STEERING COLUMN

1988 Jeep Cherokee

1988 STEERING

Jeep Steering Columns

All Models

DESCRIPTION

All models use collapsible steering columns. All columns have integral ignition switch and locking device. Optional tilt wheel is available with both A/T and M/T. Transmission shift linkage is integral on all models except those with floor shift.

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

REMOVAL & INSTALLATION

NOTE: Steering column removal and installation procedures refer to all manufacturers. Not all procedures, however, apply to all models.

STEERING COLUMN (COLUMN SHIFT)

Removal

Disconnect

battery negative cable. Disconnect transmission

shift cable rod

by prying rod from grommet in shift lever. Remove

cable clip.

Remove cable from lower bracket.

Disconnect,

as equipped, either the flexible coupling,

"Pot"

coupling or "U" joint from pinion shaft.

Disconnect

wiring connectors at column jacket. Remove

steering wheel and

horn pad. See STEERING WHEEL & HORN

REMOVAL

article. Remove damper assembly

(if equipped). On RWD models, remove

turn

signal lever.

On all

models, remove steering column-to-floor pan

attaching screws.

Expose steering column bracket. Remove instrument

panel steering

column cover. Lower reinforcement. Disconnect bezel.

Remove

indicator set screw and gearshift pointer from shift housing.

Remove

steering column bracket-to-instrument panel

attaching nuts. Lower

support bracket. Firmly grasp steering column

assembly and pull

rearward while disconnecting lower stub shaft from

pinion shaft

coupling.

NOTE: On vehicles equipped with cruise control and M/T, take care not to damage clutch pedal cruise control switch.

