STEERING GEAR - MANUAL

1988 Jeep Cherokee

1988 STEERING

Jeep Manual Steering Gears

Koyo & Saginaw Recirculating Ball

Cherokee, Comanche, Wrangler

DESCRIPTION

Jeep uses the Saginaw steering gear unit. Different models are used. The Model 525 uses 3 bolts in the side cover while the Model 535 uses 4 bolts.

Steering gears are a recirculating ball-type. Proper

engagement between sector and ball nut is obtained by adjusting screw. Worm bearing adjuster can be turned to provide proper preloading of upper and lower bearings.

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

ADJUSTMENTS

NOTE: Adjust worm bearing preload prior to performing meshload adjustment. If steering gear is removed, install INCH lb. torque wrench on worm shaft to check preload adjustments.

WORM BEARING PRELOAD

1) Place reference mark on pitman arm and sector shaft.

Remove pitman arm retaining nut. Using puller, remove pitman arm from sector shaft.

Disconnect pitman arm from ball stud or sector shaft.

Remove

horn pad. Turn steering wheel slowly against one

stop

then back 1/2 turn. Place an INCH-lb.

torque wrench with a

maximum reading of

50 INCH lbs. (6 N.m)

on steering wheel nut.

Measure

amount of torque (preload) required to rotate

steering

wheel at a constant speed for approximately 1 1/2 turns

on

Ford Motor Co. models or 90 degree

arc on all others.

Note

preload. Adjust preload if not within specification.

See WORM

BEARING PRELOAD table. Adjust preload by loosening lock nut

(if

not previously loosened) and rotating worm bearing adjuster

to

obtain correct preload.

Once

correct preload is obtained, tighten lock nut to

specification.

Perform meshload adjustment once correct preload is

obtained.

WORM BEARING PRELOAD TABLE

Application INCH

Lbs. (N.m)

Application INCH

Lbs. (N.m)

Cherokee, Comanche & Wrangler 5-8 (.6-.9)

MESHLOAD ADJUSTMENT

1) Rotate steering wheel from stop-to-stop, noting the number of revolutions. Rotate steering wheel back to the center position.

2) Ensure sector shaft cover bolts are tightened to

specification. Using an INCH lb. torque wrench, measure highest torque required to rotate steering wheel back and forth through the center position. Meshload must be adjusted if not within specification. See the MESHLOAD SPECIFICATIONS table.

MESHLOAD SPECIFICATIONS TABLE

Application INCH

Lbs. (N.m)

Application INCH

Lbs. (N.m)

Cherokee, Comanche & Wrangler (1) 4-10 (.5-1.1)

(1) - In excess of worm bearing preload. Maximum preload is 18 INCH lbs. (2.0 N.m) on Jeep models or 16 INCH lbs. (1.8 N.m) on all others.

Loosen

sector shaft adjuster screw lock nut. Adjust sector

Loosen

sector shaft adjuster screw lock nut. Adjust sector

shaft

adjuster screw to obtain correct reading. Tighten lock nut

to

specification while holding adjusting screw.

Reverse

removal procedures for components removed. Ensure

reference

mark is aligned on pitman arm and sector shaft. Tighten

pitman

arm retaining nut to specification. On Jeep models, stake

pitman

arm retaining nut in 2 places.

REMOVAL & INSTALLATION

STEERING GEAR

CAUTION: All steering component fasteners are made of special quality materials. Replacement fasteners must be of same part number or equivalent. Tighten all fasteners to proper torque. Install new cotter pin where used.

Removal

Disconnect

negative battery cable. Set front wheels in

straight-ahead

position. Note position of steering wheel. Remove

flexible

coupling shield retaining screw (if equipped).

Remove

flexible coupling-to-steering worm shaft flange

bolts or lower

universal joint pinch bolt. Remove sector shaft nut and

washer.

Place reference mark in relation of pitman arm-to-sector

shaft.

Using Puller (J-6632-01), remove pitman arm. Remove

steering

gear-to-frame bolts. Remove steering gear.

Installation

Install

flexible coupling on worm shaft. Align flat on

coupling

with flat on worm shaft. Push coupling on shaft until shaft

touches

shoulder. Install pinch bolt. Pinch bolt must pass through

shaft

undercut.

