TUNE-UP - 6-CYL

1988 Jeep Cherokee

1987-88 TUNE-UP

Jeep 6 Cylinder Tune-Up

Cherokee, Comanche, Wagoneer, Wrangler

IDENTIFICATION

ENGINE IDENTIFICATION

Engine can be identified by the fourth character of engine Build Date Code number, located on a tag attached to right side of block between No. 2 and 3 cylinders.

The same code letter is also the fourth character in the Vehicle Identification Number (VIN), located at top left corner of dashboard.

ENGINE CODE TABLE

Engine Code

Engine Code

4.0L (242") MPFI M

4.2L (258") 2-Bbl C

TUNE-UP NOTES

NOTE: When performing tune-up procedures described in this

article, these notes and precautions must be followed.

Due to late changes and corrections, always refer to Emission Control Label in engine compartment before attempting tune-up. If manual and label specifications differ, use label specifications.

When performing tune-up on vehicles equipped with a catalytic converter, do not allow or create an engine misfire in one or more cylinders for an extended period of time. Damage to converter from overheating may occur due to loading with unburned fuel.

TESTING

ENGINE COMPRESSION

Check compression pressure with engine at normal operating temperature, all spark plugs removed, throttle and choke valves wide open and engine at cranking speed.

COMPRESSION SPECIFICATIONS TABLE

Application Specification

Application Specification

Compression Ratio 9.2:1

Compression Pressure 120-150 psi (8.4-10.5 kg/cm)

Maximum Variation Between Cylinders .. 30 psi (2.1 kg/cm)

HIGH

TENSION WIRE RESISTANCE

HIGH

TENSION WIRE RESISTANCE

Do not puncture spark plug wires with any type of probe. Remove spark plug wire and check resistance using an ohmmeter.

SPARK PLUGS

SPARK PLUG TYPE TABLE

Application Champion

No.

Application Champion

No.

All Models RFN14LY

SPARK PLUG SPECIFICATIONS TABLE

Gap:

In. (mm) Torque: Ft. Lbs. (N.m)

Gap:

In. (mm) Torque: Ft. Lbs. (N.m)

0.035 (0.89) 7-15 (10-20)

FUEL PUMP

4.0L

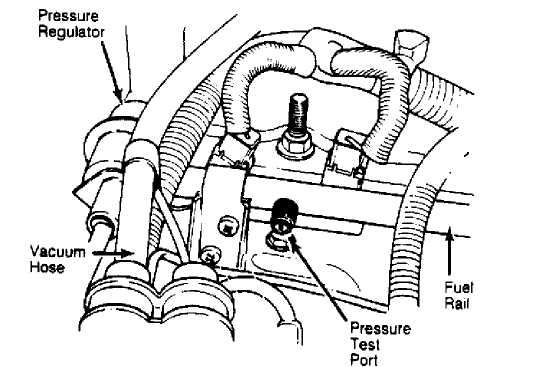

Remove

the cap from the pressure test port located in the

fuel rail. See

Fig. 1. Connect Fuel Pressure Gauge

(J-34730-1) to the

pressure fitting.

Start

vehicle. Pressure should be approximately 31 psi

(2.

1 kg/cm) with

the vacuum hose connected to the pressure regulator and

39

psi (2.6 kg/cm) with

the vacuum hose removed from the pressure

regulator.

See FUEL PUMP SPECIFICATIONS TABLE.

Check the

fuel pump flow rate. A good fuel pump will

deliver at least one

liter of fuel per minute with the fuel return

line pinched off.

If the fuel pump does not pump adequately, inspect

the fuel

system for a plugged fuel filter or filter sock.

Fuel pump

flow rate can be checked by connecting one end

of an old A/C

gauge hose to the fuel test port on the fuel rail and

inserting

the other end of the hose into a container of at least one

liter

or more capacity.

Run the fuel pump by installing a jumper wire into

diagnostic connector terminals D1-5 and D1-6. Be sure to pinch off the fuel return line or most of the fuel will be returned to the fuel tank.

Fig.

