-freeze. DO NOT use 100% anti-freeze as it will cause the formation of cooling system deposits. This results in coolant temperatures of over 300 F (149C) which can melt plastics. 100% anti-freeze has a freeze point of only -8┬░ F (-22C).

CAUTION: Propylene-Glycol Mixtures has a smaller temperature range than Etylene-Gylcol. The temperature ranges (freeze-boil) of a 50/50 Anti-Freeze/Water Mixtures are:

Propylene-Glycol -26 F (-32C) - 257 F (125C) Ethylene-Glycol -35 F (-37C) - 263 F (128C).

CAUTION: Propylene-Glycol/Ethylene-Glycol Mixtures can cause the destabilization of various corrosion inhibitors. Also Propylene-Glycol/Ethylene-Glycol has a different specific gravity than Ethylene-Glycol coolant, which will result in inaccurate freeze point calculations.

COMMAND-TRAC (4WD)

CAUTION: NEVER operate a Command-Trac vehicle in 4WD on dry,

hard-surfaced roads for a sustained period. Use 4L only when needed for added pulling power. Operating vehicle in 4WD mode on such roads will cause stress and possible damage to components, as well as make shifting difficult. To reduce shifting effort, drive vehicle in Reverse for a few feet, or drive off hard-surfaced road momentarily to allow tire slippage.

FRONT AND REAR DIFFERENTIALS (4WD)

CAUTION: DO NOT use water, steam, kerosene or gasoline for flushing a differential. ONLY use a flushing oil.

TRAC-LOK DIFFERENTIALS (4WD)

CAUTION: DO NOT flush a rear axle Trac-Lok differential. Trac-Lok differentials may be cleaned only by disassembling the unit and wiping the components with clean, lint-free cloth.

CAUTION: NEVER attempt to engage Low range when vehicle is moving faster than 2-3 MPH, as transfer case damage may result.

GASOLINE CONTAINING ALCOHOL

CAUTION: Exclusive use of gasohol is not recommended. Vehicle test results have shown that significant fuel system corrosion can result when gasohol is used exclusively.

HALOGEN BULBS

WARNING: Halogen bulbs contain pressurized gas which may explode if overheated. DO NOT touch glass portion of bulb with bare hands. Eye protection should be worn when handling or working around halogen bulbs.

METHANOL GASOLINE

CAUTION: Fuel that is more than 5% methanol should not be used in this vehicle. It can corrode metal parts in the fuel system, and damage plastic and rubber parts. Even at 5% methanol or less, solvents and corrosion preventers must be used with this fuel to avoid these problems.

OIL FILTER

CAUTION: The engine oil filter mount has metric threads. Use of a

filter with improper threads can result in oil leakage and possible engine damage. Look for M20 x 1.5 symbol on the filter.

RADIATOR CAP

CAUTION: Always disconnect the fan motor when working near the

radiator fan. The fan is temperature controlled and could start at any time even when the ignition key is in the OFF position. DO NOT loosen or remove radiator cap when cooling system is hot.

RADIATOR FAN

WARNING: Keep hands away from radiator fan.

WHEEL & TIRE WARNINGS

CAUTION: Replacing original tires with different size tires may

result in false speedometer and odometer indications. Check with dealer before using different size tires on vehicle.

CAUTION: Ensure all 4 wheels on vehicle have same tire size, type and circumference in order to provide proper vehicle handling. DO NOT mix radial-ply with bias-ply or bias-belted tires. On 4WD vehicles, if tire size, type and circumference on all 4 wheels are not the same, gear shifting will be adversely affected and can damage transfer case.

CAUTION: Temporary-use spare tires are for emergency use only. DO

NOT drive vehicle faster than 50 MPH or more than 100 miles when using spare tire. DO NOT operate vehicle in 4WD mode when using spare tire, as damage to transfer case can result. Temporary-use spare tires have a total tread life of 3,000 miles.

TRANSFER CASE

WARNING: DO NOT leave vehicle unattended with transfer case in Neutral without fully applying parking brake. Transfer case Neutral position disengages both axles and will allow vehicle to move regardless of transmission position.

CAUTION: Never attempt to engage Low range when vehicle is moving faster than 2-3 MPH (3-5 KM/H). Transfer case damage may result.

CAUTION: DO NOT operate vehicle in Low range for extended periods on dry, hard surfaced roads. Damage to components and hard shifting may result.

SPARK PLUG REPLACEMENT INTERVALS

Spark plug replacement intervals, if given, are for Original Equipment Manufacturer (OEM) installed or specified plugs. If vehicle is equipped with platinum type or other non-OEM type spark plugs, follow replacement interval specified by spark plug manufacturer.

OXYGEN SENSOR

If vehicle is equipped with an oxygen sensor, replace at 82, 500 miles or when the emissions maintenance reminder light remains on continuously with the key in the ON position, whichever occurs first.

SERVICE POINT LOCATIONS

Fig. 1: Service Point Locations (Typical) Courtesy of Chrysler Corp.

Fig. 1: Service Point Locations (Typical) Courtesy of Chrysler Corp.

