POWER STEERING PUMP

1988 Jeep Cherokee

1988 STEERING

Jeep Power Steering Pumps - Saginaw Vane-Type

Cherokee, Comanche, Grand Wagoneer, Pickup, Wagoneer, Wrangler

DESCRIPTION

Saginaw vane-type power steering pump can be identified by "ham-shaped" fluid reservoir can. Rectangular pumping vanes carried by a shaft driven rotor move fluid from intake to pressure cavities of cam ring.

Centrifugal force throws vanes against inside surface of cam ring to pick up residual oil. As more oil is picked up, it is forced into cavities of thrust plate, into 2 cross-over holes in cam ring and pressure plate and into a high pressure area between pressure plate and housing end plate.

Filling the high pressure area causes oil to flow under vanes in slots of rotor. This forces vanes to follow inside oval surface of cam ring. As vanes rotate to small area of cam ring, oil is forced out from between vanes.

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

LUBRICATION & TESTING

See POWER STEERING GENERAL SERVICING article in the STEERING section.

REMOVAL & INSTALLATION

POWER STEERING PUMP

Removal & Installation

Loosen

pump adjusting bolt (or nut) and pump mounting

bolts. Remove pump

drive belt. Disconnect pressure and return hoses

from pump. Cap

ends to prevent loss of fluid or contamination.

Remove

pump bracket-to-engine bolts. Remove pump, pulley

and mounting

bracket as an assembly. To install, reverse removal

procedure.

Bleed system.

OVERHAUL

CAUTION: When clamping pump in vise, be careful not to exert

excessive force on front hub or pump. DO NOT use hammer to remove pulley.

