WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES

1988 Jeep Cherokee

1988 Wheel Alignment INTRODUCTION

PRE-ALIGNMENT

VEHICLE CHECKS

Prior to making wheel alignment adjustments, check and adjust the following items:

1) Tire pressure must be inflated to manufacturers

recommended specifications.Tires should be equal in size and type. Runout must not be excessive. Tires and wheels should be in balance.

2) Wheel bearings must be properly adjusted. Steering

linkage and suspension must not have excessive wear and/or looseness. Check for wear in tie rod ends and ball joints.

Steering

gear box must not have excessive play. Check and

adjust to

manufacturer’s specifications.

Vehicle

must be at correct ride height with full fuel

load and spare

tire in vehicle. No extra load should be on vehicle.

Vehicle

must be level with floor and with suspension

settled. Jounce

front and rear of vehicle several times and allow it

to settle

to normal ride height.

Ensure

steering wheel spokes are centered with front

wheels in

straight-ahead position, correct by shortening one tie

rod

adjusting sleeve and lengthening opposite sleeve equal

amounts.

Ensure

wheel lug nuts are tightened to torque

specifications.

DESCRIPTION

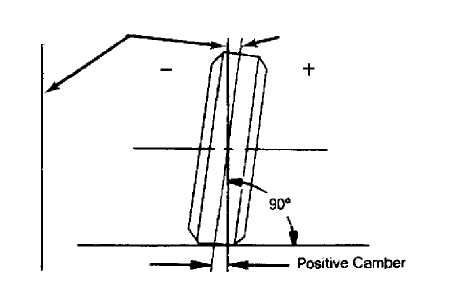

CAMBER

Camber is the inward or outward tilt of the wheel as viewed from front of vehicle. Camber is measured from centerline of vehicle. When wheel is tilted outward at top from centerline of vehicle, camber is positive. When wheel is tilted inward at top from centerline of vehicle, camber is negative. Camber is measured in degrees from vertical.

