SUSPENSION - FRONT

1988 Jeep Cherokee

1988 FRONT SUSPENSION Jeep Coil & Leaf Spring

Cherokee, Comanche, Grand Wagoneer, Wagoneer, Wrangler

DESCRIPTION

Cherokee, Comanche and Wagoneer 2WD and 4WD front

suspensions consist of solid axle (tubular axle on 2WD), 4 control arms, 2 coil springs and track bar. Track bar is used to minimize front axle side-to-side movement. Stabilizer bar and shock absorbers control suspension spring movement.

Grand Wagoneer and Wrangler models use leaf spring front suspension with shock absorbers and stabilizer bar. Wrangler also uses a track bar to maintain lateral position of front and rear axles.

ADJUSTMENTS

WHEEL ALIGNMENT

See WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES in WHEEL ALIGNMENT section.

WHEEL BEARING

NOTE: Bearings should be cleaned, inspected, replaced (if necessary) and lubricated before adjustment.

CAUTION: Never preload tapered roller bearings or damage to roller ends will result. Bearings are designed to have a slightly loose feel when properly adjusted.

2WD Models

Raise and

support vehicle. Remove wheel and tire

assembly. Remove hub dust

cap, cotter pin and nut retainer. Ensure

bearings are thoroughly

packed with lithium grease.

Rotate

hub and rotor assembly by hand, and tighten

retainer nut to 17-25

ft. lbs. (23-34 N.m) to

seat bearings.

Loosen

retainer nut 1/2 turn while rotating hub.

Then

retighten nut to 19 INCH

lbs. (2 N.m). Install

nut retainer and new

cotter pin. Clean hub dust cap and coat

inside with clean grease.

Reverse removal procedure for remaining

components.

4WD Models (Grand Wagoneer)

On

models equipped with locking hubs, remove locking

hubs.

See appropriate LOCKING HUBS article. On models without

locking

hubs, remove hub dust cap and

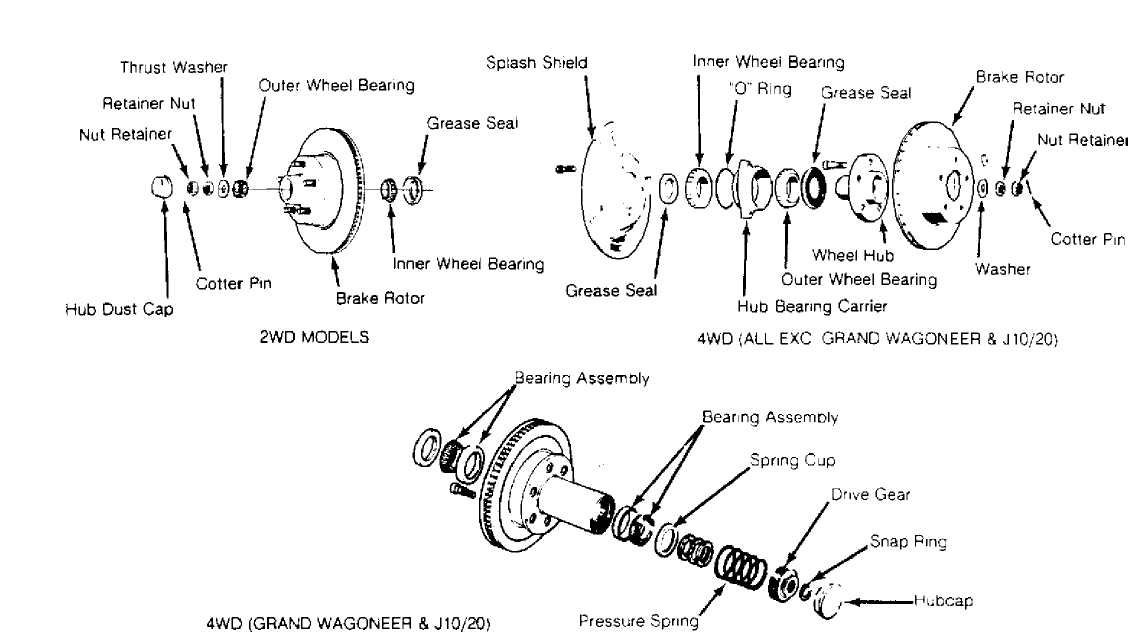

drive gear snap ring. See Fig. 1.