50111724

ADDITIONAL SERVICE INFORMATION

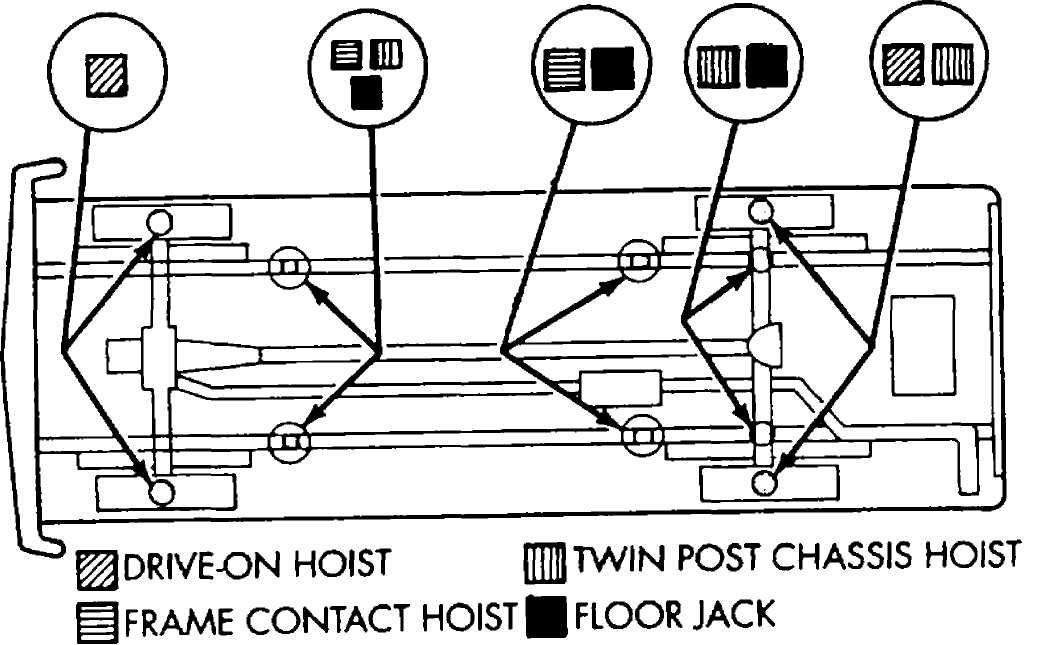

50111732

Fig. 2: Hoist Lift Point Locations Courtesy of Chrysler Corp.

NOTE: For more information regarding jacking and hoisting refer to the JACKING & HOISTING article in the

WHEEL ALIGNMENT section.

50F11721

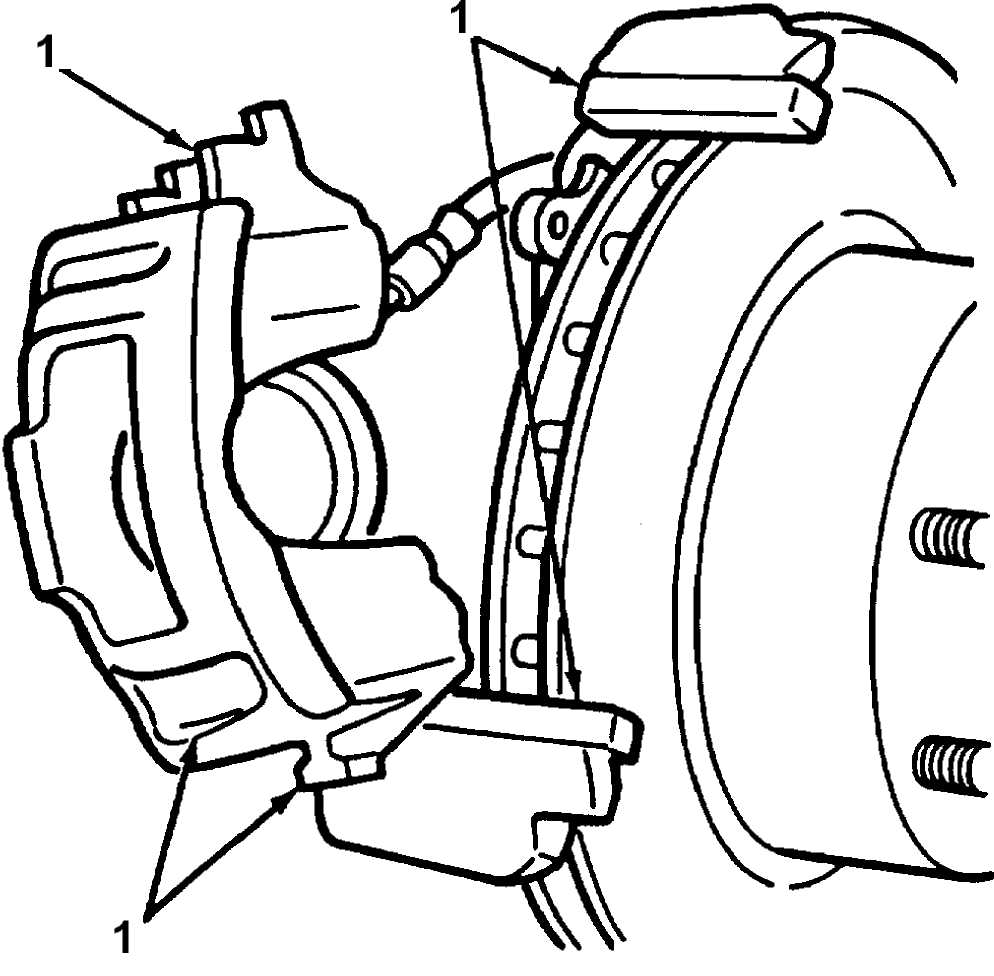

1. LUBRICATION POINTS

Fig. 3: Brake Caliper Lubrication Points Courtesy of Chrysler Corp.

NOTE: For more information regarding brake maintenance refer to the BRAKE SYSTEM article in the BRAKES section.

BUSHING

Fig. 4: Front Disconnect Housing Lubrication Point Courtesy of Chrysler Corp.

50J11733

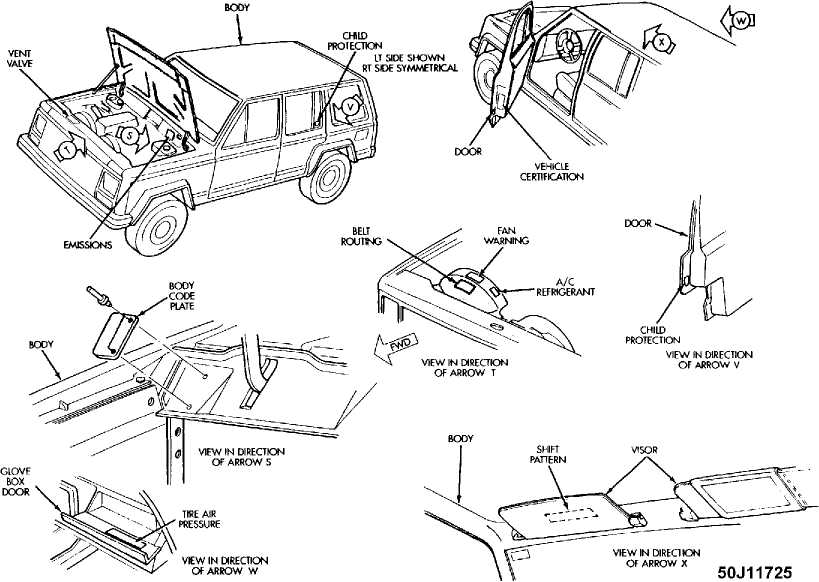

IDENTIFICATION LABEL LOCATIONS

VEHICLE, LABELS AMD PLATES

Fig. 5: Identification Label Locations Courtesy of Chrysler Corp.

