FUEL INJECTION SYSTEM - TBI

1988 Jeep Cherokee

1988 Electronic Fuel Injection JEEP/RENIX THROTTLE BODY INJECTION

2 . 5L Cherokee, Comanche, Wagoneer, Wrangler

DESCRIPTION

The Throttle Body Injection (TBI) system is a single injector system that introduces fuel into throttle body from above throttle plate. Fuel injector, located within throttle body, is controlled by the Electronic Control Unit (ECU).

The ECU is a sealed microprocessor that receives input signals from several sensors and other related engine components. Based on these inputs, ECU generates output signals that control and adjust air/fuel mixture and ignition timing as necessary for proper engine performance.

ECU also controls engine idle speed, emission control

systems, upshift indicator light (manual transmission only), and A/C compressor clutch.

OPERATION

ELECTRONIC CONTROL UNIT (ECU)

On Cherokee, Comanche and Wagoneer, ECU is located under instrument panel, above accelerator pedal. On Wrangler, ECU is located behind glove box. Input information from various engine sensors to ECU is used to determine engine operating conditions and needs. Battery voltage input is used to ensure that correct output voltage is supplied by ECU during fluctuations in battery voltage.

FUEL INJECTOR

Fuel injector is mounted in throttle body so that fuel is injected into incoming airflow. When injector solenoid is energized, armature and plunger move upward against spring. Check ball above injector nozzle moves off seat and opens small orifice at end of injector.

Fuel supplied to injector is forced around ball and through orifice, resulting in fine spray of fuel. Volume of fuel injected is dependent only on length of time that injector is energized by ECU, as fuel pressure is constant at injector. During cold engine starts, extra fuel is supplied so richer mixture will aid in starting.

FUEL PRESSURE REGULATOR

Fuel pressure regulator is integral part of throttle body. Pressure regulator has a spring chamber that is vented to same pressure as tip of injector. Because differential pressure between injector nozzle and spring chamber is same, only the length of time that injector is energized controls volume of fuel injected.

Fuel pump delivers more fuel than is required by engine. Excess fuel goes to fuel tank from pressure regulator via fuel return hose. Fuel pressure regulator function is mechanical and ECU does not control it.

FUEL PUMP

Electric roller type fuel pump is located in fuel tank. Integral check valve is used to maintain pressure in fuel delivery system after pump stops running. Fuel pump operation is controlled by ECU through a fuel pump relay.

IDLE SPEED ACTUATOR (ISA) MOTOR

ISA motor acts as movable idle stop to change throttle stop angle. Both engine idle speed and deceleration throttle stop angle are set by ISA. ECU controls ISA motor by providing appropriate voltage outputs to produce idle speed or throttle stop angle required for engine operating condition.

OXYGEN (O2) SENSOR

Oxygen sensor is equipped with a heating element that keeps sensor at proper operating temperature at all times. Oxygen sensor is located in exhaust pipe.

Maintaining proper sensor temperature at all times, system enters "Closed Loop" operation sooner and remains in "Closed Loop" during periods of extended idle. Electrical feed to oxygen sensor is through ignition switch.

The ECU receives sensor voltage signal which varies with oxygen content in exhaust gas. Signal is used by ECU as reference for setting air/fuel mixture ratio. ECU varies voltage to injector both to compensate for battery voltage fluctuations and to change duration of injector opening for control of air/fuel mixture.

MANIFOLD AIR/FUEL TEMPERATURE (MAT) SENSOR

MAT sensor provides a signal to ECU that changes depending upon temperature of air/fuel mixture in intake manifold. During high temperature conditions, ECU will compensate for changes in density of air.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

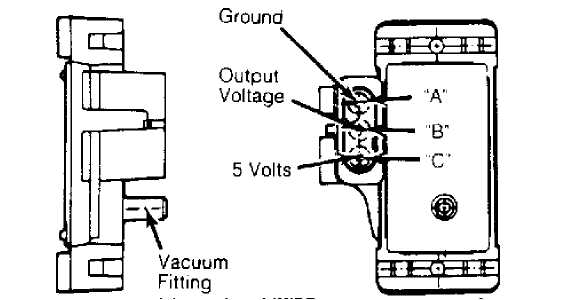

MAP sensor measures absolute pressure in intake manifold. Both mixture density and ambient barometric pressure are supplied to ECU by MAP sensor. Sensor is mounted in middle of firewall in engine compartment. Sensor receives manifold pressure information through vacuum line from throttle body. See Fig. 1.

Fig. 1: Manifold Absolute Pressure (MAP) Sensor Courtesy of Chrysler Motors.

COOLANT TEMPERATURE SENSOR (CTS)

Coolant temperature sensor is installed in intake manifold water jacket to provide coolant temperature input signal for ECU. During cold engine operation, ECU will make mixture richer, make up for fuel condensation in cold intake manifold, increase idle speed during warm-up period, increase ignition advance and keep EGR system inoperative until engine warms up.

THROTTLE POSITION SENSOR (TPS)

Throttle position sensor provides ECU with input signal, up to about 5 volts, to indicate throttle position. This allows ECU to control air/fuel mixture according to throttle position. TPS is mounted on throttle body assembly.

WIDE OPEN THROTTLE (WOT) SWITCH

WOT switch provides an input signal to ECU when engine is at wide open throttle. The ECU enriches air/fuel mixture. The WOT switch is located on the side of throttle body.

CLOSED THROTTLE (IDLE) SWITCH

Idle switch is integral with ISA motor and provides voltage signal to ECU. ECU will signal ISA motor to change throttle stop angle in response to engine operating conditions.

UPSHIFT INDICATOR LIGHT

On vehicles equipped with a manual transmission, ECU controls upshift indicator light. Indicator light is normally illuminated when ignition is turned on without engine running. Indicator light is turned off when engine is started.

Indicator light will be illuminated during engine operation in response to engine load and speed. If transmission is not shifted, ECU will turn light off after 3 to 5 seconds. A switch located on transmission prevents indicator light from being illuminated when transmission is shifted to highest gear.

ENGINE SPEED SENSOR

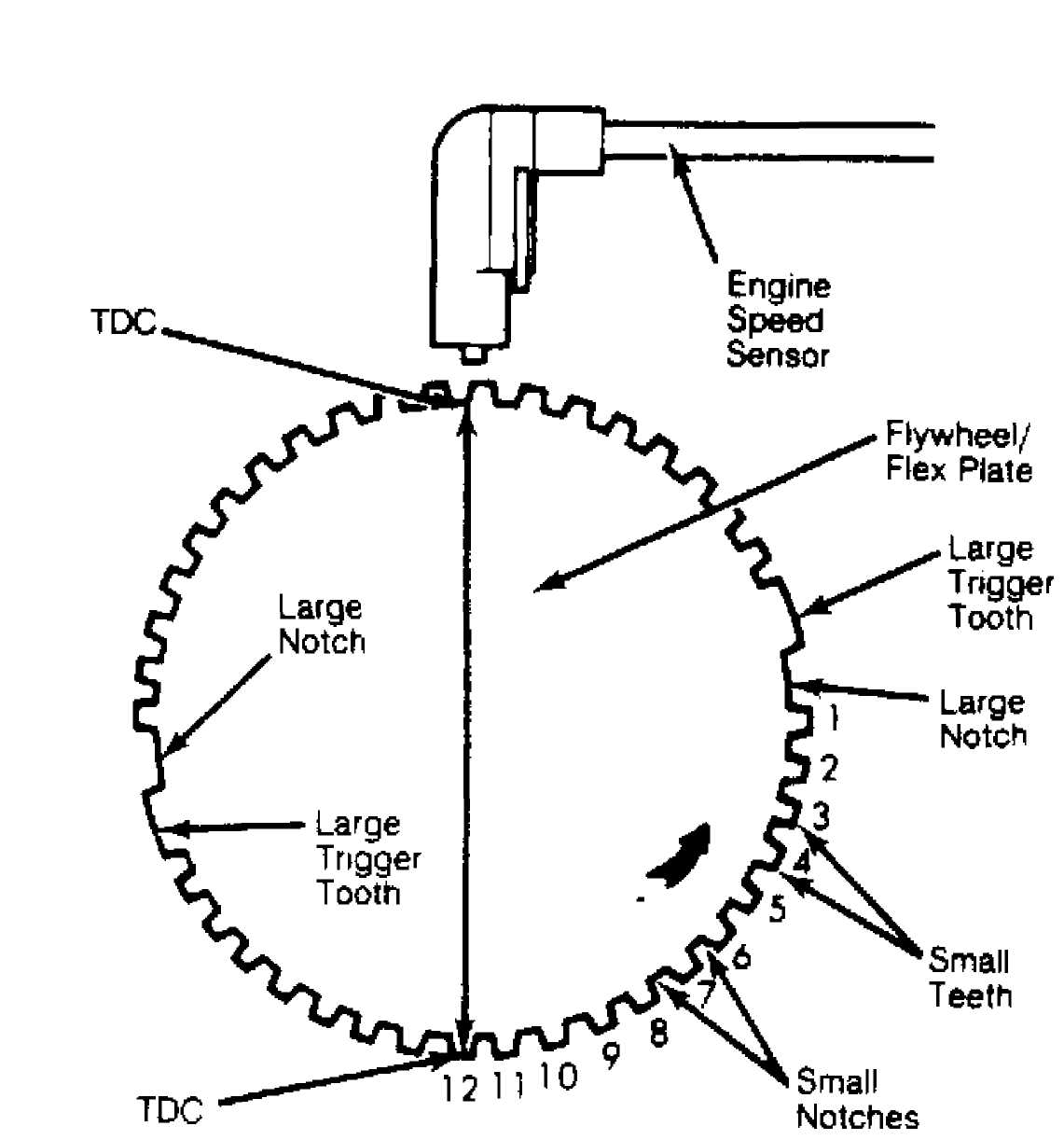

Engine speed sensor is attached to bellhousing. It senses and counts teeth on flywheel gear ring as they pass during engine operation. Signal from speed sensor provides ECU with engine speed and crankshaft angle. On flywheel gear ring, large trigger tooth and notch is located 90 degrees before each TDC point. Each trigger tooth is followed by 12 smaller teeth and notches before TDC point is reached.

As each of 12 small teeth and notches pass magnetic core in speed sensor, concentration and collapse of magnetic field induces slight voltage (spike) in sensor pick-up coil winding. See Fig. 2. Larger trigger teeth and notches induce higher voltage (spike) in sensor pick-up coil winding. These voltage spikes enable ECU to count teeth as they pass speed sensor.

Higher voltage spike (from larger tooth and notch) indicates to ECU that piston will be at TDC position after 12 smaller voltage spikes have been counted. ECU will then either advance or retard ignition timing depending upon remaining sensor inputs.

Fig. 2: Engine Speed Sensor Courtesy of Chrysler Motors.

A/C CONTROLS

ECU receives inputs from A/C when either A/C switch is in "ON" position or compressor clutch engages to lower temperature. ECU changes engine idle speed depending upon A/C compressor operation.

POWER STEERING PRESSURE SWITCH

ECU receives input from pressure switch during periods of high pump load and low engine RPM. Input signals from pressure switch to ECU are routed through A/C request and A/C select input circuits. When pump pressure exceeds 250-300 psi (17.5-21.0 kg/cm), switch contacts close transmitting an input signal to ECU. ECU raises engine idle speed immediately after receiving input from pressure switch.

RELAYS

Starter Motor Relay

Starter motor relay provides an input signal to ECU when starter motor is engaged.