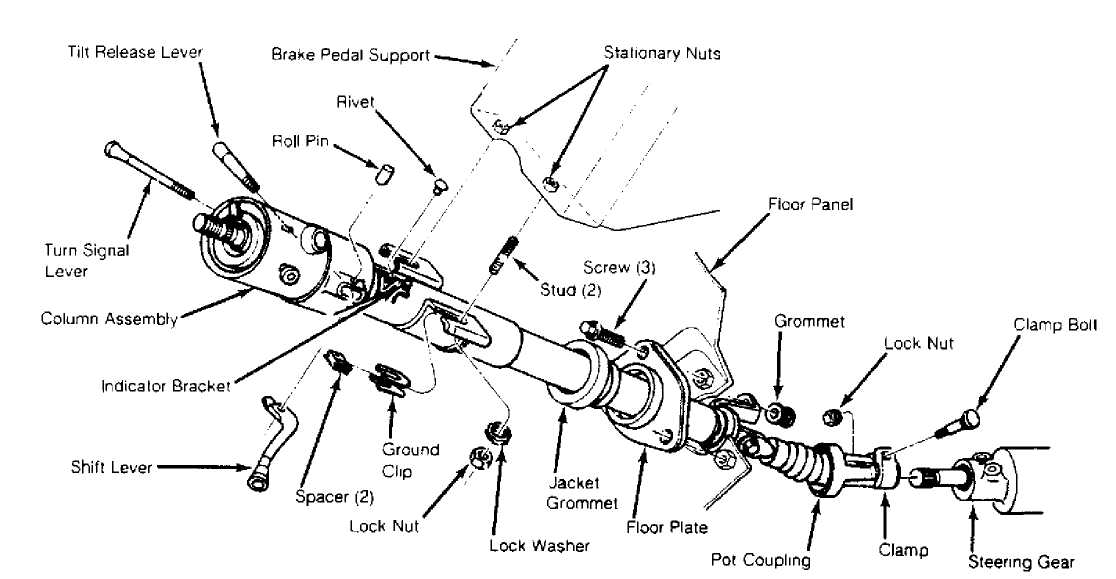

30241

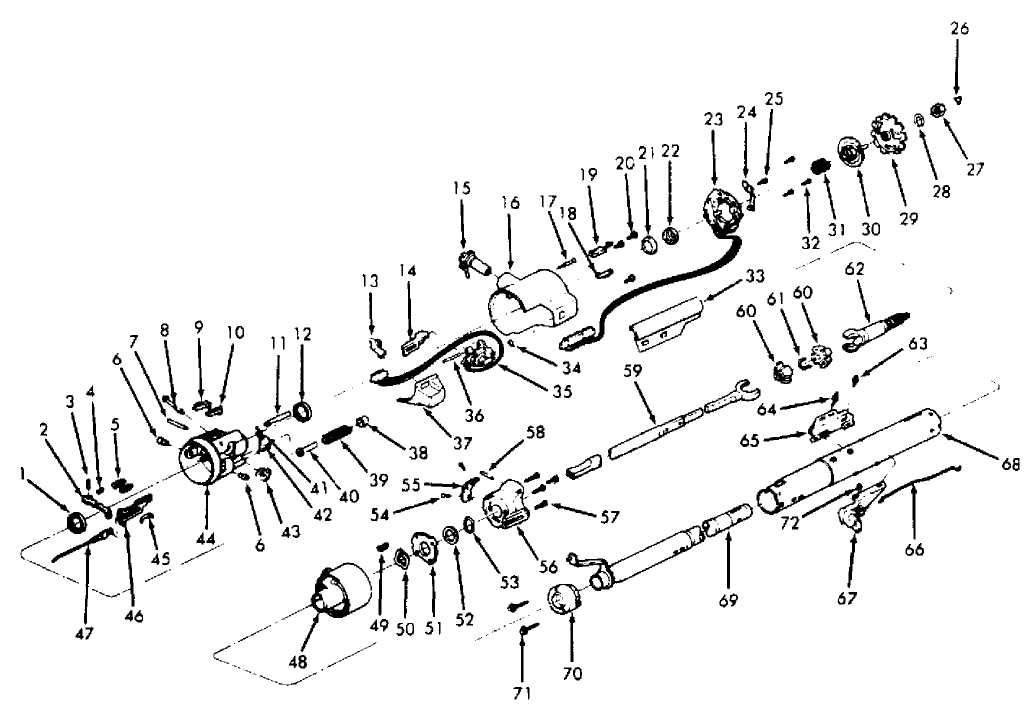

Fig. 1: Exploded View of RWD Steering Column Major Assemblies

Installation

On all

models, aligning lower shaft with lower coupling

and insert

shaft. Raise column assembly into position onto studs.

Loosely

install nuts and washers in breakaway capsules. Pull

column

rearward. Tighten nuts to specification. See TORQUE

SPECIFICATIONS.

Install a

new shift lever grommet using pliers and back-up

washer to snap

the grommet into place. Use a multipurpose grease to

aid

installation.

Connect

gearshift cable rod to shift lever by snapping rod

into

grommet with pliers. Adjust linkage. Place steering wheel on

shaft

with master splines aligned. Place damper assembly inside

steering

wheel (if equipped). Install steering

wheel retaining nut.

Tighten to 45

ft. lbs. (61 N.m).

Install

horn pad assembly. Refer to procedures in the

STEERING WHEEL &

HORN REMOVAL article. Connect wiring connectors

at

steering column jacket. Connect

battery negative cable. Test operation

of

lights and horn.

On

models with A/T, install gearshift indicator pointer.

Slowly

move gearshift lever from "LOW" position to "PARK"

position,

pausing briefly at each selector position. Loosen and

readjust to

align pointer with each position (if necessary).

Install instrument

panel

steering column cover.

STEERING COLUMN (FLOOR SHIFT)

The steering column with a floor mounted gearshift is basically the same as previously described. Standard columns and service procedures are identical except as described below.

* In place of rotating shift housing, there is a plastic shroud which is fixed to lock housing. Shroud covers jacket and lock inhibitor assembly. It is held in place by a tab that fits under side cover and one screw. Shroud can only be replaced by removing lock housing from jacket.

The

lock inhibitor assembly consists of a lever that engages

lock

levers (preventing locking of steering shaft), a

button

to operate lever and a return

spring. Assembly is attached to

lock

housing in same location as shift gate is on column

shift.

Lower steering shaft bearing is mounted in an aluminum

support.

A spring

is attached between shift housing and column jacket.

This spring

keeps housing rotated counterclockwise against

rubber bumper.

OVERHAUL

STANDARD COLUMN

NOTE: All columns are similar except for appearance of covers. Some models use ignition key light, while others do not. Disassembly and reassembly procedures cover all models. Some procedures may not apply to every steering column.

Disassembly

Pry out

wiring trough retainers. Lift off trough. New

retainers may be

required for reassembly. Use masking tape to protect

paint and a

deep socket to back-up housing. Drive retaining roll pin

out with

a punch to remove shift lever.

Remove breakaway capsules. Secure column in vise by

clamping at column bracket. DO NOT distort column. Remove turn signal lever cover-to-lock housing attaching screws. Remove cover. Remove wiper/washer switch assembly. Pull switch cover up wiper/washer lever. Remove lever sleeve-to-switch attaching screws.

Rotate

wiper/washer shaft to full clockwise position.

Remove shaft from

switch. Remove turn signal switch and upper bearing

retaining

screws. Remove retainer. Lift switch upward out of way.

Unclip

horn ground wire. Remove ignition key light retaining screw.

Lift

ignition key light out of way.

Remove

bearing housing-to-lock attaching screws. Remove

snap ring from

upper end of steering shaft. Remove bearing housing

from

shaft. Remove lock plate spring and lock

plate from shaft. Remove

shaft through

lower end of column.

Remove ignition key. Remove warning switch retaining

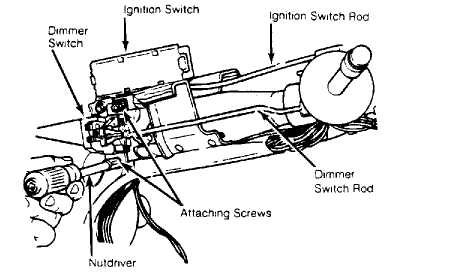

screw. Lift out key warning switch. Remove 2 ignition switch-to-column jacket retaining screws. See Fig. 2. Remove ignition switch by rotating switch 90 degrees on actuator rod. Remove 2 dimmer switch retaining screws. Disengage dimmer switch from rod.

30450

Fig. 2: Removing Ignition Switch

Remove

bellcrank mounting screws. Slide bellcrank up in

housing until it

can be disconnected from ignition switch rod. Using

key, place

cylinder in "LOCK" position. Remove key.

Using a

small diameter screwdriver or similar tool, push

inward to

release spring-loaded lock retainer while pulling lock

cylinder

from housing bore. Pull lock lever and spring assembly out

of

housing as an assembly.

Remove

4 lock housing-to-column jacket retaining

screws.