DISASSEMBLY

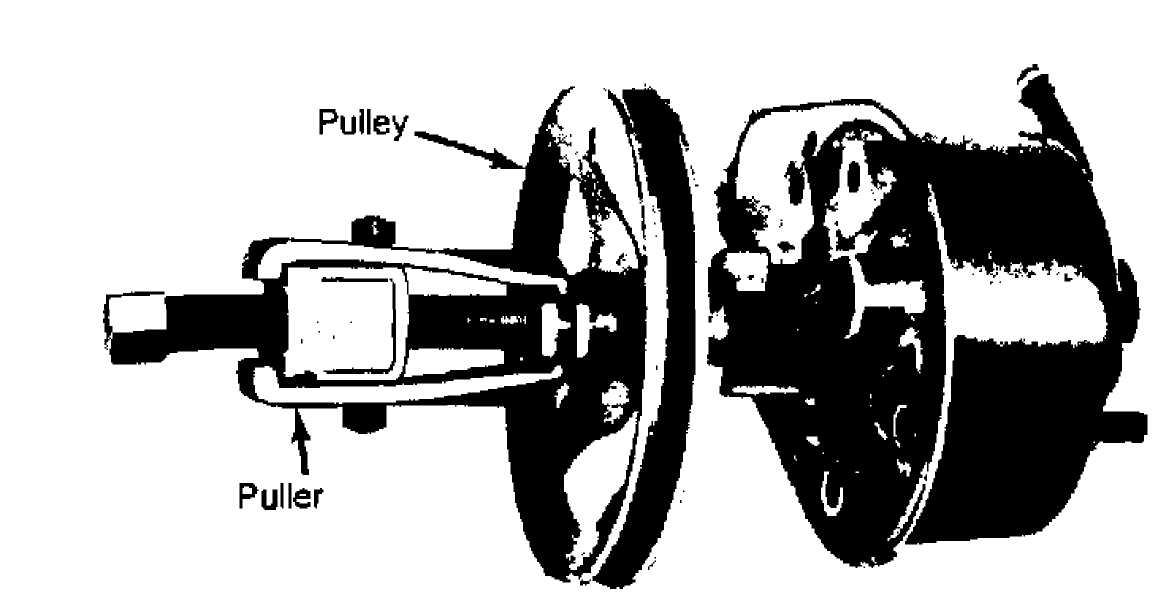

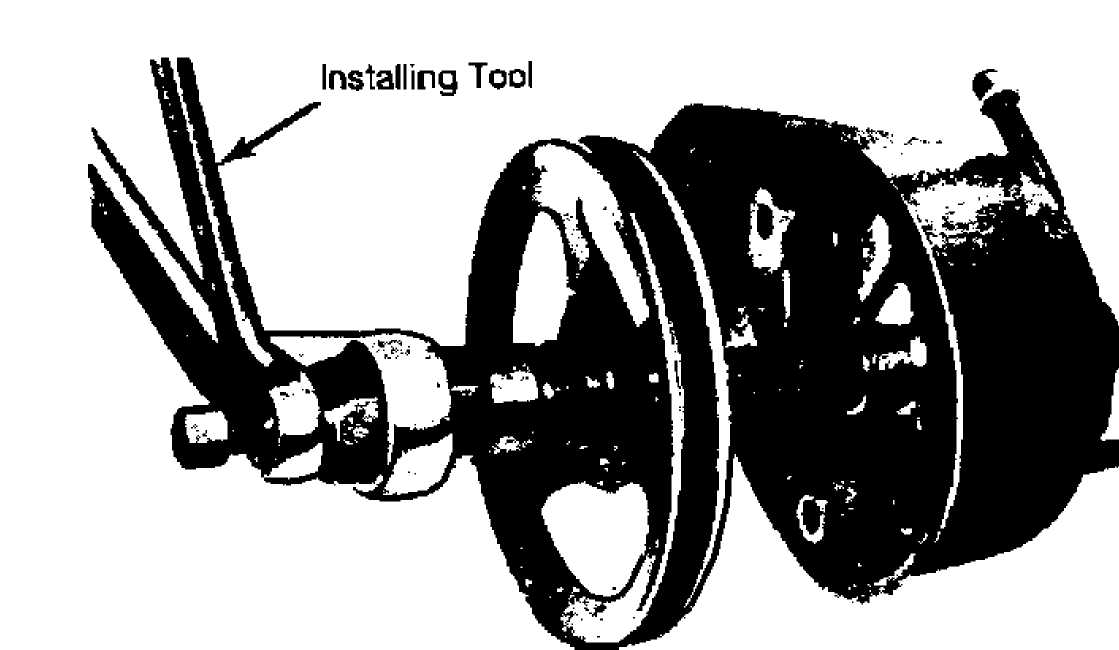

1) Drain pump reservoir. Clean exterior of unit. Remove mounting bracket(s). Using a puller, withdraw pulley from shaft. See Fig. 1.

30342

Fig. 1: Removing Pump Pulley

Clamp

pump, with shaft pointing down and at the square

boss of the

shaft housing, into a soft-jawed vise. Remove pressure

line union

and "O" ring. Remove reservoir

retaining studs.

Tap

against filler tube with plastic hammer to loosen

reservoir

on pump body. Remove reservoir from body. Remove and discard

"O"

rings.

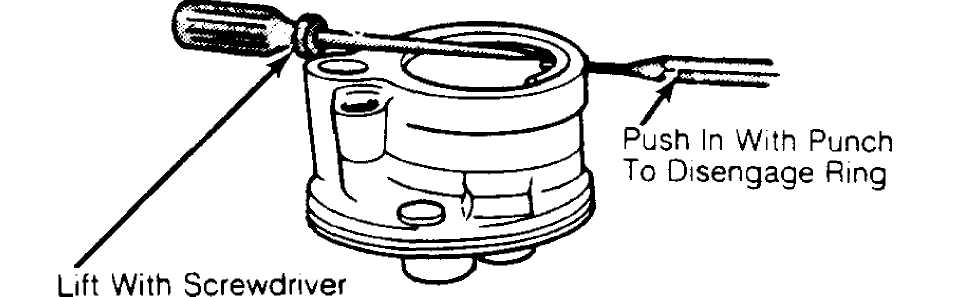

Using

1/8" punch, tap end plate retaining

ring around

until end of ring is near

hole in pump body. Inserting punch in hole,

disengage ring from

groove in pump bore. Using a screwdriver, pry ring

from

body. See Fig. 2.