System Power Relay

System power relay, located on right fender inner panel, is energized when engine is started. It remains energized for 3 to 5 seconds after ignition is off. This allows ECU to extend ISA for next start before ECU shuts down.

Fuel Pump Control Relay

Fuel pump control relay is located on right fender inner panel. Battery voltage is supplied to relay from ignition switch. When ground is provided by ECU, relay becomes energized and provides voltage to fuel pump.

A/C Compressor Clutch Relay

ECU controls A/C compressor clutch through this relay. The A/C compressor clutch relay is located beside fuel pump control relay on right fender inner panel.

EGR Valve/Canister Purge Solenoid

Vacuum to both EGR valve and vapor canister is controlled by this solenoid. When solenoid is energized, neither EGR valve nor vapor canister receive vacuum.

Solenoid is energized during closed (idle) and wide open throttle operations, engine warm-up and rapid acceleration or deceleration. If solenoid wire connector is disconnected, both EGR valve and vapor canister will receive vacuum at all times.

Load Swap Relay

The load swap relay works in conjunction with power steering switch to disengage A/C compressor clutch. If compressor clutch is engaged when power steering pressure switch contacts close, input signal from switch to ECU also activates load swap relay. Relay then cuts off current to A/C compressor clutch.

The A/C compressor clutch remains disengaged until pressure switch contacts reopen and engine idle returns to normal. The load swap relay contains a timer that delays engaging the compressor clutch for 0.5 second to ensure smooth engagement.

ADJUSTMENTS

CAUTION: When working on or near engine that is running, be very careful to avoid pulleys, belts and fan. DO NOT stand in direct line with blades of fan. DO NOT wear clothing that is loose enough to get caught in moving parts.

IDLE SPEED ACTUATOR (ISA) MOTOR

Adjust ISA

motor plunger to establish initial position of

plunger only if

motor has been removed or replaced. Remove air filter

elbow and

start engine. Run engine until engine reaches normal

operating

temperature. Turn A/C off (if equipped).

Connect

tachometer leads to diagnostic connector D1,

attaching

negative lead to terminal D1-3 and positive lead to

terminal

D1-1. See Fig. 4. Turn ignition off. ISA

motor plunger

should move to fully

extended position.

When

ISA motor plunger is fully extended, disconnect ISA

motor

wiring connector and start engine. Engine speed should be

3300-3700

RPM. If incorrect, turn hex head screw at end of

plunger to

provide engine speed of 3500 RPM.

Fully

retract ISA motor by holding closed throttle (idle)

switch

plunger inward as throttle is opened. Closed throttle switch

plunger

should not touch throttle lever in closed position. If

contact is

made, check linkage and/or cable for binding or damage.

Repair as

necessary.

Connect

ISA motor wiring harness connector and turn

ignition

off for 10 seconds. ISA motor should move

to fully extended

position. Start

engine. Engine speed should be 3500 RPM

for short

period of time and then decrease to normal idle speed.

Turn

ignition off. Disconnect tachometer. After final

adjustment

of ISA motor, use thread penetrating sealant (Loctite 290)

on

adjustment screw to prevent movement and maintain adjustment.

NOTE: If adjustment screw must be moved after thread sealant

hardens, loosen threads by heating screw with flameless heat such as soldering gun. DO NOT use flame or torch type of heat as damage to ISA motor will result.

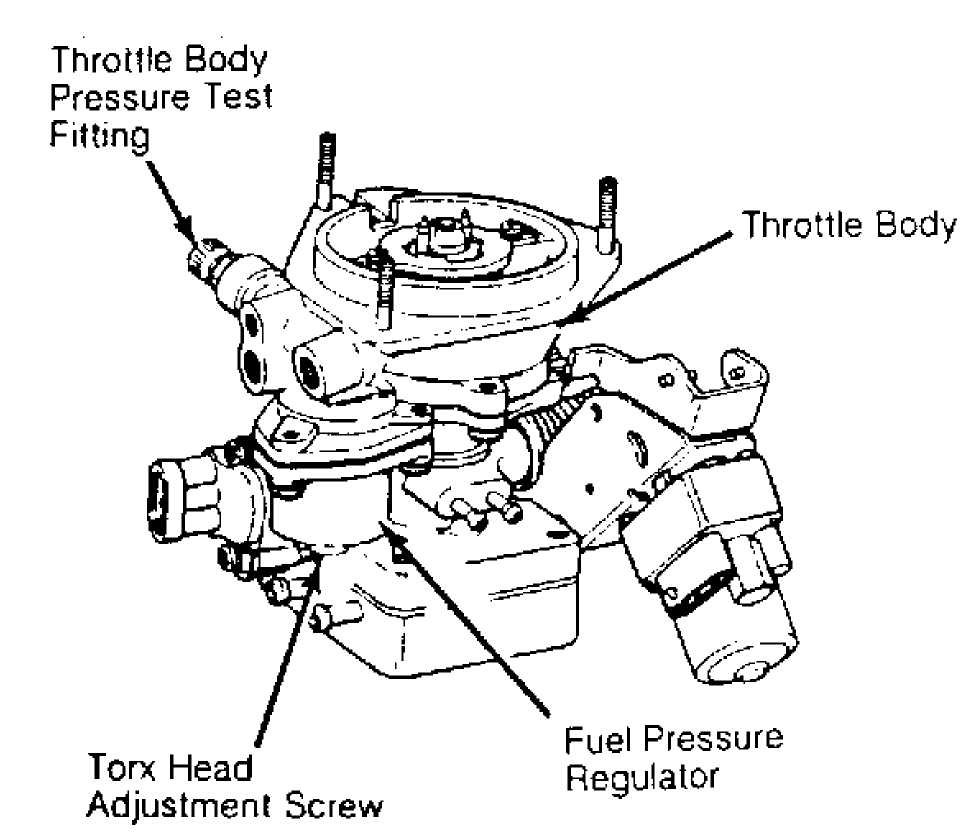

FUEL PRESSURE REGULATOR

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal injury, cover fittings with shop towel while disconnecting fittings.

1) Replacement

fuel pressure regulator must be adjusted to

establish

correct pressure. Remove air filter elbow and hose.

Connect

tachometer leads to diagnostic

connector D1, attaching negative lead

to terminal D1-3 and

positive lead to terminal D1-1. See Fig. 4.

Remove

screw plug and install fuel pressure test fitting.

NOTE: Fuel pressure test fitting is not included with throttle body. Fitting (8983 501 572) must be obtained separately.

Connect

fuel pressure gauge to test fitting. Start engine

and increase

speed to approximately 2000 RPM. Turn Torx

head screw at

bottom of regulator to

set correct pressure. Turning screw inward

increases

pressure and turning screw outward decreases pressure. See

Fig.

3.

All

models require fuel pressure of 14.5 psi

(1.0 kg/cm).

Install

lead sealing ball to cover regulator adjustment

screw after adjusting fuel pressure. Turn ignition off. Remove measuring equipment and test fitting. Install original plug screw and air filter assembly.

Fig. 3: Adjusting Fuel Pressure Regulator Courtesy of Chrysler Motors.

THROTTLE POSITION SENSOR (TPS)

1) Turn

ignition on. Check throttle position sensor input

voltage. Connect

voltmeter negative lead to terminal "B" (M/T),

or

terminal "D" (A/T) of sensor

connector. Connect voltmeter positive

lead

to terminal "C" (M/T), or

terminal "A" (A/T) of sensor connector.

NOTE: On (A/T) models, connector terminals are identified by

letters molded into back of connector. On all models, do not disconnect TPS harness connector. Insert voltmeter test leads through back of wire harness connector. On some models, it may be necessary to remove throttle body from intake manifold to gain access to sensor wire harness.

2) Move

and hold throttle plate at wide open throttle

position (M/T),

or close throttle plate completely (A/T).

Ensure

throttle

linkage contacts stop. Note voltmeter reading. Input voltage

at

terminals "B" and "C" (M/T), or

terminals "A" and "D" (A/T) should

be

5 volts.

Return

throttle plate to closed throttle position (M/T),

or

maintain throttle plate in closed position (A/T). Check

sensor

output voltage. To do so, disconnect voltmeter positive

lead from

terminal "C" and

connect it to terminal "A" (top) of sensor (M/T),

or

from terminal "A" and connect it

to terminal "B" (A/T).

Move and hold throttle plate in wide open throttle

position (M/T), or maintain throttle plate in closed position (A/T). Ensure throttle linkage contacts stop. Note voltmeter reading. Output voltage should be 4.6-4.7 volts (M/T), or .2 volt (A/T).

5) If

output voltage is incorrect, loosen bottom sensor

retaining screw

and pivot sensor in adjustment slot for a coarse

adjustment.

Loosen top sensor retaining screw for fine adjustments.

Tighten

screws after adjustment.

TESTING & TROUBLE SHOOTING

PRELIMINARY CHECKS & PRECAUTIONS

Subsystem Checks

Before testing fuel injection system for cause of

malfunction, check that following subsystems and components are in good operating condition:

Battery and charging system.

Engine state of tune.

Emission control devices.

Fuel system pressure and delivery volume.

Wiring connectors at components.

General Precautions

In order to prevent injury to operator or damage to system or component parts, use following techniques:

Turn

ignition off before connecting or disconnecting any

component

parts.

DO

NOT apply DC voltage greater than 12 volts

or any AC voltage

to system.

Disconnect battery cables before charging.

Remove

ECU from vehicle if ambient temperature could exceed

176F (80C).

DO NOT modify or circumvent any system functions.

RESISTANCE & VOLTAGE TESTS

MAT Sensor

Disconnect

wiring from MAT sensor. Using high input

impedance digital

volt-ohmmeter (DVOM), check resistance of

sensor.

Resistance should be less than 1000 ohms

when engine is warm. Replace

sensor if

it does not fall within range shown in

TEMPERATURE-TO-RESISTANCE

VALUES table.

Test

resistance in wiring harness between ECU connector

terminal No.

32 and sensor connector terminal. Also

test resistance

in wiring harness between ECU harness terminal

No. 14 and sensor

connector

terminal. See Fig. 5. Repair wiring

harness if open circuit

or resistance greater than one ohm is

indicated.

Coolant Temperature Sensor (CTS)

1) Disconnect wiring harness from CTS. Using high input impedance digital volt-ohmmeter (DVOM), check resistance of sensor. Resistance should be less than 1000 ohms when engine is warm. Replace sensor if it does not fall within range shown in TEMPERATURE-to-RESISTANCE VALUES table.

2) Test resistance in wiring harness between ECU harn terminal No. 32 and sensor connector terminal. Also test resistance in wiring harness between ECU harness terminal No. 15 and sensor connector terminal. See Fig. 5. Repair wiring harness if open circuit or resistance greater than one ohm is indicated.

TEMPERATURE-TO-RESISTANCE VALUES (CTS & MAT SENSOR) TABLE

°F °C Ohms

°F °C Ohms

(Approximate)

212 100 185

160 70 450

100 38 1600

70 20 3400

40 4 7500

20 -7 13,500

0 -18 25,000

-40 -40 100,700

Throttle Position Sensor (TPS) Test

Turn ignition on. Check voltage at terminal connector without disconnecting from TPS. Terminal "A" (M/T), or terminal "B" (A/T ) is output voltage, which should be 4.6-4.7 volts at wide open throttle (M/T), or .2 volt at closed throttle (A/T). Terminal "B" (M/T), or terminal "A" (A/T) is sensor ground. Terminal "C" (M/T), or terminal "D" (A/T) is input voltage, which is about 5 volts.