SEVERE & NORMAL SERVICE DEFINITIONS

NOTE: Use the Severe Service schedule if the vehicle to be serviced is operated under ANY (one or more) of these conditions:

Service is recommended at mileage intervals based on vehicle operation. Normal Service and Severe Service are based on the following primary operating conditions:

Severe Service

Short Trips (About 15 Miles)

Desert Or Cold Climate Operation

Towing Or Heavily Loaded

Severe Dust Conditions

Hot Weather, Stop-And-Go Driving

Sustained High Speed Driving

Extensive Idling Conditions (Taxi Or Delivery-Type Service)

Driving Off-Road Or In Salty Or Sandy Areas

Operation In Water

Normal Service

Driven More Than 10 Miles Daily

No Severe Service Operating Conditions

SEVERE SERVICE REQUIREMENTS (PERFORM W/SERVICE SCHEDULES)

NOTE: The following services are to be performed on vehicles

subjected to severe service. See SEVERE & NORMAL SERVICE DEFINITIONS. This service is to be performed in addition to the normal services listed in the NORMAL MAINTENANCE SERVICE SCHEDULES.

SEVERE SERVICE CONDITIONS/ACTIONS TABLE

|

Condition |

Action |

Item |

Perform Every (1) |

|

Short Trips (About 15 Miles) |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Desert Or Cold Climate Operation |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Towing Or Heavily Loaded |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Severe Dust Conditions |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Hot Weather, Stop-And-Go Driving |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Sustained High Speed Driving |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Extensive Idling Conditions (Taxi Or Delivery-Type Service) |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Driving Off-Road |

Replace |

4WD: Engine Oil |

50 Hours Of Operation |

|

Service |

Lubricate Front Axle, Steering & Clutch Linkages, Axle & Driveshaft U |

1,000 Miles |

|

|

Service |

Lubricate A/T External Controls |

1,000 Miles |

|

|

Inspect |

Front Wheel Bearings |

1,000 Miles |

|

|

Inspect |

Disc & Drum Brake Systems, Hoses & Lines |

1,000 Miles |

|

|

Service |

Lubricate Brake Caliper Slide Rails |

1,000 Miles |

|

|

Inspect |

Exhaust System For Leaks, Damage, Or Loose Parts |

1,000 Miles |

|

|

Service |

Remove Any Foreign Material Trapped By Exhaust Shielding |

1,000 Miles |

|

Service |

Lubricate Clutch Release Lever Pivot |

1,000 Miles |

|

|

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Operation In Water |

Service |

Lubricate Front Axle, Steering & Clutch Linkages, Axle & Driveshaft U |

Daily |

|

Service |

Lubricate A/T External Controls |

Daily |

|

|

Inspect |

Front Wheel Bearings |

Daily |

|

|

Inspect |

Disc & Drum Brake Systems, Hoses & Lines |

Daily |

|

|

Service |

Lubricate Brake Caliper Slide Rails |

Daily |

|

|

Inspect |

Exhaust System For Leaks, Damage, Or Loose Parts |

Daily |

|

|

Service |

Remove Any Foreign Material Trapped By Exhaust Shielding |

Daily |

|

Service |

Lubricate Clutch Release Lever Pivot |

Daily |

|

|

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

Driving In Salty Or Sandy Areas |

Replace |

Engine Oil |

3,000 Miles or 3 Months |

|

Service |

Lubricate Propeller Shaft Universal Joints If Equipped With Fittings |

3,000 Miles |

|

|

Replace |

Engine Oil Filter |

6,000 Miles or 6 Months |

|

|

Replace |

A/T Fluid |

12,000 Miles |

|

|

Replace |

Front & Rear Axle Fluid |

12,000 Miles |

|

|

Replace |

M/T Oil |

18,000 Miles |

|

|

(1) - Perform these services at the mileage or number of months (since the last time), whichever comes first. |

|||

NORMAL MAINTENANCE SERVICE SCHEDULES

CAUTION: The following service schedules refer to vehicles driven

under normal operating conditions. For vehicles driven under severe conditions, additional services may be necessary. See SEVERE SERVICE REQUIREMENTS (PERFORM W/SERVICE SCHEDULES) above in this article for additional service requirements.

7,500 MILE (12,000 KM) SERVICE

7,500 MILE (12,000 KM) SERVICE

|

Service Or Inspect |

|

|

Check Fluid Levels |

|

|

Inspect Coolant Hoses and Clamps |

|

|

Inspect Brake System |

|

|

Inspect Exhaust System |

|

|

Inspect Underside of Vehicle (Bolts & Threaded Fasteners) |

|

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Rotate Tires and Adjust Air Pressure (Including Spare) |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Engine Oil (2)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Includes Filter.

15,000 MILE (24,000 KM) SERVICE

15,000 MILE (24,000 KM) SERVICE l

Service Or Inspect

Verify Last Major Service Was Performed

Check Fluid Levels

Check Cooling System Hoses and Clamps

Check Coolant Strength

Check Exhaust System & Heat Shielding

Clean Battery and Battery Terminals

Accessory Drive Belts

Inspect Brake System

Inspect Underside of Vehicle (Bolts & Threaded Fasteners)

Inspect C/V Joint boots (4WD)

Check Drive Shaft Seals

Lubricate Ball Joints, Steering Linkage & Suspension

Lube Drive Shaft U-Joints and Slip Splines

Lube Front Axle Drive Joint and Pivot Bearings (4WD)

|

Check/Lube Manual Steering Gear |

|

|

Check Operation of Horn, Wipers/Washers & All Exterior Lights |

|

|

Inspect Condition of Wiper Blades |

|

|

Check Headlight Alignment |

|

|

Check Seat Belt Webbing and Release Mechanisms |

|

|

Check Parking Brake Operation |

|

|

Check Shift/Clutch Interlock Operation |

|

|

Lubricate Weatherstripping with Silicone |

|

|

Lubricate Door Hinges |

|

|

Lubricate Door Locks |

|

|

Check Body Drain Holes |

|

|

Rotate Tires and Adjust Air Pressure |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Engine Oil (5)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Includes Filter.

