1988 Jeep Cherokee

1988 Electronic Fuel Injection JEEP MULTI-POINT

4.0L Cherokee, Comanche, Wagoneer DESCRIPTION

The Multi-Point Electronic Fuel Injection (EFI) system is an electronically controlled system which combines electronic sequential fuel injection and electronic spark advance systems. Main sub-systems consist of: air induction, fuel delivery, fuel control, emission control, Electronic Control Unit (ECU), data sensors and switches.

Air induction system includes air cleaner, throttle body, Throttle Position Sensor (TPS) and the Idle Speed Stepper (ISS) motor.

Fuel delivery system provides fuel from fuel pump to the fuel control system. Fuel system is composed of an in-tank electric fuel pump, fuel filter and return line. Power is provided to operate fuel pump through a fuel pump relay located on right inner fender panel.

Fuel control system handles actual fuel delivery into the engine. Fuel pressure regulator maintains a constant fuel pressure of 31-39 psi (2.1-2.7 kg/cm). In addition to the regulator, fuel system consists of the fuel rail and 4 fuel injectors. On MPI engine, ECU controls EGR/EVAP solenoid operation.

The ECU is a digital microprocessor computer. ECU receives input signals from various switches and sensors. ECU then computes fuel injector pulse width ("on" time), spark advance, ignition module dwell, idle speed, canister purge cycles, EGR flow and feedback control from this information.

OPERATION

AIR INDUCTION

Air is drawn into combustion chamber through air cleaner and intake manifold. Amount of air entering engine is controlled by position of throttle body valve. Throttle body houses throttle position sensor (TPS) and idle speed solenoid (ISS) motor. TPS is an electrical resistor which is connected to throttle valve. TPS transmits a signal to ECU in relation to throttle valve angle. This signal is used in calculations to determine injector pulse width to provide adequate air/fuel mixture.

ECU controls idle speed by providing appropriate voltage outputs to move ISS motor pin inward or outward to maintain a predetermined idle speed. ECU continuously monitors TPS and ISS motor and issues change commands to injectors to increase or decrease amount of fuel injected.

FUEL DELIVERY

Power to fuel pump relay is supplied from ignition switch when in "ON" or "START" position, at which time the ECU supplies a ground for fuel pump relay. When relay contacts are closed, power is applied to fuel pump.

Fuel is drawn through one end of a roller-type electric fuel pump, compressed and forced out opposite end. Pump capacity is greater than maximum engine consumption so that pressure in fuel system is always maintained.

FUEL CONTROL

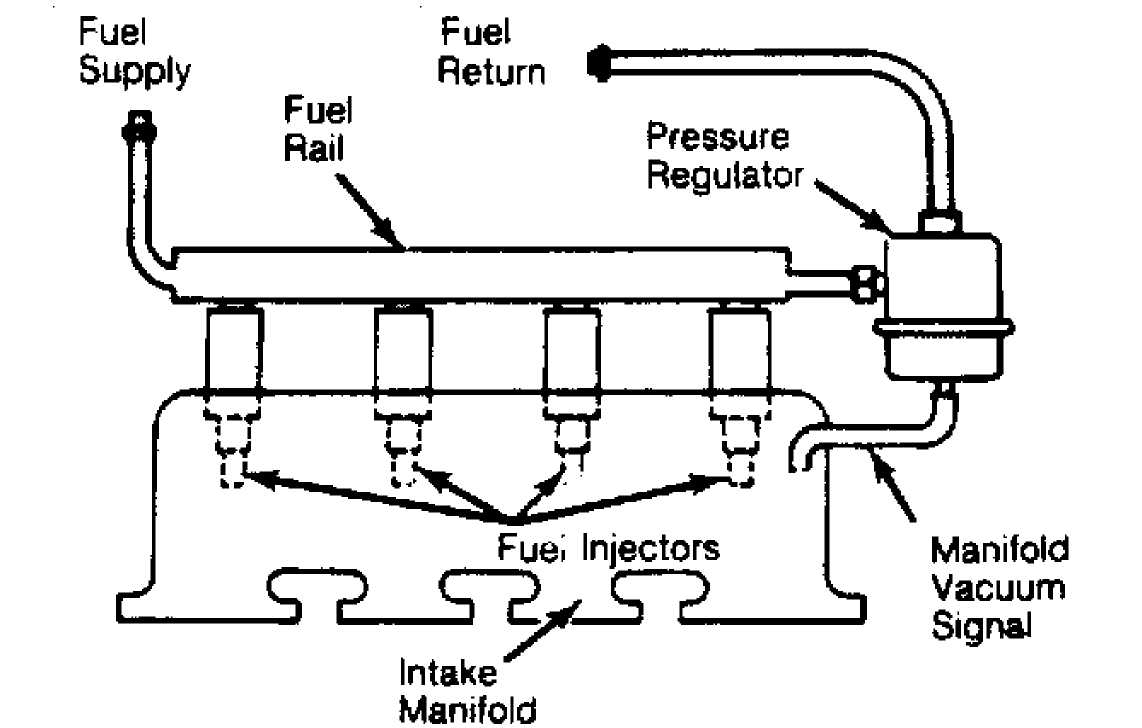

Fuel control system handles actual delivery of fuel to engine. See Fig. 1. Fuel from fuel pump enters fuel rail, injectors and pressure regulator. Based upon a manifold vacuum signal, pressure regulator maintains a constant fuel pressure in fuel system of approximately 31-39 psi (2.1-2.7 kg/cm) by allowing excess fuel to return to fuel tank.

Fuel injectors are electrically operated solenoid valves which are energized by the ECU. The ECU determines injector pulse width ("on" time) based upon input from the various sensors.

Fig.

1: Fuel Control Components Courtesy

of Chrysler Motors.

Fig.

1: Fuel Control Components Courtesy

of Chrysler Motors.

EMISSION CONTROL

ECU controls EGR valve and fuel evaporative operation. By energizing the EGR/EVAP solenoid, vacuum is shut off, making this system non-operative. When engine reaches normal operating temperatures, ECU de-energizes solenoid. When de-energized, solenoid allows vacuum to flow to EGR valve. ECU will energize solenoid whenever EGR action is undesirable, during idle, cold engine operation, wide open throttle and rapid acceleration or deceleration.

ELECTRONIC CONTROL UNIT (ECU)

ECU is a digital microprocessor computer. Data sensors provide the ECU with engine operating information in varying electrical signals. ECU calculates this information and corrects air/fuel ratio, ignition timing, and emission control as needed to maintain efficient engine operation. Other ECU output signals control upshift indicator light (manual transmission only), ignition module dwell and A/C clutch operation.

UPSHIFT INDICATOR

On vehicles equipped with a manual transmission, ECU controls upshift indicator light. Indicator light is normally illuminated when ignition is turned on without engine running. Indicator light is turned off when engine is started.

Indicator light will be illuminated during engine operation in response to engine load and speed. If transmission is not shifted, ECU will turn light off after 3 to 5 seconds. A switch located on transmission prevents indicator light from being illuminated when transmission is shifted to highest gear.

