Ā

1993 Jeep Cherokee

1993 ACCESSORIES & EQUIPMENT Chrysler Corp. Instrument Panels

Jeep; Cherokee

DESCRIPTION

Instrument panel is supplied voltage through gauges fuse. A printed circuit on rear of instrument cluster distributes voltage to gauges and indicators.

Emission Maintenance Timer

Emission Maintenance Timer and Indicator Light activate when mileage reaches scheduled maintenance interval of 82,500 miles. Timer can be reset using DRB-II.

TESTING

GAUGE TESTING

Compare resistance values of malfunctioning gauge to specifications. See OIL PRESSURE GAUGE RESISTANCE, FUEL GAUGE RESISTANCE and TEMPERATURE GAUGE RESISTANCE tables.

OIL PRESSURE GAUGE RESISTANCE TABLE

Oil Pressure (psi) Ohms

0 1

40 46

80 87

FUEL GAUGE RESISTANCE TABLE

Application Ohms

Empty 105

1/2 Full 33

Full 5

TEMPERATURE GAUGE RESISTANCE TABLE

Application & Test Temperature Ohms

100F (38C) 1365.0

220F (104C) 93.5

260F (127C) 55.1

BRAKE INDICATOR INOPERATIVE

1) Turn ignition switch on with engine off. Apply parking brake, and unplug brake warning light switch connector. Connector is located below brake master cylinder at left rear of engine compartment. Jumper between brake warning light switch connector Gray/White wire and ground. If bulb is good and indicator lights,

repair open circuit to indicator.

2) With ignition switch off, measure resistance between brake warning switch connector Gray wire (changes to Gray/White wire at splice) and ground. If reading is zero ohms, check switch and/or brake system. If reading is not zero ohms, repair open circuit to parking brake switch ground.

COOLANT TEMPERATURE GAUGE INOPERATIVE

Turn ignition switch on with engine off. Disconnect coolant temperature sending unit connector (located at left rear of engine). If needle does not indicate at low end of scale, touch connector Violet/Yellow wire to ground. If needle indicates at high end of scale, replace sending unit. If needle does not indicate at high end of scale, repair open Violet/Yellow wire to gauge.

COOLANT TEMPERATURE INDICATOR LIGHT INOPERATIVE

Turn ignition switch on with engine off. Disconnect coolant temperature sender connector (located at left rear of engine). Touch connector Violet/Yellow wire to ground. If indicator lights, replace switch. If bulb is good and indicator light remains off, repair open Violet/Yellow wire to instrument cluster terminal.

FUEL GAUGE INOPERATIVE

With ignition on and engine off, disconnect fuel gauge sending unit connector. If needle goes to "E", replace sending unit. If needle does not go to "E", connect fuel gauge sending unit connector and disconnect instrument cluster connector terminal B1. Check resistance of sending unit. If resistance is 5-105 ohms, replace gauge. If resistance is not 5-105 ohms, repair open Dark Blue wire to sending unit.