Centerline of Vehicle

1 Centerline of Wheel-*-

30409

Fig. 1: Camber Angle

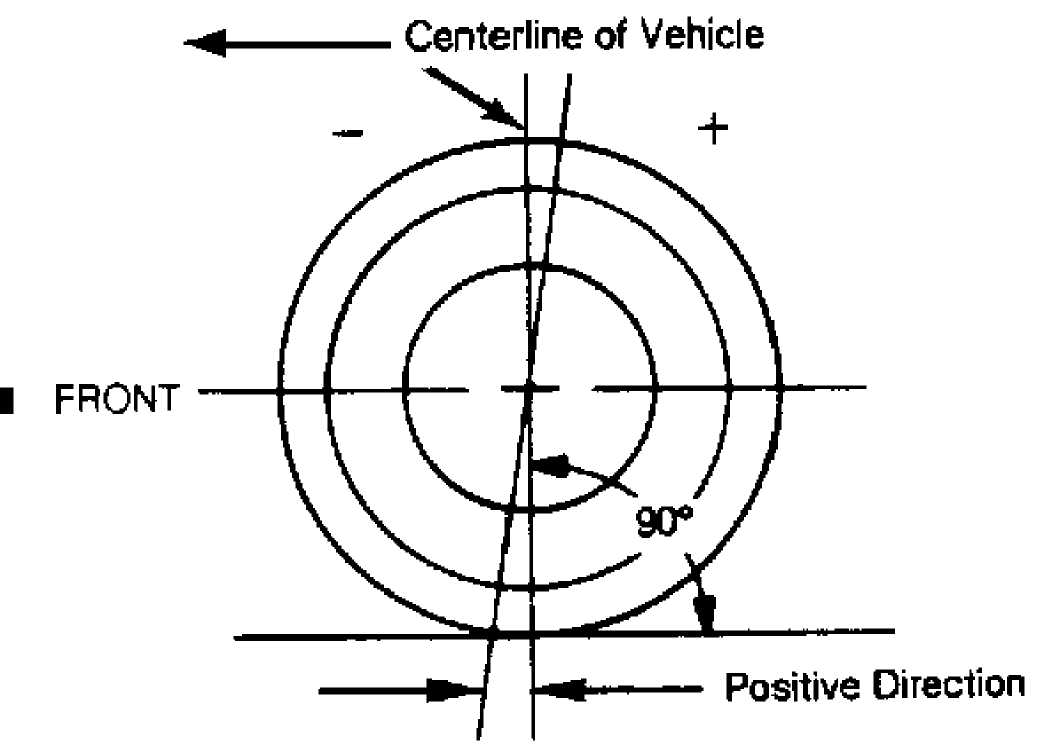

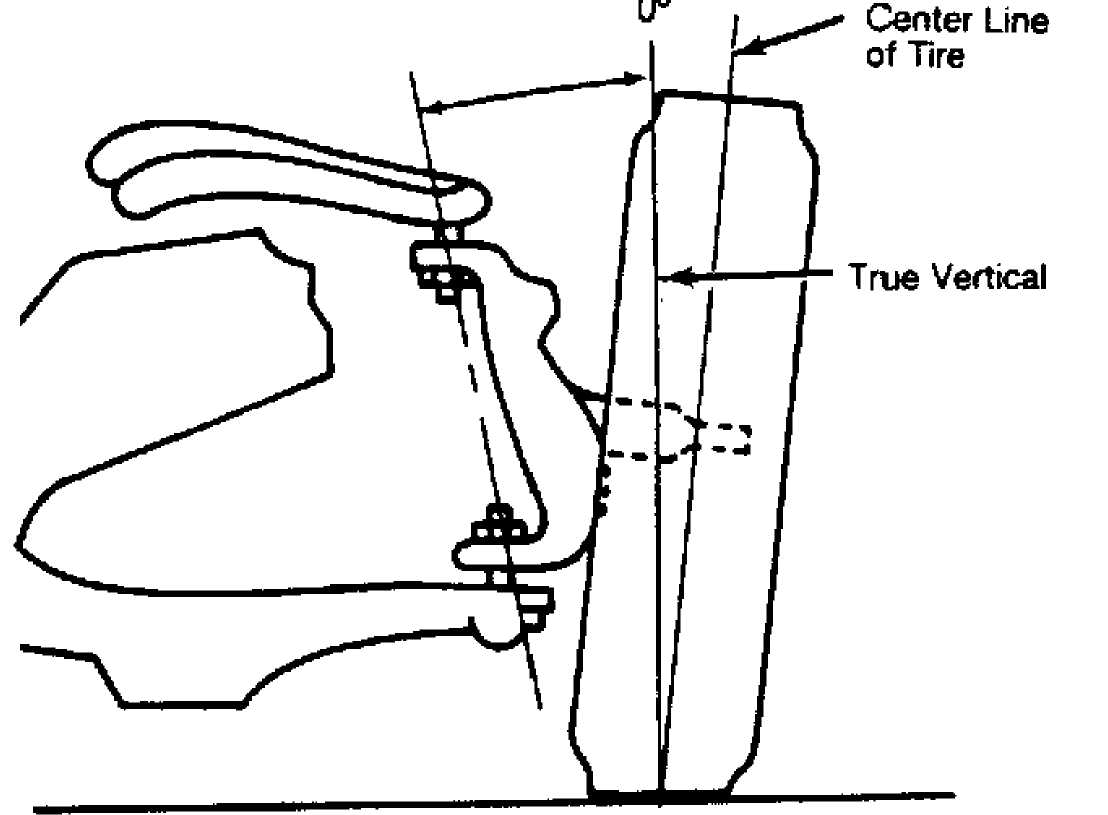

CASTER

Caster is the tilting of front steering axis. This forward

or backward tilt from vertical is viewed from side of vehicle. When axis is tilted backward from vertical, caster is said to be positive, creating a trailing action on front wheels. When axis is tilted forward, caster is negative, causing a leading action on front wheels.