30341

Fig. 2: Removing Pump End Plate Retaining Ring

Tap end

plate with a soft-faced hammer to loosen. Spring

tension should

push plate up. Remove spring. Remove pump from vise.

Invert pump and place on flat surface. Using soft-faced

hammer, tap end of drive shaft to loosen pressure plate, rotor, and thrust plate assembly from body.

Lift

pump body off rotor assembly. Flow control valve and

spring

should slide out of bore. Remove and discard end plate and

pressure

plate "O" rings.

Using a

screwdriver, pry drive shaft oil seal from body.

Lift pressure

plate and cam ring from rotor. Remove rotor vanes.

Clamp

drive shaft in soft-jawed vise, with rotor and

thrust plate

facing up. Remove rotor lock ring from shaft. Use care

not to

nick shaft or rotor. Slide rotor and thrust plate off shaft.

Remove

shaft from vise.

CLEANING & INSPECTION

Clean all

pump components (except drive shaft seal) in

clean solvent. Blow

dry. Inspect flow control valve assembly for wear,

scoring, burrs

or other damage. Inspect seal bore for burrs, nicks, or

score

marks that would allow oil to by-pass outer seal surface.

Check

all machined surfaces of body for scratches or burrs

which

might allow leaks. Check "O" ring

mating surfaces. Inspect pump

body

drive shaft bushing for excessive wear.

If

replacement is required, replace pump body and bushing

as

an assembly. Inspect end cover "O" ring

mating surface for nicks

and burrs.

Polish with oil stone (if necessary).

Inspect

rotor ring for roughness or irregularities. Use

oil stone to

correct minor irregularities. Replace ring if outside cam

surface

is worn or scored. Check thrust plate and pressure plate for

scoring

and wear.

To remove

light scoring, lap with crocus cloth until

surface is smooth and

flat. Clean thoroughly. Check that vanes slide

freely but fit

snugly into slots.

If vanes

are loose in slots, replace rotor and/or vanes.

Scoring on rotor

may be removed by lapping with crocus cloth. Clean

thoroughly.

REASSEMBLY

Lubricate

all "O" rings, seals and seal

surfaces with

power steering fluid. On

Jeeps, lubricate "O" rings with

petroleum

jelly. With pump on flat

surface, drive new shaft seal in until it

bottoms on bore

shoulder.

Clamp

body in vise with shaft pointing down. Install end

plate

and pressure plate "O" rings on

body. Install body to reservoir

"O" rings.

Install on pump body.

Place

shaft, splined end up, in soft-jawed vise. Install

thrust plate

on shaft with smooth, ported side up. Slide rotor,

counter bore

down, over splines.

Install

new rotor lock ring. Ensure ring is seated in

groove.

Install 2 dowel pins into holes in pump

cavity. Insert drive

shaft, rotor, and

thrust plate assembly into pump cavity. Align

locating

holes with dowel pins.

Slide cam

ring over rotor and onto dowel pins, with arrow

on ring facing

toward rear of housing. Install vanes in rotor slots

with radius

edge facing out towards cam ring inner surface. Position

pressure

plate on dowel pins with circular spring depression facing

rear

of housing.

Using

a 1 1/4" socket in groove of pressure

plate, press

down on socket with both thumbs to seat assembly on

"O" ring in pump

cavity.

Place spring in groove in pressure plate. Place end cover lip

edge

over spring.

Using

thumb or arbor press, press end cover down below

retaining ring

groove. Seat retaining ring in groove. Take care to

prevent

cocking end cover in bore or distorting assembly.