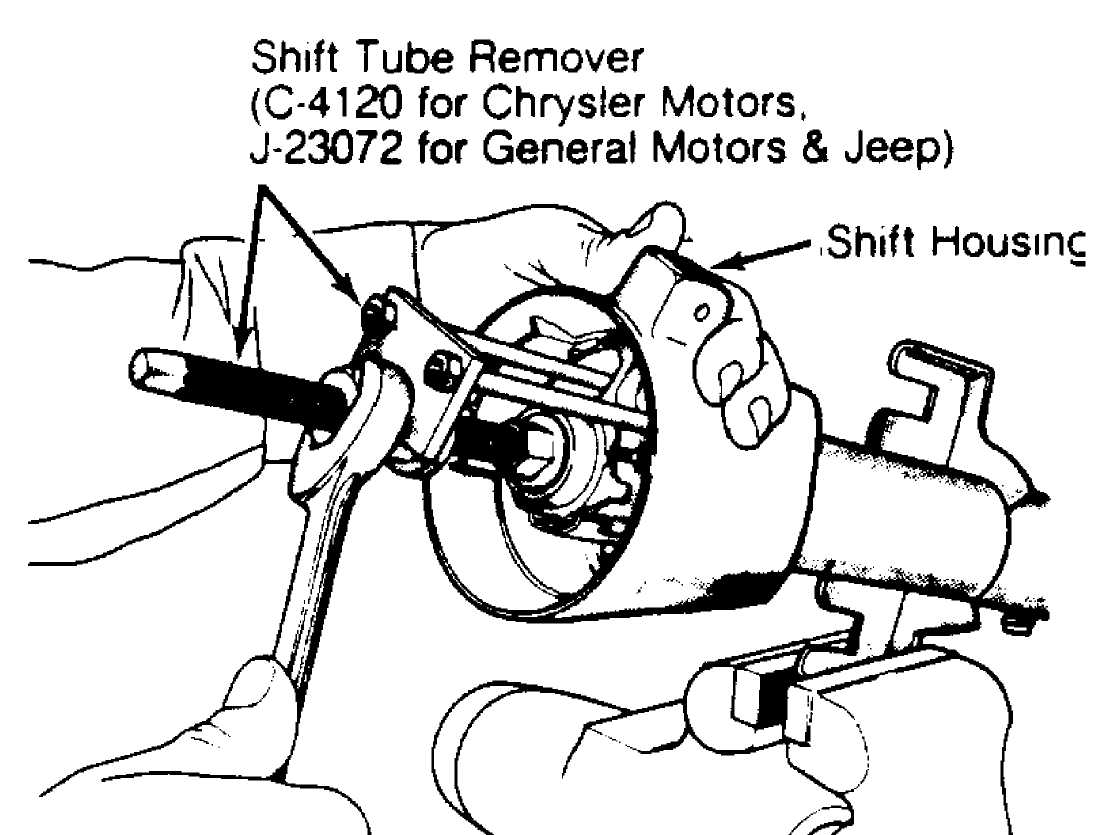

Remove housing from jacket. On A/T models, loosen shift

tube set screw

in shaft housing. On all models, using Shift Tube

Remover (J-23072 for

Jeep), remove tube through lower end of

jacket. See

Fig. 3.

9) To

disassemble flexible coupling, remove 4 bolts

and 2

cross straps. Remove flexible

coupling. "Pot" coupling is removed by

prying cover

tangs from coupling body and lifting seal and cover from

body.

Drive dowel pin down into coupling. Discard "Pot" coupling.

Pull

body off shaft and shoe assembly.

30249

30249

Fig. 3: Removing Shift Tube

Fig. 4: Removing Lock Cylinder

Reassembly

1) Coat all friction surfaces with grease. Clamp column in vise so that both ends of column are accessible. Check column tube-to-

mandrel

rivets for tightness.

mandrel

rivets for tightness.