DATA SENSORS & SWITCHES

Manifold Absolute Pressure (MAP) Sensor

MAP sensor is located in engine compartment on firewall,

behind engine. MAP sensor monitors manifold vacuum via a vacuum line

from intake manifold to sensor.

MAP sensor supplies an electrical signal which keeps ECU

informed of manifold vacuum and barometric pressure conditions. This

information is combined with data supplied by other sensors to

determine correct air/fuel ratio.

Oxygen Sensor

Oxygen (O2) sensor is mounted in exhaust manifold where it is exposed to exhaust gas flow. Its function is to monitor oxygen content of exhaust gases and to supply ECU with a voltage signal directly proportional to this content.

If oxygen content of exhaust gases is high (lean air/fuel mixture), voltage signal to ECU is low. As oxygen content decreases (mixture becomes richer), signal voltage increases.

In this way, ECU is kept constantly informed of air/fuel ratio. ECU can then alter fuel injector "on" time, in response to these signals, to obtain best air/fuel ratio of 14.7:1 under any given operating conditions.

O2 sensor is equipped with a heating element that keeps sensor at proper operating temperatures. Maintaining correct sensor temperatures at all times guarantees a more accurate signal to ECU. By using an O2 heater, fuel control system may also enter "closed loop" operating mode sooner and maintain this mode, even during periods of extended idle.

Temperature Sensors

There are 2 temperature sensors used on this system. Manifold Air Temperature (MAT) sensor, mounted in intake manifold, measures temperature of incoming air/fuel mixture and Coolant Temperature Sensor (CTS), located on left side of cylinder block just below the exhaust manifold, measures temperature of engine coolant.

Information provided by these 2 sensors to ECU allows ECU to demand slightly richer air/fuel mixtures and higher idle speeds during cold engine operation.

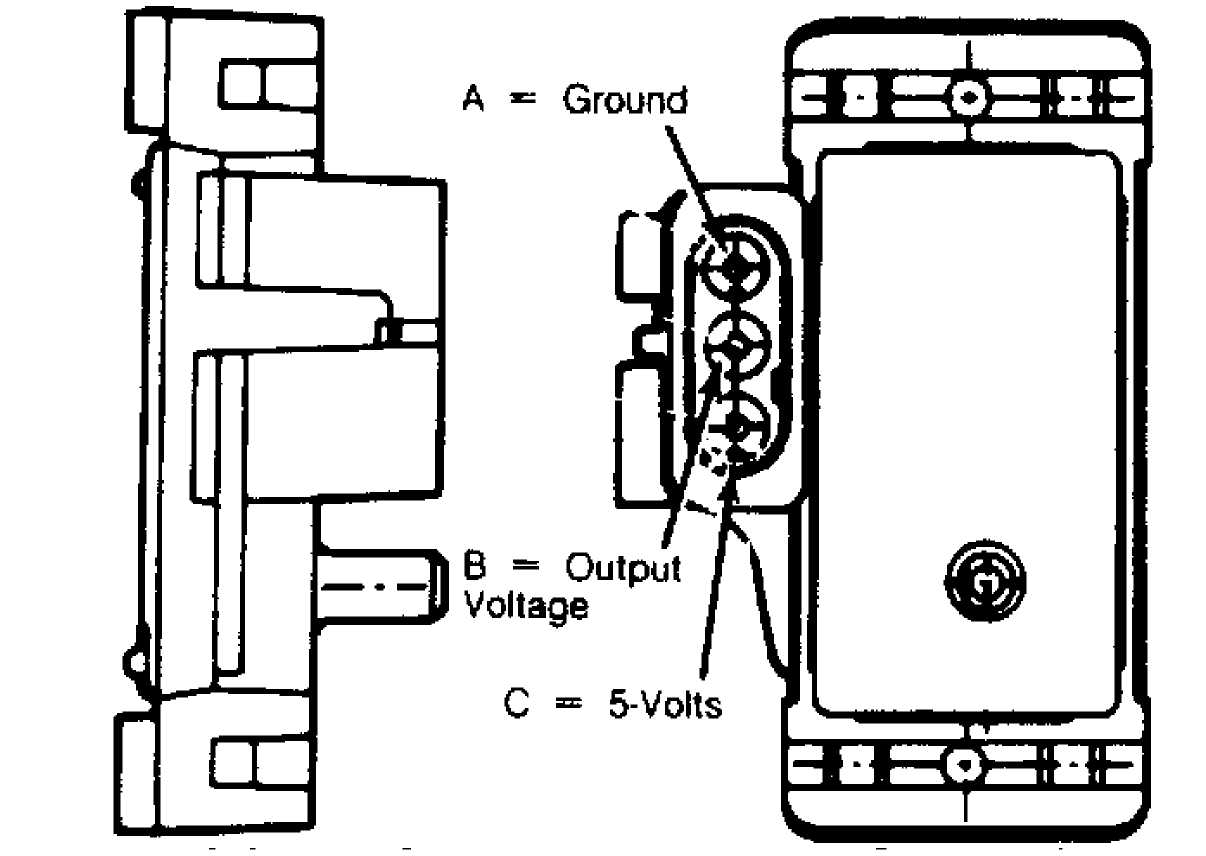

Throttle Position Sensor (TPS)

TPS is regulated by movement of throttle shaft. It is

mounted on throttle body and senses angle of throttle blade opening.

A voltage signal of up to 5 volts at wide open throttle is produced by TPS. Voltage varies with throttle angle changes. This signal is transmitted to ECU where it is used to adjust air/fuel ratio during acceleration, deceleration, idle, and wide open throttle conditions.

A dual TPS is used on models with automatic transmissions. This dual TPS not only provides ECU with input voltages but also supplies automatic transmission control unit with input signals relative to throttle position.

Knock Sensor

Knock sensor (detonation sensor) is located on lower left side of cylinder block just above oil pan. Knock sensor picks up detonation vibration from engine and converts it to an electrical signal for use by ECU.

ECU uses this information to determine when a change in ignition timing is required. Knock sensor allows for engine operation on either "premium" unleaded or "regular" unleaded fuel.

When knock occurs, ECU retards ignition timing in one or more cylinders until detonation is eliminated.

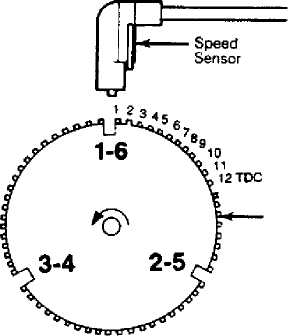

Speed Sensor

Speed sensor is secured by special shouldered bolts to flywheel/drive plate housing. Speed sensor is nonadjustable and preset at factory. Speed sensor senses TDC and engine speed by detecting flywheel teeth as they pass pick-up coil during engine operation. See Fig. 2.

Flywheel has a large trigger tooth and notch located 12 small teeth before each TDC position. When a small tooth and notch pass the magnetic core in sensor, concentration and collapse of the magnetic field created induces a small voltage spike into sensor pick-up coil windings. These small voltage spikes are sent to ECU, allowing ECU to count the teeth as they pass sensor.

