IGNITION SYSTEM - 2.5L W/RENIX ELECTRONIC IGNITION

1988 Jeep Cherokee

Distributors & Ignition Systems JEEP RENIX ELECTRONIC IGNITION

2 . 5L TBI: Cherokee, Comanche, Wagoneer, Wrangler

DESCRIPTION

The Renix electronic ignition system consists of a solid-state Ignition Control Module (ICM), a distributor, a Top Dead Center (TDC) sensor, and an Electronic Control Unit (ECU).

OPERATION

IGNITION CONTROL MODULE (ICM)

The ignition control module is located in engine compartment, just left of battery. The ICM consists of a solid-state ignition circuit and an integrated ignition coil that can be removed and serviced separately.

Electronic signals from the electronic control unit to the ICM determine the amount of ignition timing or retard needed to meet various engine requirements. The electronic control unit provides an input signal to the ICM. The ICM has only 2 outputs: a tach signal to the tachometer and diagnostic connector, and a high voltage signal from the coil to the distributor cap.

TDC SENSOR

The TDC sensor senses TDC and BDC crankshaft positions as well as engine RPM. Sensor is located on left rear side of engine and is not adjustable. Sensor is secured by special shouldered bolts to flywheel/drive plate housing.

TESTING

1) Disconnect ignition coil wire from center tower of

distributor cap. Using insulated pliers, hold coil wire about 1/2" (13 mm) away from engine block. Crank engine and check for spark between wire and engine block.

If

spark occurs, reconnect coil wire to distributor cap.

Remove

spark plug wire from one spark plug. Using insulated pliers,

hold

wire about 1/2" (13 mm) away from

engine block.

Crank

engine and check for spark between wire and engine

block. If

spark occurs, check fuel system for problems. If no spark

occurs,

check for a defective rotor, distributor cap, or spark plug

wires.

Replace parts as necessary.

If rotor,

cap and wires are okay, check for loose or

corroded connections

at coil terminals. If necessary, clean terminals

and wires.

Ensure wires are properly seated on coil terminals and not

wedged

between coil body and terminal. If okay, go to next step.

Check for

loose connectors at ICM or ECU. Verify that wire

connectors are

firmly plugged into ICM and ECU. Also check for loose

ICM or ECU

ground wire connections at oil dipstick bracket. Clean and

tighten

if necessary.

Load

test battery to ensure battery is fully charged.

Replace

battery if necessary. If battery is okay, check voltage

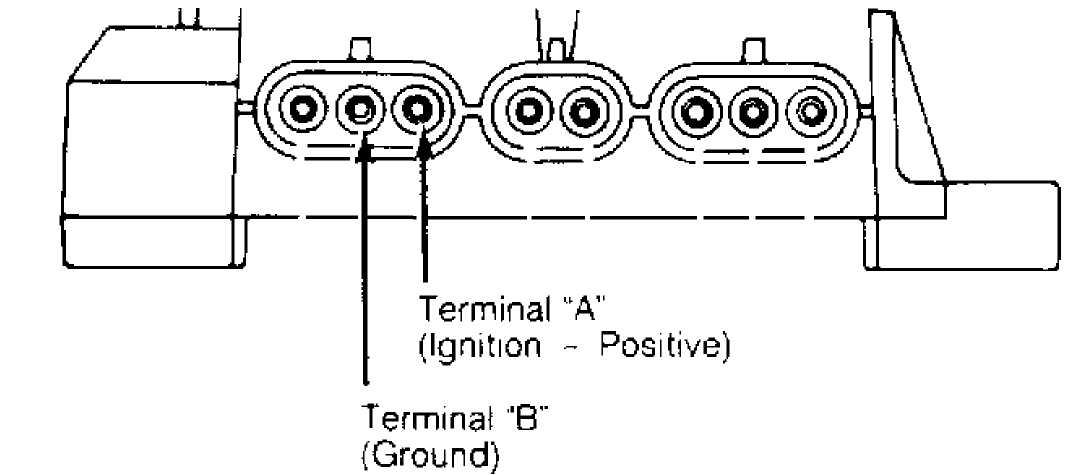

between

terminals "A" and "B" of ICM connector while

cranking engine.

See Fig. 1.

Minimum

voltage reading should be 9.5 volts. If

voltage is

okay, go to next step. If

voltage is low, check continuity of ICM and

ECU

ground wires. Repair or replace as necessary.

Using

an ohmmeter, check ignition coil resistance.

Resistance

on primary winding should be .4-.8 ohms.

Secondary

resistance should be

2500-4000 ohms. If correct, go to next

step. If

not, replace ignition coil.

Check

ECU and ICM with Tester (MS 1700) . Replace

ICM or

ECU if either fails MS 1700

test sequence.

Fig.

1: 2.5L TBI ICM Connector Terminals

Courtesy of American Motors/Jeep Corp.

Fig.

1: 2.5L TBI ICM Connector Terminals

Courtesy of American Motors/Jeep Corp.

OVERHAUL

NOTE: The 2.5L TBI distributor contains no electrical components other than the rotor and distributor cap. If any other distributor part is defective, the entire distributor assembly must be replaced.