STARTER - BOSCH/MITSUBISHI

1988 Jeep Cherokee

1988 Starters BOSCH & MITSUBISHI

Jeep with 4.0L 6-Cyl.

DESCRIPTION

NOTE: Information on Jeep 2.5L starter not available from manufacturer.

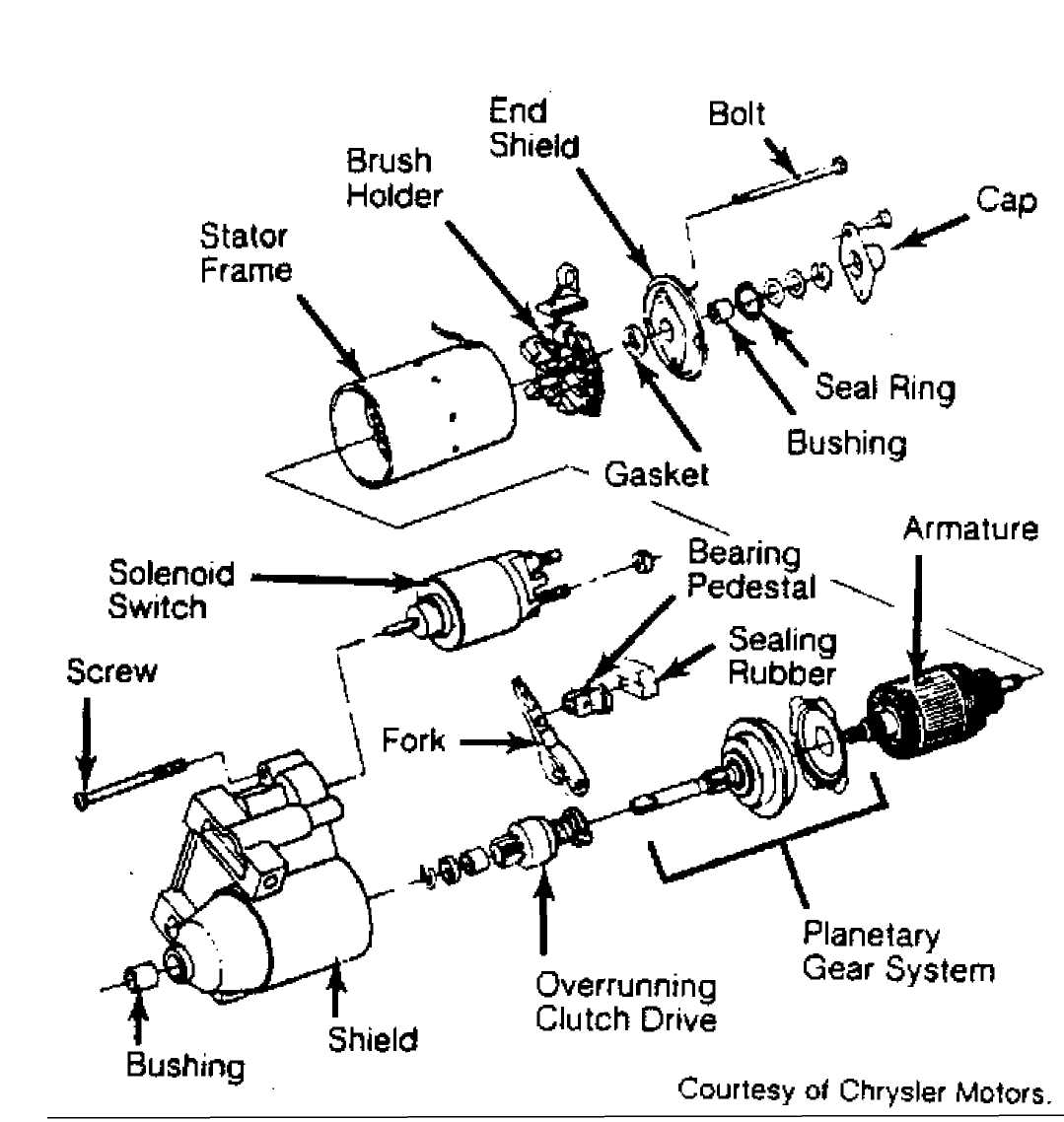

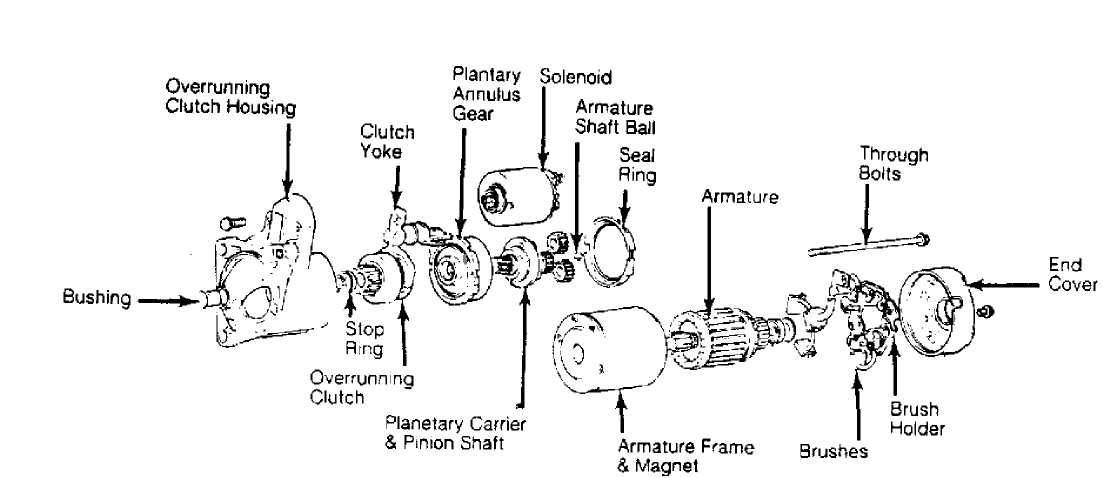

Bosch and Mitsubishi use a permanent magnet starter. A planetary gear train transmits power between starter motor and pinion shaft. The starter magnetic field is produced by 6 permanent magnets. The Mitsubishi starter is a 12-volt unit that has the solenoid mounted on the starter housing. See Fig. 3.

TROUBLE SHOOTING

NOTE: See the TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

TESTING (ON VEHICLE)

AMPERAGE DRAW TEST

NOTE: Engine should be at operating temperature before performing this test. Heavy duty oil or a tight engine will increase starter draw amperage. Tests are performed with standard volt-ammeter tester.

Connect

tester and remote starter switch. Set voltmeter

selector to

16-volt position. Select function to 0-500-amp scale.

Connect

voltmeter leads to corresponding polarity battery terminals.

Connect

ammeter leads to corresponding battery terminals.

Disconnect coil

wire from distributor cap and attach to ground to

prevent engine

from starting.

Crank

engine and observe exact reading on voltmeter. Stop

cranking

engine. Turn tester control knob clockwise until voltmeter

reads

exactly the same as when engine was cranked with remote

starter

switch. Ammeter should indicate starter draw of about

150-220 amps.

STARTER RESISTANCE TEST

Use a voltmeter that will indicate tenths of a volt. Without disconnecting any starter connections, perform the following resistance tests:

1) Perform

following tests with engine cranking and all