When a large tooth and notch pass magnetic core in sensor, increased concentration and collapse of the magnetic field induces a higher voltage spike than smaller teeth. Higher spike indicates to ECU that a piston will soon be at TDC position, 12 teeth later. Ignition timing for cylinder is either advanced or retarded by ECU based upon "sensor input".

Flywheel Teeth

Fig. 2: Speed Sensor Operation Courtesy of Chrysler Motors.

Engine Switches

Several switches provide operating information to ECU. These

include Park/Neutral switch (automatic transmission only), air conditioning clutch, and Sync Pulse switch. When A/C or Park/Neutral switches supply ECU with an "on" signal, module signals ISS motor to change idle speed to a specific RPM.

With A/C on and throttle blade above a specific angle, ECU de-energizes A/C relay, preventing A/C clutch from engaging until throttle blade angle is reduced.

Sync pulse switch, located within distributor, generates a signal to ECU, helping to properly synchronize sequential fuel injection opening with intake valve opening.

ADJUSTMENTS

NOTE: Idle speed and air/fuel mixture are controlled by ECU and are non-adjustable. On-car adjustment procedures for other components should not be necessary during normal vehicle operation or maintenance. Adjustments of components should only be required when a faulty component is replaced with a new one.

THROTTLE POSITION SENSOR (TPS)

1) Turn

ignition on. Check throttle position sensor input

voltage. Connect

voltmeter negative lead to terminal "B" (M/T),

or

terminal "D" (A/T) of sensor

connector. Connect voltmeter positive

lead

to terminal "A" (M/T and A/T) of sensor connector.

NOTE: On (A/T) models, connector terminals are identified by

letters molded into back of connector. On all models, do not disconnect TPS harness connector. Insert voltmeter test leads through back of wire harness connector. On some models, it may be necessary to remove throttle body from intake manifold to gain access to sensor wire harness.

2) Move

and close throttle plate completely (M/T and A/T).

Ensure

throttle linkage contacts stop. Note voltmeter reading. Input

voltage

at terminals "B" and "A" (M/T), or

terminals "A" and "D"

(A/T) should be 5 volts.

Return

throttle plate to closed throttle position (M/T

and

A/T). Check sensor output voltage. To do

so, disconnect voltmeter

positive lead from terminal "A"

and connect it to terminal "C" (M/T),

or

terminal "B" (A/T).

Maintain

throttle plate in closed position (M/T and A/T).

Ensure throttle

linkage contacts stop. Note voltmeter reading. Output

voltage

should be .8 volt (M/T), or 4.2

volts (A/T).

If output

voltage is incorrect, loosen bottom sensor

retaining screw and

pivot sensor in adjustment slot for a coarse

adjustment. Loosen

top sensor retaining screw for fine adjustments.

Tighten screws

after adjustment.

TESTING & TROUBLE SHOOTING

PRELIMINARY CHECKS & PRECAUTIONS

Subsystem Checks

The following systems and components must be in good condition and operating properly before assuming a fuel injection system malfunction.

Air filter.

All support systems and wiring.

Battery connections and specific gravity.

Engine Compression.

Electrical connections on components and sensors.

Emission control devices.

Ignition system.

All vacuum line, fuel hose and pipe connections.

General Precautions

In order to prevent injury to operator or damage to system or component parts, use following techniques:

Turn

ignition off before connecting or disconnecting any

component

parts.

DO

NOT apply DC voltage greater than 12 volts

or any AC voltage

to system.

Disconnect battery cables before charging.

Remove

ECU from vehicle if ambient temperature could exceed

176F (80C).

DO NOT modify or circumvent any system functions.

SYSTEM TESTING

Fuel System Test

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal injury, cover fittings with shop towel while disconnecting fittings.

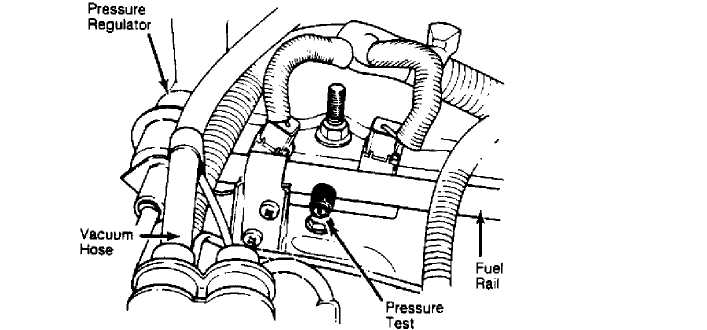

1)

See Fig. 3. fitting.

2)

(2.1 kg/cm) 39 psi (2.6 regulator.

3)

at least one off. If fuel plugged fuel

Remove cap from pressure test port located in fuel rail. Connect Fuel Pressure Gauge (J-34730-1) to pressure

Start vehicle. Pressure should be approximately 31 psi

with vacuum hose connected to pressure regulator and kg/cm) with vacuum hose removed from pressure

Check fuel pump flow rate. A good fuel pump will deliver liter of fuel per minute with fuel return line pinched pump does not pump adequately, inspect fuel system for a filter or filter sock.

Fig.

3: Fuel System Pressure Test Components

Courtesy of Chrysler Motors.

Fig.

3: Fuel System Pressure Test Components

Courtesy of Chrysler Motors.

4) Fuel pump flow rate can be checked by connecting one end of an old A/C gauge hose to fuel test port on fuel rail and inserting

other end of hose into a container of at least one liter or more capacity.

5) Run fuel pump by installing a jumper wire into diagnostic connector terminals D1-5 and D1-6. Be sure to pinch off fuel return line or most of fuel will be returned to fuel tank.