Remove

drive gear, pressure spring and spring cup. On

all

models, remove outer lock nut and lock washer. Tighten inner

lock

nut to 50 ft. lbs. (68 N.m)

while rotating wheel.

Back

off inner lock nut 45-65 degrees while

rotating

wheel. Install washer and

outer lock nut. Tighten outer lock nut to

50 ft.

lbs. (68 N.m). Reverse

removal procedure to complete

installation.

REMOVAL & INSTALLATION

WHEEL BEARINGS

Removal (2WD Models)

Raise and

support vehicle. Remove wheel assembly. Remove

brake caliper.

Suspend caliper with wire. DO NOT allow caliper to

hang on brake

hose.

Remove

hub dust cap, cotter pin, nut retainer, retainer

nut, washer and

outer wheel bearing. See Fig. 1. Remove

hub and rotor

assembly. Pry grease seal from hub. Remove inner

wheel bearing.

Inspection

Clean bearings and hub in solvent and dry with compressed air. Inspect bearings and races for wear.

Installation

To install, reverse removal procedure. Adjust wheel bearing. See WHEEL BEARING under ADJUSTMENTS in this article.

Removal (4WD Grand Wagoneer)

Raise and

support vehicle. Remove wheel assembly. Remove

brake caliper.

Suspend caliper with wire. DO NOT allow caliper to

hang on brake

hose. Remove rotor from hub.

On

models equipped with locking hubs, remove locking

hubs. See

appropriate LOCKING HUBS article. On all other models,

remove

hub dust cover and drive gear snap ring. See Fig. 1.

Remove

drive gear, pressure spring and spring cup. On

all models, remove

outer lock nut, lock washer, inner lock nut and

outer wheel

bearing. Remove hub. Pry grease seal from hub. Remove

inner wheel

bearing.

Inspection

Clean bearings and hub in solvent and dry with compressed air. Inspect bearings and races for wear.

Installation

To install, reverse removal procedure. Adjust wheel bearings. See WHEEL BEARINGS under ADJUSTMENTS in this article.

Removal (4WD Models Except Grand Wagoneer)

Raise

and support vehicle. Remove wheel assembly. Remove

brake

caliper. Suspend caliper with wire. Remove cotter pin, nut

retainer

and axle shaft nut. Remove hub/carrier assembly from

steering

knuckle. See Fig. 1.

Inspect

bearings for roughness. If bearing roughness

exists, disassemble

hub assembly.

Inspection

Clean bearings and hub in solvent and dry with compressed air. Inspect bearings and races for wear.

Installation

Ensure hub, bearing carrier and wheel bearings are packed with clean lithium grease. Reassemble hub assembly using new grease seal. Reverse removal procedure. Tighten bolts to specification. Install new cotter pin.

30211

Fig. 1: Exploded View Of 2WD Hub/Rotor Assembly & 4WD Hub/Bearing Carrier Assembly Courtesy of Chrysler Motors.

SHOCK ABSORBER

Removal & Installation

With

vehicle at normal riding height, remove nut, washer,

and rubber

grommet from top of shock absorber. Note component

locations for

reassembly reference.

Raise and

support vehicle. Remove lower shock mounting

bolts from axle

housing bracket. Remove shock absorber. Inspect units

for damage

or leakage. Replace shock absorbers in pairs only. To

install,

reverse removal procedure.

STEERING KNUCKLE

Removal

Raise and

support vehicle. Remove wheel assembly. Remove

brake caliper.

Suspend caliper with wire. Remove brake rotor or

hub/bearing

carrier assembly. See WHEEL BEARINGS in this article.

Remove

axle shaft from left side of axle housing. To

remove right axle

shaft, disconnect vacuum harness from shift motor.

Remove shift

motor and axle shaft from housing. Remove caliper anchor

plate

from steering knuckle.

On

each steering knuckle, remove ball joint stud cotter

pin and

retaining nuts. Using brass hammer, strike steering knuckle

at

ball joint stud bore area to loosen ball joint from

steering

knuckle.