To install remaining components, reverse removal

procedure. Align reference mark on pitman arm and sector shaft. Ensure splines are properly aligned. Tighten bolts to specification. On Jeep models, stake sector shaft nut in 2 areas.

SECTOR SHAFT SEAL

NOTE: On some models, sector shaft seal may be replaced without removing steering box. It may be necessary to remove steering gear to gain access to remove sector shaft seal.

Removal & Installation

1) Place steering gear at center of travel. Remove sector

shaft nut. Place reference mark in relation of pitman arm-to-sector shaft. Using puller, remove pitman arm.

Remove

sector shaft cover retaining bolts. Lift sector

shaft and cover

from housing. Using a screwdriver, pry sector shaft

seal from

housing. Use care not to damage housing area. Note direction

of

seal installation.

Loosen

sector shaft adjusting screw lock nut. Rotate

adjusting screw

clockwise and remove cover from sector shaft. Inspect

gear

lubricant for contamination. Steering gear must be overhauled

if

contamination exists.

Lubricate new sector shaft seal with steering gear

lubricant. Position seal in housing bore. Using proper sized socket, tap seal into housing until it bottoms.

Install

sector shaft so center tooth of sector shaft

enters

center tooth of ball nut. Fill housing with lubricant. Install

new

sector shaft cover gasket on gear housing (if equipped).

Apply a

thin bead of sealant to sector shaft

cover on models which do not use

a

gasket.

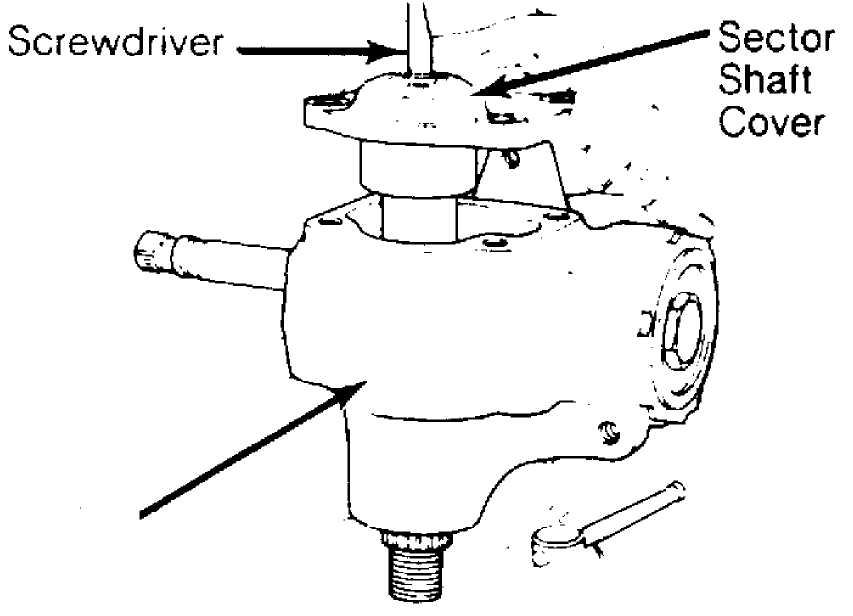

Using

a screwdriver through the center hole, align

adjusting screw and

install cover on sector shaft. See Fig. 1. Turn

adjusting

screw counterclockwise until screw bottoms, then back off

1/4

turn.

Coat cover

bolts with non-hardening sealant. On all

models, install cover

retaining bolts. Tighten to specification.

Install sector shaft

lock nut. Perform adjustments on steering box.

See ADJUSTMENTS in

this article.

Housing

Fig. 1: Installing Sector Shaft Cover

OVERHAUL

STEERING GEAR

Disassembly

Place

steering gear in a holding fixture. Worm shaft

should be centered

in steering gear. Remove sector shaft cover bolts.

Remove sector

shaft and cover from housing.

Remove sector shaft adjusting screw lock nut. Rotate

adjusting screw clockwise to remove cover from shaft. DO NOT lose shim located on adjusting screw.

3) Loosen

worm bearing adjuster lock nut. Remove worm bearing

adjuster

and worm shaft lower bearing. Remove worm shaft and ball nut

assembly

from housing. Remove upper bearing.

CAUTION: DO NOT allow ball nut to rotate down worm shaft as ball guides may be damaged.