GAUGES & INDICATORS INOPERATIVE

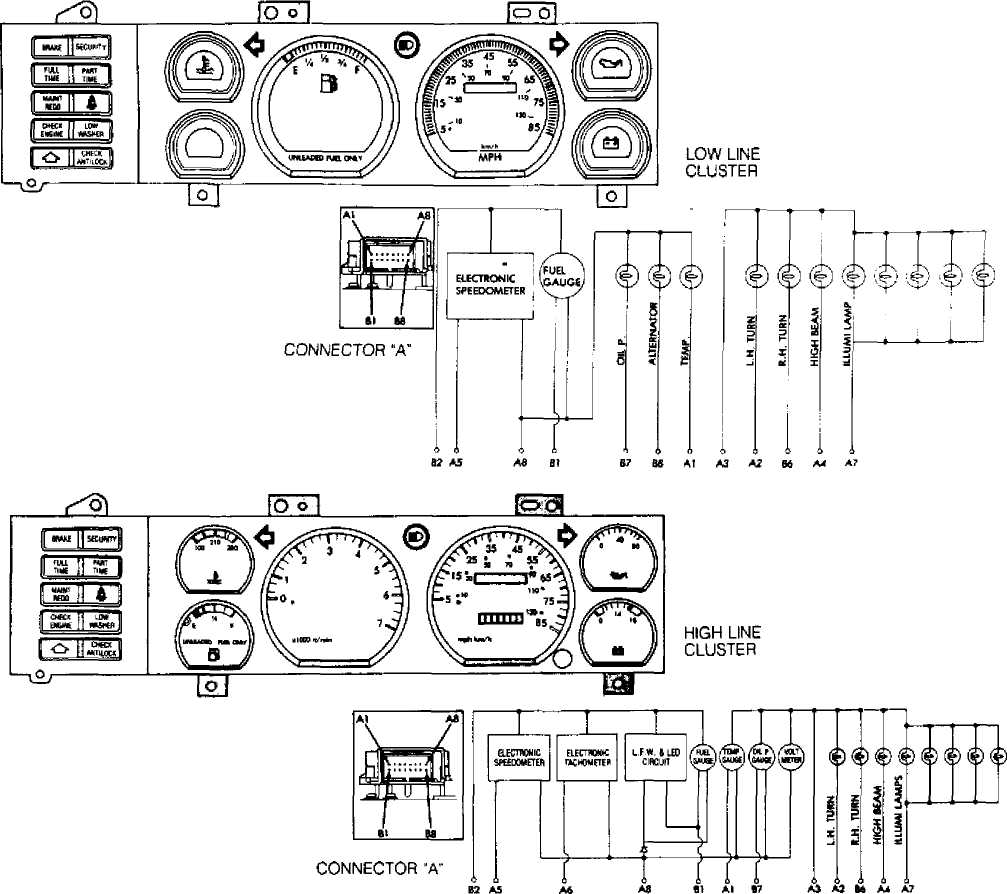

Check gauge fuses. Replace if blown. Test instrument cluster connector terminal A3 ground wire. See Figs. 1 and 2. If any resistance to ground is detected, repair open Black wire in ground circuit.

PANEL LIGHTS: ALL LIGHTS INOPERATIVE, PARKING LIGHTS WORKING

Check PARK fuse and instrument lights fuse. Replace if

necessary. Repair short to ground in 12-volt supply wire to blown

fuse.

Using voltmeter, probe battery side of instrument lights

fuse while turning headlight switch dimming rheostat from LO to HI. If

results are not zero volts for LO and battery voltage for HI, replace

headlight switch.

Using DVOM, check resistance at ground (bulb) side of

instrument lights fuse with parking lights off. If resistance to

ground is almost zero (allowing for bulb filaments), system is good.

If resistance is zero ohms, 12-volt supply wire from fuse is shorted

to ground. Repair short.

LOW FUEL WARNING LIGHT INOPERATIVE

Turn ignition on with engine off. Disconnect wire to terminal B1 of instrument cluster connector. See Figs. 1 and 2. Wait 10 seconds. If indicator light glows, system is good. Replace sending unit. If indicator light does not glow, replace low fuel warning

module (on back of instrument cluster). OIL PRESSURE GAUGE INOPERATIVE

Turn ignition on with engine off. Disconnect oil pressure

sender connector, located on right side of engine, next to

distributor. If needle goes to high indication, system is good.

If needle does not indicate at high end of scale, touch

oil pressure sending unit connector Gray wire to ground. If needle

indicates at low end of scale, replace sending unit. If needle does

not indicate at low end of scale, repair open in Gray wire circuit to

gauge (instrument cluster terminal B7). See Figs. 1 and 2.

OIL PRESSURE INDICATOR INOPERATIVE

Turn ignition on with engine off. Touch oil pressure switch connector Gray wire to ground. If light glows, replace switch. If light does not glow and bulb is good, repair open in Gray wire to instrument cluster connector terminal B7. See Figs. 1 and 2.