22,500 MILE (36,000 KM) SERVICE

22,500 MILE (36,000 KM) SERVICE

|

Service Or Inspect |

|

|

Verify Last Major Service Was Performed |

|

|

Check Fluid Levels |

|

|

Check Cooling System Hoses and Clamps |

|

|

Check Exhaust System & Heat Shielding |

|

|

Inspect Brake Hoses |

|

|

Inspect Underside of Vehicle (Bolts & Threaded Fasteners) |

|

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Lube Parking Brake Ratio Lever Pivot |

|

|

Lube Manual Gearshift Control (4WD Transfer Case) |

|

Inspect Front Brake Pads & Rotors

Inspect Rear Brake Linings & Drums

Inspect Brake System Hoses & Lines

Inspect Shocks for Leakage

Inspect Tire Wear Pattern

Rotate Tires and Adjust Air Pressure (Including Spare)

Replace

Engine Oil

Oil Filter

Lubrication Specifications

Application

Specification

Automatic Transmission

30RH (3-Speed) (1) Mopar 7176 ATF PLUS

AW4 (4-Speed) Dexron-IIE/Mercon ATF

Brake Master Cylinder DOT 3 (SAE J-1703F) Brake Fluid

Engine Coolant 50/50 Ethylene-Glycol & Water Mix

Engine Oil (2)

Temperatures Above 0F (-18C) SAE 10W-30 API SH/CD ECII

Temperatures Below 32F (0C) SAE 5W-30 API SH/CD ECII

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

(8) - Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Engine Oil (5)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Includes Filter.

30,000 MILE (48,000 KM) SERVICE

30,000 MILE (48,000 KM) SERVICE

Service Or Inspect

l

Verify Last Major Service Was Performed

Check Fluid Levels

Check Cooling System Hoses and Clamps

Check Coolant Strength

Check Exhaust System & Heat Shielding

Clean Battery and Battery Terminals

Inspect/Adjust Drive Belt Tension (4.0L)

Inspect Underside of Vehicle (Bolts & Threaded Fasteners)

Inspect C/V Joint boots (4WD)

Check Drive Shaft Seals

Lubricate Ball Joints, Steering Linkage & Suspension

Lube Drive Shaft U-Joints and Slip Splines

Lube Front Axle Drive Joint and Pivot Bearings (4WD)

Check/Lube Manual Steering Gear

Suspension Bushings, Springs, Arms & Rear Jounce Bumpers

Parking Brake System

Lubricate Body Components

Inspect Shocks for Leakage

Inspect Tire Wear Pattern

Rotate Tires and Adjust Air Pressure (Including Spare) Replace

Engine Oil

Oil Filter

Spark Plugs

Air Filter Element

Automatic Transmission Fluid, Filter and Adjust Bands

Transfer Case Fluid

Front & Rear Axle Fluid

Lubrication Specifications

Application Specification

Automatic Transmission

30RH (3-Speed) (1) Mopar 7176 ATF PLUS

AW4 (4-Speed) Dexron-IIE/Mercon ATF

Brake Master Cylinder DOT 3 (SAE J-1703F) Brake Fluid

Engine Coolant 50/50 Ethylene-Glycol & Water Mix

Engine Oil (2)

Temperatures Above 0F (-18C) SAE 10W-30 API SH/CD ECII

Temperatures Below 32F (0C) SAE 5W-30 API SH/CD ECII

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application

(1) Quantity

Automatic Transmission (2) 30RH (3-Speed)

Fluid Change 4.0 Qts . (3 . 8L)

Overhaul (Dry Fill) 8.75 Qts. (8.2L)

AW4 (4-Speed)

Fluid Change 2.0 Qts . (1. 7L)

Overhaul (Dry Fill) 8.5 Qts. (8.0L)

Cooling System

2.5L (3) 10.0 Qts. (9.5L)

4.0L (4) 12.0 Qts. (11.4L)

Engine Oil (5)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

Manual Transmission (6)

AX4 (4-Speed AISIN) 7.4 Pts. (3.5L)

T4 (Borg-Warner) 3.9 Pts. (1.8L)

AX5 (5-Speed AISIN)

2.5L (2WD) 7.0 Pts. (3.5L)

2.5L (4X4) 6.6 Pts. (3.2L)

T5 (Borg-Warner) 4.5 Pts. (2.1L)

AX15 (5-Speed AISIN)

4.0L (2WD) 6.4 Pts. (3.1L)

4.0L (4X4) 6.5 Pts. (3.15L)

Transfer Case

Command-Trac (NV 231) 2.2 Pts. (1.0L)

Selec-Trac (NV 242) 3.0 Pts. (1.4L)

Drive Axles (6)

Front Axle (Model 30)

Command-Trac (Disconnect) 3.76 Pts. (1.65L)

(Disconnect Housing) (7) 5.0 Ozs. (0.15L)

Selec-Trac (Non-Disconnect) 3.13 Pts. (1.5L)

Rear Axle

1989-94 (8) 2.5 Pts. (1.2L)

1995-96

Model 35 (8) 3.5 Pts. (1.6L)

8-1/4" (8) 4.4 Pts. (2.1L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Total quantity required will vary, after adding amount shown

check dipstick and fill to proper level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

- Fill to bottom edge of filler plug hole.

- Add 5 ozs. of gear lubricant through indicator switch hole.

- If equipped with TRAC-LOK, add 4 ozs. of Limited-Slip

differential lubricant additive first, then add new fluid.

Service Labor Times

Application

(1) Hours

2.5L

Automatic Transmission 4.2

Manual Transmission 2.4

4.0L

Automatic Transmission 4.3

Manual Transmission 2.5

(1) - Add .6 hr. for vehicles equipped with 4WD.

37,500 MILE (60,000 KM) SERVICE

37,500 MILE (60,000 KM) SERVICE

|

Service Or Inspect |

|

|

Verify Last Major Service Was Performed |

|

|

Check Fluid Levels |

|

|

Check Fuel Lines, Connections |

|

|

Check Cooling System Hoses and Clamps |

|

|

Check Exhaust System & Heat Shielding |

|

|

Inspect Brake System |

|

|

Inspect Underside of Vehicle (Bolts & Threaded Fasteners) |

|

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Rotate Tires and Adjust Air Pressure (Including Spare) |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Manual Transmission Fluid |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Automatic Transmission (2) 30RH (3-Speed)

Fluid Change 4.0 Qts . (3 . 8L)

Overhaul (Dry Fill) 8.75 Qts. (8.2L)

AW4 (4-Speed)

Fluid Change 2.0 Qts . (1. 7L)

Overhaul (Dry Fill) 8.5 Qts. (8.0L)

Cooling System

2.5L (3) 10.0 Qts. (9.5L)

4.0L (4) 12.0 Qts. (11.4L)

Engine Oil (5)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

Manual Transmission (6)