Inspect

split ring seat in steering knuckle ball joint

stud bore for

damage. If damaged, use Split Ring Seat

Remover/Installer to

remove split ring seat.

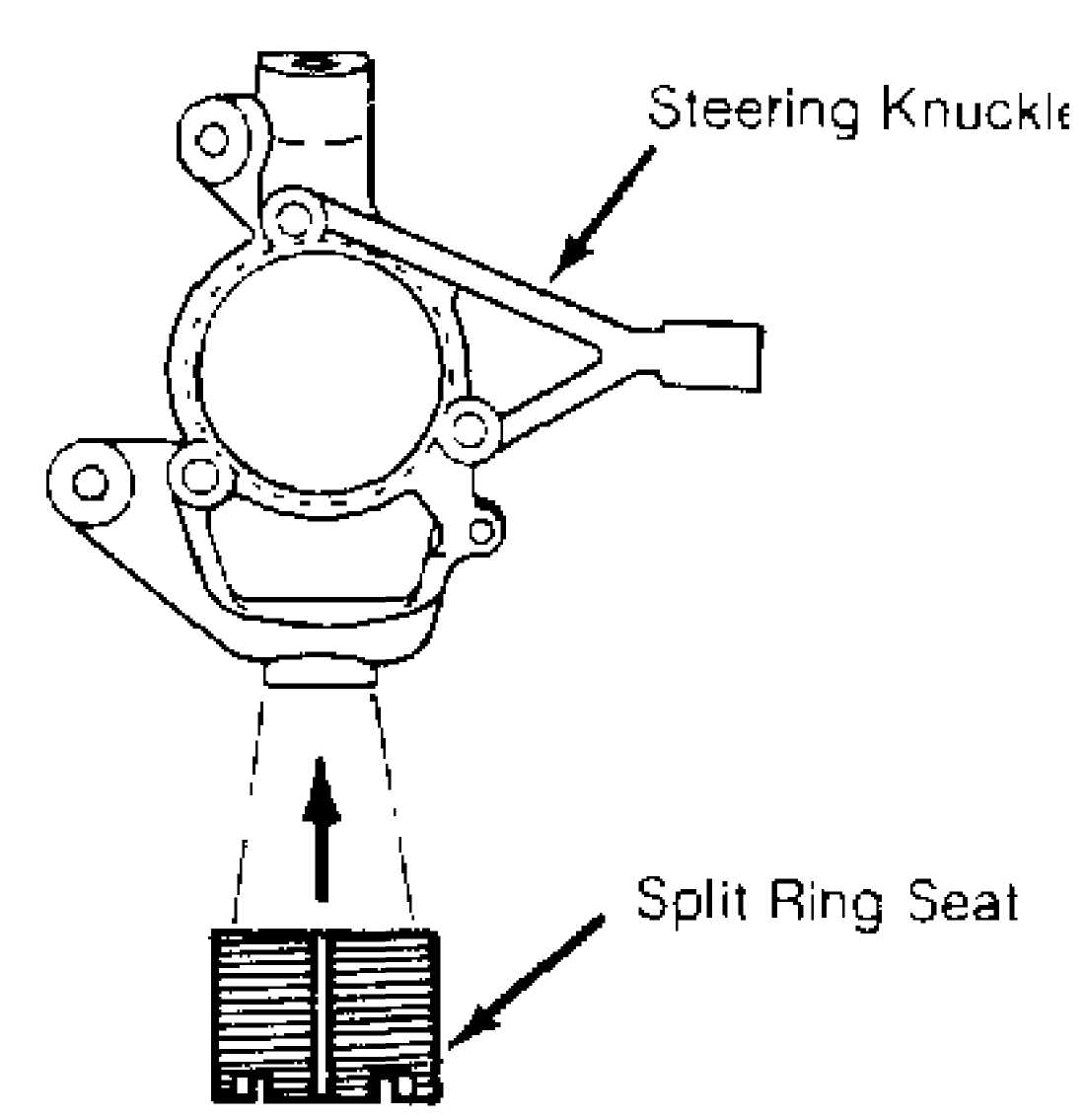

30212

Fig. 2: Determining Steering Knuckle Split Ring Seat Position Courtesy of Chrysler Motors.

