Ā

1993 Jeep Cherokee

1993 ELECTRICAL

Chrysler Corp. Starters - Bosch & Mitsubishi

Jeep; Cherokee, Grand Cherokee, Wrangler

DESCRIPTION

Both Bosch and Mitsubishi starters are permanent-magnet type. A planetary gear train transmits power between starter motor and pinion shaft. Both starters are 12-volt units with solenoid mounted on starter housing.

TROUBLE SHOOTING

STARTER MOTOR NOISE

STARTER TROUBLE SHOOTING CHART

|

CONDITION |

POSSIBLE CAUSE |

CORRECTION |

|

Very high frequency whine before engine starts; engine starts ok |

Excessive distance between pinion gear and flywheel/drive plate gear. |

Shim starter motor toward flywheel/ drive plate. |

|

Very high frequency whine after engine starts with ignition key released, engine starts okay. |

Insufficient distance between starter motor pinion gear & flywheel/ drive plate runout can cause noise to be intermittent. |

Shim starter away from flywheel/drive plate. Check flywheel drive plate for bent, unusual wear, and excess runout. Replace flywheel/ drive plate as needed. |

|

A loud "whoop" after engine starts while starter motor is engaged. |

Most probably cause is defective overrun clutch. Overrun clutch replacement normally corrects this condition. |

Replace overrun clutch or drive assembly. |

|

A "Rumble, " "Growl," or "Knock" as starter motor coasts to stop after engine starts. |

Most probably cause is, bent or unbalanced starter motor armature. Armature replacement normally corrects this condition. |

Replace starter motor armature. |

TESTING (ON-VEHICLE)

COLD CRANKING TEST

NOTE: Ensure battery is fully charged. A cold engine increases starter draw amperage.

1) Connect battery load/charging system tester to battery,

and connect remote starter switch to starter relay. Set voltmeter selector to 18-volt position. Adjust ammeter reading to zero.

2) Disconnect coil wire from distributor cap. Attach coil wire to ground to prevent engine from starting. Crank engine, and note cranking voltage and amperage. Replace or repair starter if it is not to specifications. See appropriate STARTER SPECIFICATIONS.

STARTER RELAY TEST

Remove starter relay from Power Distribution Center (PDC).

Using an ohmmeter, check for continuity between terminals No. 30 and

87A. If no continuity exists, replace relay. See Fig. 1.

Check resistance between terminals No. 85 and 86. If

resistance is not 70-80 ohms, replace starter relay.

Connect battery to terminals No. 85 and 86. Check for

continuity between terminals No. 30 and 87. If no continuity exists,

replace starter relay.

93C76101

Fig. 1: Identifying Starter Relay Terminals Courtesy of Chrysler Corp.

SOLENOID TEST

Continuity Test

Disconnect wire from solenoid field coil terminal (large

terminal connected to starter body). Using an ohmmeter, test for

continuity between field terminal and solenoid terminal (small

terminal). Continuity should exist.

Test for continuity between solenoid terminal and solenoid

housing. Continuity should exist. If continuity does not exist in

either test, solenoid has open circuit. Replace solenoid.

Functional Test

With a fully-charged battery, connect a heavy gauge jumper

wire between battery terminal and solenoid terminal wire connector at

starter relay. If engine cranks, solenoid is okay.

If engine does not crank, check battery cable for voltage

to starter solenoid BAT terminal. Jump starter relay terminals as in

step 1), checking for voltage at solenoid terminal No. 50. Repair as

necessary. If engine still does not crank, repair or replace starter.

BENCH TESTING

ARMATURE TEST

Short Circuit

Place armature in a growler. While rotating armature slowly, hold growlerÆs blade parallel to and touching armature core. Blade vibrates if armature is shorted. Replace shorted armature.

Ground

Fig. 2: Testing Starter Armature For Ground Courtesy of Chrysler Corp.