Using a

punch, tap retaining ring ends around in groove

until opening is

opposite flow control valve bore. This ensures

maximum retention

of retaining ring.

Install

new "O" rings to reservoir,

mounting studs, and

flow control valve.

Place reservoir on pump body. Align mounting stud

holes.

Install studs.

10) Using

a soft-faced hammer, tap reservoir down on pump.

Install

flow control valve spring and valve assembly slotted end up.

Install

new "O" ring on pressure hose

fitting uppermost groove.

CAUTION: DO NOT install pressure hose "O" ring in lower groove. This will restrict relief outlet orifice.

11) Install

pressure hose fitting. Tighten mounting studs.

Tighten

hose fitting. Remove pump from vise. Install mounting bracket

and

pulley.

Seals

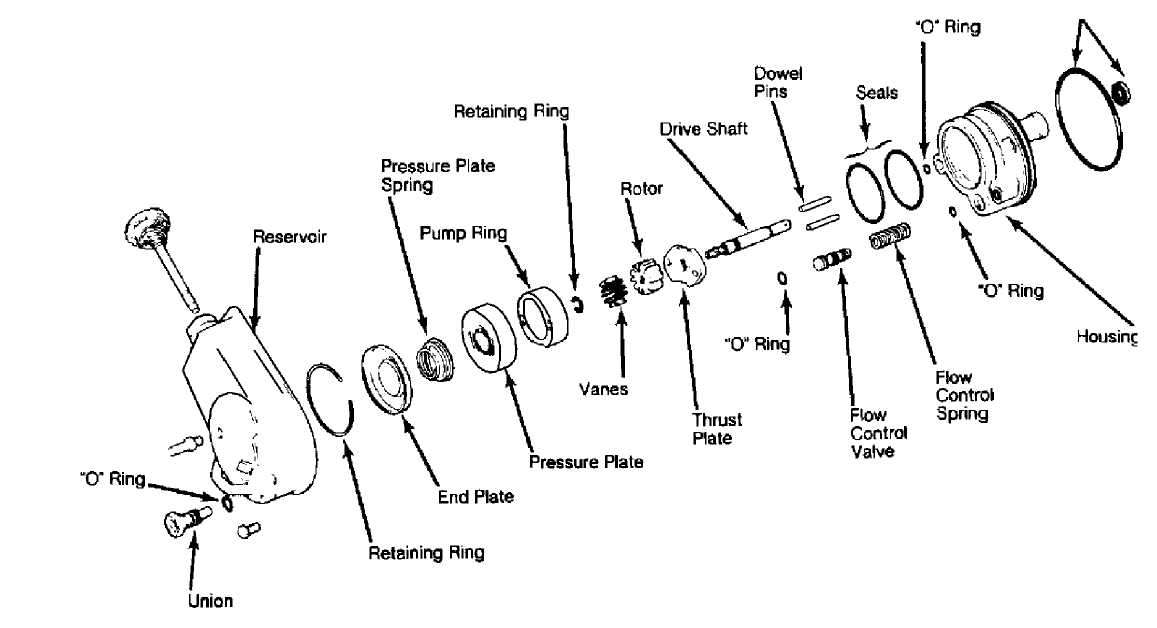

Fig.

30553

3: Exploded View of Power Steering Pump

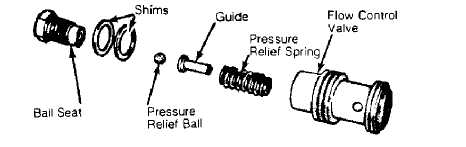

30345

Fig. 4: Exploded View of Control Valve Assembly

30344

Fig. 5: Installing Pump Pulley

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft.

Lbs. (N.m)

Gear End Hose Fittings 20 (27)

Pump End Hose Fittings 20 (27)

Bracket Bolts 35 (48)