1: Fuel System Pressure Test Components

Courtesy of American Motors/Jeep Corp.

Fig.

1: Fuel System Pressure Test Components

Courtesy of American Motors/Jeep Corp.

4.2L

Perform fuel pump test with air cleaner removed and fuel

inlet line or filter disconnected at carburetor. Disconnect fuel return line at fuel filter and plug nipple on filter. Make all tests at idle speed. See FUEL PUMP SPECIFICATIONS TABLE.

FUEL PUMP SPECIFICATIONS TABLE

Application Pressure Volume

** psi (kg/cm2) (1) Pts. (L)

4.0L (2) 31 (2.1) 1.0 (.47)

4.0L (3) 39 (2.6) 1.0 (.47)

4.2L 4.0-5.0 (.28-.35) 1.0 (.47)

- Volume per 30 seconds.

- With the vacuum hose connected to the pressure regulator.

- With the vacuum hose removed from the pressure regulator.

ADJUSTMENTS

VALVE ARRANGEMENT

* E-I-I-E-I-E-E-I-E-I-I-E (Front-to-rear).

VALVE CLEARANCE

All engines are equipped with hydraulic lifters. Valve clearance is not adjustable.

IGNITION COIL WIRE

Remove ignition coil wire from coil and distributor cap. Check terminals for corrosion and clean (if necessary). Check coil wire resistance. Replace wire if resistance is excessive.

HIGH TENSION WIRE RESISTANCE (OHMS) TABLE

Wire Length Minimum Maximum

0-15" 3000 10,000

15-25" 4000 15,000

25-35" 6000 20,000

Over 35" 8000 25,000

DISTRIBUTOR

4.0L

Information not available from manufacturer.

4.2L

All models are equipped with Motorcraft Solid State Ignition (SSI) systems. No adjustments are required.

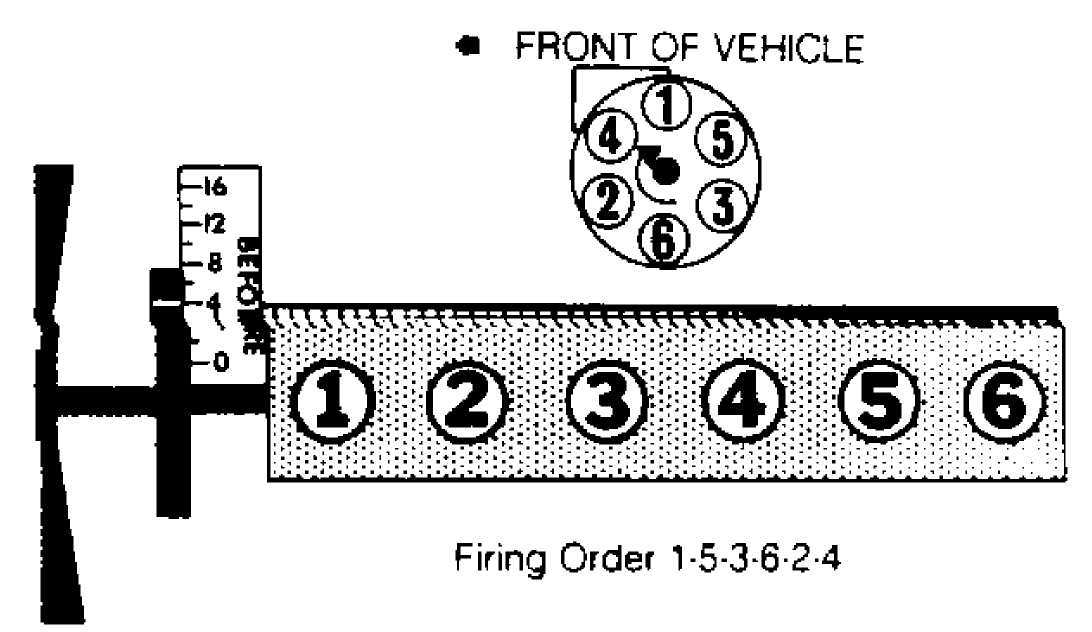

Fig. 2: 4.0L & 4.2L Timing Marks & Firing Order Magnetic probe located at 9.5 degrees ATDC on 4.2L.