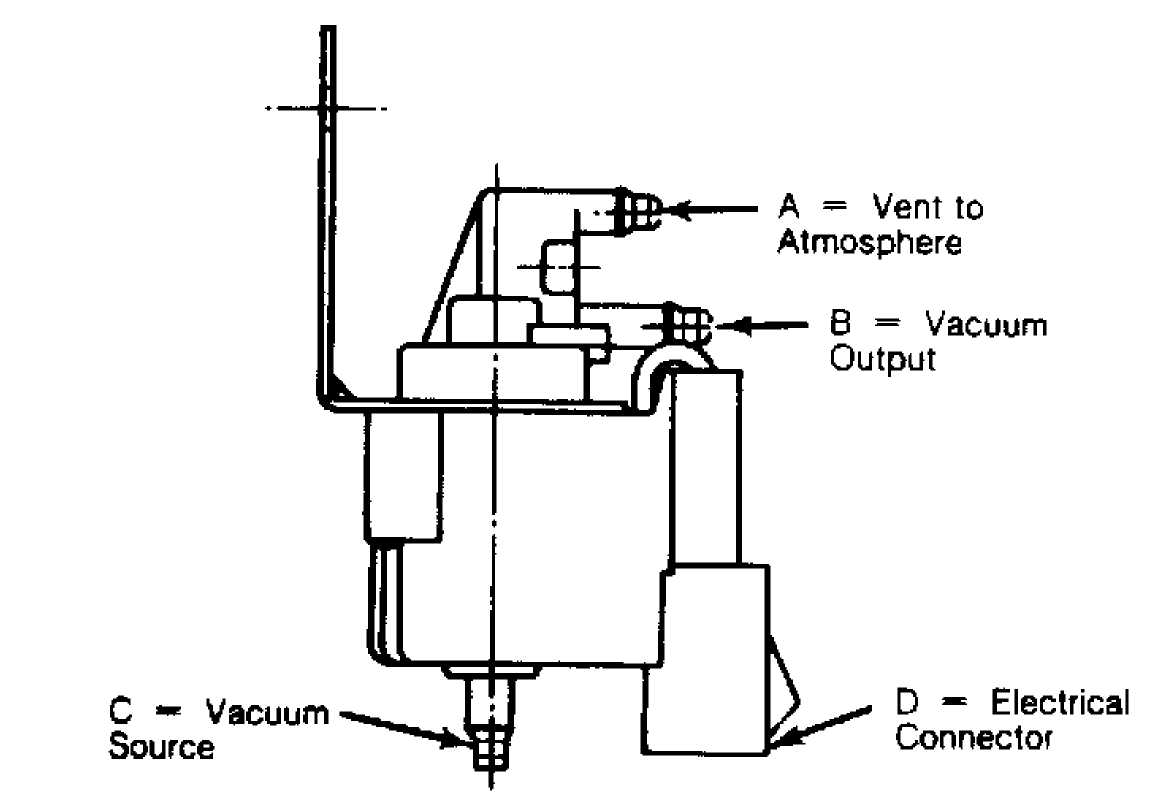

EGR Solenoid Test

Verify

that vacuum is present at vacuum fitting "C" of

EGR

solenoid. See Fig. 4. Remove vacuum

connector from "A" and "B".

Connect

a vacuum gauge to "B".

Start

and idle engine. There should be no vacuum at "B".

Disconnect

electrical connector "D" from solenoid. There should

now

be vacuum at "B".

Fig.

4: EGR Solenoid Test Points Courtesy

of Chrysler Motors.

Fig.

4: EGR Solenoid Test Points Courtesy

of Chrysler Motors.

MAP Sensor Test

Inspect

MAP sensor hoses and connections. Repair as

necessary.

With ignition on and engine off, test MAP sensor output

voltage

at connector terminal "B". (Marked

on sensor body). See

Fig. 5.

Output voltage should be 4 to

5 volts.

To verify

wiring harness condition, test ECU terminal C-6

for same voltage

described. Test MAP sensor supply voltage at sensor

connector

terminal "C" with ignition on.

Voltage

should be 4.5-5.5 volts. Same voltage

should also

be at terminal C-14 of ECU

wire harness connector. Using Diagnostic

Tester (M.S. 1170),

test MAP sensor ground circuit at terminal

D-3

and terminal "A" of

sensor connector.

Using an

ohmmeter, test MAP sensor ground circuit at ECU

connector between

terminal D-3 of ECU connector and terminal B-11

with an ohmmeter.

If ohmmeter or diagnostic tester indicates an open

circuit, inspect for a defective sensor ground connection, located on right side of cylinder block. If ground connection is good, ECU may need to be replaced.

Fig. 5: MAP Sensor Test Points Courtesy of Chrysler Motors.

O2 Sensor Heating Element Test

Disconnect O2 sensor connector. Connect an ohmmeter to terminals "A" and "B" only (marked on the connector) of O2 sensor connector. Resistance should be between 5 and 7 ohms. Replace sensor if ohmmeter indicates an infinity reading.

CTS Test

Disconnect

wire harness connector from CTS sensor. Test

resistance

of sensor with a high impedance digital ohmmeter.

Resistance

should be less than 1000 ohms with engine

warm. See

TEMPERATURE-TO-RESISTANCE

VALUES table.

Test

resistance of wire harness between ECU terminal D-3

and sensor

connector terminal. Repeat test at terminal C-10 of ECU

and

sensor connector terminal. Repair wire harness if an open circuit

is

indicated.

MAT Sensor Test

Disconnect

wire harness connector from MAT sensor. Test

resistance

of sensor with a high impedance digital ohmmeter.

Resistance

should be less than 1000 ohms with engine

warm. Replace

sensor if resistance is not within specified range.

See

TEMPERATURE-TO-RESISTANCE VALUES

table.

Test

resistance of wire harness between ECU wire harness

connector

terminal D-3 and sensor connector terminal. Repeat

test

with terminal C-8 at ECU and sensor connector terminal.

Repair wire

harness if an open circuit or

resistance is greater than one ohm is

indicated.