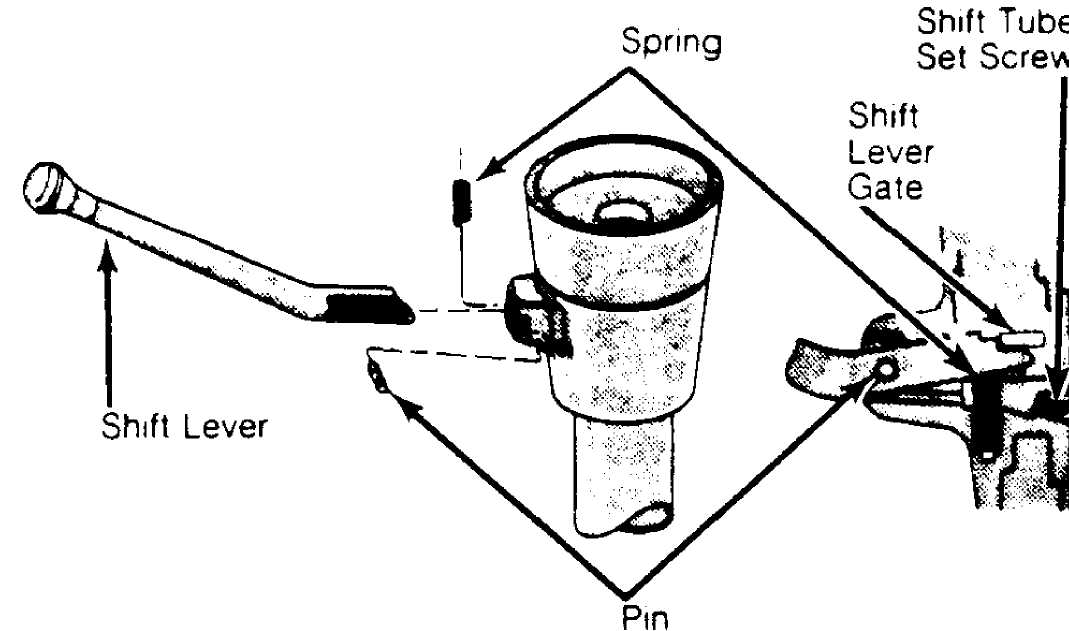

2) Use new 1/8" diameter by 1/4" long (1/8" grip) aluminum blind rivets (if necessary). DO NOT use steel rivets as rivets must shear upon impact. Position crossover load spring and shift lever in gearshift housing. Tap pivot pin into place. See Fig. 5.

30250

Fig. 5: Installing Column Shift Lever Courtesy of Chrysler Motors

Assemble

key cylinder plunger spring. Install assembly on

lock

housing. Install shift lever gate on lock housing. Place shift

lever

in mid position (if equipped). Seat lock

housing on top of

jacket by aligning

keyway in housing with slot in jacket. Install

housing-to-jacket

screws. Tighten alternately to 90 INCH

lbs. (10 N.

m) .

Install

dimmer switch rod by firmly pushing rod into

switch.

Compress switch until 2 (.093") drill

bit shanks can be

inserted into

alignment holes. Reposition upper end of push rod in

pocket

of wiper/washer switch. Remove lower column cover (if

necessary).

Remove drill bits.

Switch

should click when lever is lifted and again as

lever returns,

just before it reaches stop in down position. Grease

and

assemble 2 lock levers, lock lever spring

and pin. See Fig. 6.

Install assembly

into lock housing. Seat pin firmly in bottom of

slots.

Ensure that lock lever spring leg is firmly in place in lock

casting

notch. See Fig. 7.

30251

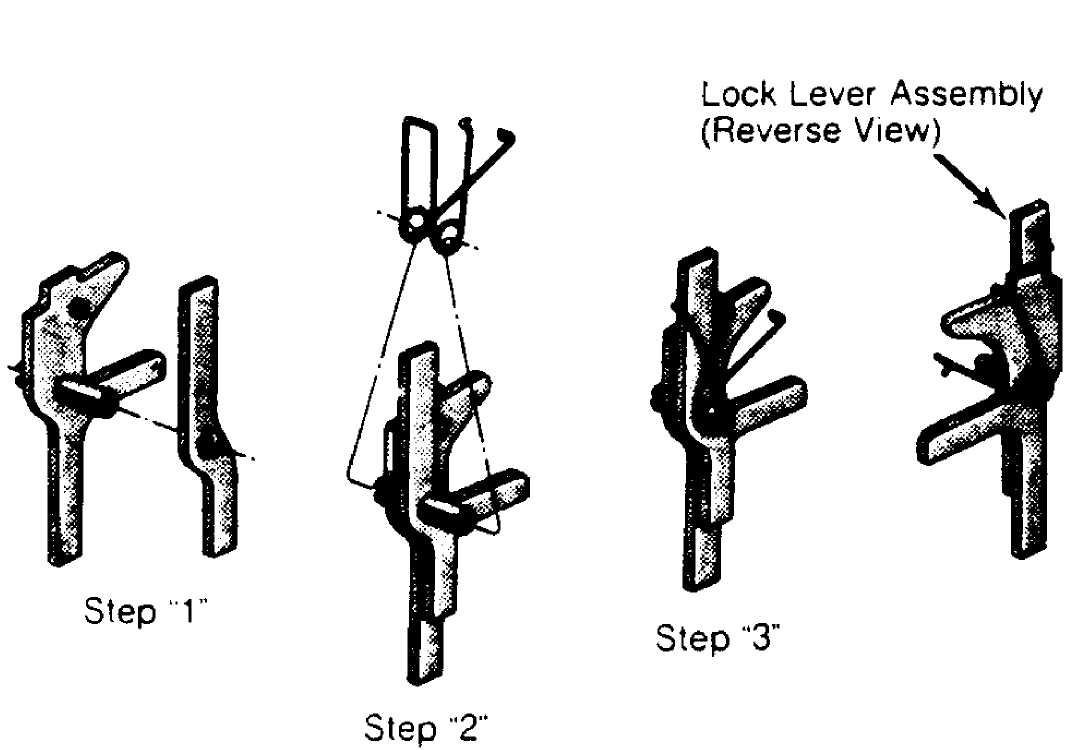

Fig. 6: Assembling Lock Lever & Spring Assembly

Lock

Lever & Spring

Assembly

Lock

Lever & Spring

Assembly

30452

Fig. 7: Installing Lock Lever & Spring Assembly

6) Install ignition switch actuator rod from bottom through oblong hole in lock housing. Attach rod to bellcrank. Position bellcrank assembly into lock housing while pulling ignition switch and

rod down column. Install bellcrank onto its mounting surface. Gearshift lever should be in "PARK" position.

Place

ignition switch on actuator rod. Rotate switch 90

degrees

to lock rod into position. Install ignition lock by turning

key

to "LOCK" position. Remove key. Insert cylinder into

housing far

enough to contact switch

actuator. Insert key. Press inward. Rotate

cylinder.