IGNITION TIMING (4.0L)

Information not available from manufacturer. IGNITION TIMING (4.2L)

NOTE: Engines are equipped with a receptacle for a magnetic probe timing light, located 9.5 degrees ATDC. Do not use this location to check timing with a conventional light, use a magnetic probe timing light.

Standard Timing Procedure

1) Apply

parking brake, and place transmission in Neutral

(Park

for automatic transmissions). Operate

engine to normal operating

temperature. Turn ignition off. Install timing light.

Connect

tachometer. Disconnect and plug vacuum hose at

distributor.

Disconnect vacuum switch assembly wire connector, located

on

top of valve cover. Start engine and increase engine speed to

1600

RPM.

Compare timing to specification. See

IGNITION TIMING SPECIFICATIONS table. To adjust timing, loosen distributor clamp bolt and turn distributor. Recheck timing after clamp bolt is tightened.

Alternate Timing Procedure

Apply

parking brake and place transmission in Neutral

(Drive

for automatic transmissions). Operate

engine to obtain normal

operating

temperature. Turn ignition off. Install timing light.

Disconnect and plug vacuum switch hose (Red and Black

wires connected to switch). Disconnect distributor vacuum advance hose and connect hose to vacuum switch. Disconnect wire connector from knock sensor, located in cylinder head.

3) Using a jumper wire, ground knock sensor wire connector to engine block. Start engine. With engine at idle speed (solenoid energized), check timing. Adjust timing to one degree more than specification (if required). See Emission Control Label.

IGNITION TIMING

SPECIFICATIONS (DEGREES BTDC@RPM) - 4.2L

Application Man.

Trans. Auto.

Trans.

50 State 9 @ 1600 9 @ 1600

High Altitude 16 @ 1600 16 @ 1600

HOT (SLOW) IDLE RPM

4.0L

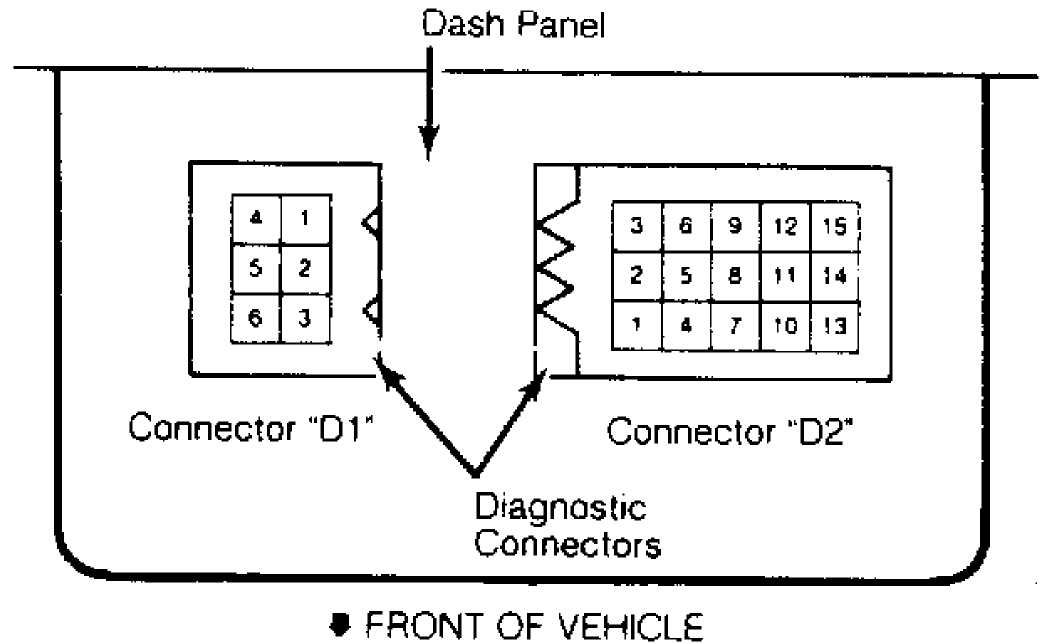

Fig. 3: Diagnostic Connector Terminal Identification Courtesy of Chrysler Motors.