Installation

If

split ring seat is replaced, ensure seat is adjusted

to

proper depth into steering knuckle ball joint stud bore. Using

split

ring seat remover /installer, install split ring seat to a

depth

of .206" (5.23 mm).

This

depth is measured from steering knuckle surface to

top

(notched edge) of split ring seat. See Fig. 2. To

install,

reverse removal procedures.

When

installing right axle shaft, ensure shift collar is

positioned on

intermediate shaft and axle shaft is fully engaged over

intermediate

shaft. Install shift motor. Ensure shift fork engages

with

collar. Tighten all bolts to specification.

UPPER & LOWER BALL JOINTS

Removal

Raise and

support vehicle. Remove wheel assembly. Inspect

upper and lower

ball joints for damage, torn grease seals or

excessive wear.

Replace as necessary.

Remove

steering knuckle assembly. See STEERING KNUCKLE in

this

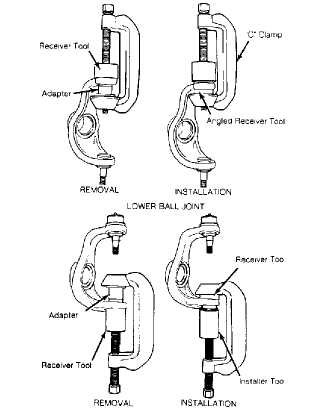

article. Position Ball Joint Receiver (J-34503-1) over top of

upper

ball joint. Place Adapter (J-34503-3) in "C" Clamp

(J-34503).

Install "C" clamp, adapter and receiver.

Tighten "C" clamp screw to

remove

ball joint. See Fig. 3.

To

remove lower ball joint, position Ball Joint Receiver

(J-34503-1)

onto "C" Clamp (J-34503) and Adapter (J-34503-3) at

base

of clamp. See Fig. 3.

Install "C" clamp, adapter and

receiver.

Tighten "C" clamp to remove ball joint. See

Fig. 3.

Installation

1) Place

upper ball joint in position. Position Ball Joint

Installer

(J-34503-3) over new upper ball joint. Install Receiver

(J-34503-2)

and "C" clamp. Position clamp, and receiver against axle

housing bracket, over installer and ball joint. Tighten "C" clamp and fully seat ball joint. See Fig. 3.

2) To

install lower ball joint, position Ball Joint

Installer

(J-34503-12), "C" clamp and

Receiver (J-34503-4) See

Fig. 3. Tighten "C" clamp to install ball joint. Ensure ball joint is fully seated. Reverse removal procedures for remaining components. Tighten bolts to specification.

Fig. 3: Removing & Installing Upper & Lower Ball Joints Courtesy of Chrysler Motors.

UDPER BALL JOINT

COIL SPRING

Removal

Raise and

support vehicle. Remove wheel assembly. Place

reference mark on

drive shaft and front axle flange. Disconnect drive

shaft at

front axle. Place jack stand under axle housing. Disconnect

lower

control arms at axle housing.

Disconnect

stabilizer bar links and lower shock absorber

mounting

bolts at axle housing. Disconnect track bar at the sill

bracket

(if equipped). Disconnect center link at

pitman arm.

Lower axle

housing to relieve spring pressure. Remove

spring retainer

mounting bolt, then remove retainer and coil spring.

Note

component locations for reassembly reference.

NOTE: Coil springs are rated separately for each side of vehicle depending on optional equipment and type of service. Ensure springs are marked for installation in original positions.

Installation

Install

coil spring and spring retainer. Tighten retainer

mounting bolt.

Raise axle housing into position. Connect lower

control arms to

axle housing.

Install

lower shock absorber mounting bolts, center

link-to-pitman arm,

track bar-to-frame bracket and stabilizer bar

links-to-axle

housing. To complete installation, reverse removal

procedure.

LEAF SPRING

Removal & Installation

Raise and support vehicle. Raise axle assembly with jack to relieve spring tension. On Wrangler models, loosen stabilizer bar link nut. On all other models, remove stabilizer bar. Remove spring "U" bolts and plate. Disconnect front and rear shackles from frame. Lower spring assembly. To install, reverse removal procedure.