When parts

align, cylinder will move inward and spring

loaded retainers will

snap into place, locking cylinder in housing.

With cylinder and

ignition switch in "LOCK" position, tighten

ignition

switch mounting screws.

Feed key

warning switch wires behind wiring post and down

through space

between housing and jacket. Remove ignition key.

Position

cylinder in housing. Tighten mounting screws. Install lower

bearing

support (floor shift), bearing and spring on steering shaft.

Install

and lubricate rubber "O" ring in

lower groove on

upper end of steering

shaft. Insert steering shaft assembly into

column

assembly. Press upper bearing into upper bearing housing.

Bearing

must be fully seated.

Push

up on steering shaft to compress bearing and spring.

Hold

shaft in this position until snap ring is installed. Install

lock

plate on steering shaft. Install

upper bearing spring. Install upper

bearing housing with bearing

previously installed. Tighten bearing

housing

retaining screws to 35 INCH lbs (4

N.m).

Install

upper bearing snap ring on steering shaft,

locking

assembly into position. Install 4 screws

attaching bearing

housing to lock

housing. Install ignition key lamp assembly in bearing

housing.

Install turn signal switch in bearing housing.

Feed turn

signal switch and ignition key lamp wires

through opening between

bearing housing and lock housing and down

along bottom of jacket.

Install bearing retainer plate. Tighten

screws. Ensure that

ground wires from turn signal switch are

positioned toward ground

clips before tightening.

Assemble

wiper switch, shaft, cover or speed control

switch, switch cover

and knob. Place wiper/washer switch assembly into

lock housing,

feeding wires through lock housing. Fasten wires to turn

signal

switch. Install dimmer switch rod and dimmer switch.

Install

turn signal lever cover. Install breakaway

capsules. Install

wiring trough in place, being careful not to pinch

wires. Install

new retainers (if necessary).