AX4 (4-Speed AISIN) 7.4 Pts. (3.5L)

T4 (Borg-Warner) 3.9 Pts. (1.8L)

AX5 (5-Speed AISIN)

2.5L (2WD) 7.0 Pts. (3.5L)

2.5L (4X4) 6.6 Pts. (3.2L)

T5 (Borg-Warner) 4.5 Pts. (2.1L)

AX15 (5-Speed AISIN)

4.0L (2WD) 6.4 Pts. (3.1L)

4.0L (4X4) 6.5 Pts. (3.15L)

Transfer Case

Command-Trac (NV 231) 2.2 Pts. (1.0L)

Selec-Trac (NV 242) 3.0 Pts. (1.4L)

Drive Axles (6)

Front Axle (Model 30)

Command-Trac (Disconnect) 3.76 Pts. (1.65L)

(Disconnect Housing) (7) 5.0 Ozs. (0.15L)

Selec-Trac (Non-Disconnect) 3.13 Pts. (1.5L)

Rear Axle

1989-94 (8) 2.5 Pts. (1.2L)

1995-96

Model 35 (8) 3.5 Pts. (1.6L)

8-1/4" (8) 4.4 Pts. (2.1L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Total quantity required will vary, after adding amount shown

check dipstick and fill to proper level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

- Fill to bottom edge of filler plug hole.

- Add 5 ozs. of gear lubricant through indicator switch hole.

- If equipped with TRAC-LOK, add 4 ozs. of Limited-Slip

differential lubricant additive first, then add new fluid.

45,000 MILE (72,000 KM) SERVICE

45,000 MILE (72,000 KM) SERVICE i

Service Or Inspect

Verify Last Major Service Was Performed

Check Fluid Levels

Check Fuel Lines, Connections

Check Cooling System Hoses and Clamps

Check Coolant Strength

Clean Battery and Battery Terminals

Check Exhaust System & Heat Shielding

Check Operation of Horn, Wipers/Washers & All Exterior Lights

Inspect Condition of Wiper Blades

Check Headlight Alignment

Check Seat Belt Webbing and Release Mechanisms

Check Parking Brake Operation

Check Shift/Clutch Interlock Operation

Inspect Underside of Vehicle (Bolts & Threaded Fasteners)

Inspect C/V Joint boots (4WD)

Check Drive Shaft Seals

Lubricate Ball Joints, Steering Linkage & Suspension

Lube Drive Shaft U-Joints and Slip Splines

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Lube Parking Brake Ratio Lever Pivot |

|

|

Lube Manual Gearshift Control (4WD Transfer Case) |

|

|

Inspect Front Brake Pads & Rotors |

|

|

Inspect Rear Brake Linings & Drums |

|

|

Inspect Brake System Hoses & Lines |

|

|

Inspect Shocks for Leakage |

|

|

Inspect Tire Wear Pattern |

|

|

Lubricate Weatherstripping with Silicone |

|

|

Lubricate Door Hinges |

|

|

Lubricate Door Locks |

|

|

Check Body Drain Holes |

|

|

Rotate Tires and Adjust Air Pressure |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Flush and Fill Engine Coolant, if not done in last 36 months |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Cooling System

2.5L (2) 10.0 Qts. (9.5L)

4.0L (3) 12.0 Qts. (11.4L)

Engine Oil (4)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

52,500 MILE (84,000 KM) SERVICE

52,500 MILE (84,000 KM) SERVICE

Service Or Inspect

l

Verify Last Major Service Was Performed

Check Fluid Levels

Check Fuel Lines, Connections

Check Cooling System Hoses and Clamps

Check Exhaust System & Heat Shielding

Inspect Brake System

Inspect Underside of Vehicle (Bolts & Threaded Fasteners)

Inspect C/V Joint boots (4WD)

Check Drive Shaft Seals

Lubricate Ball Joints, Steering Linkage & Suspension

Lube Drive Shaft U-Joints and Slip Splines

Lube Front Axle Drive Joint and Pivot Bearings (4WD)

Check/Lube Manual Steering Gear

Rotate Tires and Adjust Air Pressure (Including Spare) Replace

Engine Oil

Oil Filter

Flush and Fill Engine Coolant, if not done in last 36 months

Lubrication Specifications

Application Specification

Automatic Transmission

30RH (3-Speed) (1) Mopar 7176 ATF PLUS

AW4 (4-Speed) Dexron-IIE/Mercon ATF

Brake Master Cylinder DOT 3 (SAE J-1703F) Brake Fluid

Engine Coolant 50/50 Ethylene-Glycol & Water Mix

Engine Oil (2)

Temperatures Above 0F (-18C) SAE 10W-30 API SH/CD ECII

Temperatures Below 32F (0C) SAE 5W-30 API SH/CD ECII

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

(6) - Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Cooling System

2.5L (2) 10.0 Qts. (9.5L)

4.0L (3) 12.0 Qts. (11.4L)

Engine Oil (4)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

60,000 MILE (96,000 KM) SERVICE

60,000 MILE (96,000 KM) SERVICE i

Service Or Inspect

Verify Last Major Service Was Performed

Check Fluid Levels

Check Cooling System Hoses and Clamps

Check Coolant Strength

Check/Adjust Accessory Drive Belts

Ignition Timing

Clean EGR Passages (if equipped)

Check Exhaust System & Heat Shielding

Clean/Inspect Battery and Battery Terminals

Inspect Brake System

Inspect Exhaust System

Inspect Underside of Vehicle (Bolts & Threaded Fasteners)

Inspect C/V Joint boots (4WD)

Check Drive Shaft Seals

Lubricate Ball Joints, Steering Linkage & Suspension

Lube Drive Shaft U-Joints and Slip Splines

Lube Front Axle Drive Joint and Pivot Bearings (4WD)

Check/Lube Manual Steering Gear

|

Suspension Bushings, Springs, Arms & Rear Jounce Bumpers |

|

|

Parking Brake System |

|

|

Inspect Shocks for Leakage |

|

|

Inspect Tire Wear Pattern |

|

|

Rotate Tires and Adjust Air Pressure (Including Spare) |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Spark Plugs |

|

|

Ignition Cables |

|

|

Distributor Cap and Rotor |

|

|

Air Filter Element |

|

|

EGR Valve & Tube (1989-92) |

|

|

Emission System Vacuum Hoses |

|

|

Vacuum Operated Emission Components (1989-92) |

|

|

PCV Valve (1) |

|

|

Drive Belt (V-Type) (2) |

|

|

Accessory Drive Belts |

|

|

Fuel Filter (In-Line) |

|

|

Flush and Fill Engine Coolant, if not done in last 24 months |

|

|

Automatic Transmission Fluid, Filter and Adjust Bands |

|

|

Transfer Case (Drain and Refill) |

|

|

Front & Rear Axle Fluid |

|

|

(1) - Replacement is recommended by Chrysler at this time, but it is not required to maintain the warranty on the PCV valve. (2) - Check and replace as needed. |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Automatic Transmission (2) 30RH (3-Speed)