UPPER CONTROL ARM &

AXLE HOUSING PIVOT BUSHING

Removal

To remove

right side upper control arm for 6-cylinder

models, disconnect

right side engine mount. Raise and support engine

so rear control

arm mounting bolt clears exhaust pipe. On all models,

raise and

support vehicle.

Remove

upper control arm mounting bolt from axle housing.

Disconnect

control arm mounting bolt at frame rail. Remove upper

control

arm. Repeat procedure for opposite control arm. Inspect

control

arm for damage or distortion and replace as needed.

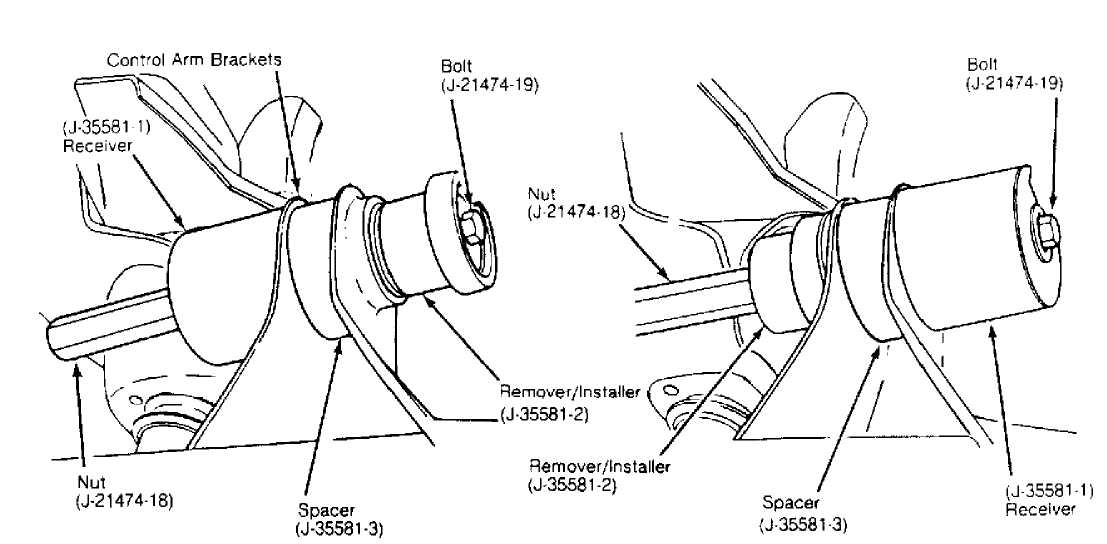

Check pivot bushings for excessive distortion,

deterioration or wear. If bushing replacement is necessary, install Spacer (J-33581-3) between ears of control arm bracket on axle housing. See Fig. 4.

NOTE: Spacer is not used on axle housings with solid control arm brackets.

CAUTION: Do not attempt to remove upper control arm pivot bushing without spacer. Tool is designed to support bracket and prevent distortion during bushing removal.

4) Install

Upper Control Arm Pivot Bushing Remover/Installer

Set

(J-35581, which must include Spacer J-35581-3, Remover/Installer

J-35581-2, Receiver J-35581-1, Bolt J-21474-19 and Nut J-21474-18) onto pivot bushing. See Fig. 4.

5) Rotate nut to press bushing from axle housing and into receiver. See Fig. 4. Once bushing is removed, remove bushing remover/installer set but leave spacer in position for new bushing installation.

Installation

Position

bushing on Remover/Installer (J-35581-2) and Nut

(J-21474-18).

Position bushing and installer components in

control

arm bracket. Assemble remaining installer components. See

Fig. 4.

Rotate

nut to press bushing into housing until fully

seated in bore. See

Fig. 4. Remove bushing installer

components.

Reverse removal procedure

for remaining components.

Removal Instailatiori

30214

Fig. 4: Removing & Installing Upper Control Arm Bushing Courtesy of Chrysler Motors.

LOWER CONTROL ARM & BUSHING

Removal

Raise and

support vehicle. Disconnect lower control arm

mounting bolts at

axle housing and frame brackets. Remove lower

control arm.

Inspect

control arm for damage and bushings for excessive

distortion or

wear. Replace control arm and/or bushings as necessary.

Installation

Position lower control arm in front and rear brackets. Install mounting bolts and nuts. Tighten mounting bolts to specification.