DRIVE CLUTCH CHECK

Using growler or a self-powered test light, touch one lead to armature shaft and other lead to each commutator bar. See Fig. 2. If light glows at any point during procedure, armature is grounded. Replace grounded armature.

While holding drive clutch housing, rotate pinion. Drive pinion should rotate smoothly in only one direction (pinion should engage and lock in opposite direction). If drive unit does not operate properly or if pinion is worn or burred, replace drive clutch.

REMOVAL & INSTALLATION

STARTER

Removal & Installation (2.5L)

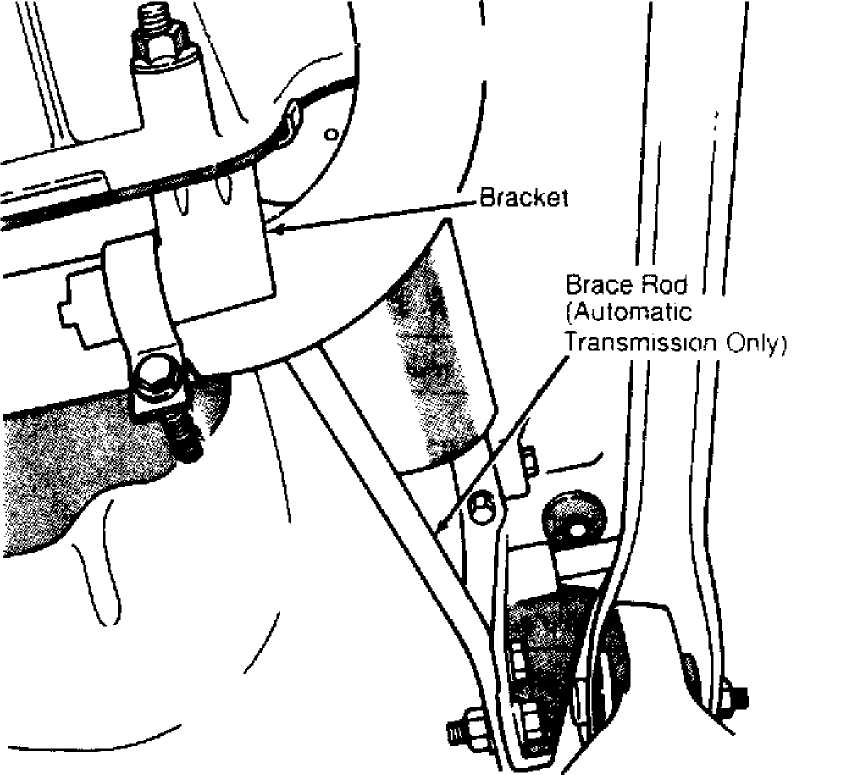

Disconnect negative battery cable. Remove exhaust pipe

clamp from bracket. See Fig. 3. On Cherokee with automatic

transmission, remove nut and bolt from forward end of brace rod.

Remove brace rod and bracket.

On vehicles with manual transmission, remove nut, bolt and

bracket from bellhousing. On all models, disconnect battery cable and

solenoid feed wire from starter solenoid. To install, reverse removal

procedure.

Fig. 3: Removing Engine Exhaust Clamp & Brace (2.5L) Courtesy of Chrysler Corp.

Removal & Installation (4.0L)

Disconnect negative battery cable. Raise and support vehicle.

Disconnect starter battery cable and solenoid feed wire. Remove starter from flywheel housing. To install, reverse removal procedure.