terminals connected.

Connect a voltmeter at following locations:

Positive

lead to battery positive post and negative lead

to battery

terminal on starter.

Positive

lead to starter housing and negative lead to

negative post on

battery.

Positive

lead to battery negative post and negative lead

to battery cable

connector on engine block.

2) Each of these 3 connections should show a voltmeter

reading of .2 volt or less. If reading exceeds .2 volt, clean or repair cables and connections in circuit. Connect a voltmeter at following locations:

Positive

lead to battery positive post and negative lead

to cable clamp.

Positive

lead to battery negative post and negative lead

to cable clamp.

3) If

reading is other than zero on voltmeter, clean or

repair cables

and connections in circuit. Connect a voltmeter at

following

location:

* Positive

lead to battery positive post and negative lead

to starter

solenoid lead to the field coils.

4) If

reading exceeds .3 volt, clean or repair

cables and

connections in circuit.

SOLENOID TEST

Connect a

heavy jumper wire on starter relay between

battery and solenoid

terminals. If engine cranks, solenoid is okay. Go

to RELAY TEST.

If engine

does not crank, check wiring and connections

from relay to

starter. Repair or replace as necessary. If engine still

fails to

crank, starter is defective.

RELAY TEST

On

automatic transmission/transaxle vehicles, put gear

selector in

"NEUTRAL" or "PARK". On

manual transmission/transaxle

vehicles,

put gear selector in "NEUTRAL". Set parking brake and

block

wheels. DO NOT remove relay connector. Using a 12-volt test

light,

check for battery voltage

between starter relay battery terminal and

ground.