Apply

parking brake and place transmission in Neutral

(Drive for

automatic transmissions). Operate engine

to normal

operating temperature. Turn ignition off.

Ensure

all accessories are off. Connect positive

tachometer

lead to terminal "D1-1" and negative lead to "D2-7"

of

diagnostic connectors. See Fig. 3.

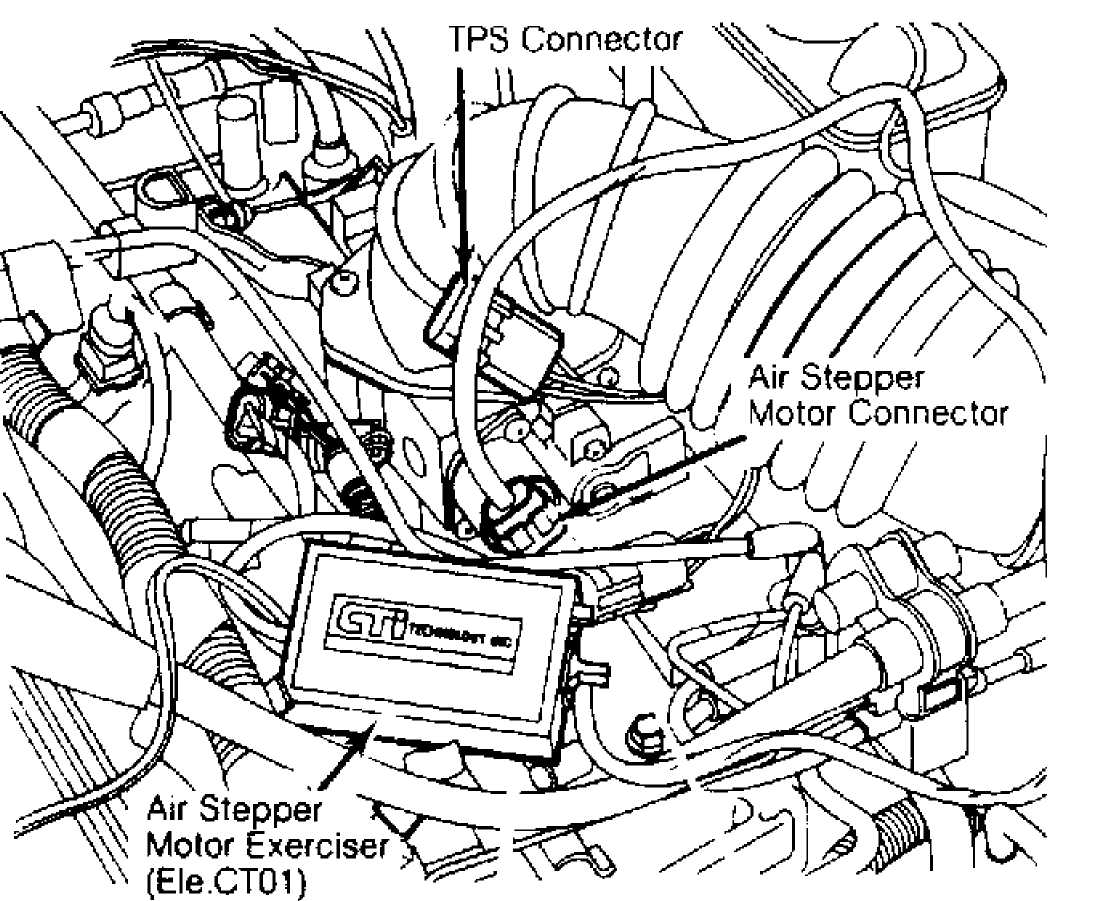

Disconnect air stepper motor

connector

and TPS wiring connector. See Fig. 4.