30410

Fig. 2: Caster Angle

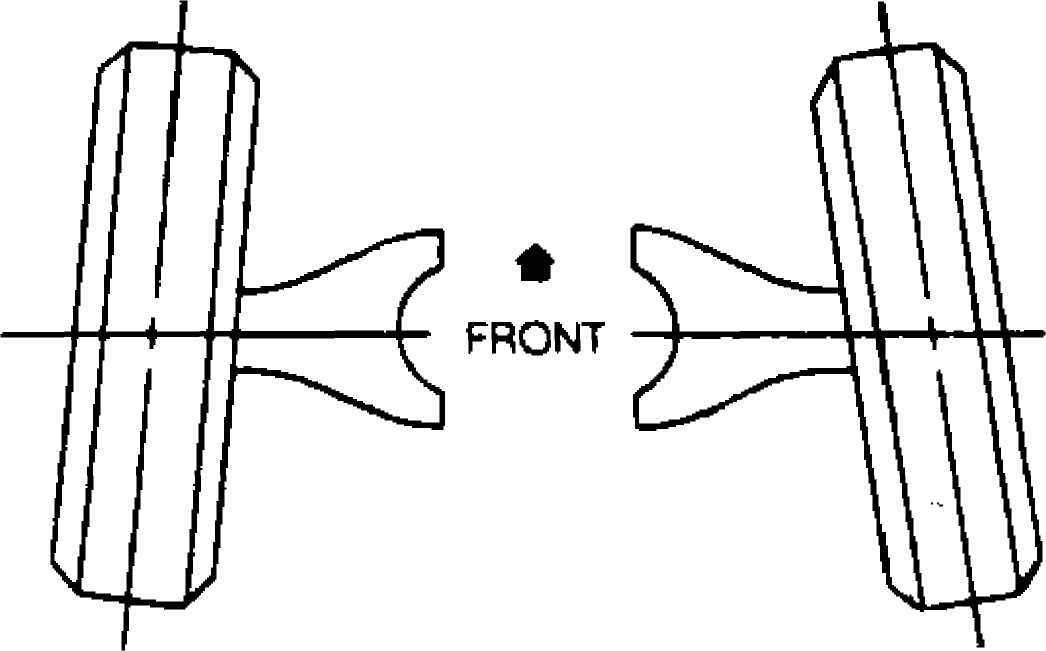

TOE

Toe is the measured difference in inches of distance between the front edge of the tires and the rear edge of the tires at spindle height. Toe can be measured in inches or degrees.

ADJUSTMENT

TOE

Measure

toe with front wheels straight-ahead and steering

wheel locked in

a centered position. Adjust toe by loosening clamps

and adjusting

sleeve or adjusting ends on right and left tie rods

equally and

in opposite directions to maintain steering wheel in

centered

position.

If

steering wheel is not centered to begin with,

determine which

tire assembly is toed in or out more than the other

and compensate adjustment more to that side to center steering wheel. A couple of tries will probably be necessary to properly center steering wheel.

3) When tightening clamps, make sure that clamp bolts are positioned so there will be no interference with other parts throughout entire travel of steering linkage.

30412

Fig. 3: Wheel Toe

To adjust, turn sleeves an equal amount in opposite directions.