PART TIME OR 4WD INDICATOR INOPERATIVE

Apply parking brake. Start engine. Place 4WD selector

lever in 4WD LOCK or 4WD position. Unplug 4WD switch, and touch

harness connector Black/Yellow wire to ground. If indicator light

glows, wiring system is good. Check 4WD switch operation, and replace

switch if defective.

If indicator light does not glow and bulb is good, repair

open in Black/Yellow wire circuit to indicator light.

TACHOMETER INOPERATIVE

Tachometer input is from engine PCM pin No. 43. Check

Gray/Light Blue wire for short or open circuits. If wire is okay, see appropriate G - TESTS W/CODES article in the ENGINE PERFORMANCE Section.

VOLTMETER (GAUGE) INOPERATIVE

Turn ignition on with engine off. If voltmeter does not indicate battery voltage, check voltage at instrument cluster connector terminal A8. See Figs. 1 and 2. If battery voltage exists at terminal A8, replace voltmeter. If battery voltage does not exist at terminal A8, repair open White/Black wire circuit to gauges fuse.

|

NO. |

LAMP |

TERMINAL NAME |

|

1 |

A |

.OW WASHER |

|

2 |

ąÆ |

:heck engine |

|

ąÆ |

GN |

|

|

4 |

^ *" |

GN |

|

S |

^ |

GN |

|

6 |

ąĪ |

CHECK ANTILOCK |

|

7 |

D |

UP SHIFT |

|

┬╗ |

E |

MAKE |

|

9 |

F |

SECURITY |

|

10 |

F |

SAH |

|

11 |

G |

=ULL TIME |

|

12 |

H |

>ART TIME |

|

13 |

1 |

MAINT REQD |

|

14 |

1 |

GN |

|

15 |

J |

SEAT BELT |

|

16 |

^--^ |

3ND |

Fig. 1: Instrument Cluster Connector ID & Location Courtesy of Chrysler Corp.

91C14466

Fig. 2: Instrument Cluster Connector Terminal ID Courtesy of Chrysler Corp.