Fluid Change 4.0 Qts . (3 . 8L)

Overhaul (Dry Fill) 8.75 Qts. (8.2L)

AW4 (4-Speed)

Fluid Change 2.0 Qts . (1. 7L)

Overhaul (Dry Fill) 8.5 Qts. (8.0L)

Cooling System

2.5L (3) 10.0 Qts. (9.5L)

4.0L (4) 12.0 Qts. (11.4L)

Engine Oil (5)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

Manual Transmission (6)

AX4 (4-Speed AISIN) 7.4 Pts. (3.5L)

T4 (Borg-Warner) 3.9 Pts. (1.8L)

AX5 (5-Speed AISIN)

2.5L (2WD) 7.0 Pts. (3.5L)

2.5L (4X4) 6.6 Pts. (3.2L)

T5 (Borg-Warner) 4.5 Pts. (2.1L)

AX15 (5-Speed AISIN)

4.0L (2WD) 6.4 Pts. (3.1L)

4.0L (4X4) 6.5 Pts. (3.15L)

Transfer Case

Command-Trac (NV 231) 2.2 Pts. (1.0L)

Selec-Trac (NV 242) 3.0 Pts. (1.4L)

Drive Axles (6)

Front Axle (Model 30)

Command-Trac (Disconnect) 3.76 Pts. (1.65L)

(Disconnect Housing) (7) 5.0 Ozs. (0.15L)

Selec-Trac (Non-Disconnect) 3.13 Pts. (1.5L)

Rear Axle

1989-94 (8) 2.5 Pts. (1.2L)

1995-96

Model 35 (8) 3.5 Pts. (1.6L)

8-1/4" (8) 4.4 Pts. (2.1L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Total quantity required will vary, after adding amount shown

check dipstick and fill to proper level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

- Fill to bottom edge of filler plug hole.

- Add 5 ozs. of gear lubricant through indicator switch hole.

- If equipped with TRAC-LOK, add 4 ozs. of Limited-Slip

differential lubricant additive first, then add new fluid.

Service Labor Times

Application (1) Hours

1989-92

2.5L

Automatic Transmission 9.3

Manual Transmission 7.5

4.0L

Automatic Transmission 10.1

Manual Transmission 8.3

1993-96

2.5L

Automatic Transmission 7.6

Manual Transmission 5.8

4.0L

Automatic Transmission 7.8

Manual Transmission 6.0

(1) - Add .6 hour for vehicles equipped with 4WD.

67,500 MILE (108,000 KM) SERVICE

67,500 MILE (108,000 KM) SERVICE

Service Or Inspect

l

Verify Last Major Service Was Performed

Check Fluid Levels

Check Cooling System Hoses and Clamps

Check Exhaust System & Heat Shielding

Inspect Underside of Vehicle (Bolts & Threaded Fasteners)

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Lube Parking Brake Ratio Lever Pivot |

|

|

Lube Manual Gearshift Control (4WD Transfer Case) |

|

|

Inspect Front Brake Pads & Rotors |

|

|

Inspect Rear Brake Linings & Drums |

|

|

Inspect Brake System Hoses & Lines |

|

|

Inspect Shocks for Leakage |

|

|

Inspect Tire Wear Pattern |

|

|

Rotate Tires and Adjust Air Pressure (Including Spare) |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Cooling System

2.5L (2) 10.0 Qts. (9.5L)

4.0L (3) 12.0 Qts. (11.4L)

Engine Oil (4)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

75,000 MILE (120,000 KM) SERVICE

75,000 MILE (120,000 KM) SERVICE i

Service Or Inspect

Verify Last Major Service Was Performed

Check Fluid Levels

Check Fuel Lines, Connections

Check Cooling System Hoses and Clamps

Check Coolant Strength

Check Exhaust System & Heat Shielding

Clean Battery and Battery Terminals

Inspect Brake System

Check Operation of Horn, Wipers/Washers & All Exterior Lights

Inspect Condition of Wiper Blades

|

Check Headlight Alignment |

|

|

Check Seat Belt Webbing and Release Mechanisms |

|

|

Check Parking Brake Operation |

|

|

Check Shift/Clutch Interlock Operation |

|

|

Inspect Underside of Vehicle (Bolts & Threaded Fasteners) |

|

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Lubricate Weatherstripping with Silicone |

|

|

Lubricate Door Hinges |

|

|

Lubricate Door Locks |

|

|

Check Body Drain Holes |

|

|

Rotate Tires and Adjust Air Pressure |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Manual Transmission Fluid |

|

|

Flush and Fill Engine Coolant, if not done in last 24 months |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

Application Specification

Automatic Transmission

30RH (3-Speed) (1) Mopar 7176 ATF PLUS

AW4 (4-Speed) Dexron-IIE/Mercon ATF

Brake Master Cylinder DOT 3 (SAE J-1703F) Brake Fluid

Engine Coolant 50/50 Ethylene-Glycol & Water Mix

Engine Oil (2)

Temperatures Above 0F (-18C) SAE 10W-30 API SH/CD ECII

Temperatures Below 32F (0C) SAE 5W-30 API SH/CD ECII

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Automatic Transmission (2) 30RH (3-Speed)

Fluid Change 4.0 Qts . (3 . 8L)

Overhaul (Dry Fill) 8.75 Qts. (8.2L)

AW4 (4-Speed)

Fluid Change 2.0 Qts . (1. 7L)

Overhaul (Dry Fill) 8.5 Qts. (8.0L)

Cooling System

2.5L (3) 10.0 Qts. (9.5L)

4.0L (4) 12.0 Qts. (11.4L)

Engine Oil (5)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

Manual Transmission (6)

AX4 (4-Speed AISIN) 7.4 Pts. (3.5L)

T4 (Borg-Warner) 3.9 Pts. (1.8L)

AX5 (5-Speed AISIN)

2.5L (2WD) 7.0 Pts. (3.5L)

2.5L (4X4) 6.6 Pts. (3.2L)