Closed Throttle (Idle) Switch Test

NOTE: ALL testing of idle switch must be done with ISA motor plunger in fully extended position. If switch cannot be tested without extending plunger, it is possible that ISA motor has failed. See IDLE SPEED ACTUATOR MOTOR ADJUSTMENT.

Turn

ignition on. Check idle switch voltage at diagnostic

connector

D2, between terminals No. 13 and 7.

See Fig. 4. At

closed

throttle, voltage should be near

zero volts. When switch is off

closed throttle position, voltage

reading should be greater than 2

volts.

If

voltage is always zero, test for short to ground in

harness or

switch. Also check for open circuit between switch and

terminal

No. 25 of ECU connector. If reading is

always greater than 2

volts, check for

open circuit in wiring harness between switch

connector and ECU.

Also check for open between ground and switch

connector. Replace

or repair wiring harness as necessary.

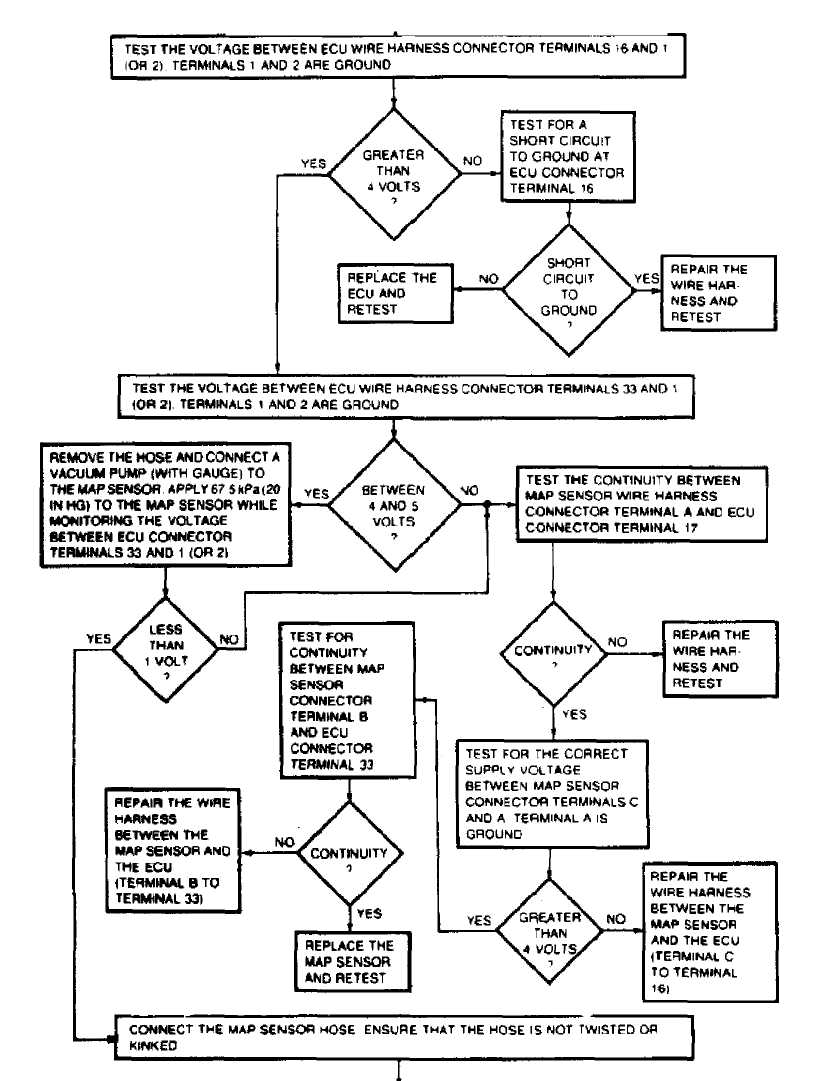

Manifold Absolute Pressure (MAP) Sensor Test

Check

and repair vacuum hose connections at throttle body

and MAP

sensor. Check output voltage at MAP sensor connector terminal

"B"

(marked on sensor body) with ignition on, engine off.

Voltage

reading should be 4-5 volts. If

engine is hot and idling in Neutral,

reading should be 1.5-2.1

volts. Check voltage at terminal No. 33

of

ECU connector. Reading should be same as

that at terminal "B" on MAP

sensor

connector. See Fig. 4.

With

ignition on, check MAP sensor supply voltage at

terminal "C".

Reading should be 4.5-5.5 volts. Same

voltage reading

should be obtained at terminal No. 16 on

ECU harness connector. If

necessary,

repair or replace wiring harness. Using Diagnostic Tester

(MS 1700), test ECU if necessary. Check MAP sensor ground circuit at terminal "A" and terminal No. 17 of ECU connector. Repair wiring if necessary.

3) Using ohmmeter, check MAP sensor ground circuit between terminals No. 17 and 2 of ECU connector. If circuit is incomplete, check sensor ground connection on bellhousing, near starter motor. Replace ECU if ground is good. If terminal No. 17 is shorted to 12 volts, repair problem BEFORE ECU is replaced.

DIAGNOSTIC TOOLS

To properly test throttle body fuel injection system, service technician must have the following equipment available:

Digital

volt-ohmmeter (DVOM) or volt-ohmmeter with minimum input

impedance

of one megohm.

12-volt test light, jumper wires and probes.

Hand vacuum pump with gauge.

Ignition timing light.

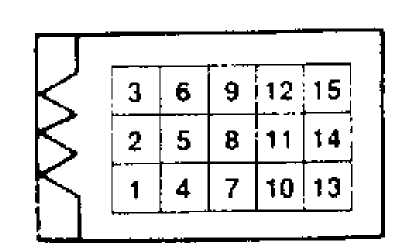

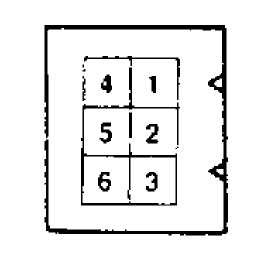

CONNECTOR D1

1.Tach{RPM) Input

Ignition

Ground

Starter Solenoid

Battery

Fuel Pump

CONNECTOR D2

1. Upshift Light (M/T)

2, System

Power Relay

3- Park/Neutral Switch

System Power {Bait. Pos.)

A/C Clutch Relay

WOT Switch

Ground

Air/Fuel Temperature

M.P.A. (Ignition Output)

EGR/Canister Purge Solenoid

ISA Motor Extend {Forward)

Coolant

Temperature Sensor

13- Closed Throttle

Switch

ISA Motor Reverse

Automatic Transmission Diagnosis

Fig. 4: Jeep/Renix Fuel Injection Diagnostic Connectors Courtesy of Chrysler Motors.

DIAGNOSTIC TESTS

NOTE: When diagnosing fuel system problems using following

procedures, no specialized service equipment is needed. Following diagnostic procedures are NOT applicable if special tester M.S. 1700 is used.

Six different test flow charts are used to fully evaluate fuel injection system:

TEST 1: IGNITION OFF

This test checks that system power provides for ECU memory keep-alive voltage.

function.

TEST 2: IGNITION ON: POWER

This test checks system power function and fuel pump power

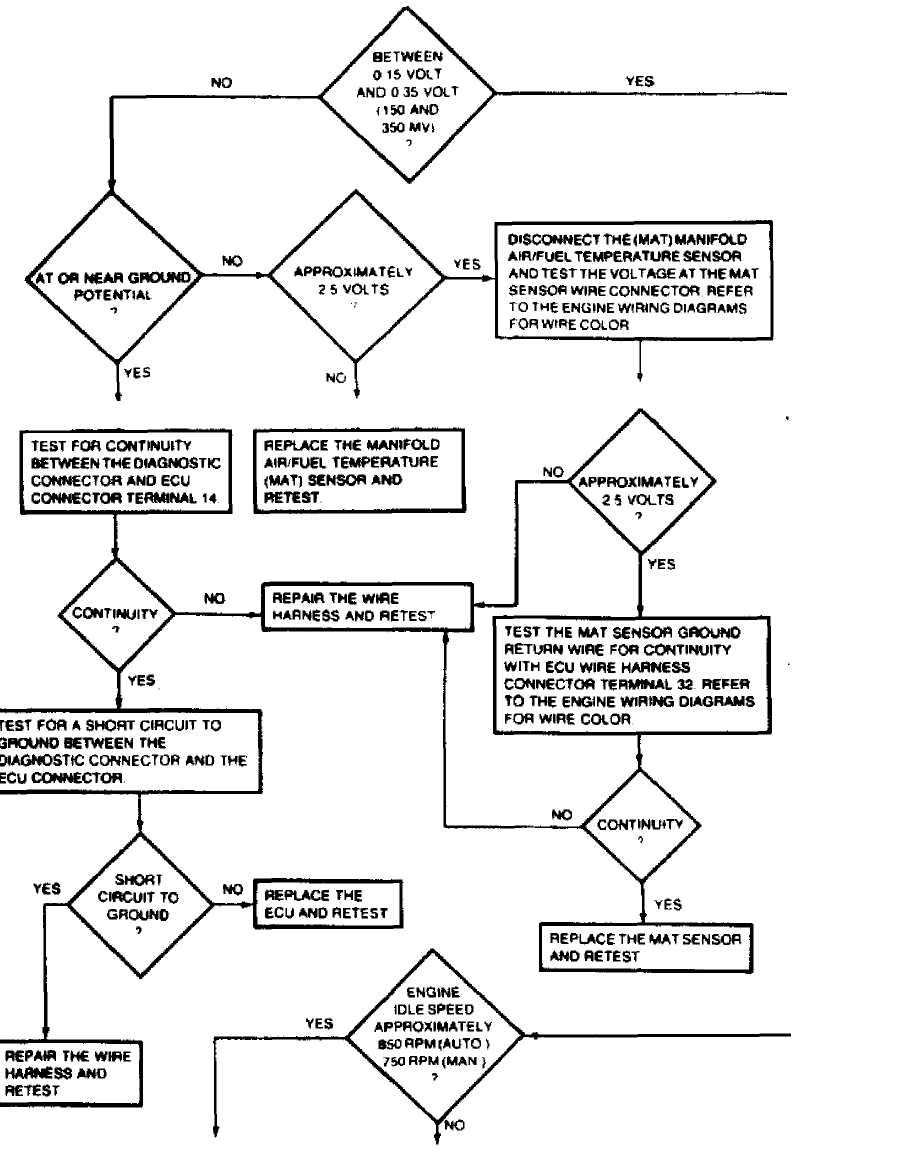

TEST 3 & 3A: IGNITION ON: INPUT

These tests check the following components and their circuits: closed throttle (idle) switch, Throttle Position Sensor (TPS), MAP sensor, A/T gear selector switch, Coolant Temperature Sensor (CTS) and MAT sensor. Coolant temperature and MAT sensors are tested in cold condition. This procedure also checks all interrelated wiring circuits as well.