Fig. 4: Installing Air Stepper Motor Exerciser Courtesy of Chrysler Motors.

Install

Air Stepper Motor Exerciser (Ele.CT01) on the air

stepper

motor connector. See Fig. 4. Install the

Red terminal of the

air stepper exerciser on the positive battery

post and the Black

terminal on the

negative battery terminal.

Start

engine and place stepper motor exerciser switch on

the "LOW"

position and note engine RPM. Idle speed should be 750F50

RPM.

Disconnect and remove air stepper motor exerciser.

If

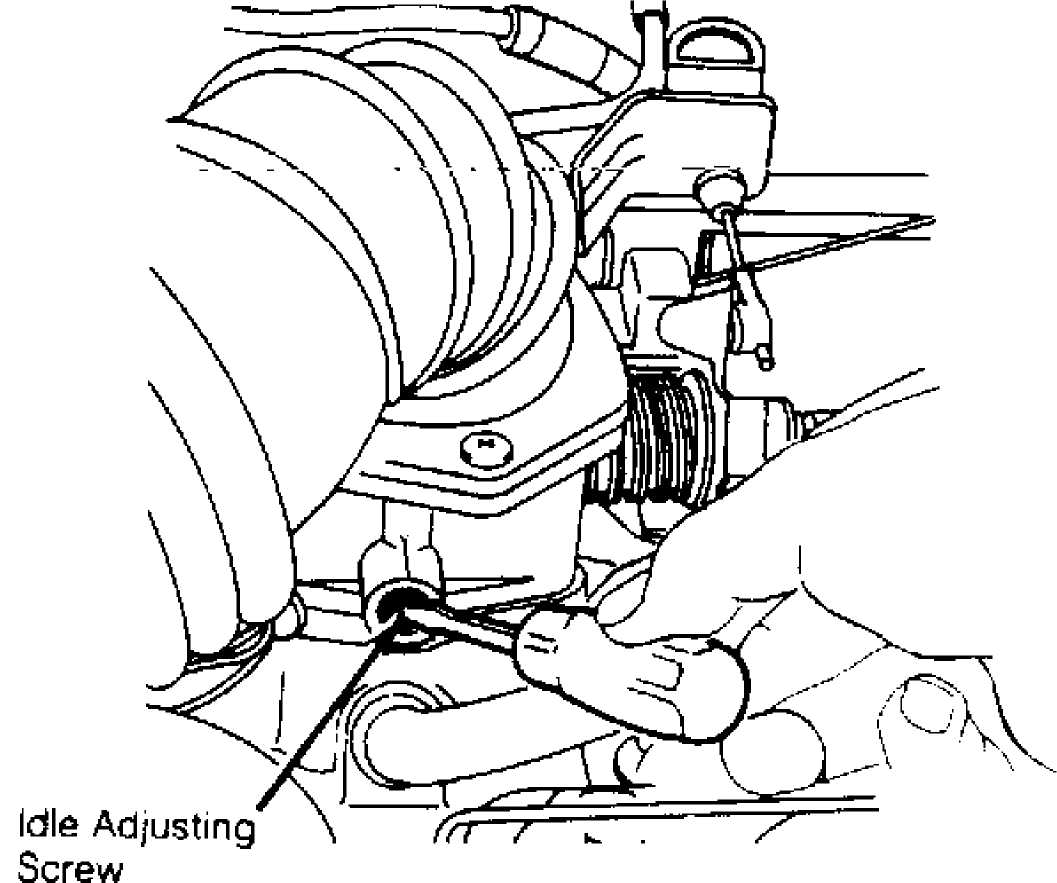

adjustment is required, turn ignition off. Remove the

welch

plug from the RPM adjusting screw cavity. See Fig. 5. Turn

RPM

adjusting screw inward 2

turns. Start the engine and note engine RPM.

Fig. 5: Adjusting Idle RPM Courtesy of Chrysler Motors.

6) Adjust idle RPM screw to obtain idle speed of 750F50 RPM. Once correct idle RPM is obtained, seal the welch plug cavity with RTV sealant. Reconnect air stepper motor and TPS.