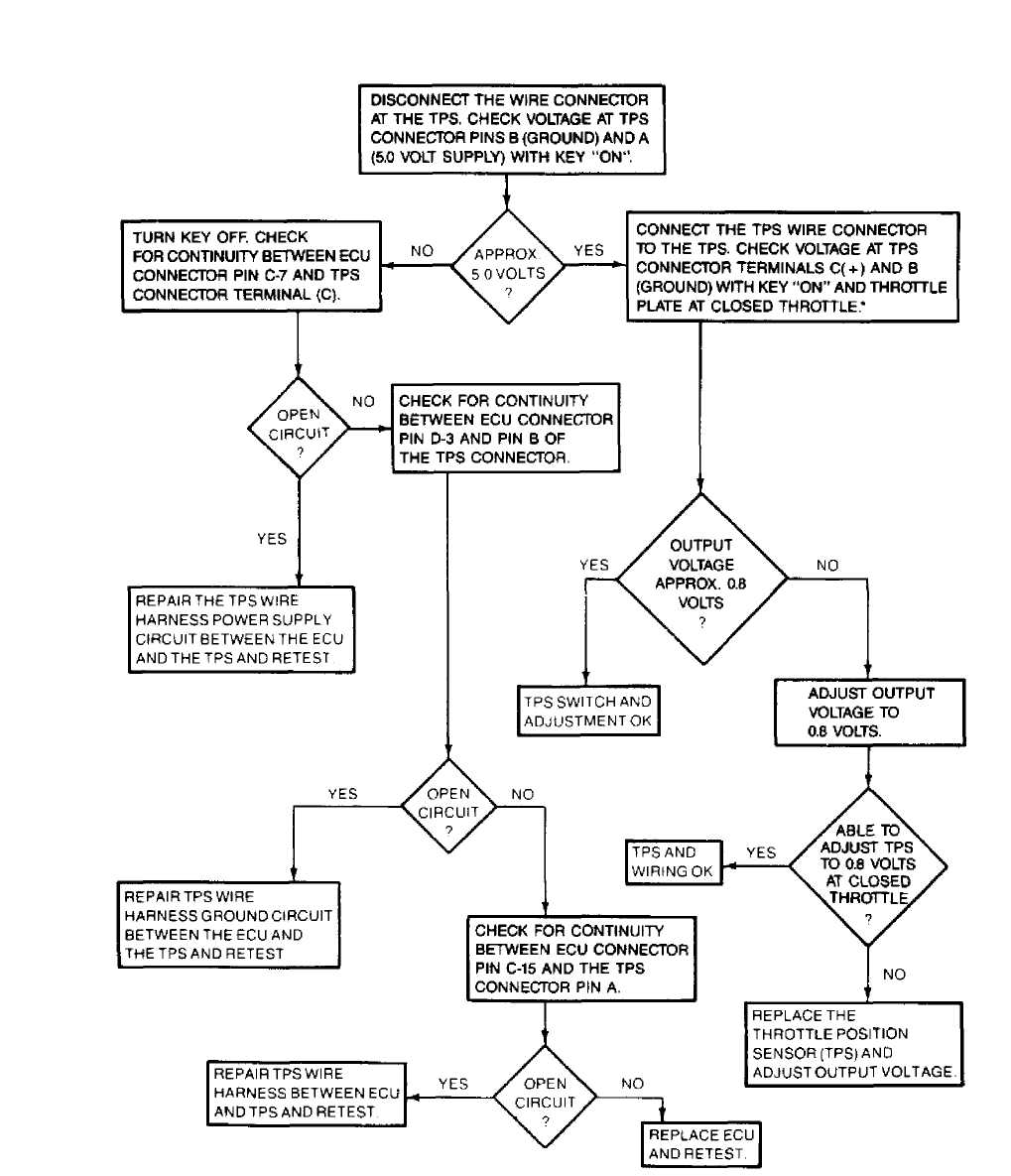

TPS Test

See THROTTLE POSITION SENSOR TEST PROCEDURE chart in this article.

TEMPERATURE-TO-RESISTANCE VALUES (CTS & MAT SENSOR) TABLE

°F °C Ohms

°F °C Ohms

(Approximate)

212 100 185

160 70 450

100 38 1600

70 20 3400

40 4 7500

20 -7 13,500

0 -18 25,000

-40 -40 100,700

Knock Sensor Test

Start

engine until engine reaches normal operating

temperature. Connect

Diagnostic Tester (M.S. 1700). Observe

knock

value on tester. Using tip of screw driver, gently tap on

cylinder

block next to knock sensor and

observe knock sensor value on tester.

Knock

sensor value should increase while tapping on

cylinder block. If

knock sensor value does not increase while tapping

on cylinder

block, check knock sensor for proper connection. If

connection is

good, replace knock sensor.

Speed Sensor Test

Disconnect speed sensor connector from ignition control module. Place an ohmmeter between terminals "A" and "B". (Marked on connector) Reading should be 125-275 ohms with engine hot. Replace sensor if readings are not within specifications.

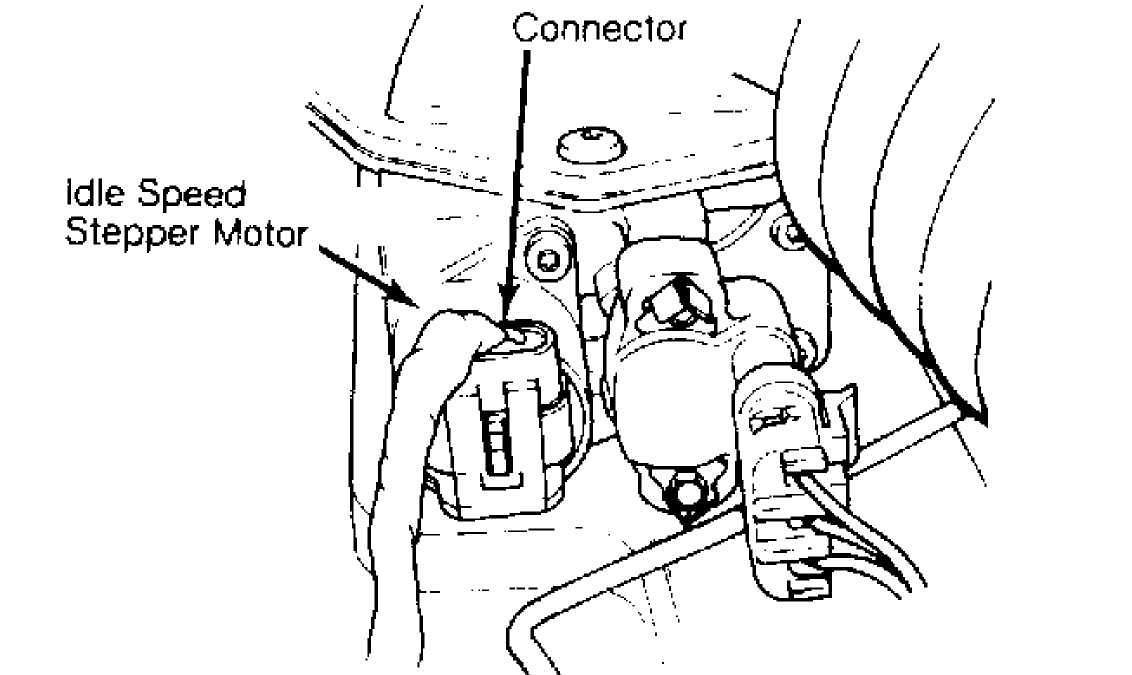

Idle Speed Stepper (ISS) Motor

Set

parking brake and block drive wheels. Route all

tester cables

away from cooling fans, drive belts, pulleys and

exhaust system.

Always allow engine speed to return to normal before

disconnecting

testing tools.

With ignition off, disconnect ISS motor connector at

throttle body. Connect Exerciser Tool (Part No. 8980 002 646) into ISS motor. See Fig. 6.

3) Connect

Red clip to battery positive cable. Connect

Black clip to battery

negative cable. Red light on exerciser tool

will illuminate when

properly connected. Start engine.

NOTE: When switch on exerciser tool is in "High" or "Low"

position, light on exerciser tool will flash indicating voltage pulses are being sent to ISS motor.

Fig. 6: ISS Motor Test Connector Courtesy of Chrysler Motors.

Fuel Injector Test

Move

exerciser tool switch to "High" position. Engine

speed

should increase. Move switch to "Low" position. Engine

speed

should decrease. If engine speed increases or decreases

while using

exerciser tool, ISS motor is functioning properly.

Disconnect

exerciser tool and reconnect ISS motor

connector. If engine speed

does not change, turn ignition off and

remove ISS motor from

throttle body.

With

ignition off, switch exerciser tool between "High"

and

"Low" positions. Check movement of ISS motor pintle.

Pintle

should move in and out. If pintle does not move, replace

ISS motor.

Start

engine and test new ISS motor for proper

operation. If pintle

operates properly, check ISS motor bore in

throttle body for

blockage and clean as necessary. Reinstall ISS

motor into

throttle body.

See FUEL INJECTOR TEST PROCEDURE chart in this article.

REMOVAL & INSTALLATION

COOLANT TEMPERATURE SENSOR (CTS)

Removal & Installation

Drain cooling system. Remove air cleaner assembly.

Disconnect CTS wire connector. Remove CTS from engine block. Install replacement CTS and connect CTS wire connector. Install air cleaner assembly. Fill cooling system.

OXYGEN SENSOR

Removal & Installation

Raise and support vehicle. Disconnect O2 sensor wire

connector. Remove O2 sensor from exhaust manifold. Install O2 sensor and tighten to 30 ft. lbs. (41 N.m). Connect O2 sensor wire connector and lower vehicle.

KNOCK SENSOR

Removal & Installation

Raise and support vehicle. Disconnect knock sensor wire connector. Remove knock sensor from cylinder block. Install knock sensor and connect knock sensor wire connector. Lower vehicle.