REMOVAL & INSTALLATION

INSTRUMENT CLUSTER

Removal & Installation

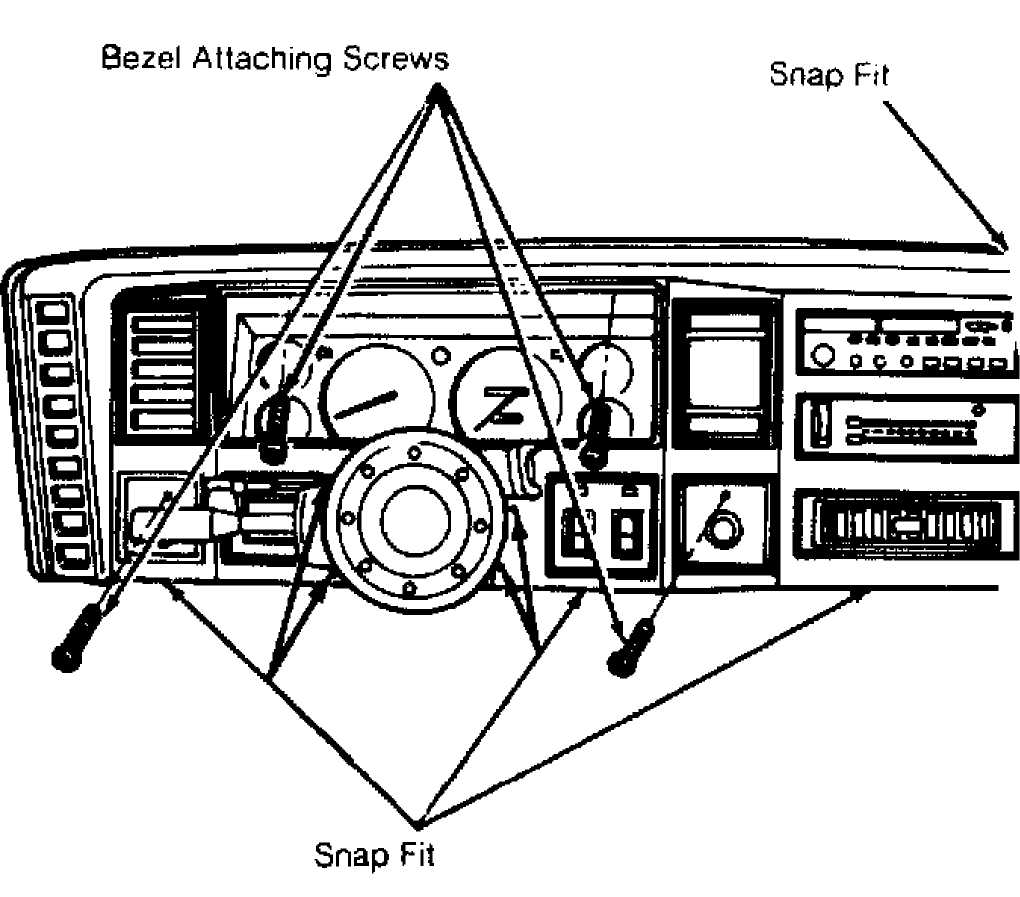

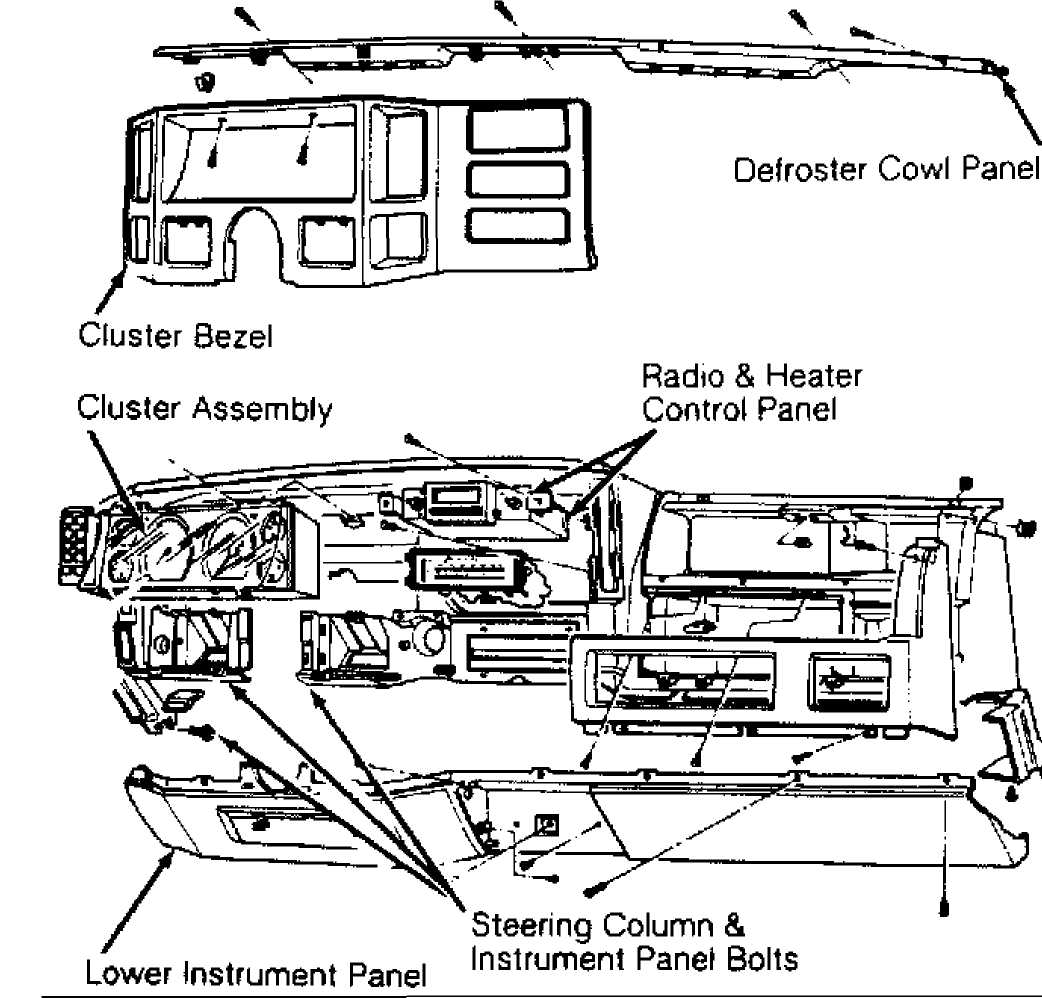

Disconnect negative battery cable. Remove 4 instrument

cluster bezel attaching screws, and unsnap instrument cluster bezel.

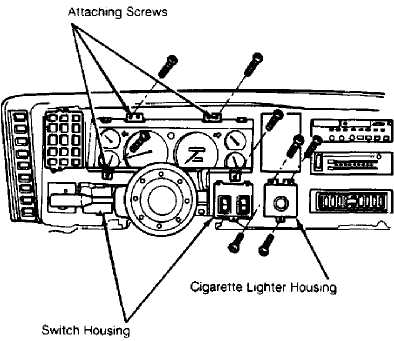

See Fig. 3. Remove cigarette lighter housing attaching screw. Remove

switch housing attaching screws. See Fig. 4.

Remove instrument cluster attaching screws. Pull out

cluster assembly far enough to disconnect 2 multiple plugs, and remove

instrument cluster. See Figs. 5 and 6. To install, reverse removal