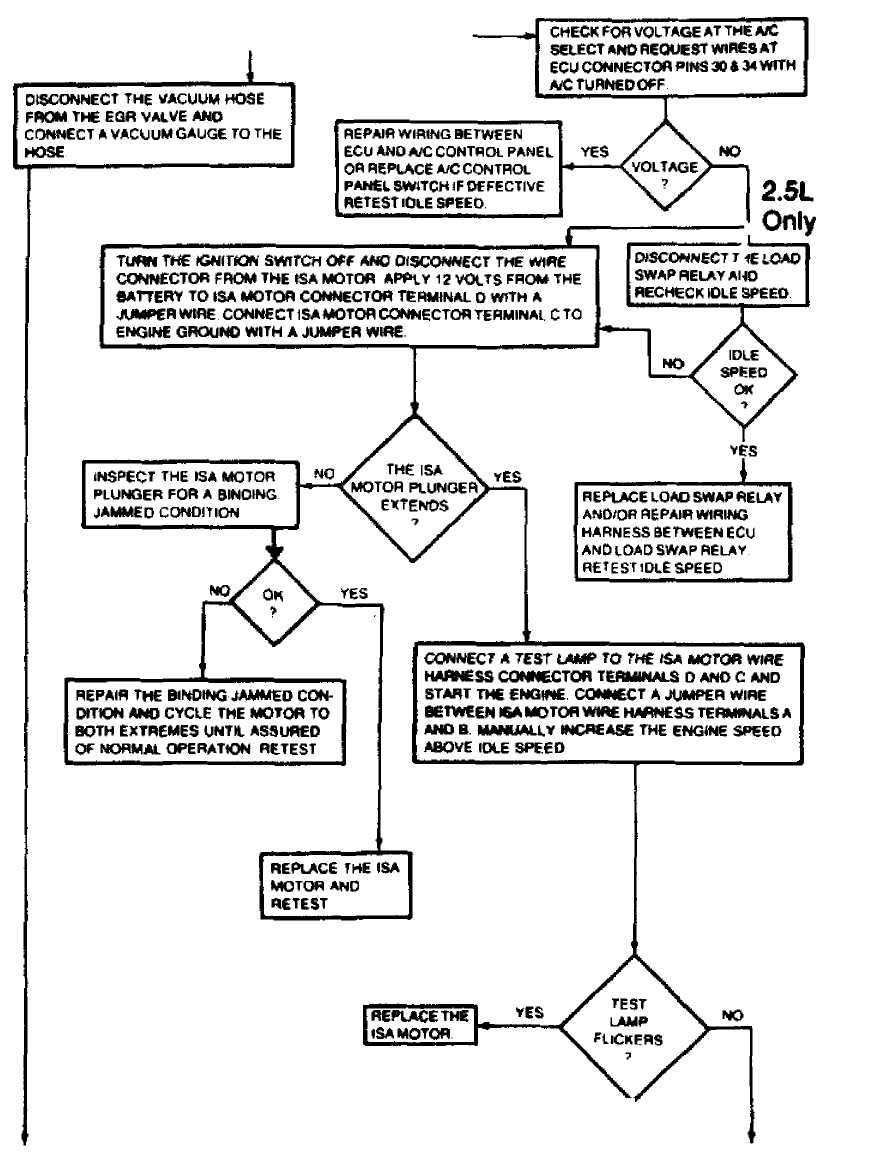

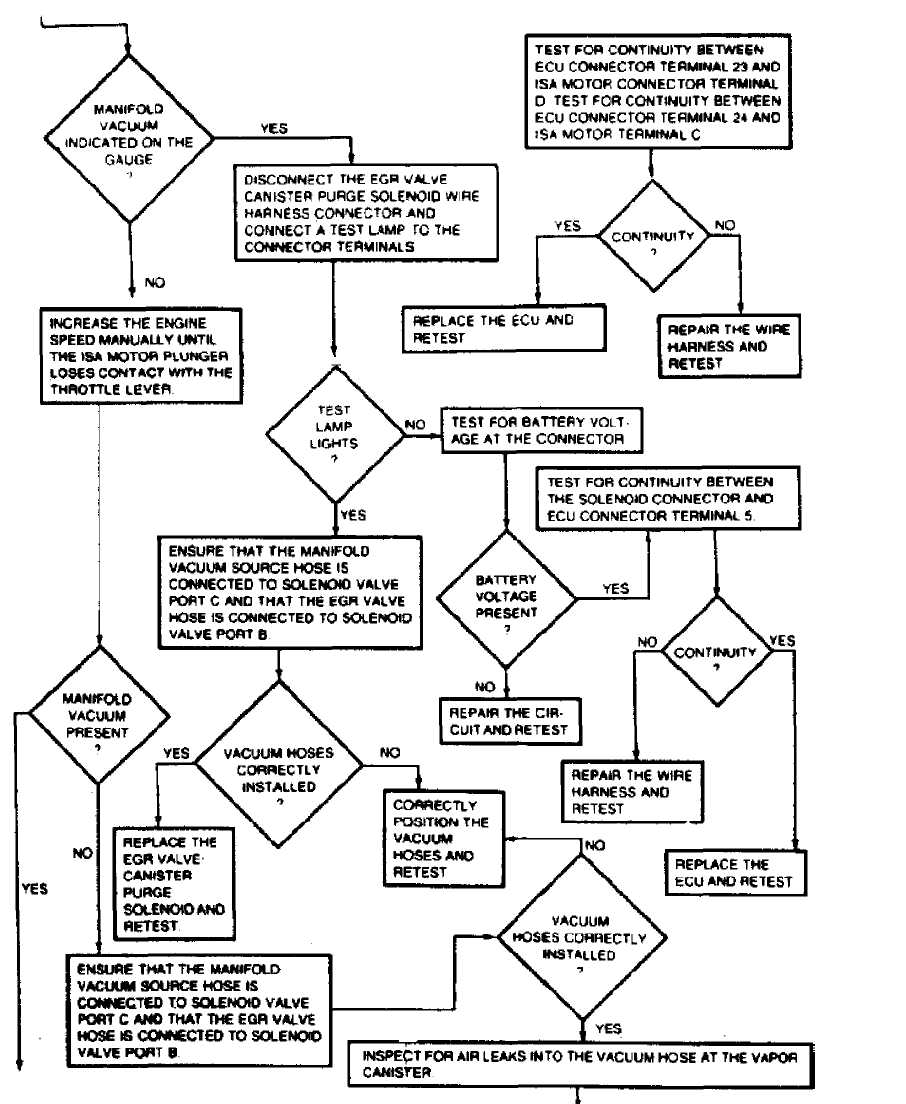

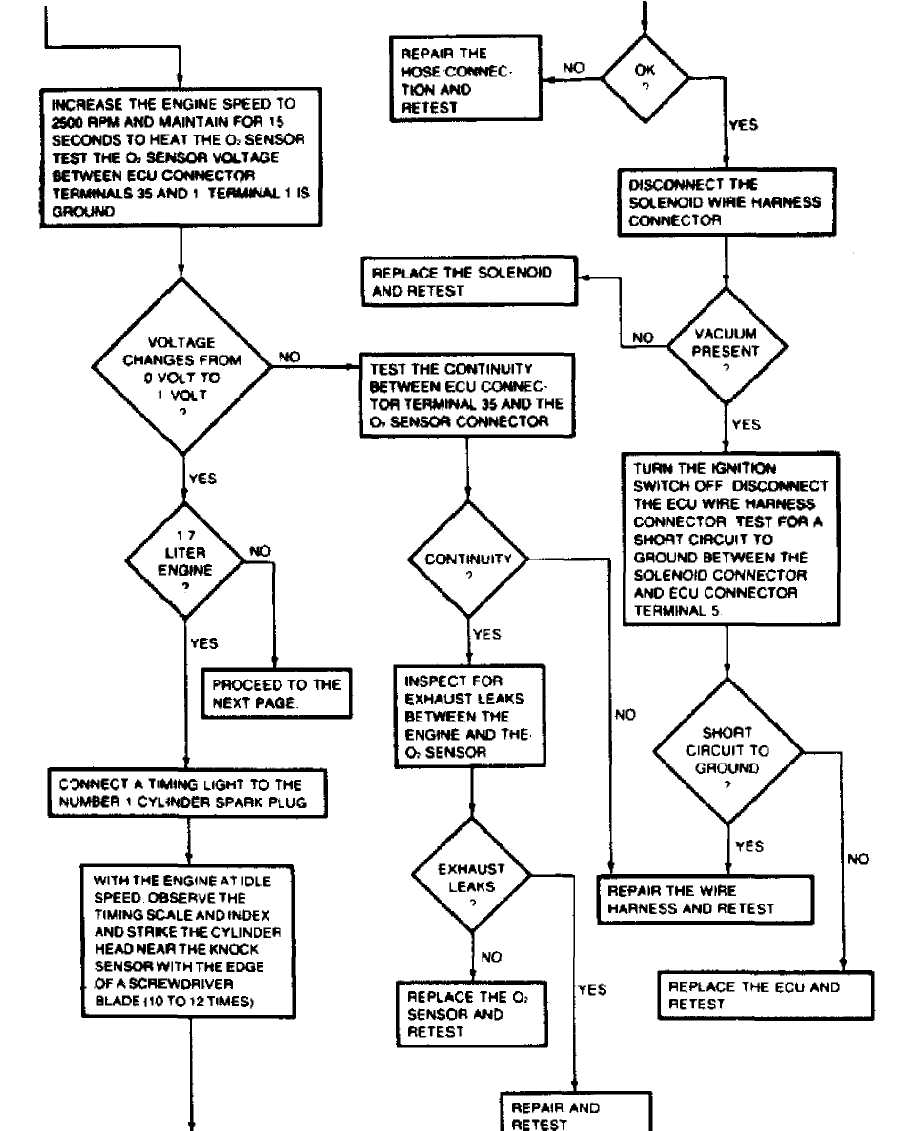

TEST 4 & TEST 4A: SYSTEM OPERATIONAL

These tests check engine start-up circuit, fuel injector, "Closed Loop" air/fuel mixture function, coolant temperature sensor function, MAT sensor function, detonation sensor "Closed Loop" ignition retard/advance function, EGR valve and canister purge solenoid function, idle speed control and A/C control functions.

TEST 5: BASIC ENGINE

This test indicates failures in related engine components that are not part of fuel injection system.

TEST 6: MANUAL TRANSMISSION UPSHIFT

This test checks upshift indicator light function on vehicles with manual transmissions.

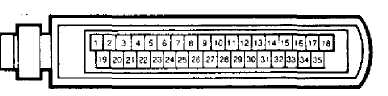

Ground

Ground

Ignition Switch

Battery

EGR Valve/Canister Purge

Fuel Pump Relay

System

Power Relay

: 8- WOT Switch

9. Not Used

System Ground

Speed Sensor

Park/Neutral Switch (A/T)

TPS

(Ground)

14 MAT Sensor

15. Coolant Temperature Sensor

16, MAP

Sensor (Supply Voltage)

17 MAP Sensof

(Ground)

IB Upshift Light (M/T)

19, System Power (Batt Pos.)

20. Not

Used

21 Injector

A/C Compressor Clutch

ISA Motor Retract (Reverse)

ISA

Motor Extend (Forward)

25 Closed

Throttle (idle) Switch

Not Used

ignition Interference

Speed Sensor

Start Signal

A/C Select

Thmitle Position Sensor

Temperature Sensor Ground

MAP Sensor (Output Voltage)

A/C Request

Oxygen 0, Sensor Input

Fig. 5: Jeep/Renix Fuel Injection ECU Connector Courtesy of Chrysler Motors.

REMOVAL & INSTALLATION

COOLANT TEMPERATURE SENSOR (CTS)

Removal & Installation

Allow engine to cool down. Disconnect CTS wiring harness. Remove CTS from intake manifold and rapidly plug hole to prevent coolant loss. Install replacement CTS and connect CTS wiring harness.