SPEED SENSOR

Removal & Installation

Disconnect speed sensor wire connector. Remove 2 speed sensor retaining bolts at transmission housing. Install speed sensor and connect speed sensor wire connector.

STARTER MOTOR RELAY

Removal & Installation

Disconnect negative battery cable. Identify, tag and

disconnect wiring to relay. Remove relay retaining screws and remove relay from inner fender panel. Install replacement relay and connect relay wires. Connect negative battery cable. Test relay operation.

MANIFOLD AIR/FUEL TEMPERATURE (MAT) SENSOR

Removal & Installation

Disconnect wire connector from MAT sensor. Remove MAT sensor from intake manifold. To install, reverse removal procedure.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

Removal & Installation

Disconnect wire connector, vacuum hose, and retaining nuts from MAP sensor. Remove sensor from firewall. To install, reverse removal procedure.

FUEL INJECTOR

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal injury, cover fittings with shop towel while disconnecting fittings.

Removal

Disconnect fuel lines from fuel rail assembly. Disconnect injector wire harness connector. Remove fuel rail retaining bolts. Remove vacuum hose from fuel pressure regulator valve. Remove fuel injector retaining clips and remove fuel injectors. See Fig. 7. On models with (A/T), it may be necessary to remove throttle pressure cable and bracket to remove fuel rail assembly.

NOTE:

O-rings must be replaced before fuel lines are reassembled.

Installation

Install fuel injectors into fuel rail assembly and install retaining clips. Position fuel rail onto manifold while lining up injectors with holes in intake manifold. Secure injector retaining bolts. Connect injector wire connectors to proper injectors. Install fuel lines into fuel rail assembly. Connect vacuum hose to pressure regulator. Install throttle pressure bracket and cable (A/T).

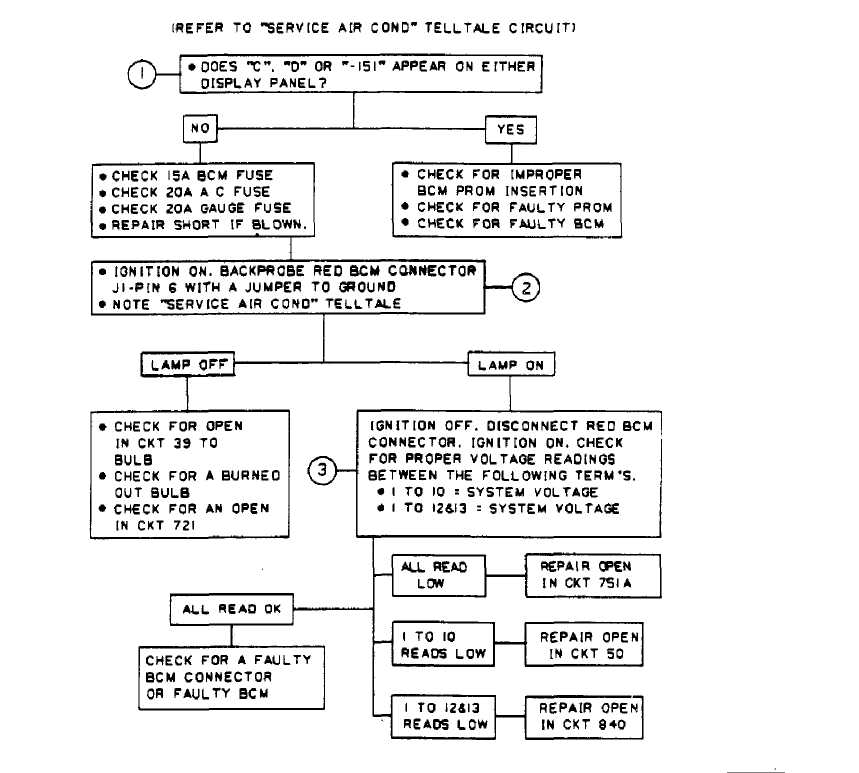

CHART

A-1, INOPERATIVE "SERVICE AIR COND." LIGHT

CHART

A-1, INOPERATIVE "SERVICE AIR COND." LIGHT

Fig.

7: Fuel Rail Assembly Courtesy

of Chrysler Motors.

Fig.

7: Fuel Rail Assembly Courtesy

of Chrysler Motors.

FUEL PRESSURE REGULATOR

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal injury, cover fittings with shop towel while disconnecting fittings.

Removal & Installation

Remove injector fuel rail assembly. Remove 2 pressure regulator retaining screws. Remove regulator from fuel rail. To install, reverse removal procedure. Adjust regulator after installation.

IDLE SPEED STEPPER (ISS) MOTOR

Removal & Installation

1) Disconnect ISS motor connector. Remove ISS motor retaining screws and ISS motor. To install, reverse removal procedure. No idle speed adjustment is necessary. Idle speed is controlled by the Electronic Control Unit (ECU).

THROTTLE POSITION SENSOR

Removal & Installation

Disconnect TPS wire connector. Bend retaining bolts lock tabs and remove retaining bolts. Remove TPS from throttle plate assembly. To install, reverse removal procedure. Adjust TPS after installation. See ADJUSTMENTS in this article.

EGR VALVE

Removal & Installation

Disconnect vacuum hose from EGR valve. Remove bolts which hold EGR valve to intake manifold. Remove valve and discard gasket. Clean intake manifold gasket mating surface. To install valve, reverse removal procedure. Always use new gasket. See Fig. 8.

Fig.

8: EGR Valve

Courtesy of Chrysler Motors.