If ball

nut fails to rotate smoothly on worm shaft,

disassembly is

required. Remove ball guide clamp and guides. Rotate

worm shaft

in both directions to remove balls. Note and record number

of

balls in each circuit area of the ball nut.

Note

direction of ball nut on worm shaft prior to removal.

Remove ball

nut from worm shaft.

CAUTION: Note and record number of balls removed from each circuit of ball nut during disassembly. Determine location of ball nut on worm shaft prior to removal. Ball nut must be installed on worm shaft with shallow teeth in proper direction.

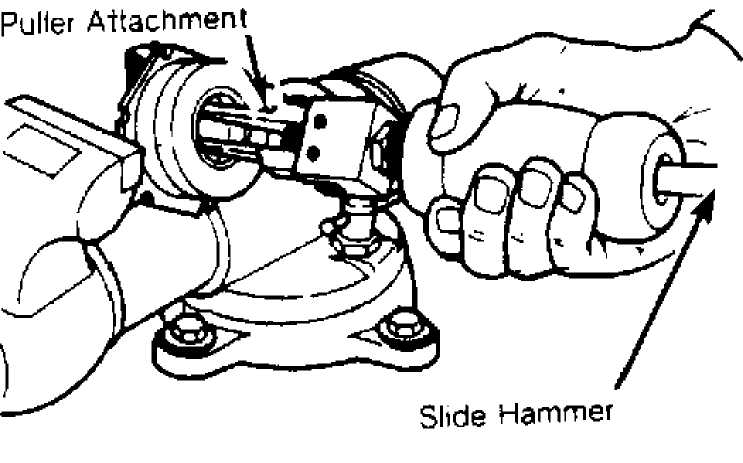

Use

slide hammer and puller attachment to remove worm

bearing

adjuster bearing cup. See Fig. 2. Using a

bearing driver or

socket, remove

bearing cup from housing.

Remove

bearings from housing. Pry out all seals from

housing. Note

direction of seals.

30301

Fig. 2: Removing Worm Adjuster Bearing Cup

Cleaning & Inspection

1) Clean components with solvent and dry with compressed air. Inspect bearings and races for signs of wear. Inspect ball nut and

worm shaft for wear or pitting.

2) Inspect

sector shaft fit at side cover bushing assembly

(if

equipped). Bushing is replaceable.

3) Inspect

housing for cracks or damage. Inspect bearings for

damage. Inspect

sector gear teeth for chipping or excessive wear.

Replace

components as necessary.