procedure.

Fig. 3: Removing Instrument Cluster Bezel Courtesy of Chrysler Corp.

Fig. 4: Removing Instrument Cluster Courtesy of Chrysler Corp.

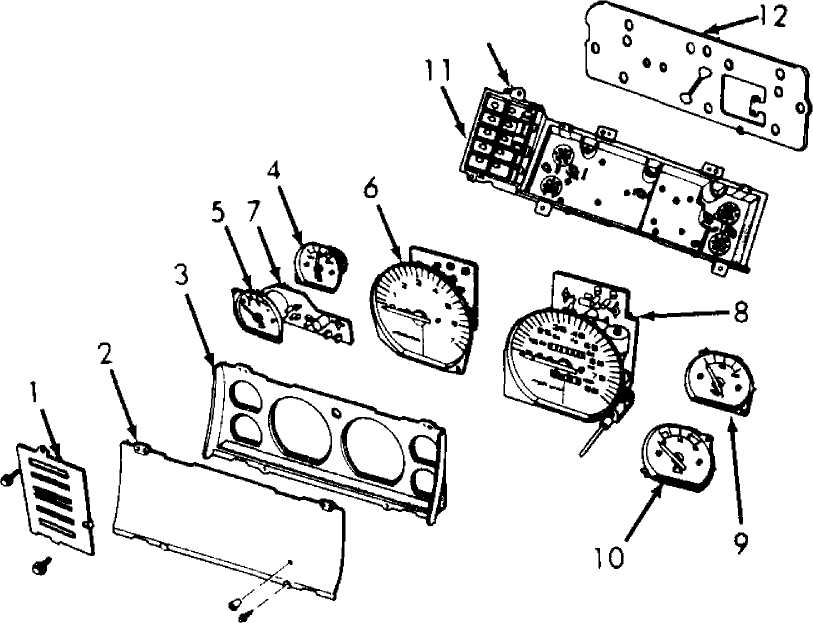

13

Tell-Tale Display

Lens

Gauge Bezel

Temperature Gauge

Fuel Gauge

Tachometer

Low Fuel Warning Module

Speedometer

Oil Pressure Gauge

Voltmeter

Mounting Bezel

Printed Circuit (Gauges)

Printed Circuit (Tell-Tale)

Fig. 5: Exploded View Of Instrument Cluster Courtesy of Chrysler Corp.

Fig. 6: Exploded View Of Instrument Panel Courtesy of Chrysler Corp.

WIRING DIAGRAMS

See appropriate chassis wiring diagram in WIRING DIAGRAMS.