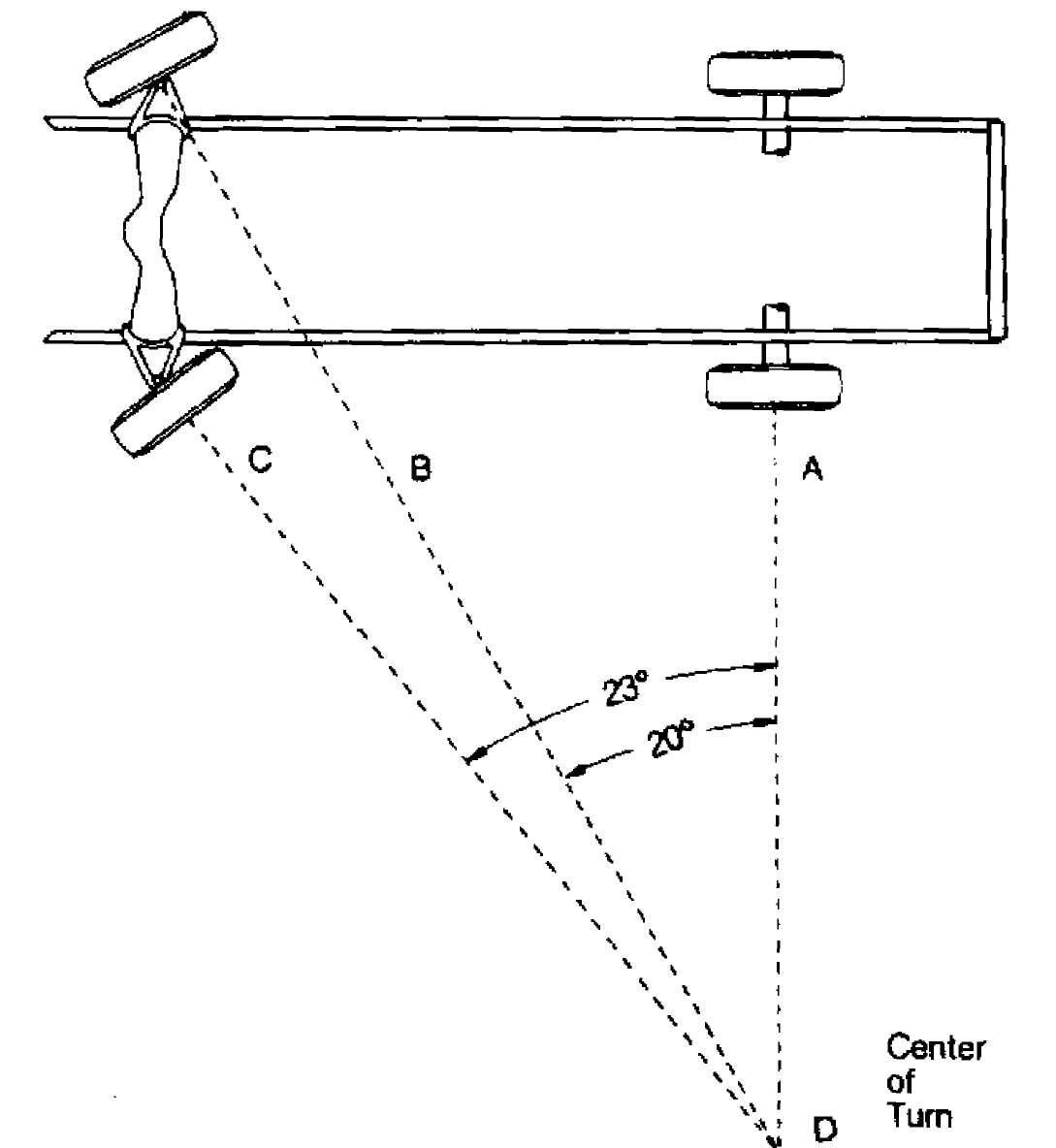

TOE-OUT ON TURNS

This is a

check for bent or damaged parts, and not a

service adjustment.

With caster, camber and toe-in properly adjusted,

check toe-out

with weight of vehicle on wheels.

Use

full-floating turn table under each wheel. Turn left

wheel

in 20 degrees on scale of turn table and

read scale of turn

table on right wheel. Reading should be within

2 degrees of left

wheel.

Repeat test for right wheel.

Incorrect

readings of toe-out generally indicates a bent

steering arm.

Replace arm and recheck wheel alignment adjustments. Do

not

attempt to correct by straightening parts.

30413

Fig. 4: Wheel Toe-Out on Turns

STEERING AXIS INCLINATION

1) This is a check for bent or damaged parts, and not a

service adjustment. Vehicle must be level, both crosswise and lengthwise. Camber should be properly adjusted.

If camber

cannot be brought within limits and steering

axis inclination is

correct, steering knuckle is bent. If camber and

steering axis

inclination are both incorrect by approximately the

same amount,

upper and lower control arms are bent.

Replace

parts and recheck all wheel alignment

adjustments. Do not attempt

to correct by straightening parts.

Steering

Axis Inclination

Steering

Axis Inclination

30414

Fig. 5: Steering Axis Inclination

TORQUE SPECIFICATIONS

WHEEL LUG NUT TORQUE SPECIFICATIONS TABLE Application

Ft. Lbs. (N.m)

Grand Wagoneer 85 (115)

All Other Models 75 (102)

ALIGNMENT SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS TABLE

Application

Application

Specification

Cherokee, Comanche,

Wrangler & Wagoneer

Ride Height in Inches

Adjustment Procedures

Camber in Degrees (Fraction) -1/2 to 1/2

Camber in Degrees (Decimal) -0.50 to 0.50

Caster in Degrees (Fraction) 7 to 8

Caster in Degrees (Decimal) 7.0 to 8.0

Toe-In in Inches (Fraction) 1/32 to 1/32

Toe-In in Inches (Decimal) 0.031 to 0.031

Toe-In in Degrees (Fraction) 1/16 to 1/16

Toe-In in Degrees (Decimal) 0.063 to 0.063

Toe-Out on Turns

Inner NS

Outer NS

Steering Axis Inclination (SAI) 8 1/2 °

Grand Wagoneer

Ride Height in Inches

Adjustment Procedures

Camber in Degrees (Fraction) 0 to 1/2

Camber in Degrees (Decimal) 0 to 0.5

Caster in Degrees (Fraction) 4 to 5

Caster in Degrees (Decimal) 4.0 to 5.0

Toe-In in Inches (Fraction) 3/64 to 3/32

Toe-In in Inches (Decimal) 0.047 to 0.094

Toe-In in Degrees (Fraction) 3/32 to 3/16

Toe-In in Degrees (Decimal) 0.094 to 0.188

Toe-Out on Turns

Inner NS

Outer NS

Steering Axis Inclination (SAI) 8 1/2 °

NS - Information not available from manufacturer.

RIDING

HEIGHT SPECIFICATIONS

RIDING

HEIGHT SPECIFICATIONS

Inflate tires to proper air pressure. Specifications can be found on door pillar or in glove box. Cargo compartment must by empty. Fuel tank should be full. Bounce vehicle up and down to normalize ride height. Ride height specifications in regard to setting camber and caster are not provided by the manufacturer.