Use a

jumper wire on starter relay between battery and

ignition

terminals. If engine cranks starter relay is good. If starter

does

not crank go to next step.

Connect

another jumper wire to starter relay between

ground

terminal and ground. Repeat above test. If engine cranks,

starter

relay is good. Inspect transmission linkage for improper

adjustment

(automatic transmission), defective

neutral safety switch

(automatic transmission) or poor ground

connection between relay

housing and mounting surface.

TESTING (ON BENCH)

STARTER SOLENOID

With

starter removed, disconnect field coil wire from

field coil

terminal on starter. Using an ohmmeter, check for

continuity

between solenoid and field coil terminals.

Check for

continuity between solenoid terminal solenoid

housing. Continuity

should be present in both tests. If continuity is

present,

solenoid is good. If no continuity is present, replace

solenoid.

Reconnect field coil wire to field coil terminal.

ARMATURE FOR SHORT CIRCUIT

Place armature in a growler and hold a thin steel blade parallel 3/16" above core while rotating armature slowly. If armature

is shorted, blade will vibrate and be attracted to core. Replace shorted armature.

ARMATURE FOR GROUND

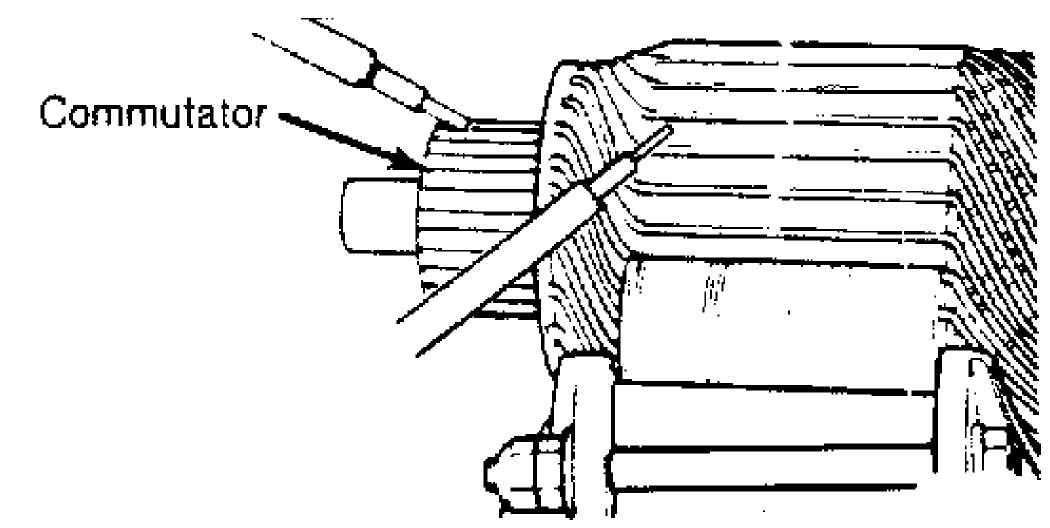

Using a self-powered test light and touch one lead to armature shaft and other lead to each commutator bar. See Fig. light glows, armature is grounded and should be replaced.

1. If

Fig.

1: Testing Starter Armature for Ground

Fig.

1: Testing Starter Armature for Ground

FIELD COILS FOR GROUND

Using a self-powered test light and touch one probe to series field coil lead and other probe to field frame. If light glows, replace field coil housing assembly.

DRIVE CLUTCH UNIT

While holding clutch housing, rotate pinion. Drive pinion should rotate smoothly in one direction only (should not rotate in opposite direction). If drive unit does not operate properly, or if pinion is worn or burred, replace drive unit.

Fig. 2: Exploded View of Bosch Starter

Fig.

3: Exploded View of Mitsubishi Starter

OVERHAUL

Overhaul information not available.

SPECIFICATIONS

BOSCH & MITSUBISHI STARTER SPECIFICATIONS Application (1)

Specification

Cranking

Amperage Draw 120-220

Amps

Cranking

Amperage Draw 120-220

Amps

No Load Test Voltage 11-11.5 Volts

No Load Test Amperage Draw 75-85 Amps

No Load Test Minimum RPM 2500-3625

Solenoid Closing Voltage (All) 7.3-7.8 Volts

(1) - New brushes are 11/16" (17.5 mm) long.