SPARK CONTROL SYSTEM

1988 Jeep Cherokee

1988 Exhaust Emission Systems JEEP SPARK CONTROL SYSTEMS

DESCRIPTION

Jeep vehicles use spark control devices to assist ignition system in controlling exhaust emissions. They are Spark Control Temperature Override (CTO) valve, Non-Linear Vacuum Regulator (NLVR) valve, Forward Delay Valve, Reverse Delay Valve and on 4-cylinder engines, Vacuum Spark Control Delay Valve. System application depends upon engine size, emissions category and vehicle model.

COOLANT TEMPERATURE SENSOR (CTS)

The coolant temperature sensor is located in the intake manifold coolant jacket. This sensor provides a voltage signal to the Electronic Control Unit (ECU). The ECU uses this signal to determine engine temperature. During cold engine operation, the ECU responds by increasing ignition advance and inhibiting EGR operation.

NON-LINEAR VACUUM REGULATOR VALVE (NLVR)

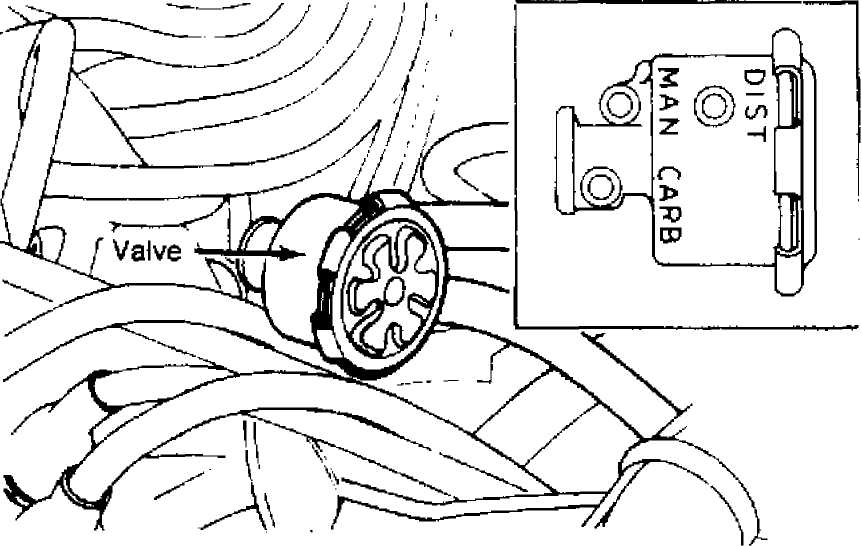

Fig. 1: Non-Linear Vacuum Regulator Valve Courtesy of Chrysler Motors.

OPERATION

NLVR valve is used on carbureted 6.0L models. This valve supplies vacuum advance unit with a regulated combination of manifold and carburetor ported vacuum when engine load is low and switches to supply only carburetor ported vacuum as load increases.

NON-LINEAR VACUUM REGULATOR VALVE

There are 2 input ports on NLVR: intake manifold vacuum and carburetor ported vacuum. One outlet port connects to distributor vacuum unit. At curb idle, regulated vacuum is supplied to advance unit, when manifold vacuum is high and ported vacuum is very low. See Fig. 1.

NLVR regulates vacuum signal so it is between these 2 vacuum source levels at idle. As engine load increases and vacuum signal is above 7.5 in. Hg vacuum, regulator valve switches to ported vacuum output.

FORWARD DELAY VALVE

Some engines use this valve to improve driveability and reduce hydrocarbon emissions. Valve functions to delay effects of sudden increases in vacuum. This prevents sudden spark advance during deceleration.

REVERSE DELAY VALVE

Some engines use this valve to improve cold driveability and reduce hydrocarbon emissions. Valve is installed in vacuum line to delay effects of manifold vacuum decrease causing retarded ignition timing.

VACUUM ADVANCE COOLANT TEMPERATURE OVERRIDE (VA-CTO)

This valve is used on carbureted 6.0L engines to improve driveability when engine is cold. It is located in vacuum advance circuit. When vacuum is greater at port "4" than at port "1", air must flow through orifice to equalize pressure. This creates momentary delay that prevents sudden decrease in spark advance. When vacuum is greater at port "1" than at port "4", air flows freely through check valve and pressure is instantly equalized.

TESTING

NON-LINEAR VACUUM REGULATOR VALVE (NLVR)

Connect vacuum gauge to distributor port "DIST" on NLVR. With engine at idle speed, a vacuum reading of 7 in. Hg vacuum should be shown. As throttle is opened and engine speed increases, ported vacuum level should be indicated. If not, replace NLVR. See Fig. 1.

FORWARD DELAY VALVE

Connect

external vacuum source to port on Black (or Red)

side of delay

valve. Connect vacuum gauge to port on colored side of

valve.

Apply

a constant 10 in. Hg vacuum. Note time

required for

gauge pointer to move from 0-8 in.

Hg.

If valve

fails to meet time limits, replace valve. If

valve meets

specifications, install so that Black (or Red) side is

toward

vacuum source.

FORWARD DELAY VALVE TIME LIMITS (1)

Valve

Color Min. Time Max Time

Valve

Color Min. Time Max Time

Black/Purple 3.2

Black/Gray 8

Black/Brown 16

Black/Orange 1.5

Black/White 50

Black/Yellow 80

Black/Green 160

(1) - Time in seconds.

4.8 12 24

2.5 77

120

240

REVERSE

DELAY VALVE

REVERSE

DELAY VALVE

Connect

external vacuum source to port on White side of

delay valve.

Connect vacuum gauge to port on colored (non-White) side

of

valve.

Apply

a constant 10 in. Hg vacuum, note time

required for

gauge pointer to move from 0-8 in.

Hg.

If

valve fails to meet time limits, replace valve. If

valve meets

specifications, install with non-White side toward vacuum

source.

REVERSE DELAY VALVE TIME LIMITS

(1)

Valve

Color

Min. Time

Max. Time

4.8

12

18

24

120

450

White/Purple 3.2

White/Gray 8

White/Gold 12

White/Brown 16

White/Yellow 80

White/Red 300

White/Orange 1.5 2.5

(1) - Time in seconds.

VACUUM

SPARK CONTROL DELAY VALVE

Connect

"T" fitting at ports "1" and

"4". Connect vacuum

gauge to

each fitting. Start engine. Vacuum should be equal at both

ports.

See Fig. 2.

When

throttle is suddenly depressed, vacuum at port "1"

will

instantly decrease and vacuum at port "4" should

be maintained

momentarily. If valve fails these tests, replace

valve.

Fig.

2: Vacuum Spark Control Delay Valve

Courtesy of Chrysler Motors.