Bearing Assembly

Shoe Release Lever

Release Lever Pin

Release Lever Spring

Spring

6 Pivot Pin

Dowel Pin

Drive Shaft

9 Steering Wheel Lock Shoe

Steering Wheel Lock Shoe

Lock Bolt

Bearing Assembly

Tilt Lever Opening Shield

Dimmer Switch Rod Activator

Cylinder Lock Assembly

Lock

Housing Cover

17 Lock Retaining Screw

Buzzer Switch Retaining Clip

Buzzer

Switch Assembly

20 Screw

21. Inner Race

22 Inner Race Seal

Turn

Signal/F-lasher

Switch Assembly

Turn Signal Arm Assembly

25 Screw 26. Retainer

Jam Nut

Retaining Ring

Lock Plate

Turn Signal Cancelling Cam

Sprsng

Screw

Wiring Trough

Pin Preload Spring

Pivot & Switch Assembly

Switch

Actuator Pivot Pin

37 Column Cover End

Cap

Spring Retainer

Tilt Spring

Spring Guide

Spring

Screw

Switch Actuator Sector

Steering Column Housing

Rack

Preload Spring

46. Switch Actuator

Rack

47 Ignition Switch Acluator

49

Gearshift Lever Sowl

49 Shift

Lever Spring

Wave Washer

Jacket Mounting Ptate

Thrust Washer

Shift Tube Retaining Ring

Screw

Shift Lever Gate

Column Housing Support

Screw

Dowel Pin

Lower Steering Shaft Assembly

Centering Sphere

Joint Preload Spring

Race & Upper Shaft Assembly

Screw

Mounting Stud

Ignition

Switch Assembly

66 Dimmer Switch Rod

Dimmer Switch Assembly

Steering Column Jacket

Shift Tube Assembly

Adapter & Bearing Assembly

Screw

72,

Nut

30254

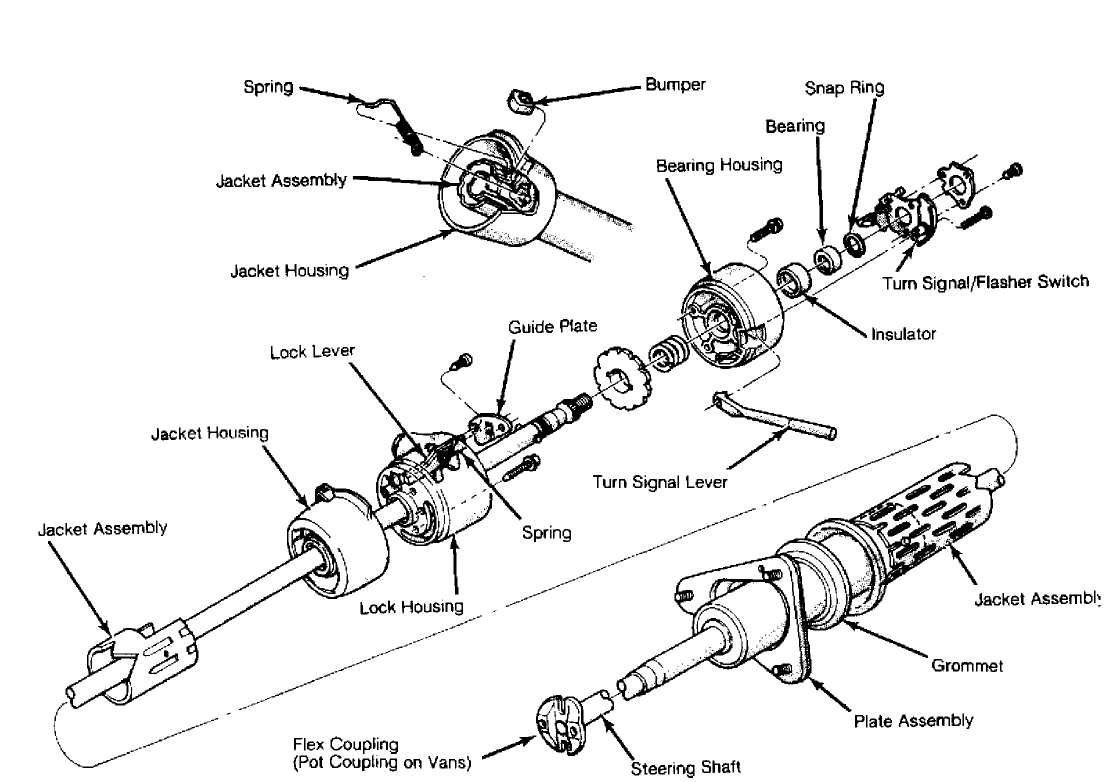

Fig. 8: Exploded View of Tilt Steering Column

TILT WHEEL COLUMN

Disassembly

Remove

lower bracket assembly-to-lower bearing support

bolts. On column

shift models, remove shift housing cover. On floor

shift models,

unsnap and remove shroud extensions. Remove wiring

protector from

column jacket.

Mount

column in vise at capsule bracket. Mount Holding

Fixture (C-4132)

onto column. Mount holding fixture and column in

vise.

Remove

tilt lever. To remove hazard warning knob, push in

knob while

unscrewing. Remove ignition key light assembly. Pull knob

off

wiper/washer switch assembly. Pull hider up switch lever. Remove

2

sleeve-to-wiper/washer switch

retaining screws. Remove sleeve.

Rotate

shaft in wiper switch fully clockwise. Remove shaft

by pulling

straight out of wiper/washer switch. Carefully remove

plastic

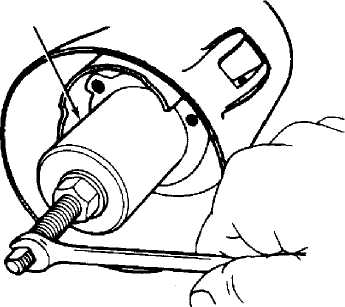

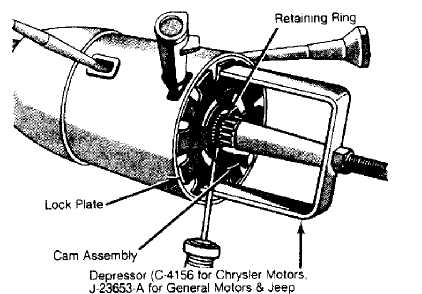

cover from lock plate. Using Lock Plate Depressor (J-23653-A

for

Jeep), depress lock plate. Pry retaining ring from groove.

Remove

lock plate, canceling cam and upper bearing plate.

Remove

switch actuator screw and arm. Remove 3 turn

signal switch

attaching screws. Place

shift bowl in "LOW" position. Wrap a piece of

tape

around wires to prevent snagging when removing switch. Remove

switch

and wiring.

Remove key

light. Place lock cylinder in "LOCK" position.

Insert a

small screwdriver into slot next to switch mounting screw

boss.

Depress spring latch at bottom of slot. Remove lock.

Using a

paper clip, remove key warning switch. Bend one

end of clip into

a hook. Insert hook into exposed loop of wedge

spring. Pull clip.

Remove spring and switch. DO NOT allow spring to

fall into

steering column.

Remove

3 housing cover screws. Remove housing

cover.

Remove wiper/washer switch. Using a punch, press out wiper

switch

pivot pin (if necessary).

Tilt lever opening shield and dimmer

switch

actuator rod may be removed from

cap (if necessary).

Place

column in fully upright position. Using a large

Phillips

screwdriver, remove tilt spring retainer. Insert screwdriver

in

opening. Push in approximately 3/16". Turn

approximately 1/8 turn

clockwise

until ears align with grooves in housing. Remove spring and

guide.

Remove

dimmer switch mounting screws. Remove dimmer

switch. Separate

dimmer switch from rod by pulling on rod. Push upper

steering

shaft in far enough to remove steering shaft inner race seat

and

inner race. With ignition switch in "ACC" position,

remove

ignition switch mounting screws and switch. Place Pivot

Pin Remover

(J-21854-01 for Jeep) over pivot pin. Thread small

portion of screw

firmly into pin.

Hold screw

from turning with one wrench while turning nut

clockwise with a

second wrench to withdraw pivot pin from support.

Remove opposite

pivot pin in same manner. Use tilt release lever to

disengage

lock shoes. Remove bearing housing assembly by pulling

upward to

extend rack fully.

Move housing assembly left to disengage rack from

actuator. Rotate housing clockwise to free dimmer switch actuator rod. Remove activator assembly. Remove coupling from lower end of steering shaft. Double coupling is retained to shaft with a roll pin. Remove shaft assembly from upper end.

CAUTION: DO NOT drop or bump steering shaft as plastic pins may shear.