OVERHAUL

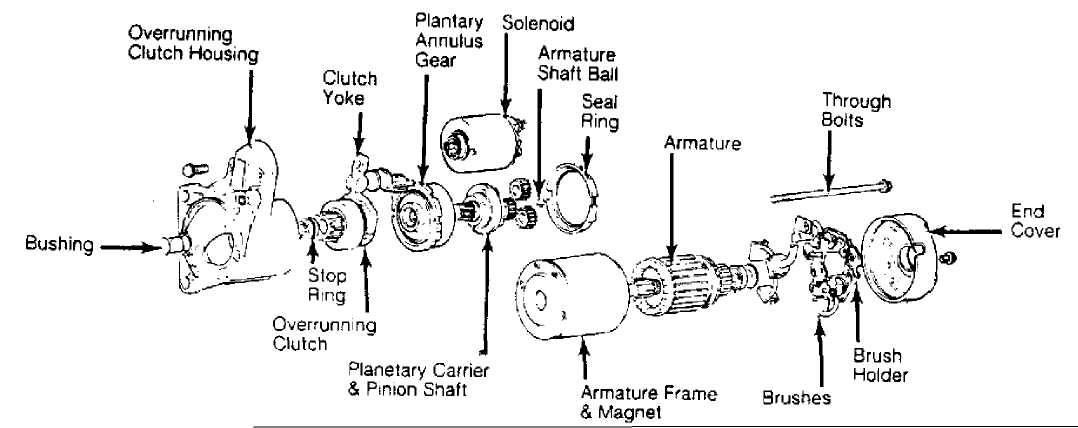

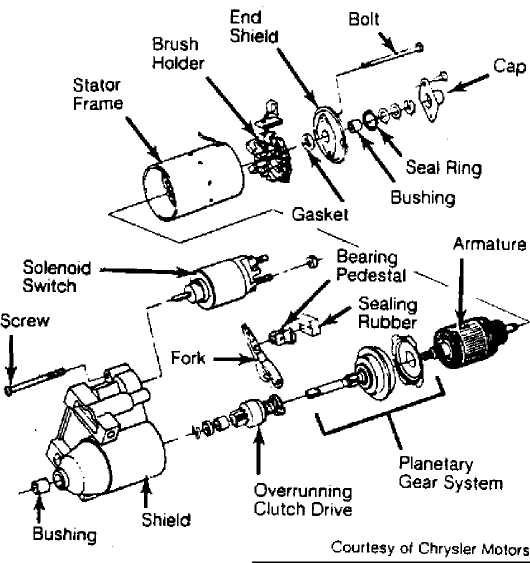

NOTE: For exploded views of starters, see Figs. 4 and 5.

Fig. 4: Exploded View Of Mitsubishi Starter (4.0L) Courtesy of Chrysler Corp.

Fig. 5: Exploded View Of Bosch Starter (2.5L) Courtesy of Chrysler Corp.

STARTER SPECIFICATIONS

BOSCH

BOSCH STARTER SPECIFICATIONS TABLE

Application Specification

Carbon Brush Minimum Length 314" (8.0 mm)

Commutator

Diameter 1.23-1.27" (31.2-32.3 mm)

Runout 0004" (.01mm)

Armature

Core Runout 002" (.05 mm)

End Play 002" (.05 mm)

Cranking Test

Test Voltage 12.5 Volts

Minimum Voltage 9.6 Volts

Amps 160 Amps

No-Load Test @ 11.5 Volts

Maximum Amps 7 5 Amps

Minimum RPM 2900 RPM

Solenoid Hold-In Test Winding Voltage 2-2 Volts

Solenoid Pull-In Test Winding Voltage 6-7.3 Volts

MITSUBISHI

MITSUBISHI STARTER SPECIFICATIONS TABLE

Application Specification

Carbon Brush Minimum Length 354" (9 mm)

Commutator

Diameter 1.118-1.161" (28.4-29.5 mm)

Runout 001" (.03 mm)

Armature

Core Runout 003" (.08 mm)

End Play 023" ( .58 mm)

Cranking Test

Test Voltage 12.5 Volts

Minimum Voltage 9.6 Volts

Amps 130

No-Load Test @ 11.5 Volts

Maximum Amps 80 Amps

Minimum RPM 2500 RPM

Solenoid Hold-In Test Winding Voltage ... 3.5 Volts (Min.)

Solenoid Pull-In Test Winding Voltage ... 7.8 Volts (Max.)

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft. Lbs. (N.m)

Starter-To-Block Bolts 33 (45)