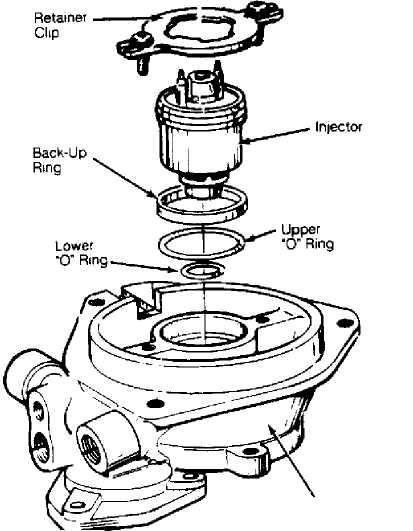

FUEL INJECTOR

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal injury, cover fittings with shop towel while disconnecting fittings.

Removal

Remove air cleaner assemby. Remove injector wiring connector. Remove injector retainer screws and clip. Using small pliers, carefully grasp center collar of injector between electrical terminals and carefully remove injector with lifting/twisting motion. Discard both "O" rings. See Fig. 6.

Installation

Using

light oil, lubricate new upper and lower "O"

rings.

Install "O"

rings in housing bore. Install back-up ring over

upper

"O" ring. Position

replacement injector in fuel body.

Center nozzle in lower housing bore and use a

pushing/twisting motion to seat injector. Align wire connectors in proper orientation. Install retainer clip and screws. Connect injector wiring. Install air cleaner.

Throttle

Body

Fig. 6: Fuel Injector & Throttle Body Assembly Courtesy of Chrysler Motors.

FUEL PRESSURE REGULATOR

Removal & Installation

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal injury, cover fittings with shop towel while disconnecting fittings.

With throttle body assembly removed, remove 3 screws holding fuel pressure regulator in throttle body. Remove fuel pressure regulator assembly. Note location of components for installation. Discard gaskets. To install, reverse removal procedure. Adjust regulator after installation. See ADJUSTMENTS in this article.

IDLE SPEED ACTUATOR (ISA) MOTOR

Removal & Installation

Disconnect

throttle return spring. Disconnect wiring

harness connector from

ISA motor. Remove ISA motor retaining nuts and

remove ISA motor

from bracket.

To install

ISA motor assembly, reverse removal procedure.

Adjust ISA motor

after installation. See ADJUSTMENTS in this article.

THROTTLE BODY ASSEMBLY

Removal

Remove air

inlet duct and adapter plate. Remove throttle

cable and return

spring. Disconnect electrical leads from fuel

injector, WOT

switch, and ISA motor.

Disconnect

fuel supply and return lines at throttle body.

See

Fig. 7. Tag and disconnect vacuum hoses.

Disconnect TPS wiring.

Remove throttle body assembly. If throttle

body assembly is being

replaced, transfer ISA motor and WOT

switch bracket assembly to new

unit.

Installation

Fig. 7: Intake Manifold & Throttle Body Assembly Courtesy of Chrysler Motors.

THROTTLE POSITION SENSOR

Install replacement throttle body assembly on manifold using new gasket. Reconnect all hoses, wires and cable in reverse order of disassembly. Adjust ISA motor after installation. See ADJUSTMENTS in this article.

Removal & Installation

Remove throttle body assembly as previously described. Remove Torx head retaining screws. Remove throttle position sensor from throttle shaft lever. To install, reverse removal procedure. Adjust TPS after installation. See ADJUSTMENTS in this article.

MANIFOLD AIR/FUEL TEMPERATURE (MAT) SENSOR

Removal & Installation

Disconnect wire harness connector from MAT sensor. Remove MAT sensor from intake manifold. To install, reverse removal procedure. See Fig. 7.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

Removal & Installation

Disconnect wire harness connector, vacuum hose, and retaining nuts from MAP sensor. Remove sensor from firewall. To install, reverse removal procedure.

ELECTRONIC CONTROL UNIT (ECU)

Removal & Installation

On

Wrangler, remove passenger assist handle and glove box

assembly.

Remove ECU bracket retaining nuts from engine compartment

side of

firewall. Disconnect ECU wiring harness. Remove ECU from

bracket.

To install, reverse removal procedure.

On all

other models, remove retaining screws and bracket

that supports

ECU above accelerator pedal. Remove ECU and disconnect

wiring

harness. To install, reverse removal procedure.

EGR VALVE

Removal & Installation

Disconnect vacuum hose from EGR valve. Remove bolts which hold EGR valve to intake manifold. Remove valve and discard gasket. To install valve, reverse removal procedure. Always use new gasket. See Fig. 7.

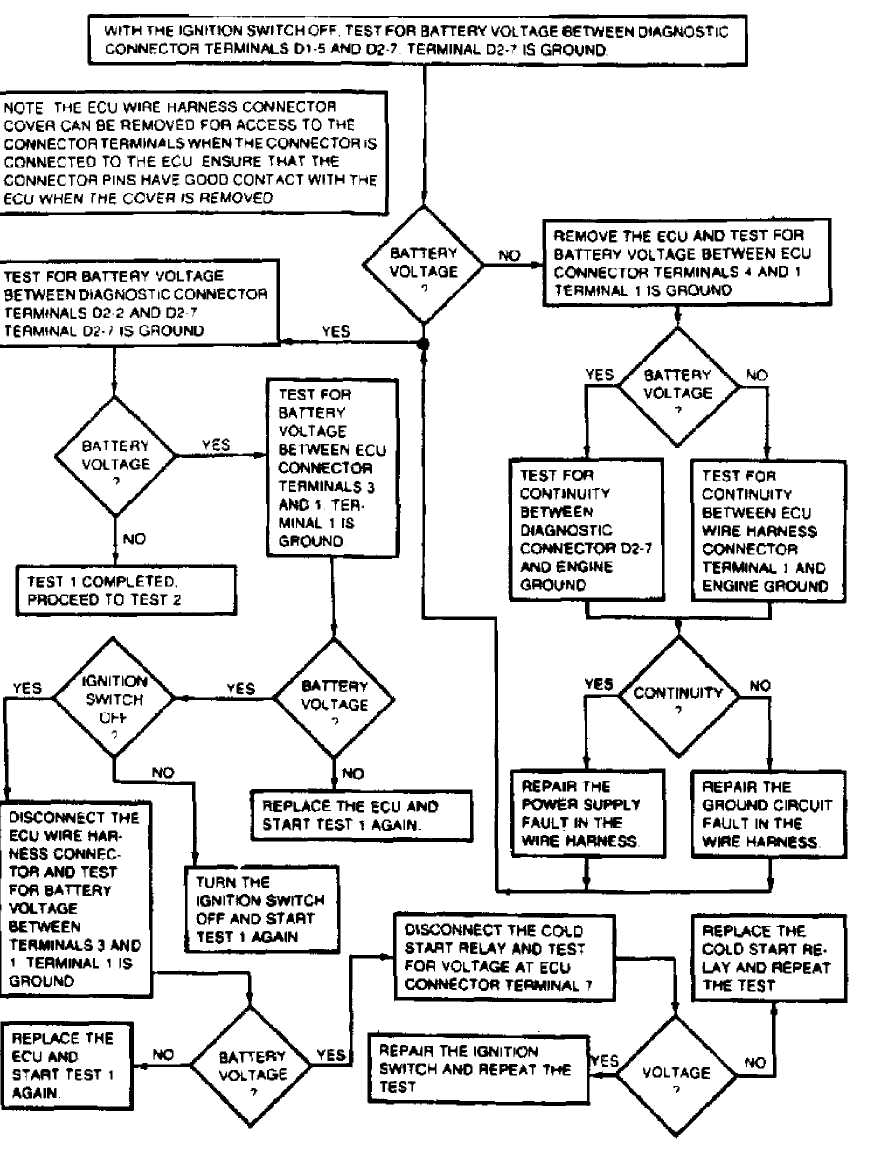

TROUBLESHOOTING AND DIAGNOSIS

Fig.

Fig.

36961

: TEST 1:

TEST1: IGNITION OFF

I

IGNITION OFF

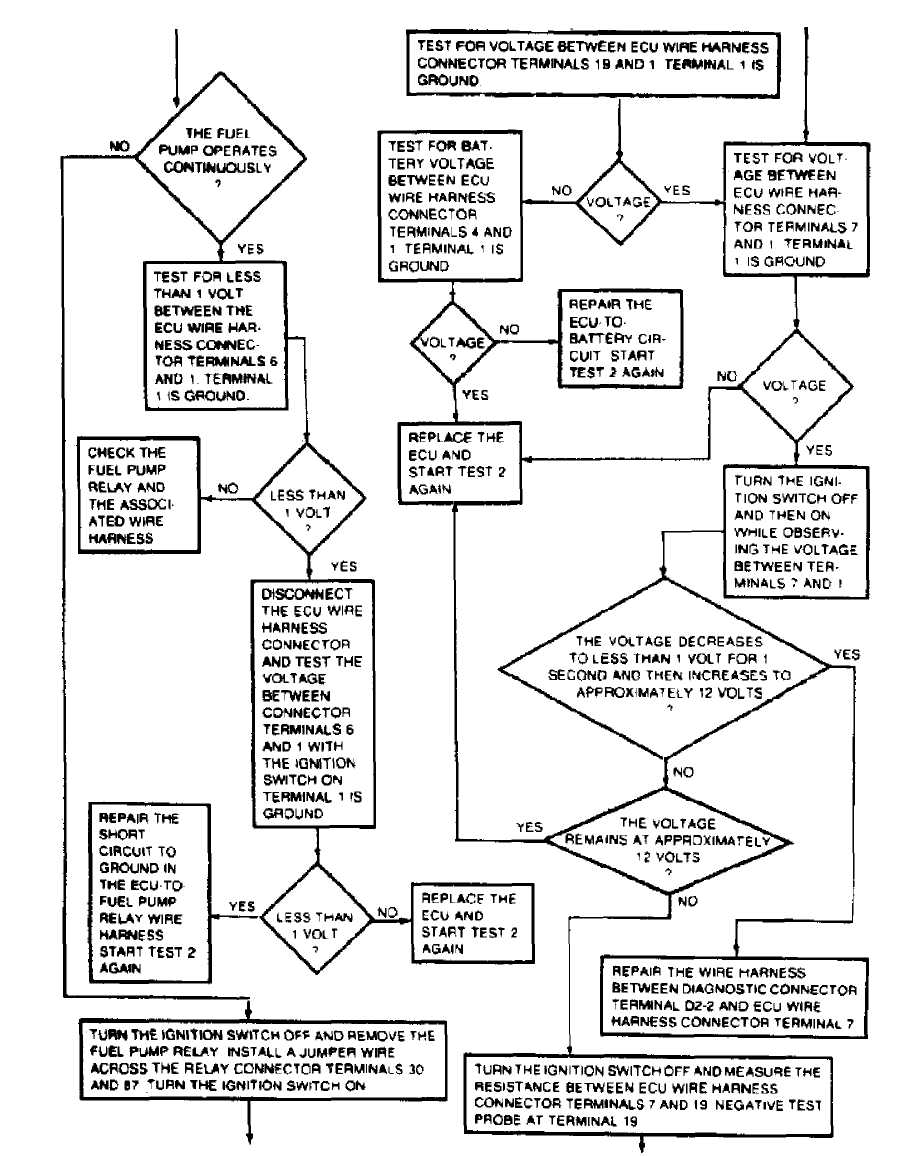

TEST 2: IGNITION ON: POWER

Fig. 9:

36962

TEST 2:

CONTINUED ON NEXT GRAPHIC

IGNITION ON: POWER

CONTINUED FROM PREVIOUS GRAPHIC

Fig.