T5 (Borg-Warner) 4.5 Pts. (2.1L)

AX15 (5-Speed AISIN)

4.0L (2WD) 6.4 Pts. (3.1L)

4.0L (4X4) 6.5 Pts. (3.15L)

Transfer Case

Command-Trac (NV 231) 2.2 Pts. (1.0L)

Selec-Trac (NV 242) 3.0 Pts. (1.4L)

Drive Axles (6)

Front Axle (Model 30)

Command-Trac (Disconnect) 3.76 Pts. (1.65L)

(Disconnect Housing) (7) 5.0 Ozs. (0.15L)

Selec-Trac (Non-Disconnect) 3.13 Pts. (1.5L)

Rear Axle

1989-94 (8) 2.5 Pts. (1.2L)

1995-96

Model 35 (8) 3.5 Pts. (1.6L)

8-1/4" (8) 4.4 Pts. (2.1L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Total quantity required will vary, after adding amount shown

check dipstick and fill to proper level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

- Fill to bottom edge of filler plug hole.

- Add 5 ozs. of gear lubricant through indicator switch hole.

- If equipped with TRAC-LOK, add 4 ozs. of Limited-Slip

differential lubricant additive first, then add new fluid.

82,500 MILE (132,000 KM) SERVICE

82,500 MILE (132,000 KM) SERVICE

|

Service Or Inspect |

|

|

Verify Last Major Service Was Performed |

|

|

Check Fluid Levels |

|

|

Check Cooling System Hoses and Clamps |

|

|

Check Exhaust System & Heat Shielding |

|

|

Inspect Brake System |

|

|

Inspect Underside of Vehicle (Bolts & Threaded Fasteners) |

|

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Rotate Tires and Adjust Air Pressure (Including Spare) |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

O2 Sensor (1989) |

|

|

Flush and Fill Engine Coolant, if not done in last 24 months |

|

|

Lubrication Specifications |

|

Application Specification

Automatic Transmission

30RH (3-Speed) (1) Mopar 7176 ATF PLUS

AW4 (4-Speed) Dexron-IIE/Mercon ATF

Brake Master Cylinder DOT 3 (SAE J-1703F) Brake Fluid

Engine Coolant 50/50 Ethylene-Glycol & Water Mix

Engine Oil (2)

Temperatures Above 0F (-18C) SAE 10W-30 API SH/CD ECII

Temperatures Below 32F (0C) SAE 5W-30 API SH/CD ECII

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Cooling System

2.5L (2) 10.0 Qts. (9.5L)

4.0L (3) 12.0 Qts. (11.4L)

Engine Oil (4)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

90,000 MILE (144,000 KM) SERVICE

90,000 MILE (144,000 KM) SERVICE

|

Service Or Inspect |

|

|

Verify Last Major Service Was Performed |

|

|

Check Fluid Levels |

|

|

Check Fuel Lines, Connections |

|

|

Check Cooling System Hoses and Clamps |

|

|

Check Coolant Strength |

|

|

Clean Battery and Battery Terminals |

|

|

Check/Adjust Accessory Drive Belt Tension |

|

|

Check Exhaust System & Heat Shielding |

|

|

Check Operation of Horn, Wipers/Washers & All Exterior Lights |

|

|

Inspect Condition of Wiper Blades |

|

|

Check Headlight Alignment |

|

|

Check Seat Belt Webbing and Release Mechanisms |

|

|

Check Parking Brake Operation |

|

|

Check Shift/Clutch Interlock Operation |

|

|

Inspect Underside of Vehicle (Bolts & Threaded Fasteners) |

|

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Lube Parking Brake Ratio Lever Pivot |

|

|

Lube Manual Gearshift Control (4WD Transfer Case) |

|

|

Inspect Front Brake Pads & Rotors |

|

|

Inspect Rear Brake Linings & Drums |

|

|

Inspect Brake System Hoses & Lines |

|

|

Inspect Shocks for Leakage |

|

|

Inspect Tire Wear Pattern |

|

Lubricate Weatherstripping with Silicone

Lubricate Door Hinges

Lubricate Door Locks

Check Body Drain Holes

Rotate Tires and Adjust Air Pressure

Replace

Engine Oil

Oil Filter

Air Filter Element

Spark Plugs

Automatic Transmission Fluid, Filter and Adjust Bands

PCV Valve (1) (2)

Drive Belt (V-Type) (2) (3)

(1) - Replacement is recommended by Chrysler at this time, but it

is not required to maintain the warranty on the PCV valve.

- Not required, if belt or PCV Valve was previously replaced

- Check and replace as needed.

Lubrication Specifications

Application Specification

Automatic Transmission

30RH (3-Speed) (1) Mopar 7176 ATF PLUS

AW4 (4-Speed) Dexron-IIE/Mercon ATF

Brake Master Cylinder DOT 3 (SAE J-1703F) Brake Fluid

Engine Coolant 50/50 Ethylene-Glycol & Water Mix

Engine Oil (2)

Temperatures Above 0F (-18C) SAE 10W-30 API SH/CD ECII

Temperatures Below 32F (0C) SAE 5W-30 API SH/CD ECII

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Automatic Transmission (2) 30RH (3-Speed)

Fluid Change 4.0 Qts . (3 . 8L)

Overhaul (Dry Fill) 8.75 Qts. (8.2L)

AW4 (4-Speed)

Fluid Change 2.0 Qts . (1. 7L)

Overhaul (Dry Fill) 8.5 Qts. (8.0L)

Cooling System

2.5L (3) 10.0 Qts. (9.5L)

4.0L (4) 12.0 Qts. (11.4L)

Engine Oil (5)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

Manual Transmission (6)

AX4 (4-Speed AISIN) 7.4 Pts. (3.5L)

T4 (Borg-Warner) 3.9 Pts. (1.8L)

AX5 (5-Speed AISIN)

2.5L (2WD) 7.0 Pts. (3.5L)

2.5L (4X4) 6.6 Pts. (3.2L)

T5 (Borg-Warner) 4.5 Pts. (2.1L)

AX15 (5-Speed AISIN)

4.0L (2WD) 6.4 Pts. (3.1L)

4.0L (4X4) 6.5 Pts. (3.15L)

Transfer Case

Command-Trac (NV 231) 2.2 Pts. (1.0L)

Selec-Trac (NV 242) 3.0 Pts. (1.4L)

Drive Axles (6)

Front Axle (Model 30)

Command-Trac (Disconnect) 3.76 Pts. (1.65L)

(Disconnect Housing) (7) 5.0 Ozs. (0.15L)

Selec-Trac (Non-Disconnect) 3.13 Pts. (1.5L)

Rear Axle

1989-94 (8) 2.5 Pts. (1.2L)

1995-96

Model 35 (8) 3.5 Pts. (1.6L)

8-1/4" (8) 4.4 Pts. (2.1L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Total quantity required will vary, after adding amount shown

check dipstick and fill to proper level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

- Fill to bottom edge of filler plug hole.