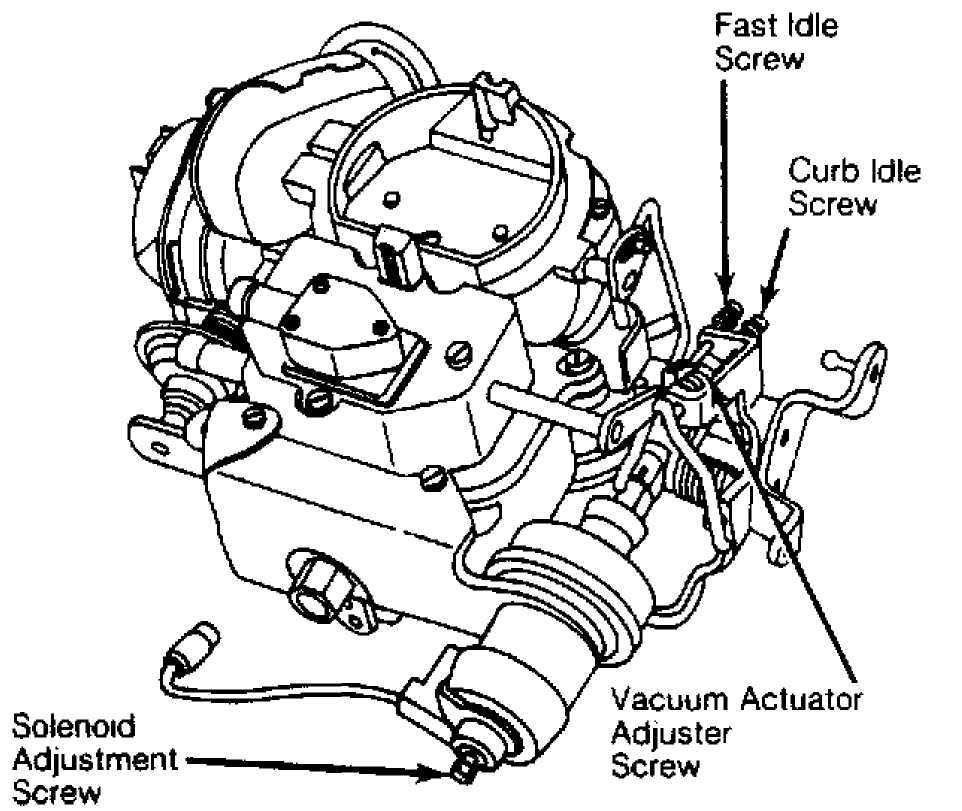

4.2L

Warm

engine to normal operating temperature. Apply parking

brake.

Place automatic transmission in Drive (Neutral on

manual

transmission). Disconnect and

plug vacuum hose from vacuum actuator.

Disconnect

solenoid wire connector.

Adjust

curb idle screw to obtain correct curb idle. See

CURB

IDLE SPEED (RPM) table. Apply 10-15 in. Hg

vacuum to vacuum

actuator. With

throttle positioner fully extended, adjust screw on

throttle

lever, to set vacuum actuator RPM to specification. See

VACUUM

ACTUATOR & SOLENOID IDLE (RPM) table.

Disconnect vacuum pump.

Apply

battery voltage to solenoid with a jumper wire. Turn

A/C

on (if equipped). Open throttle, allowing

solenoid to fully

extend. Adjust

solenoid adjusting screw to obtain solenoid idle RPM.

See VACUUM ACTUATOR & SOLENOID IDLE (RPM) table. Reconnect solenoid connector and vacuum hose.

CURB IDLE SPEED (RPM) TABLE - 4.2L

Application Man. Trans. Auto. Trans.

50 State 680 600

High Altitude 700 650

VACUUM ACTUATOR &

SOLENOID IDLE (RPM) TABLE -

4.2L

Application Vacuum

Actuator Solenoid Energized

Man. Trans 1100 900

Auto. Trans 900 800

Fig. 6: Adjusting 4.2L Idle RPM Courtesy of Chrysler Motors.