36963

10: TEST 2:

IGNITION ON: POWER (Cont.)

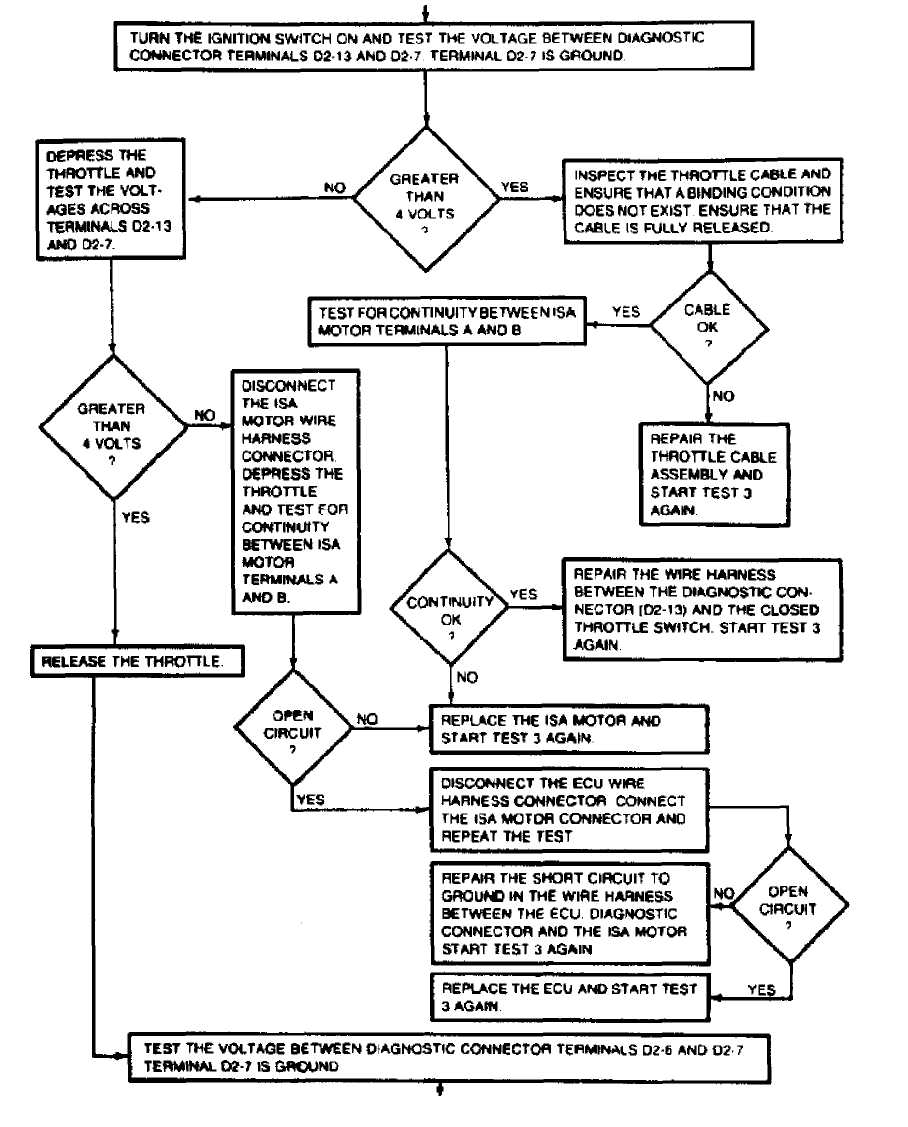

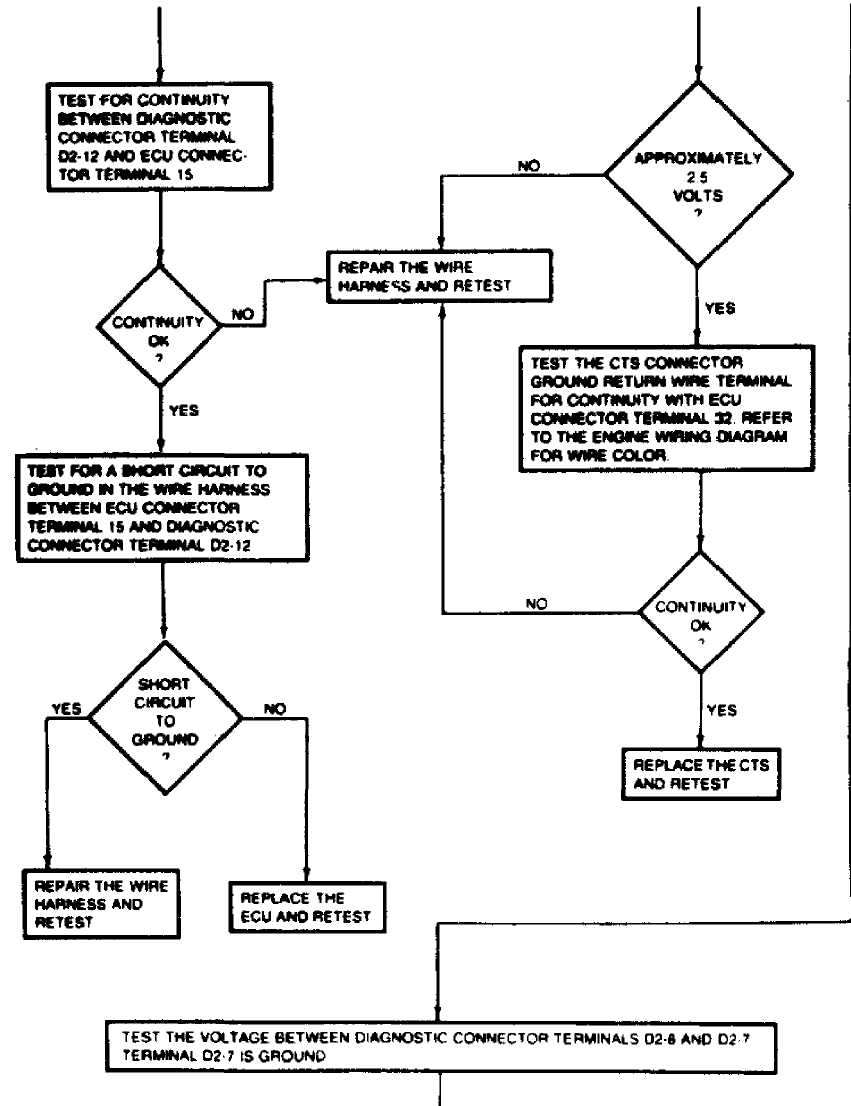

TEST 3: IGNITION ON: INPUT

Fig.

11:

Fig.

11:

36965

TEST 3:

CONTtNUED ON NEXT GRAPHIC

IGNITION ON: INPUT

CONTINUED FROM PREVIOUS GRAPHIC

Fig.

Fig.

36966

12: TEST

3: IGNITION ON: INPUT (Cont.)

TEST 3: IGNITION ON: INPUT (Cont.)

I

CONTINUED ON NEXT GRAPHIC

36967

Fig. 13: TEST 3: IGNITION ON: INPUT (Cont.)