- Add 5 ozs. of gear lubricant through indicator switch hole.

- If equipped with TRAC-LOK, add 4 ozs. of Limited-Slip

differential lubricant additive first, then add new fluid.

Service Labor Times

Application (1) Hours

2.5L

Automatic Transmission 4.2

Manual Transmission 2.4

4.0L

Automatic Transmission 4.3

Manual Transmission 2.5

(1) - Add .6 hr. for vehicles equipped with 4WD.

97,500 MILE (156,000 KM) SERVICE

97,500 MILE (156,000 KM) SERVICE

|

Service Or Inspect |

|

|

Verify Last Major Service Was Performed |

|

|

Check Fluid Levels |

|

|

Check Cooling System Hoses and Clamps |

|

|

Check Exhaust System & Heat Shielding |

|

|

Inspect Brake System |

|

|

Inspect Underside of Vehicle (Bolts & Threaded Fasteners) |

|

|

Inspect C/V Joint boots (4WD) |

|

|

Check Drive Shaft Seals |

|

|

Lubricate Ball Joints, Steering Linkage & Suspension |

|

|

Lube Drive Shaft U-Joints and Slip Splines |

|

|

Lube Front Axle Drive Joint and Pivot Bearings (4WD) |

|

|

Check/Lube Manual Steering Gear |

|

|

Rotate Tires and Adjust Air Pressure (Including Spare) |

|

|

Replace |

|

|

Engine Oil |

|

|

Oil Filter |

|

|

Lubrication Specifications |

|

|

Application Specification Automatic Transmission |

|

30RH (3-Speed) (1) Mopar 7176 ATF PLUS

AW4 (4-Speed) Dexron-IIE/Mercon ATF

Brake Master Cylinder DOT 3 (SAE J-1703F) Brake Fluid

Engine Coolant 50/50 Ethylene-Glycol & Water Mix

Engine Oil (2)

Temperatures Above 0F (-18C) SAE 10W-30 API SH/CD ECII

Temperatures Below 32F (0C) SAE 5W-30 API SH/CD ECII

Front Axle (3) SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle SAE 80W-90 API GL-5 (MIL-L-2105C)

Rear Axle (Trac-Lok) (4) SAE 80W-140 API GL-5

Rear Axle (Trailer Towing) (5) SAE 75W-140 Synthetic

Hydraulic Clutch DOT 3 (SAE J-1703F) Brake Fluid

Manual Transmission SAE 75W-90 API GL-5

Manual Steering Box Multi-Purpose NLGI Grade 2EP

Power Steering Pump Power Steering Fluid

Transfer Case Dexron-IIE ATF

Parking Brake Cable Guides NLGI Grade 2, GC-LB

Brake Caliper Bushings GE 661 or DOW 111 Silicone Grease

Caliper Slide Pins GE 661 or DOW 111 Silicone Grease

Door & Hood Hinges Light Engine Oil

Wheel Bearings Multi-Purpose NLGI Grade 2EP, GC-LB

Drive Shaft U-Joints Multi-Purpose NLGI Grade 2EP, GC-LB

Steering Linkage (6)(7) .... Multi-Purpose NLGI Grade 2EP, GC-LB

Ball Joints (6)(8) Multi-Purpose NLGI Grade 2EP, GC-LB

Weatherstrip Silicone Spray Lubricant

Wheel Lug Nut Torque 80-110 ft. lbs. (115-145 N.m)

- DO NOT use Dexron-II ATF, Clutch chatter can result.

- SAE 10W-30 SH/CD is preferred.

- DO NOT use heavier weight lubricant, as it will cause axle

engagement difficulties, use only SAE 80W-90 lube.

(4) - Add 4 ozs. (118 ml) of Limited-Slip differential lubricant

additive when changing fluid.

(5) - For vehicles operating under heavy-duty towing conditions,

use SAE 75W-140 Synthetic lube.

NOTE: Before using SAE 75W-140 Synthetic, old fluid must be DRAINED and FLUSHED with clean mineral based (non-synthetic) axle lubricant. Then refill with new synthetic lube.

- Use low pressure grease gun to prevent seal damage.

- Fill until lubricant squeezes out from the base of seals.

- Fill ball joint until seal starts to swell.

Fluid Capacities

Application (1) Quantity

Cooling System

2.5L (2) 10.0 Qts. (9.5L)

4.0L (3) 12.0 Qts. (11.4L)

Engine Oil (4)

2.5L 4.0 Qts. (3.8L)

4.0L 6.0 Qts. (5.7L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

- Includes 2.3 qts. (2.2L) for coolant recovery bottle.

- Includes 1.0 qt. (0.9L) for coolant recovery bottle.

- Includes Filter.

105,000 MILE (168,000 KM) SERVICE

105,000 MILE (168,000 KM) SERVICE

Service Or Inspect

Verify Last Major Service Was Performed

Check Fluid Levels

Check Fuel Lines, Connections

Check Cooling System Hoses and Clamps

Check Coolant Strength

Check Exhaust System & Heat Shielding

Clean Battery and Battery Terminals

Inspect Brake System

Check Operation of Horn, Wipers/Washers & All Exterior Lights

Inspect Condition of Wiper Blades

Check Headlight Alignment

Check Seat Belt Webbing and Release Mechanisms

Check Parking Brake Operation

Check Shift/Clutch Interlock Operation

Inspect Underside of Vehicle (Bolts & Threaded Fasteners)

Inspect C/V Joint boots (4WD)

Check Drive Shaft Seals

Lubricate Ball Joints, Steering Linkage & Suspension

Lube Drive Shaft U-Joints and Slip Splines

Lube Front Axle Drive Joint and Pivot Bearings (4WD)

Check/Lube Manual Steering Gear

Lubricate Weatherstripping with Silicone

Lubricate Door Hinges

Lubricate Door Locks

Check Body Drain Holes

Rotate Tires and Adjust Air Pressure

Replace

l

Engine Oil

Oil Filter