Reassembly

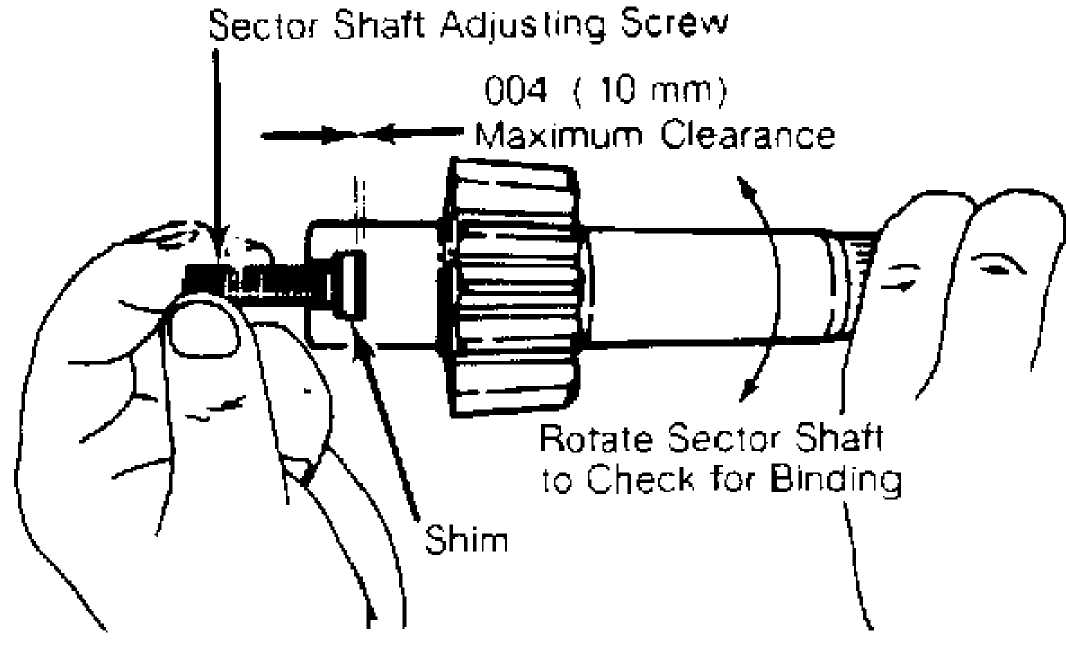

1) Install sector shaft adjusting screw and shim in sector shaft. Using feeler gauge, measure clearance between adjusting screw and bottom of sector shaft "T" slot. See Fig. 3.

30302

Fig. 3: Checking Sector Shaft "T" Slot Clearance

2) Different thickness shims should be used if clearance is not within specification. See ADJUSTING SCREW CLEARANCE SPECIFICATIONS table.

ADJUSTING SCREW CLEARANCE SPECIFICATIONS TABLE

Application

Cherokee, Comanche & Wrangler

In. (mm) .002 (.05)

3)

Once correct shim is determined, install

shim and adjusting screw. Hold sector adjuster screw while turning

sector shaft. If sector shaft does not

turn freely, increase clearance by

3)

Once correct shim is determined, install

shim and adjusting screw. Hold sector adjuster screw while turning

sector shaft. If sector shaft does not

turn freely, increase clearance by

replacing shims as necessary.

Install

ball nut on worm shaft. Ensure ball nut is

installed so shallow

end of teeth are to the left as viewed from

steering wheel end of

worm shaft. Align grooves in worm and nut by

sighting through

ball guide holes.

There

are 2 types of ball guides used. One type

contains a

hole in the middle, while

the other does not. If ball guides contain

the

middle hole, install ball guides in the ball nut.

Divide

balls into 2 equal groups. Insert each

group into a

ball guide, while slowly turning worm shaft away

from the hole. Repeat

procedure for remaining circuit.

On guides

with no holes, separate guide halves and fill

each one half of

each circuit with balls. Install remaining guide

half. Hold

guides and plug ends with grease to prevent the balls from

falling

out.

Fill each

circuit of ball nut with half of remaining balls

in one circuit,

and half in other. DO NOT turn worm shaft while

installing. It

may be necessary to use small punch to aid in ball

installation.

Install ball guides. On both types, install ball guide

ñlamp.

9) To

install, reverse removal procedure. Lubricate all

seals,

bearings and sector shaft prior to installation. Coat worm

bearing

adjuster, sector shaft adjuster screw and sector shaft cover

bolts

with non-hardening sealant prior to installation.

Screw worm

bearing adjuster down until nearly all end

play has been removed.

Lubricate steering gear by rotating worm shaft

until ball nut is

at end of its travel.

Pack as much grease as possible into steering gear

housing without losing it out sector shaft opening. Rotate ball nut to other end of its travel and pack more grease into housing.

Fig. 4: Exploded View of Saginaw Model 525 Steering Gear (Typical)

TORQUE SPECIFICATIONS

Rotate

ball nut until it is in center of its travel.

Insert sector shaft

assembly, containing adjusting screw and shim into

housing.

Center tooth of sector gear must engage center rack tooth

space

in ball nut.

Pack

housing with grease. Apply a thin bead of sealant to

sector shaft

cover on models which do not use gasket. Install cover

and gasket

on housing. Engage sector adjuster screw with tapped hole

in

center of sector cover by turning screw counterclockwise.

Turn

adjusting screw until sector cover is flush with

housing.

Install sector cover bolts but do not tighten unless there is

a

lash between sector shaft and worm shaft.

Tighten

sector cover bolts to specification. Adjust

steering gear preload

and meshload. See ADJUSTMENTS in this article.

TORQUE SPECIFICATIONS TABLE

Application Ft.

Lbs. (N.m)

Application Ft.

Lbs. (N.m)

Adjuster Screw Lock Nut 25 (34)

Flex Coupling Pinch Bolt 45 (61)

Sector Shaft Nut 185 (252)

Sector Cover Bolt 32 (43)

Steering Gear-to-Frame Bolt 75 (102)

Worm Bearing Adjuster Lock Nut 50 (68)