EGR SOLENOID

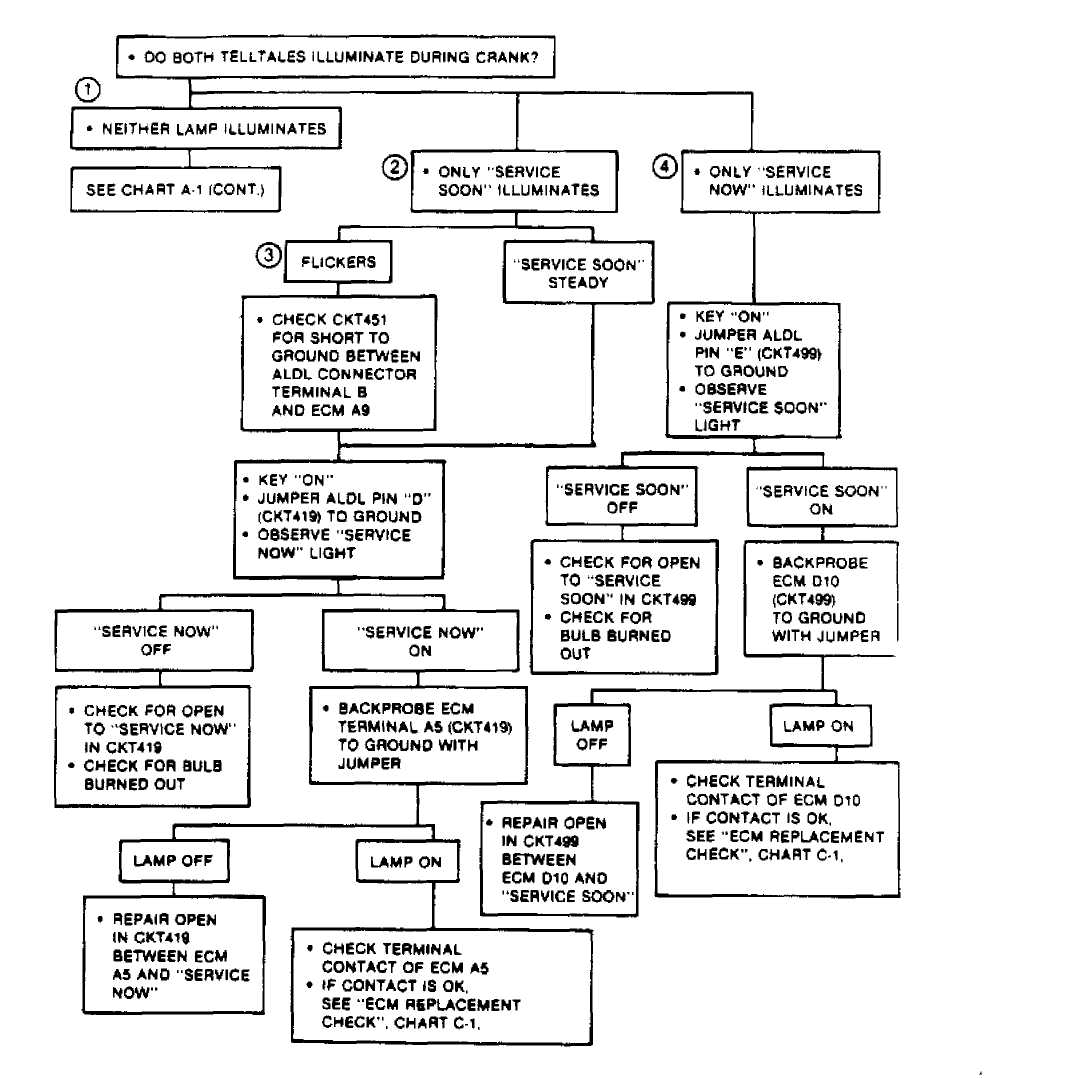

CHART B-1, INOPERATIVE "SRVICE AIR COND." LIGHT

Disconnect solenoid vacuum hoses. Disconnect solenoid wiring connector. Remove solenoid retaining bolts and solenoid. To install valve, reverse removal procedure.

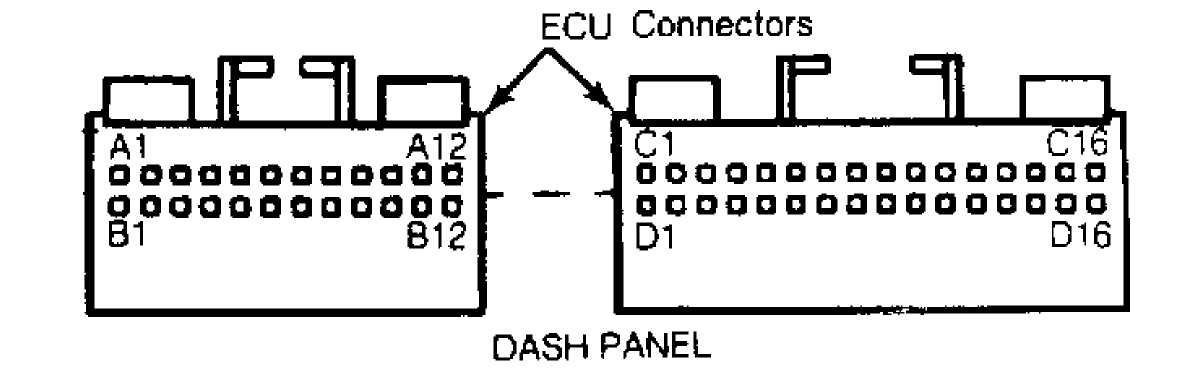

ECU CONNECTOR PIN IDENTIFICATION 24-PIN CONNECTOR MPFI TABLE

Terminal

No.

Terminal

No.

Wire Function

A1 Injector No. 3

A2 Injector No. 6

A3 Injector No. 2

A4 Injector No. 4

A5 Fuel Pump Relay

A6 Not Used

A7 Oxygen Sensor Relay

A8 Shift Light

A9 Latch Relay

A10 EGR/Evap. Solenoid

A1 1 Not Used

A12 A/C Relay

B1 Injector No. 1

B2 Injector No. 5

B3 AIS A

B4 AIS A1

B5 AIS C

B6 AIS C1

B7 Battery (Pos.)

B8 Ignition

B9 Not Used

B10 Latched B (Pos.)

B11 Ground

B12 Ground

Fig. 9: Multi-Point Injection ECU Connector Courtesy of Chrysler Motors.

ECU CONNECTOR PIN IDENTIFICATION 32-PIN CONNECTOR MPFI TABLE

Terminal

No.

Terminal

No.

Wire Function

C1 Speed Sensor (Pos.)

C2 A/C Request

C3 Start

C4 P/N Switch

C5 Sync. (Neg. )

C6 MAP Sensor

C7 TPS Sensor

C8 Air Temp. Sensor

C9 Not Used

C10 Coolant Temp. Sensor

C11 Injection Supply

C12 TX Serial Data

C13 Not Used

C14 MAP Sensor Supply Voltage

C15 TPS Supply Voltage

C16 Sync. (Pos.)

D1 Speed Sensor (Neg.)