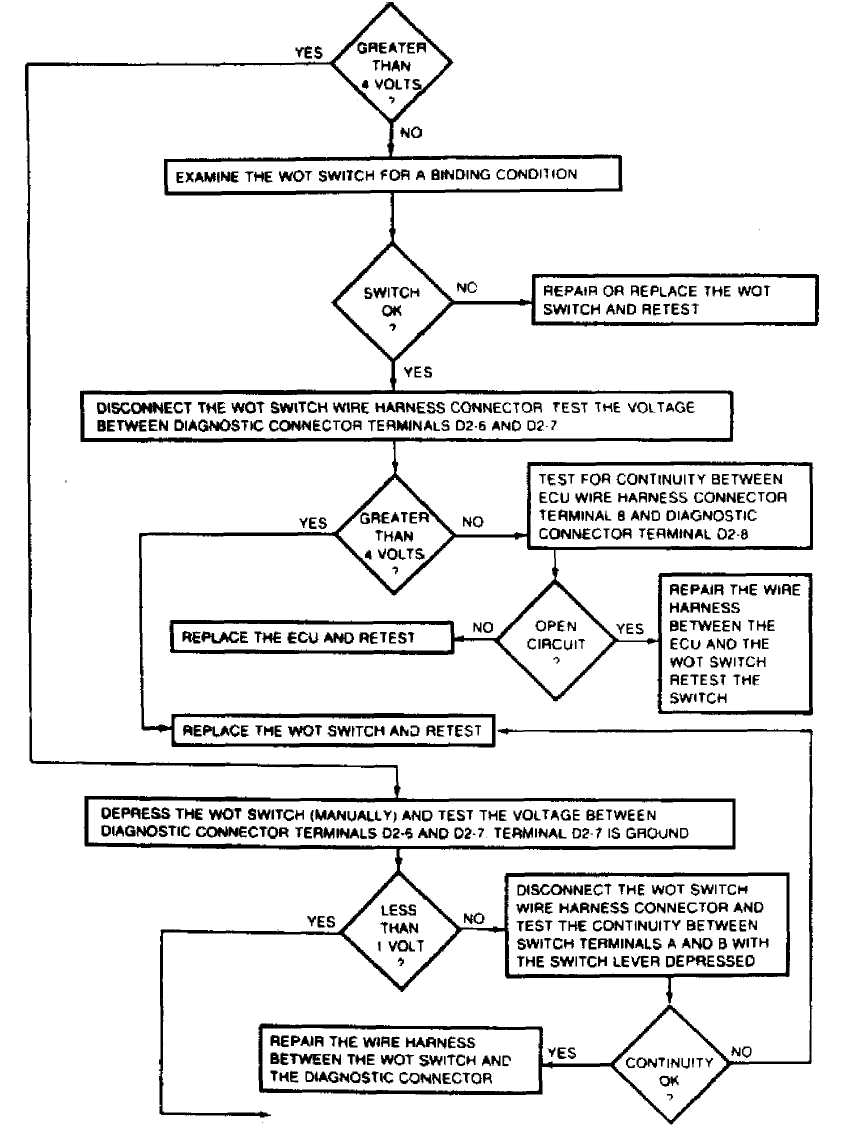

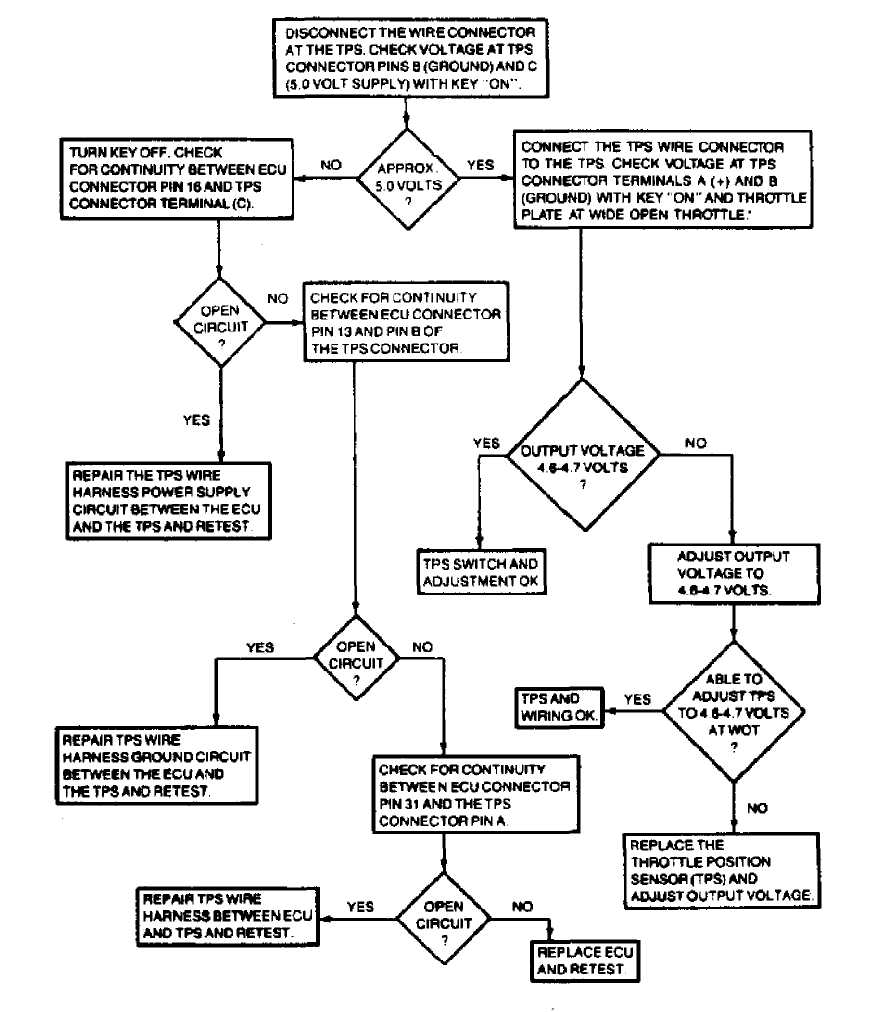

TEST ÇÀ: IGNITION ON: THROTTLE POSITION SENSOR

• DO MOT UNFASTEN THE SENSOR WIRE HARNESS CONNECTOR INSERT THE VOLTMETER TEST LEADS THAOUOH THE BACK OFTHE WIRE HARNESS CONNECTOR TQMAKE CONTACT WITH THE SENSOR TERMtNALS. ON SOME MODELS, IT MAY ALSO BE NECESSARY TO REMOVE THE THROTTLE BODY FROM THE INTAKE MANIFOLD. TO QAIN ACCESS TO THE SENSOR WIRE HARNESS CONNECTOR.

36971

Fig. 14: TEST 3A: IGNITION ON: THROTTLE POSITION SENSOR (M/T)

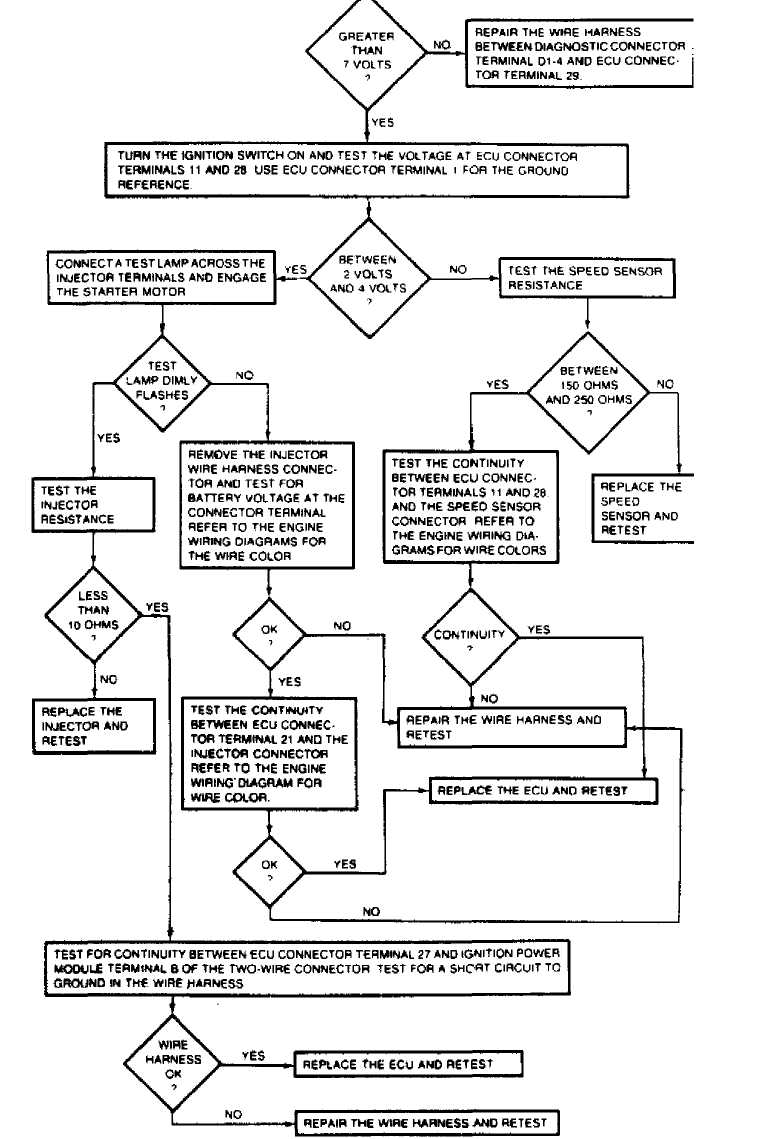

TEST 4: SYSTEM OPERATIONAL (Cont.)

36973

Fig. 15: TEST 4: SYSTEM OPERATIONAL

TEST 4A: SYSTEM OPERATIONAL

CONTINUED ON NEXT GRAPHIC

36974

Fig. 16: TEST 4: SYSTEM OPERATIONAL (Cont.)

CONTINUED

FROM PREVIOUS GRAPHIC

CONTINUED

FROM PREVIOUS GRAPHIC

CONTINUED ON NEXT GRAPHIC 36975

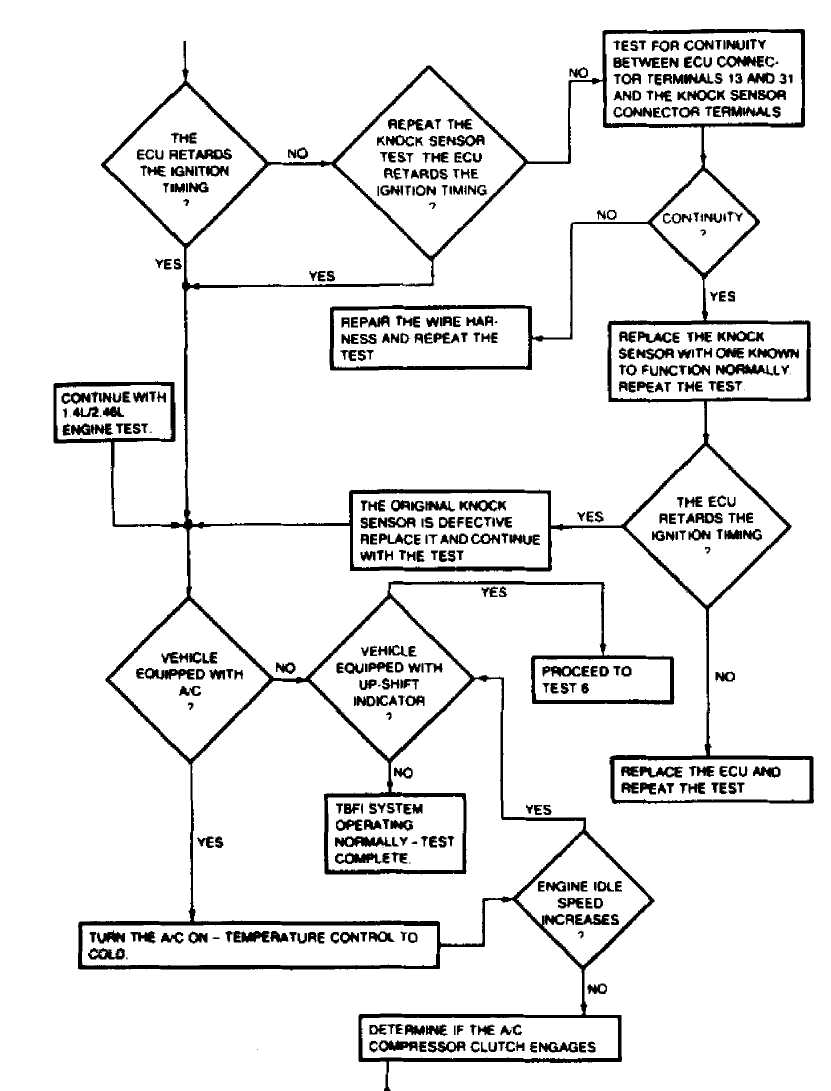

Fig. 17: TEST 4A: SYSTEM OPERATIONAL

CONTINUED FROM PREVIOUS GRAPHIC

36976

Fig. 18: TEST 4A: SYSTEM OPERATIONAL (Cont.)

CONTINUED FROM PREVIOUS GRAPHIC

CONTINUED ON NEXT GRAPHIC

36977

Fig. 19: TEST 4A: SYSTEM OPERATIONAL (Cont.)

CONTINUED FROM PREVIOUS GRAPHIC

CONTINUED ON NEXT GRAPHIC 36978

Fig. 20: TEST 4A: SYSTEM OPERATIONAL (Cont.)

CONTINUED FROM PREVIOUS GRAPHIC

Fig.

21:

Fig.

21:

36979

TEST 4A:

SYSTEM OPERATIONAL (Cont.)

TEST 4A: SYSTEM OPERATIONAL (Cont.)

CONTINUED ON NEXT GRAPHIC

36980

Fig. 22: TEST 4A: SYSTEM OPERATIONAL (Cont.)