NOTE: Idle mixture adjustment is not part of a normal tune-up. DO NOT adjust mixture unless carburetor has been disassembled

or vehicle fails emissions testing. IDLE MIXTURE (TACHOMETER (LEAN DROP) PROCEDURE)

NOTE: On 4.2L engines, ensure idle speed and timing are set prior to adjusting the idle mixture. If mixture adjustment time exceeds 3 minutes, run engine at 2000 RPM in Neutral for one minute, and resume adjustment. On 4.0L engines, idle mixture adjustment is not possible.

4.2L

Remove

carburetor and locate roll pins blocking idle

mixture screws.

Drill through throttle body on closed end of roll pin

hole. Drive

pins out with punch. Reinstall carburetor. Install

tachometer.

Operate

engine to normal operating temperature, and adjust

curb

idle speed. Place automatic transmission selector in Drive

(Neutral

for manual transmissions). Turn mixture

screws inward until

RPM drops. Turn screws outward until highest RPM is reached.

3) Turn

mixture screws inward to obtain the correct decrease

in

RPM. See LEAN DROP (RPM) table. Adjust both screws equally.

When

mixture is correctly adjusted, replace roll pin to block

adjustment

screws.

NOTE: If final RPM differs more than 30 RPM from specified curb

idle speed, reset curb idle, and repeat mixture adjustment.

LEAN DROP (RPM) TABLE

Application Man. Trans. Auto. Trans.

4.2L 50 50

THROTTLE POSITION SENSOR (TPS)

NOTE: Adjustment of TPS only applies to the 4.0L models. It may be necessary to remove throttle body from intake manifold, to access sensor wiring harness.

Checking & Adjusting - 4.0L (Automatic Transmission)

Locate the

square TPS connector. Note connector terminal

identification

stamped on the back of the connector. Turn ignition on.

Connect

voltmeter through back of wiring harness

connector. Connect

negative voltmeter lead to terminal "D" and

positive

voltmeter lead to terminal "A" to check input voltage. DO

NOT

disconnect TPS connector.

Hold

throttle plate closed against idle stop and note

voltage. Input

voltage should be approximately 5 volts.

Disconnect

voltmeter positive lead and

connect to terminal "B" to measure output

voltage.

With

throttle plate closed, measure the output voltage.

The

output voltage should be approximately 4.2 volts.

If output

voltage is not within specification, loosen TPS

retaining screws.

Partially

tighten one retaining screw. Rotate TPS to

obtain correct output

voltage. Tighten retaining screws once correct

voltage is

obtained.

Checking & Adjusting - 4.0L (Manual Transmission) 1) Turn ignition on. Connect voltmeter through back of wiring harness connector. Connect negative voltmeter lead to terminal "B" and positive voltmeter lead to terminal "A". DO NOT disconnect TPS connector.

2) Hold throttle plate in the closed throttle position

against idle stop and note input voltage reading. Input voltage should be approximately 5.0 volts.

Disconnect

positive lead from terminal "A" and connect to

terminal

"C" to check output voltage. Output voltage should be

checked

with throttle plates fully closed.

Output

voltage should be approximately 0.8 volts.

If

output voltage is not within

specification, loosen TPS bottom

retaining screw and pivot sensor

for a large adjustment or top

retaining

screw for a fine adjustment.

Adjust

sensor to obtain correct output voltage. Tighten

retaining

screws. Remove voltmeter.

COLD (FAST) IDLE RPM

4.2L

Disconnect and plug EGR valve vacuum hose. With engine running at normal operating temperature, place fast idle screw on second step of fast idle cam and against shoulder of high step. Turn screw to adjust fast idle speed.

FAST IDLE SPEED (RPM) TABLE

Application Man. Trans. Auto. Trans.

4.2L 1700 1700

AUTOMATIC CHOKE SETTING

Choke coil cover is riveted in place and no adjustment is necessary or possible.