D2 A/C Select

D3 Sensor Ground

D4 Not Used

D5 Not Used

D6 Not Used

D7 Not Used

D8 Knock Sensor Ground

D9 Oxygen Sensor Input

D10 Injector Supply

D11 RX Serial Data

D12 Not Used

D13 Spark/Dwell

D14 Not Used

D15 Not Used

D16 Knock Sensor

*

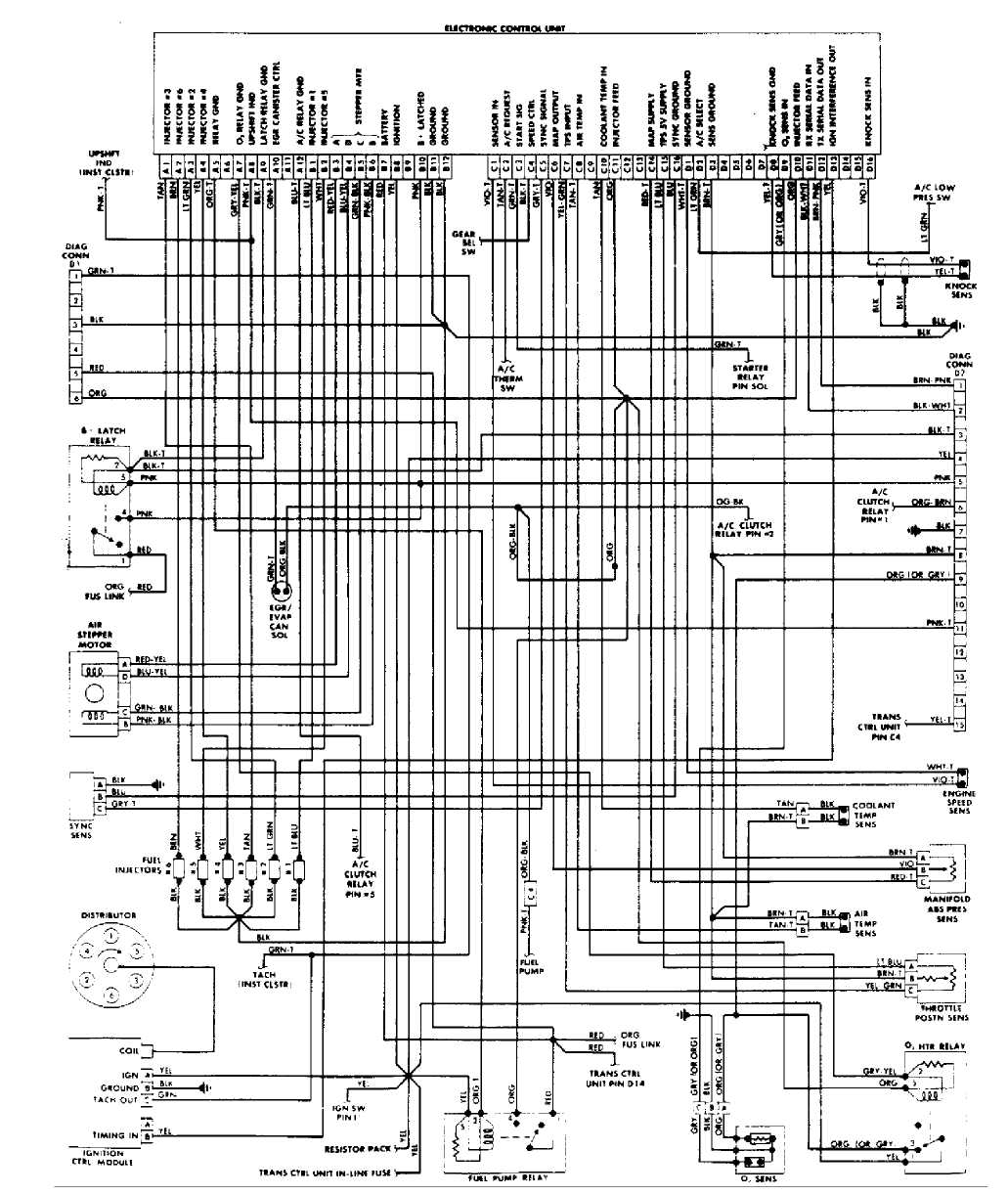

FRONT OF VEHICLE

CONNECTOR

D1 CONNECTOR D2

|

1. Tach Signal |

1. ECU Output (TX) |

|

2 Not Used |

2. RX Data (ECU) |

|

3. ECU Ground |

3. Latch Relay |

|

4. Not Used |

4. Ignition |

|

5. Battery (Pos} |

5. Latch Battery (Pos.) |

|

6. Fuel Pump (Pos.) |

6. A/C Clutch |

|

|

7. Ignition Ground |

|

|

8. Sensor Ground |

|

|

9. Oj Sensor Heater |

|

|

10. Not Used |

|

|

11. Shift Light |

|

|

12. Not Used |

|

|

13. Not Used |

|

|

14, Not Used |

|

|

15. Auto Transmission Diagnosis |

Fig. 10: Multi-Point Injection Diagnostic Connector Courtesy of Chrysler Motors.

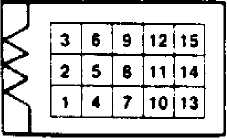

Fig. 11: Comanche Multi-Point Fuel Injection Wiring Diagram (Wiring Diagram Not Available for Cherokee & Wagoneer Models)

’ DO NOT UNFASTEN THE SENSOR WIRE HARNESS CONNECTOR. INSERT THE VOLTMETER TEST LEADS THROUGH THE BACK OF THE WIRE HARNESS CONNECTOR TO MAKE CONTACT WITH THE SENSOR TERMINALS.

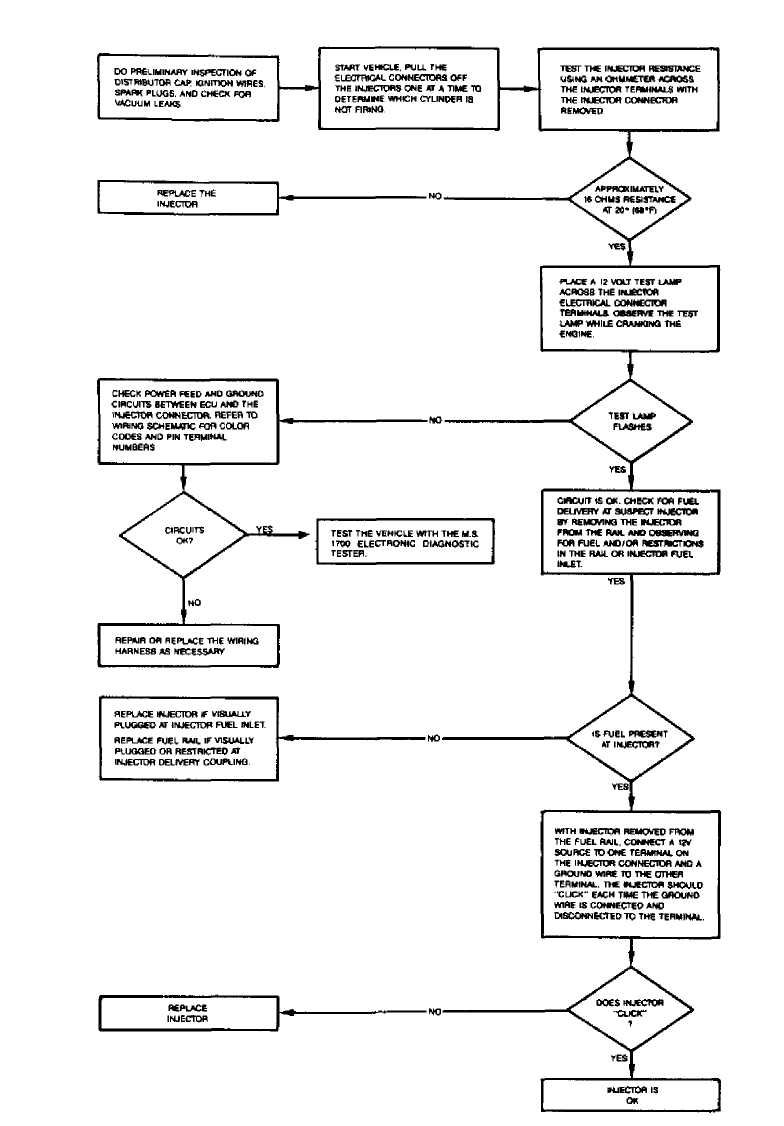

FUEL INJECTOR TEST PROCEDURE CHART

Fig. 13: Fuel Injector Test Procedure Chart