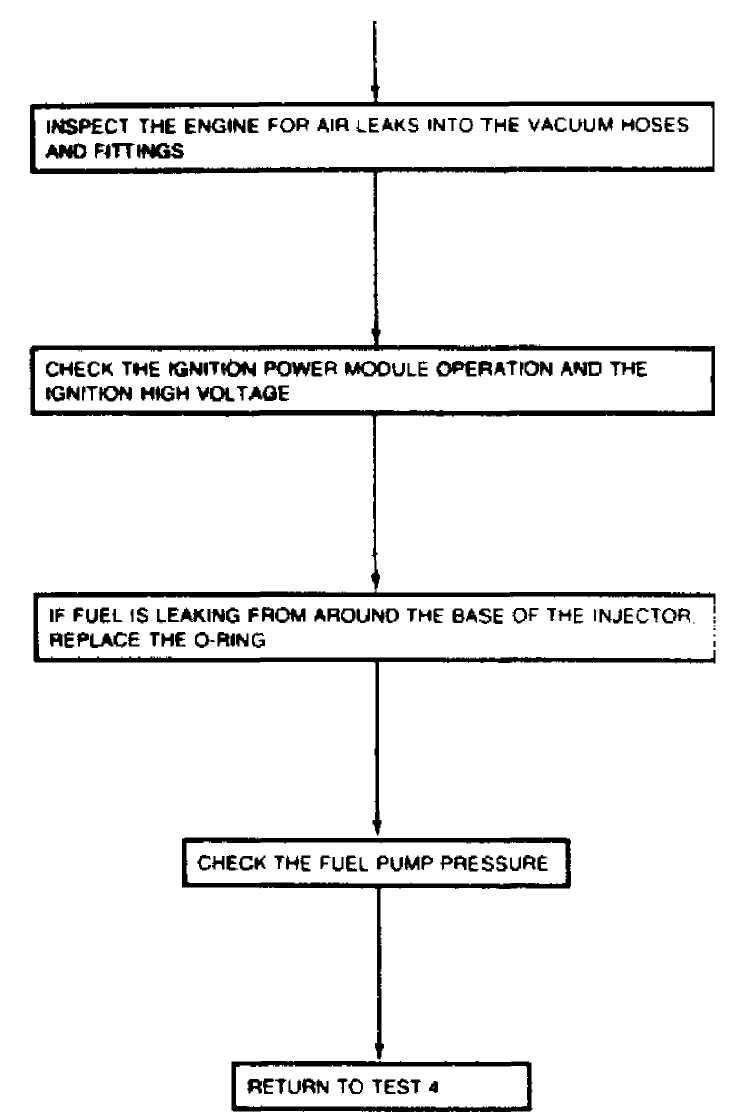

TEST 5: BASIC ENGINE

36983

Fig. 23: TEST 5: BASIC ENGINE

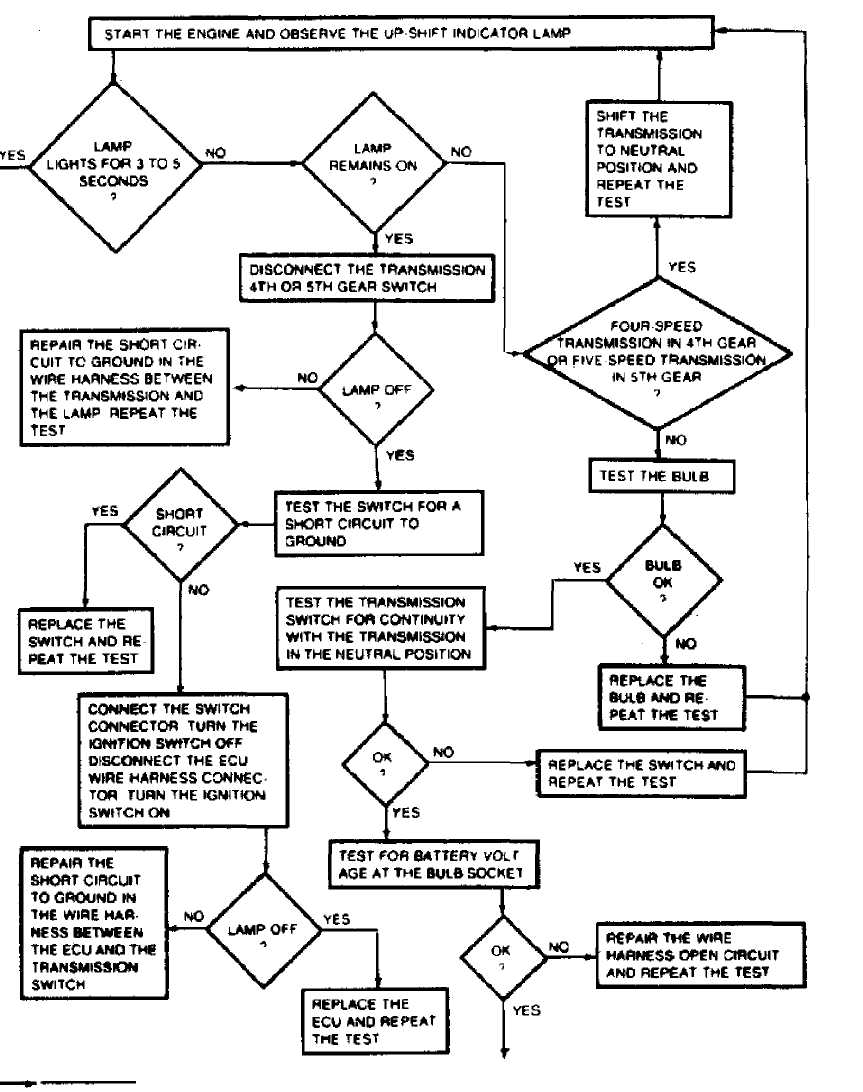

TEST 6: MANUAL TRANSMISSION UP-SHI FT

i

Fig. 24:

CONTINUED ON NEXT GRAPHIC

TEST 6: MANUAL TRANSMISSION UPSHIFT

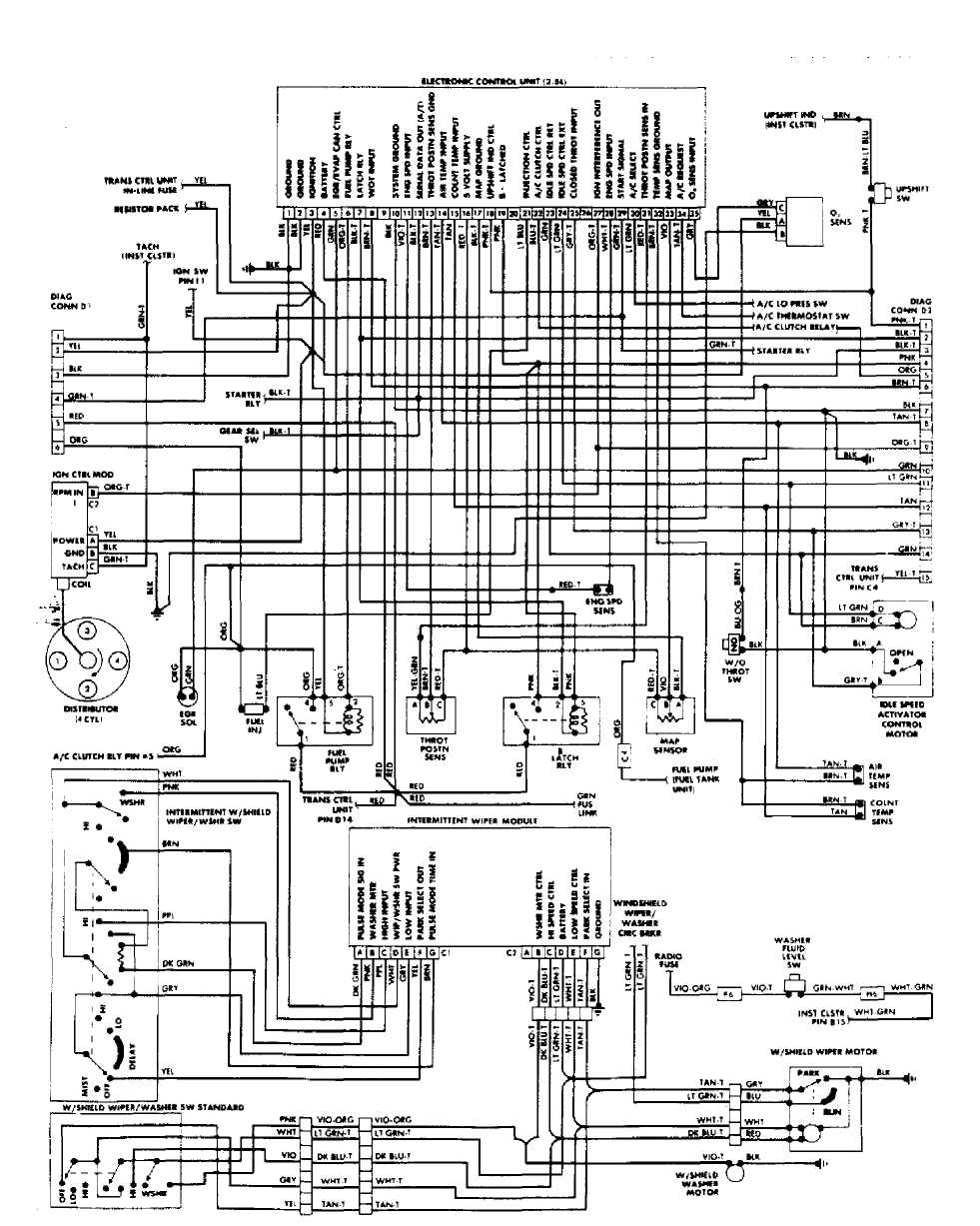

WIRING DIAGRAMS

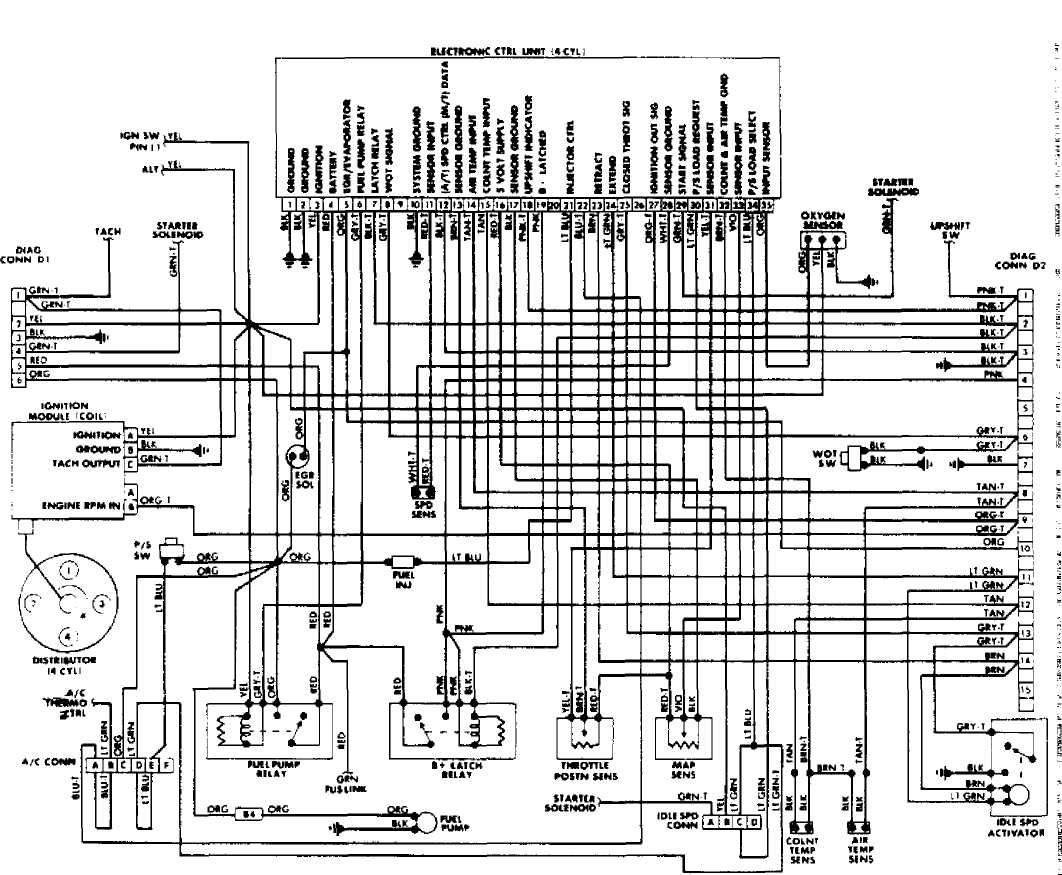

Fig.

25: Cherokee, Comanche &

Wagoneer Throttle Body Fuel Injection

System Wiring Diagram

Fig.

25: Cherokee, Comanche &

Wagoneer Throttle Body Fuel Injection

System Wiring Diagram

Fig. 26: Wrangler Throttle Body Fuel Injection System Wiring Diagram