SERVICING

EMISSION CONTROL

See EMISSIONS section.

SPECIFICATIONS

IGNITION

Distributor

All vehicles use a Motorcraft breakerless solid state distributor.

PICK-UP COIL RESISTANCE

TABLE - OHMS @ 75F

(24C)

Application

Specification

All

Models 400-800

TOTAL SPARK ADVANCE TABLE @ 2000 RPM

Application

W/ Vac. Advance W/O Vac. Advance

4.0L N/A N/A

4.2L 30.5 7.5-12.5

(1) - Information not available from manufacturer. IGNITION COIL

IGNITION COIL OUTPUT TABLE @ 1000 RPM

Application Output

All Models 24KV Minimum

IGNITION COIL RESISTANCE TABLE

Temperature Primary

Ohms Secondary Ohms

75F (24C) 1.13-1.23 7700-9300

200F (93C) 1.5 12,000

FUEL SYSTEM

CARBURETORS & FUEL INJECTION TABLE

Application Model

4.0L MPFI

4 . 2L Carter BBD 2-Bbl .

BATTERY

BATTERY SPECIFICATIONS TABLE

Application Cold

Cranking Reserve Capacity

** (1) Amps Minutes

Standard 421 75

Optional 452 81

(1) - At 0F (-18C).

STARTER

All models equipped with Mitsubishi starters. STARTER SPECIFICATIONS TABLE

Application

Volts Amps Test RPM

All

Models 11.22 80 2500

ALTERNATOR

All models use Delco-Remy solid state alternators with internal voltage regulator.

ALTERNATOR SPECIFICATIONS TABLE

Application Field Current Rated

Application

** Draw @ 12 Volts Amp Output

Standard (1) 4.0-5.0 Amps 56

Optional (1) 4.0-5.0 Amps 66

Optional (1) 4.0-5.0 Amps 78

(1) - At 80F (27C).

ALTERNATOR REGULATORS

All models use Delco-Remy solid state regulators, integral with alternator. Regulator is nonadjustable.

BELT ADJUSTMENT

BELT

ADJUSTMENT TABLE TENSION IN LBS. (KG) USING STRAND

TENSION GAUGE

Application New Belts Used Belts

"V"-Belts 125-155 (57-70) 90-115 (41-52)

Serpentine 180-200 (82-91) 140-160 (63-72)

REPLACEMENT INTERVALS

REPLACEMENT INTERVALS TABLE

Component Interval (Miles)

Air Filter 30,000

Fuel Filter 30,000

Oil & Filter 7500

PCV Valve 30,000

Spark Plugs 30,000

CAPACITIES

FLUID CAPACITIES TABLE

Application Quantity

Auto. Trans. (Dexron II)

Wrangler 8.0 qts. (7.6L)

All Others 8.5 qts. (8.0L)

Cooling System

Wrangler 10.5 qts. (9.9L)

All Others 12.0 qts. (11.4L)

Crankcase (Includes Filter)

Wrangler 5.0 qts. (4.7L)

All Others 6.0 qts. (5.7L)

Drive Axle

Front 2.5 pts. (1.2L)

Rear

Comanche

Standard Capacity 2 . 5 pts . (1.2L)

Metric Ton Axle 4.8 pts. (2.3L)

All Others 2.5 pts. (1.2L)

Fuel Tank

Cherokee & Wagoneer

Standard 13.5 gals. (51L)

Optional 20 gals. (76L)

Comanche

Standard 16 gals. (60L)

Optional 23.5 gals. (89L)

Wrangler

Standard 15 gals. (57L)

Optional 20 gals. (75L)

Manual Transmission

AX4 7.8 pts. (3.7L)

AX5 7.4 pts. (3.5L)

BA 10/5 3.5 pts. (1.6L)

Transfer Case (Dexron II)

Wrangler 3.25 pts. (1.5L)

All Others

Command Trac 2 . 2 pts . (1. 0L)

Select Trac 3.0 pts. (1.4L)

SYSTEM REFRIGERANT CAPACITIES TABLE

Application Ozs.

All Models 36