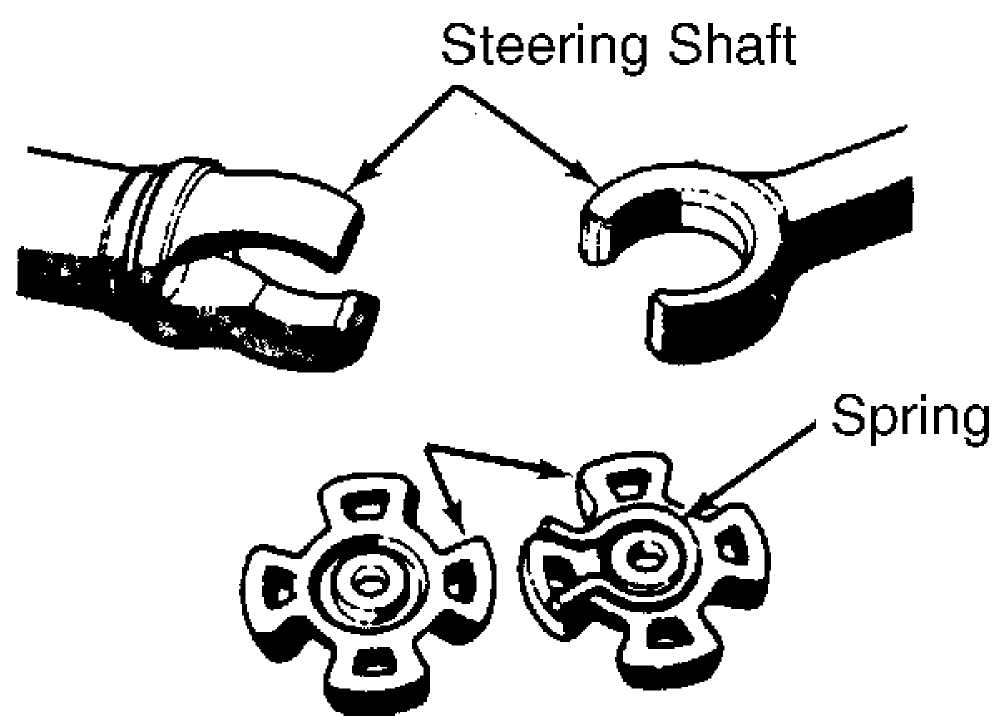

13) Disassemble

steering shaft assembly by removing center

spheres

and anti-lash springs. See Fig. 9. Remove 4

bolts securing

support

to lock plate. Remove support from end of column jacket.

Remove

2 attaching screws and shift gate from

support (if necessary).

Dimmer switch is

removed with support.

Centering Spheres

30258

Fig. 9: Shaft Centering Spheres

14) Using a screwdriver, remove shift tube retaining ring. Remove thrust washer. Remove 2 screws from lower bearing. Remove lower bearing from jacket. Using Puller (J-23073-01 for Jeep), remove shift tube from bowl. Insert bushing on end of puller in shift tube to force tube from bowl. DO NOT hammer shift tube as plastic joints may shear.

Fig. 10: Removing Shift Tube from Bowl on Models With Tilt Wheel

15) From lower end of jacket, remove shift tube from jacket. Remove jacket mounting plate by sliding from jacket notches and tipping down toward bowl hub at 12 o’clock position under jacket

opening. Remove wave washer. Remove bowl from jacket. Remove shift lever spring from bowl by winding spring up with pliers and pulling out.

By

removing spring retaining screw and moving spring

clockwise,

remove lock bolt spring. Using a hammer and punch, lightly

tap

drive shaft from sector. Remove drive shaft, sector and bolt.

Remove

rack, spring and shim (if used). Remove

tilt release lever pin.

Relieve

load on lever release by holding shoes inward.

Wedge a block

between top of shoes and bearing housing. Remove release

lever

and release lever spring. Using punch and hammer, remove lock

shoe

pin. Remove lock shoes and lock shoe springs.

Remove

bearings from bearing housing only if they are to

be replaced.

Remove separator and ball from bearing. Place housing on

work

bench. Using a punch against back surface of race, hammer race

from

housing. DO NOT reuse bearings.

Reassembly

1) During reassembly, coat all friction surfaces with

multipurpose grease. Clamp column in vise so that both ends of column are accessible. Install bearings in bearing housing (if removed).

Install

lock shoe springs, lock shoes and shoe pin in

bearing housing.

Use a .180" rod to line up shoes for

pin

installation. With tilt lever

opening on left side and with the shoes

facing up, the 4

slot shoe should also face up.

Install

spring, release lever and pin in bearing housing.

Install drive

shaft in housing. Lightly tap sector onto drive shaft

far enough

to bottom on shaft. Install lock bolt. Engage lock bolt

with

sector cam surface. Install rack and spring. Block tooth on

rack

should engage block tooth on sector.

Install

external tilt release lever. Install bolt spring

and spring

retaining screw. Tighten to 35 INCH lbs.

(4 N.m). Install

shift

lever spring in bowl by winding up with pliers and pushing in.

Slide

bowl into jacket. Install wave washer and jacket mounting plate.

Work

jacket mounting plate into jacket notches by tipping

jacket

mounting plate toward bowl hub at 12 o’clock

position and under

jacket opening. Slide jacket mounting plate in

jacket notches.

Carefully install shift

tube in lower end of jacket.

Align

key in tube with keyway in bowl. Using Puller (J-

23073-01

for Jeep), pull shift tube into bowl. See Fig.

11. DO NOT

push

or tap on end of shift tube. By pulling bowl up and compressing

wave

washer, install thrust washer and retaining pin.