TRACK BAR

Removal

1) Raise and support vehicle. Remove cotter pin and mounting

nut at frame rail bracket. Remove retaining bolt at axle housing bracket. Remove track bar. Inspect track bar and bushing for damage or wear. Replace as needed.

2) If a snapping noise was noted at the front of vehicle, inspect track bar bushing inner sleeve for signs of wear. If sleeve has been contacting axle bracket, spread bracket flanges approximately 1/8" to provide space for a Hardened Washer Part No. (G2436163).

Installation

Position

track bar in axle housing bracket. Install

spacer/washer between

rear flange of bracket and track bar bushing.

DO NOT install

spacer/washer at the front of bracket.

Loosely

install mounting bolt. Ensure mounting bolt

passes through

spacer/washer. Connect track bar at frame rail

bracket. Tighten

ball stud mounting nut-to-frame rail bracket.

Tighten all bolts

to specification. Install new cotter pin.

FRONT STABILIZER BAR & LINKS

Removal

Raise and

support vehicle. Disconnect stabilizer bar from

upper portion of

stabilizer bar links. Note location of grommets and

washers for

reassembly reference.

Disconnect

stabilizer bar from frame rail brackets.

Remove stabilizer bar.

Inspect bar for damage. Check rubber grommets,

bushings and

bracket supports for distortion and/or deterioration.

Replace

worn components as necessary.

If

necessary, disconnect lower links at axle housing

brackets and

remove. Inspect links for damage and rubber grommets for

excessive

wear, distortion and/or deterioration. Replace components

as

necessary.

Installation

Lubricate

stabilizer bar bushings and grommets with

rubber grease. Connect

links to axle housing brackets. Install

washers and rubber

grommets on links.

Install

rubber bushings and brackets onto stabilizer bar

and connect

components to frame rails. Connect stabilizer bar to

stabilizer

links. Tighten mounting bolts to specification.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft.

Lbs. (N.m)

Application Ft.

Lbs. (N.m)

Axle Shaft Nut 175 (237)

Brake Caliper Anchor Plate Bolt 70-85 (95-115)

Brake Caliper-to-Anchor

Plate Pin 25-35 (34-48)

Center Link-To-Pitman Arm Nut 25-45 (34-61)

Control Arm To-Axle

Housing Bracket Bolt

Lower 118-148 (160-200)

Upper 48-63 (65-85)

Upper Frame Bolt 59-74 (80-100)

Drive Shaft "U" Joint Strap Bolt 12-17 (16-23)

Lug Nuts 75 (102)

Shock Absorber

Lower Mounting Bolt

W/Coil

Springs 12-16 (16-22)

W/Leaf Springs 35-55 (48-75)

Upper Nut

Grand Wagoneer 25-40 (34-54)

All Others 14 (19)

Spring-to-Frame Bracket Bolt 95-115 (129-156)

Spring-to-Shackle Bolt 85-105 (115-142)

Spring "U" Bolt

9/16" x 18 85-105 (115-142)

1/2" x 20 45-65 (61-88)

Stabilizer Bar Mounting Bolt

Grand Wagoneer 27-45 (37-61)

All Others Stabilizer Bar Bracket-to-Frame Rail

W/Coil Springs 48-63 (65-85)

W/Leaf Springs 25-35 (34-48)

Stabilizer Bar Link-to-Axle

Bracket Bolt 59-81 (80-110)

Stabilizer Bar Link-to-Axle

Plate Nut 35-55 (48-75)

Stabilizer Bar-to-Link Bolt 35-55 (48-75)

Stabilizer Bar-to-Link Nut

Grand Wagoneer 48-62 (65-84)

All Others 23-31 (31-42)

Steering Knuckle-to-Hub Bolt 75 (101)

Steering Knuckle-to-Ball Joint Mounting Nut

W/Coil Springs 65-85 (88-115)

W/Leaf Springs 87-113 (118-153)

Steering Knuckle-to-

Tie Rod Nut 25-45 (34-61)

Track Bar Bracket-to-Frame

Rail Bolt 66-81 (90-110)

Track Bar Bracket-to-Axle Nut 66-81 (90-110)

Track Bar-to-Frame Bracket Nut 30-40 (41-54)