Puller (C-4119 For Chrysler Motors, J-23073-01 For General Motors & Jeep)

30259

Fig. 11: Installing Shift Tube on Models With Tilt Wheel

7) Slide dimmer switch actuator rod through hole in support. Feed rod between bowl and jacket. Install support by aligning notch in support with notch in jacket. Insert 4 screws through support into

jacket mounting plate. Tighten screws to 60 INCH lbs. (7 N.m). Install lower bearing on lower end of jacket (if removed).

Install

centering spheres and anti-lash spring in upper

steering shaft.

Install lower steering shaft from same side of spheres

that

spring ends protrude. Perform a trial fit of assembly to ensure

that

master serration of upper shaft is on same side as master

serration

of lower shaft assembly.

Position

shift bowl fully counterclockwise. Install

ignition switch

actuator rod between bowl and jacket from bottom.

Guide back of

coupling into support slot. Assemble bearing housing

over

steering shaft. Engage rack over end of ignition switch

actuator

rod.

Fig. 12: Installing Lock Plate Retaining Ring

Position

access hole of bearing housing over end of

dimmer switch actuator

rod. Rotate housing counterclockwise to

assemble.

Holding lock shoes in disengaged position, assemble bearing

housing

over steering shaft until pivot holes line up with holes in

support.

Install

pivot pins. Assemble as far as possible, using

palm

pressure of hand to prevent enlarging support pivot hole. Using

a

small hammer and punch, tap pins into

place. Replace wiper/washer

pivot assembly. Press pivot pin in

cover (if removed). Check pivot

assembly

for ease of movement.

If

movement is restricted, tap other end of pin for

clearance.

Install wiper/washer switch. Replace tilt lever opening

shield

in cover (if removed). Position cap over

dimmer switch actuator

rod. Guide end of actuator rod into pivot

slot during cover assembly.

Hold cap so that cover will slide

over it.

Place

housing in full upward position. Ensure there is

grease between

guide and peg on support, tilt spring and tilt spring

retainer.

Install guide. Using a screwdriver in retaining slot, turn

retainer

clockwise to engage. Install bearing inner race and seat.

Install

lock housing cover. Tighten 3 screws to

100 INCH

lbs.

(11 N.m). Assemble

key warning switch to spring clip with formed

end

of clip under end of switch and with spring bowed away from

switch

on side opposite contact. Push

switch and spring into hole in lock

housing

cover with contacts facing lock cylinder bore.

Install

key light (if equipped). Install turn

signal

switch wires and connector

through cover, bearing housing and shift

bowl. Push in hazard

plunger. Install turn signal switch. Tighten

screws

to 25 INCH lbs. (3 N.m).

Install hazard warning knob and screw.

Pull

knob out.

Install

canceling cam spring, canceling cam (carrier

assembly) and lock

plate. Using Lock Plate Depressor (J-23653-A for

Jeep), depress

lock plate. See Fig. 12. Install a new

retaining ring.

Install tilt release lever (if removed).

Install turn signal switch

lever.

Install

ignition lock. Turn key to "LOCK" position.

Remove key.

Insert cylinder into housing far enough to contact shaft.

Press

inward while moving ignition switch actuator rod up and down

to

align parts.

When

parts align, cylinder will move inward and a spring

loaded

retainer will snap into place locking cylinder in housing.

To

replace ignition switch, position key cylinder in "LOCK"

position.

Remove key. Place ignition switch in "LOCK"

position (second detent

from bottom).

Fit

ignition switch actuator rod into slider hole.

Loosely install on

column with 2 screws. Push switch lightly

toward

lock housing to take out slack

in actuator rod. Tighten screws to 34

INCH

lbs. (4 N.m). DO

NOT move switch out of detent position.

Install

dimmer switch by firmly seating push rod into

switch.

Compress switch until 2 (.093") drill

bit shanks can be

inserted into

alignment holes. Reposition upper end of push rod in

pocket

of wiper/washer switch. Remove lower column cover (if

necessary).

With

a light upward pressure on switch, install 2 screws.

Remove

drill bits. Switch should click when lever is lifted and again

as

lever returns, just before it reaches lower stop. Install

wire

protector over wires on column jacket, being careful not to

pinch

wires.

Remove

column from vise. Position lower bracket assembly

on

steering column. Install 2 bolts. Tighten

to 105 INCH lbs. (12 N.

m).

Aligning master splines, install coupling

assembly on steering

shaft. Support coupling under joint. Drive

in roll pin.

NOTE: DO NOT remove bearings from housing unless they are to be

replaced. Install new bearings if bearings are removed from housing. Never reuse old bearings.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft.

Lbs. (N.m)

Application Ft.

Lbs. (N.m)

Flexible Coupling Bolts 17 (23)

Steering Wheel Retaining Nut 45 (61)

Support Plate Bolts 17 (23)

INCH Lbs. (N.m)

Bearing Housing-to-Lock Housing Screws 35 (4)

Bracket-to-Column Bolt 124 (14)

Column Clamp Stud 20 (2)

Column Clamp Stud Nut 106 (12)

Hazard Switch 27 (3)

Housing Cover Screws 100 (11)

Ignition Switch Screws 35 (4)

Lock Housing-to-Jacket 90 (10)

Shift Tube Support Screws 60 (7)

Steering Column Lower Bracket Bolts 106 (12)

Tilt Release Spring Retaining Screw 35 (4)

Turn Signal Retaining Plate 27 (3)

Upper Bracket Nuts 106 (12)